EC - Max 30 30 MM, Brushless, 60 Watt: Part Numbers

EC - Max 30 30 MM, Brushless, 60 Watt: Part Numbers

Uploaded by

furkanfurkanfurkanCopyright:

Available Formats

EC - Max 30 30 MM, Brushless, 60 Watt: Part Numbers

EC - Max 30 30 MM, Brushless, 60 Watt: Part Numbers

Uploaded by

furkanfurkanfurkanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

EC - Max 30 30 MM, Brushless, 60 Watt: Part Numbers

EC - Max 30 30 MM, Brushless, 60 Watt: Part Numbers

Uploaded by

furkanfurkanfurkanCopyright:

Available Formats

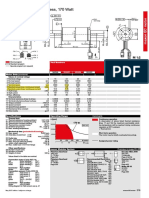

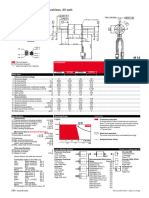

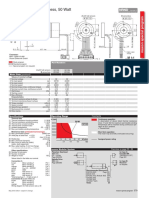

EC -max 30 ∅30 mm, brushless, 60 Watt

ECmotor

maxon EC

maxon -max

M 1:2

Stock program Part Numbers

Standard program

Special program (on request)

272762 272763 272764 272765

Motor Data

Values at nominal voltage

1 Nominal voltage V 12 24 36 48

2 No load speed rpm 7980 9340 9490 9350

3 No load current mA 302 191 130 95.4

4 Nominal speed rpm 6590 8040 8270 8130

5 Nominal torque (max. continuous torque) mNm 63.6 60.7 63.7 64.1

6 Nominal current (max. continuous current) A 4.72 2.66 1.88 1.4

7 Stall torque mNm 381 458 522 519

8 Stall current A 26.8 18.8 14.5 10.7

9 Max. e ciency % 80 81 82 82

Characteristics

10 Terminal resistance phase to phase W 0.447 1.27 2.48 4.49

11 Terminal inductance phase to phase mH 0.049 0.143 0.312 0.573

12 Torque constant mNm/A 14.2 24.3 35.9 48.6

13 Speed constant rpm/V 672 393 266 197

14 Speed/torque gradient rpm/mNm 21.2 20.6 18.4 18.2

15 Mechanical time constant ms 4.86 4.73 4.21 4.17

16 Rotor inertia gcm2 21.9 21.9 21.9 21.9

Specifications Operating Range Comments

Thermal data n [rpm] Continuous operation

17 Thermal resistance housing-ambient 7.4 K/W

18 Thermal resistance winding-housing 0.5 K/W In observation of above listed thermal resistance

19 Thermal time constant winding 2.76 s 15000 60 (lines 17 and 18) the maximum permissible wind-

20 Thermal time constant motor 1000 s 272763 ing temperature will be reached during continuous

21 Ambient temperature -40…+100°C operation at 25°C ambient.

22 Max. winding temperature +155°C 10000 = Thermal limit.

Mechanical data (preloaded ball bearings)

23 Max. speed 15 000 rpm Short term operation

5000

24 Axial play at axial load < 6.0 N 0 mm The motor may be briefly overloaded (recurring).

> 6.0 N 0.14 mm

25 Radial play preloaded

26 Max. axial load (dynamic) 5N 20 40 60

27 Max. force for press fits (static) 98 N Assigned power rating

(static, shaft supported) 1300 N 1.0 2.0 3.0

28 Max. radial load, 5 mm from flange 25 N

Other specifications

29 Number of pole pairs 1 maxon Modular System Overview on page 28–36

30 Number of phases 3 Planetary Gearhead Encoder MR

31 Weight of motor 305 g ∅32 mm 500/1000 CPT,

1.0 - 8.0 Nm 3 channels

Values listed in the table are nominal. Page 339/341 Page 404

Connection motor (Cable AWG 20) Koaxdrive Recommended Electronics: Encoder HEDL 5540

