Maxon EC60 400watt

Maxon EC60 400watt

Uploaded by

ElectromateCopyright:

Available Formats

Maxon EC60 400watt

Maxon EC60 400watt

Uploaded by

ElectromateOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Maxon EC60 400watt

Maxon EC60 400watt

Uploaded by

ElectromateCopyright:

Available Formats

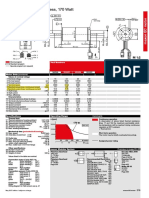

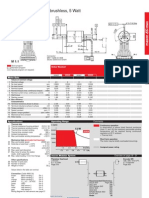

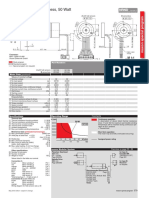

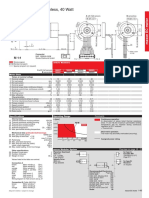

EC 60 Æ60 mm, brushless, 400 Watt, approved

maxon EC motor

M 1:4

Stock program

Standard program Order Number

Special program (on request)

167132 167131

Motor Data

Values at nominal voltage

1 Nominal voltage V 48.0 48.0

2 No load speed rpm 5370 3100

3 No load current mA 733 304

4 Nominal speed rpm 4960 2680

5 Nominal torque (max. continuous torque) mNm 747 830

6 Nominal current (max. continuous current) A 9.38 5.85

7 Stall torque mNm 11800 6820

8 Starting current A 139 46.4

9 Max. efficiency % 86 85

Characteristics

10 Terminal resistance phase to phase W 0.345 1.03

11 Terminal inductance phase to phase mH 0.273 0.82

12 Torque constant mNm / A 84.9 147

13 Speed constant rpm / V 113 65.0

14 Speed / torque gradient rpm / mNm 0.457 0.457

15 Mechanical time constant ms 3.98 3.98

16 Rotor inertia gcm2 831 831

Specifications Operating Range Comments

Thermal data n [rpm]

17 Thermal resistance housing-ambient 1.3 K / W Continuous operation

18 Thermal resistance winding-housing 0.5 K / W In observation of above listed thermal resistance

19 Thermal time constant winding 33.7 s (lines 17 and 18) the maximum permissible winding

20 Thermal time constant motor 1200 s temperature will be reached during continuous

21 Ambient temperature -20 ... +100°C operation at 25°C ambient.

22 Max. permissible winding temperature +125°C = Thermal limit.

Mechanical data (preloaded ball bearings)

23 Max. permissible speed 7000 rpm Short term operation

24 Axial play at axial load < 30 N 0 mm The motor may be briefly overloaded (recurring).

> 30 N max. 0.14 mm

25 Radial play preloaded

26 Max. axial load (dynamic) 26 N Assigned power rating

27 Max. force for press fits (static) 320 N

(static, shaft supported) 8000 N

28 Max. radial loading, 5 mm from flange 240 N

Other specifications maxon Modular System Overview on page 16 - 21

29 Number of pole pairs 1

30 Number of phases 3 Planetary Gearhead Encoder HEDL 9140

31 Weight of motor 2450 g Æ81 mm 500 CPT,

Protection to IP54 20 - 120 Nm 3 channels

Page 246 Page 273

Values listed in the table are nominal.

Resolver Res

Connection motor (Cable AWG 16) Æ26 mm

Cable 1 Motor winding 1 10 V

Cable 2 Motor winding 2 Page 278

Cable 3 Motor winding 3 Brake AB 41

Connection sensors (Cable AWG 24) Æ41 mm

white Hall sensor 3 24 VDC, 2.0 Nm

brown Hall sensor 2 Page 318

green Hall sensor 1 Recommended Electronics:

yellow GND DECS 50/5 Page 288

grey VHall 4.5 ... 24 VDC DEC 50/5 289

blue Temperature sensor (PTC) DEC 70/10 295

pink Temperature sensor (PTC) DES 50/5 296

Temperature monitoring DES 70/10 296

PTC resistance Micropille 110°C, EPOS 70/10 303

R 25°C < 0.5 kW, R 105°C = 1.2 ... 1.5 kW, Sold & Serviced By: Notes 20

R 115°C = 7 ... 13 kW, R 120°C = 18 ... 35 kW ELECTROMATE

Wiring diagram for Hall sensors see page 27 INDUSTRIAL SALES LIMITED

Option: Motor connection with plug PRECISION TECHNOLOGY & QUALITY

Toll Free Phone (877) SERVO98

162 Toll Free Fax (877) SERVO99 May 2009 edition / subject to change

sales@electromate.com

www.electromate.com

You might also like

- Maxon EC-Powermax30 200wattDocument1 pageMaxon EC-Powermax30 200wattElectromateNo ratings yet