red Motor winding 1 Pin 1 ∅32 mm Notes Page 32 500 CPT,

black Motor winding 2 Pin 2 1.0 - 4.5 Nm ESCON 36/3 EC 427 3 channels

white Motor winding 3 Pin 3 Page 343 ESCON Mod. 50/4 EC-S 427 Page 417

N.C. Pin 4 Planetary Gearhead ESCON Module 50/5 427 Brake AB 20

Connector Part number ∅42 mm ESCON 50/5 428 24 VDC

Molex 39-01-2040 3 - 15 Nm DEC Module 50/5 430 0.1 Nm

Connection sensors (Cable AWG 26) Page 346 EPOS2 Module 36/2 434 Page 456

yellow Hall sensor 1 Pin 1 EPOS2 24/5, 50/5 435

brown Hall sensor 2 Pin 2 EPOS2 P 24/5 438

grey Hall sensor 3 Pin 3 EPOS4 Module/CB 50/5 442

blue GND Pin 4 MAXPOS 50/5 447

green VHall 3…24 VDC Pin 5

N.C. Pin 6

Connector Part number

Molex 430-25-0600

Wiring diagram for Hall sensors see p. 41

May 2017 edition / subject to change maxon EC motor 231

You might also like

- STP Design 50KLDDocument3 pagesSTP Design 50KLDmurugaraj92% (13)

- 5th Edition Chapter-2 - Solutions-Manual-Mechanics-Dynamics-Meriam PDFDocument253 pages5th Edition Chapter-2 - Solutions-Manual-Mechanics-Dynamics-Meriam PDFfurkanfurkanfurkan100% (1)

- QiadvancedDocument29 pagesQiadvancedpewep2100% (2)

- 1000 Series (AA-AH YA-YD) UHDocument58 pages1000 Series (AA-AH YA-YD) UHВладислав Леонов100% (1)

- C-051-020-LST-0003-Rev 3-Utilities Summary ListDocument20 pagesC-051-020-LST-0003-Rev 3-Utilities Summary ListMidha NeerNo ratings yet

- 12 171 enDocument1 page12 171 enLuka MadridNo ratings yet

- Catalog Motor EC90Flat 323772Document1 pageCatalog Motor EC90Flat 323772Lucas SuplinoNo ratings yet

- 450W BrushlessDocument1 page450W Brushlessgabriel.rmarquesNo ratings yet

- Maxon EC-Max40 70wattDocument1 pageMaxon EC-Max40 70wattElectromateNo ratings yet

- 16 275 enDocument1 page16 275 enmawadNo ratings yet

- Maxon EC-Max16 5wattDocument1 pageMaxon EC-Max16 5wattElectromateNo ratings yet

- EC 40 40 MM, Brushless, 170 Watt: Part NumbersDocument1 pageEC 40 40 MM, Brushless, 170 Watt: Part NumbersfurkanfurkanfurkanNo ratings yet

- En 21 250Document1 pageEn 21 250compimagmaticNo ratings yet

- EC 90 Flat: 90 MM, Brushless, 600 WattDocument1 pageEC 90 Flat: 90 MM, Brushless, 600 WattDiy DoeNo ratings yet

- 17 en 170 Lstage DatasheetDocument1 page17 en 170 Lstage DatasheetSana SyedNo ratings yet

- Maxon EC22 20watt Integrated ElectronicsDocument2 pagesMaxon EC22 20watt Integrated ElectronicsElectromateNo ratings yet

- Maxon EC-Powermax30 200wattDocument1 pageMaxon EC-Powermax30 200wattElectromateNo ratings yet

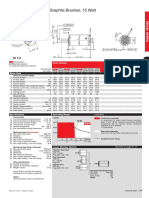

- 30 MM, Graphite Brushes, 60 Watt: Order NumberDocument1 page30 MM, Graphite Brushes, 60 Watt: Order NumberRatanieriNo ratings yet

- 81 PDFDocument1 page81 PDFRatanieriNo ratings yet

- Maxon EC6 1.2wattDocument1 pageMaxon EC6 1.2wattElectromateNo ratings yet

- 12 156 enDocument1 page12 156 enLuka MadridNo ratings yet

- En 21 300Document1 pageEn 21 300Oskar Askarbek PazylbekovNo ratings yet

- Maxon EC-Max22 25wattDocument1 pageMaxon EC-Max22 25wattElectromateNo ratings yet

- Maxon EC20 Flat 3wattDocument1 pageMaxon EC20 Flat 3wattElectromateNo ratings yet

- Maxon EC-Max30 40wattDocument1 pageMaxon EC-Max30 40wattElectromateNo ratings yet

- Maxon Motor Amax26 SpecDocument1 pageMaxon Motor Amax26 SpecjangetialNo ratings yet

- Maxon EC60 400wattDocument1 pageMaxon EC60 400wattElectromateNo ratings yet

- Maxon EC45 Flat 30wattDocument1 pageMaxon EC45 Flat 30wattElectromateNo ratings yet

- Maxon Ec45 136210Document1 pageMaxon Ec45 136210compimagmaticNo ratings yet

- Maxon Re40Document1 pageMaxon Re40compimagmaticNo ratings yet

- F2140 Eng DatasheetDocument4 pagesF2140 Eng Datasheettngyew leeNo ratings yet

- Maxon EC90 Flat 90wattDocument1 pageMaxon EC90 Flat 90wattElectromateNo ratings yet

- Maxon Re40 DC Motor 148866 Datasheet PDFDocument1 pageMaxon Re40 DC Motor 148866 Datasheet PDFtoony reyesNo ratings yet

- Maxon RE30 Graphite Brushes 60wattDocument1 pageMaxon RE30 Graphite Brushes 60wattElectromateNo ratings yet

- RE 25 25 MM, Precious Metal Brushes CLL, 10 Watt: Part NumbersDocument1 pageRE 25 25 MM, Precious Metal Brushes CLL, 10 Watt: Part NumbersWALTER ANDRES CORDOBA CACERENo ratings yet

- En 22 129Document1 pageEn 22 129Best of BestNo ratings yet

- Maxon DCXDocument23 pagesMaxon DCXMurtaza KhanNo ratings yet

- EC 20 Flat 20 MM, Brushless, 5 Watt: Part NumbersDocument1 pageEC 20 Flat 20 MM, Brushless, 5 Watt: Part Numbersivanlawms6745No ratings yet

- Maxon RE50 Graphite Brushes 200wattDocument1 pageMaxon RE50 Graphite Brushes 200wattElectromateNo ratings yet

- En 21 242Document1 pageEn 21 242Zoltán SoósNo ratings yet

- 12 149 enDocument1 page12 149 enLuka MadridNo ratings yet

- Maxon RE-Max17 Graphite Brushes 4.5wattDocument2 pagesMaxon RE-Max17 Graphite Brushes 4.5wattElectromateNo ratings yet

- Maxon RE65 Graphite Brushes 250wattDocument1 pageMaxon RE65 Graphite Brushes 250wattElectromateNo ratings yet

- A-Max-32-236643 10 EN 109Document1 pageA-Max-32-236643 10 EN 109Lovas NorbertNo ratings yet

- BLDC Motor 6 MM: ECX SPEED 6 M BrushlessDocument1 pageBLDC Motor 6 MM: ECX SPEED 6 M Brushlesskishan kharelNo ratings yet

- Motor Maxon 323772Document1 pageMotor Maxon 323772Henry Daniel VerdugoNo ratings yet

- Maxon RE25 Precious Metal Brushes 10wattDocument1 pageMaxon RE25 Precious Metal Brushes 10wattElectromateNo ratings yet

- Maxon Motor Amax22 SpecDocument1 pageMaxon Motor Amax22 SpecjangetialNo ratings yet

- MAXON Brushed Motor A-Max 26, 4.5 WDocument1 pageMAXON Brushed Motor A-Max 26, 4.5 WRadu BabauNo ratings yet

- Motor 30 WattDocument1 pageMotor 30 WattPRED4T0R85No ratings yet

- Motores Maxon 2017Document1 pageMotores Maxon 2017--No ratings yet

- Maxon A-Max32 Graphite Brushes 20wattDocument2 pagesMaxon A-Max32 Graphite Brushes 20wattElectromateNo ratings yet

- Maxon RE40 Graphite Brushes 150wattDocument1 pageMaxon RE40 Graphite Brushes 150wattElectromateNo ratings yet

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Shape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationFrom EverandShape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Electromagnetic Foundations of Electrical EngineeringFrom EverandElectromagnetic Foundations of Electrical EngineeringRating: 1 out of 5 stars1/5 (1)

- Some Power Electronics Case Studies Using Matlab Simpowersystem BlocksetFrom EverandSome Power Electronics Case Studies Using Matlab Simpowersystem BlocksetNo ratings yet

- Explanation of Maxon EC Motor TerminologyDocument1 pageExplanation of Maxon EC Motor TerminologyfurkanfurkanfurkanNo ratings yet