- Maxon EC6 1.2wattDocument1 pageMaxon EC6 1.2wattElectromateNo ratings yet

- Maxon EC-Max40 70wattDocument1 pageMaxon EC-Max40 70wattElectromateNo ratings yet

- EC 90 Flat: 90 MM, Brushless, 600 WattDocument1 pageEC 90 Flat: 90 MM, Brushless, 600 WattDiy DoeNo ratings yet

- En 21 300Document1 pageEn 21 300Oskar Askarbek PazylbekovNo ratings yet

- Maxon EC90 Flat 90wattDocument1 pageMaxon EC90 Flat 90wattElectromateNo ratings yet

- En 21 250Document1 pageEn 21 250compimagmaticNo ratings yet

- En 21 242Document1 pageEn 21 242Zoltán SoósNo ratings yet

- EC 40 40 MM, Brushless, 170 Watt: Part NumbersDocument1 pageEC 40 40 MM, Brushless, 170 Watt: Part NumbersfurkanfurkanfurkanNo ratings yet

- RE50Document1 pageRE50Yhony Gamarra VargasNo ratings yet

- Motores PDFDocument1 pageMotores PDFJorge Alejandro Barrutia BorbollaNo ratings yet

- 450W BrushlessDocument1 page450W Brushlessgabriel.rmarquesNo ratings yet

- Catalog Motor EC90Flat 323772Document1 pageCatalog Motor EC90Flat 323772Lucas SuplinoNo ratings yet

- Maxon EC-Max16 5wattDocument1 pageMaxon EC-Max16 5wattElectromateNo ratings yet

- Maxon EC22 50wattDocument1 pageMaxon EC22 50wattElectromateNo ratings yet

- 16 275 enDocument1 page16 275 enmawadNo ratings yet

- 12 156 enDocument1 page12 156 enLuka MadridNo ratings yet

- Maxon EC-Max30 40wattDocument1 pageMaxon EC-Max30 40wattElectromateNo ratings yet

- Maxon RE50 Graphite Brushes 200wattDocument1 pageMaxon RE50 Graphite Brushes 200wattElectromateNo ratings yet

- 81 PDFDocument1 page81 PDFRatanieriNo ratings yet

- 30 MM, Graphite Brushes, 60 Watt: Order NumberDocument1 page30 MM, Graphite Brushes, 60 Watt: Order NumberRatanieriNo ratings yet

- Maxon EC90 Flat 90watt With EncoderDocument1 pageMaxon EC90 Flat 90watt With EncoderElectromateNo ratings yet

- En 22 160Document1 pageEn 22 160gabriel.rmarquesNo ratings yet

- Maxon RE30 Graphite Brushes 60wattDocument1 pageMaxon RE30 Graphite Brushes 60wattElectromateNo ratings yet

- EC - Max 30 30 MM, Brushless, 60 Watt: Part NumbersDocument1 pageEC - Max 30 30 MM, Brushless, 60 Watt: Part NumbersfurkanfurkanfurkanNo ratings yet

- EC 22 22 MM, Brushless, 50 Watt: Part NumbersDocument1 pageEC 22 22 MM, Brushless, 50 Watt: Part NumbersfurkanfurkanfurkanNo ratings yet

- EC 20 Flat 20 MM, Brushless, 5 Watt: Part NumbersDocument1 pageEC 20 Flat 20 MM, Brushless, 5 Watt: Part Numbersivanlawms6745No ratings yet

- Maxon EC22 20watt Integrated ElectronicsDocument2 pagesMaxon EC22 20watt Integrated ElectronicsElectromateNo ratings yet

- Maxon RE25 Precious Metal Brushes 10wattDocument1 pageMaxon RE25 Precious Metal Brushes 10wattElectromateNo ratings yet

- Maxon Ec45 136210Document1 pageMaxon Ec45 136210compimagmaticNo ratings yet

- Maxon RE65 Graphite Brushes 250wattDocument1 pageMaxon RE65 Graphite Brushes 250wattElectromateNo ratings yet

- Motor Maxon 323772Document1 pageMotor Maxon 323772Henry Daniel VerdugoNo ratings yet

- 12 171 enDocument1 page12 171 enLuka MadridNo ratings yet

- Maxon EC20 Flat 3wattDocument1 pageMaxon EC20 Flat 3wattElectromateNo ratings yet

- 17 en 170 Lstage DatasheetDocument1 page17 en 170 Lstage DatasheetSana SyedNo ratings yet

- Maxon Re40 DC Motor 148866 Datasheet PDFDocument1 pageMaxon Re40 DC Motor 148866 Datasheet PDFtoony reyesNo ratings yet

- Maxon Re40Document1 pageMaxon Re40compimagmaticNo ratings yet

- 12 149 enDocument1 page12 149 enLuka MadridNo ratings yet

- RE 25 25 MM, Precious Metal Brushes CLL, 10 Watt: Part NumbersDocument1 pageRE 25 25 MM, Precious Metal Brushes CLL, 10 Watt: Part NumbersWALTER ANDRES CORDOBA CACERENo ratings yet

- Maxon EC45 Flat 30wattDocument1 pageMaxon EC45 Flat 30wattElectromateNo ratings yet

- Maxon Motor Amax26 SpecDocument1 pageMaxon Motor Amax26 SpecjangetialNo ratings yet

- Maxon EC-Max22 25wattDocument1 pageMaxon EC-Max22 25wattElectromateNo ratings yet

- Maxon A-Max26 Precious Metal Brushes 7wattDocument1 pageMaxon A-Max26 Precious Metal Brushes 7wattElectromateNo ratings yet

- F2140 Eng DatasheetDocument4 pagesF2140 Eng Datasheettngyew leeNo ratings yet

- MAXON Brushed Motor A-Max 26, 4.5 WDocument1 pageMAXON Brushed Motor A-Max 26, 4.5 WRadu BabauNo ratings yet

- Maxon Motor Amax22 SpecDocument1 pageMaxon Motor Amax22 SpecjangetialNo ratings yet

- Motores Maxon 2017Document1 pageMotores Maxon 2017--No ratings yet

- Maxon EC20 Flat 5wattDocument1 pageMaxon EC20 Flat 5wattElectromateNo ratings yet

- Maxon RE-Max17 Graphite Brushes 4.5wattDocument2 pagesMaxon RE-Max17 Graphite Brushes 4.5wattElectromateNo ratings yet

- Analog Dialogue, Volume 48, Number 1: Analog Dialogue, #13From EverandAnalog Dialogue, Volume 48, Number 1: Analog Dialogue, #13Rating: 4 out of 5 stars4/5 (1)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- The Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationFrom EverandThe Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationNo ratings yet

- Flexible Power Transmission: The HVDC OptionsFrom EverandFlexible Power Transmission: The HVDC OptionsRating: 5 out of 5 stars5/5 (1)

- New High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesDocument2 pagesNew High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesElectromateNo ratings yet

- Exor X5 Wireless Press ReleaseDocument1 pageExor X5 Wireless Press ReleaseElectromateNo ratings yet

- Electromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaDocument1 pageElectromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaElectromateNo ratings yet

- ADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesDocument2 pagesADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesElectromateNo ratings yet

- New LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsDocument1 pageNew LDL Programmable Linear Actuator From SMAC Moving Coil ActuatorsElectromateNo ratings yet

- Mecademic Robotics Releases New Firmware For Its Meca500 RobotDocument2 pagesMecademic Robotics Releases New Firmware For Its Meca500 RobotElectromateNo ratings yet

- Meet The World's Most Precise Six-Axis RobotDocument1 pageMeet The World's Most Precise Six-Axis RobotElectromateNo ratings yet

- Electromate Recognized With 2021 AHTD Foundation AwardDocument1 pageElectromate Recognized With 2021 AHTD Foundation AwardElectromateNo ratings yet

- Electromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseDocument2 pagesElectromate Made It To The 2021 List of Best Workplaces™ in Ontario Press ReleaseElectromateNo ratings yet

- Harmonic Drive Releases New CSF-ULW Ultra-Light Weight GearheadDocument1 pageHarmonic Drive Releases New CSF-ULW Ultra-Light Weight GearheadElectromateNo ratings yet

- Electromate® Inc. Recertified As A Great Place To Work® Feb. 18, 2020Document2 pagesElectromate® Inc. Recertified As A Great Place To Work® Feb. 18, 2020ElectromateNo ratings yet

- New Large, Hollow-Shaft Gear Unit From Harmonic Drive LLCDocument1 pageNew Large, Hollow-Shaft Gear Unit From Harmonic Drive LLCElectromateNo ratings yet

- New LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsDocument1 pageNew LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsElectromateNo ratings yet

- Complete Guided Wheel Motion Solutions From BWC New Product Press ReleaseDocument2 pagesComplete Guided Wheel Motion Solutions From BWC New Product Press ReleaseElectromateNo ratings yet