- EC 40 40 MM, Brushless, 170 Watt: Part NumbersDocument1 pageEC 40 40 MM, Brushless, 170 Watt: Part NumbersfurkanfurkanfurkanNo ratings yet

- EC 22 22 MM, Brushless, 50 Watt: Part NumbersDocument1 pageEC 22 22 MM, Brushless, 50 Watt: Part NumbersfurkanfurkanfurkanNo ratings yet

- C++ Programming Language: Week-2 C and C++Document28 pagesC++ Programming Language: Week-2 C and C++furkanfurkanfurkanNo ratings yet

- Prestressed Concrete Poles - State-of-the-Art PDFDocument52 pagesPrestressed Concrete Poles - State-of-the-Art PDFEduardo QuintanaNo ratings yet

- Statistical Molecular Thermodynamics: Christopher J. CramerDocument7 pagesStatistical Molecular Thermodynamics: Christopher J. CramerLuciano Sánchez AramburuNo ratings yet

- Mig Ta500 400500JDocument5 pagesMig Ta500 400500JandraNo ratings yet

- BS en 50443 2011 Effects of ElectromagneticDocument32 pagesBS en 50443 2011 Effects of Electromagneticmehrnoosh fakhariNo ratings yet

- History of JetDocument50 pagesHistory of JetMarko IstenicNo ratings yet

- Iso 21013-4 2012 EnglishDocument16 pagesIso 21013-4 2012 EnglishLuis SuarezNo ratings yet

- On The Energy Impact of Urban Heat Island and Global Warming On BuildingsDocument14 pagesOn The Energy Impact of Urban Heat Island and Global Warming On Buildingsfausto de lucaNo ratings yet

- Falowniki VFS11 PDFDocument2 pagesFalowniki VFS11 PDFkhoa nguyenNo ratings yet

- 1 Introduction To Climate ChangeDocument7 pages1 Introduction To Climate ChangemaryamNo ratings yet

- Energy Conservation Building CodeDocument5 pagesEnergy Conservation Building CodeSwapnil JainNo ratings yet

- DC MachineDocument33 pagesDC MachineSlim ShaddysNo ratings yet

- Transformer Life Extension Options and Considerations 20130820Document107 pagesTransformer Life Extension Options and Considerations 20130820baoHVLAB100% (1)

- 5070 - w18 - QP - 11 CIE O Level Chemistry PDFDocument16 pages5070 - w18 - QP - 11 CIE O Level Chemistry PDFNuman TariqNo ratings yet

- Danfoss APP 16 22 LDocument11 pagesDanfoss APP 16 22 LBanupriya BalasubramanianNo ratings yet

- Lesson 5. Cell Transport NOTESDocument76 pagesLesson 5. Cell Transport NOTESPaolo RapanizaNo ratings yet

- Sommaire: I-What Is Nuclear Energy? II - Operation of Nuclear EnergyDocument8 pagesSommaire: I-What Is Nuclear Energy? II - Operation of Nuclear Energyahmed alexisNo ratings yet

- CryoMac 4 50 GPM LNG Fueling NozzleDocument2 pagesCryoMac 4 50 GPM LNG Fueling Nozzlefaisal.hammad.workNo ratings yet

- HDEPDocument5 pagesHDEPkmsrajuNo ratings yet

- X45 Esco MedicalDocument2 pagesX45 Esco MedicalfebriNo ratings yet

- Liquid Penetrant Testing ModuleDocument59 pagesLiquid Penetrant Testing ModuleDITANo ratings yet

- Rexroth PumpDocument22 pagesRexroth PumpArbey Gonzalez100% (1)

- Curriculum Vitae ATTDocument1 pageCurriculum Vitae ATTSoekhaidir SuripnoNo ratings yet

- Influencing Parameter of Strain Gauge BehaviorDocument15 pagesInfluencing Parameter of Strain Gauge Behaviorsneha sahuNo ratings yet

- Power Electronics: Silicon Controlled RectifiersDocument26 pagesPower Electronics: Silicon Controlled Rectifiers20je0565 Miran ShaikhNo ratings yet

- Human Intelligence and The Environment by Noam ChomskyDocument5 pagesHuman Intelligence and The Environment by Noam ChomskyRana Divyank ChaudharyNo ratings yet

- Catalog Robot Zyj800bDocument74 pagesCatalog Robot Zyj800b96phamminhNo ratings yet