- Differential Protection Strategies For Synchronous Motor A Case StudyDocument5 pagesDifferential Protection Strategies For Synchronous Motor A Case StudylocomaniacoNo ratings yet

- Abb-General Purpose Brake Motors PDFDocument21 pagesAbb-General Purpose Brake Motors PDFbilgipaylasimNo ratings yet

- NMAT Tips & TricksDocument5 pagesNMAT Tips & TricksAbdur Rahmaan HudliNo ratings yet

- Electronic Structure of Atoms: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDocument41 pagesElectronic Structure of Atoms: Theodore L. Brown H. Eugene Lemay, Jr. and Bruce E. BurstenDiego Ricardo CarriazoNo ratings yet

- Guess Paper IX PhysicsDocument3 pagesGuess Paper IX Physicsrigahob761No ratings yet

- Dynamics LectureDocument19 pagesDynamics LectureHERMINIO MENDOZANo ratings yet

- ρ in the: Answer all questionsDocument5 pagesρ in the: Answer all questions000No ratings yet

- Levi, E. - Multiphase Electric Machines For Variable-Speed ApplicationsDocument17 pagesLevi, E. - Multiphase Electric Machines For Variable-Speed ApplicationsSherif M. Dabour100% (2)

- Negative Mass Propulsion: F. WinterbergDocument14 pagesNegative Mass Propulsion: F. WinterbergTeabeamet Teabe Amet LuureAmetNo ratings yet

- IGCSE 91 Forces and Motion QPDocument23 pagesIGCSE 91 Forces and Motion QPsciencedocsmanNo ratings yet

- Andrei Melnichenko InventionsDocument7 pagesAndrei Melnichenko InventionsPopescu George BogdanNo ratings yet

- MCQ DC Machines MasterDocument16 pagesMCQ DC Machines MasterDeepak Choudhary DCNo ratings yet

- Elasticity & Oscillations: Ut Tension, Sic Vis As Extension, So Force. Extension Is Directly Proportional To ForceDocument11 pagesElasticity & Oscillations: Ut Tension, Sic Vis As Extension, So Force. Extension Is Directly Proportional To ForceJustin Paul VallinanNo ratings yet

- Magnetohydrodynamic Power Generation: June 2013Document12 pagesMagnetohydrodynamic Power Generation: June 2013Virruru NarendraNo ratings yet

- PrezentacijaDocument110 pagesPrezentacijaAnonymous NslCHhNo ratings yet

- NBPhO19 EngDocument2 pagesNBPhO19 EngDino SelimovicNo ratings yet

- Power Analyzer: ObjectiveDocument5 pagesPower Analyzer: ObjectiveAsad TariqNo ratings yet

- CentripetalDocument6 pagesCentripetalR MathewNo ratings yet

- Fundamentals of MagnetismDocument7 pagesFundamentals of MagnetismMunir MuktarNo ratings yet

- Bus Bar Arrangement at SPDocument18 pagesBus Bar Arrangement at SPmukesh kumar meenaNo ratings yet

- The Sussex VT1: As Interpreted by Les Carpenter G4CNHDocument27 pagesThe Sussex VT1: As Interpreted by Les Carpenter G4CNHrogerio pessanha dos santosNo ratings yet

- Characteristics of Waves: Questions AnswersDocument2 pagesCharacteristics of Waves: Questions AnswersAnonymous yQ5QclspuNo ratings yet

- 10 MMA WeldingDocument16 pages10 MMA WeldingfehmohdNo ratings yet

- Na Quiz Test - 2014Document1 pageNa Quiz Test - 2014S JainNo ratings yet

- Week OneDocument44 pagesWeek OneSideman123No ratings yet

- Note ASG-MT-1196 - 27/8/2018 1BC, 2BC, 3BC, 4BC, 5BC PH-2Document1 pageNote ASG-MT-1196 - 27/8/2018 1BC, 2BC, 3BC, 4BC, 5BC PH-2Anonymous dH3DIEtzNo ratings yet

- Physics - Unit 2 - Module 1 - Lab 1 - Potential DividerDocument5 pagesPhysics - Unit 2 - Module 1 - Lab 1 - Potential DividerDaleyt56 DaleyNo ratings yet

- 4 - Impulse and MomentumDocument20 pages4 - Impulse and MomentumBg PJchppNo ratings yet

- Service Manuals LG Microwave MS3447GRS MS3447GRS Service ManualDocument33 pagesService Manuals LG Microwave MS3447GRS MS3447GRS Service ManualHoudini0001100% (1)

- Mechanical Accelerometer System AnalysisDocument4 pagesMechanical Accelerometer System AnalysisAlejandro López SaldañaNo ratings yet