XQP.3... O 2/3: PEN Loop WAY Proportional Pressure Compensated Flow Regulators

XQP.3... O 2/3: PEN Loop WAY Proportional Pressure Compensated Flow Regulators

Uploaded by

PitupyCopyright:

Available Formats

XQP.3... O 2/3: PEN Loop WAY Proportional Pressure Compensated Flow Regulators

XQP.3... O 2/3: PEN Loop WAY Proportional Pressure Compensated Flow Regulators

Uploaded by

PitupyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

XQP.3... O 2/3: PEN Loop WAY Proportional Pressure Compensated Flow Regulators

XQP.3... O 2/3: PEN Loop WAY Proportional Pressure Compensated Flow Regulators

Uploaded by

PitupyCopyright:

Available Formats

XQP.3...

OPEN LOOP 2/3 WAY PROPORTIONAL

PRESSURE COMPENSATED FLOW REGULATORS

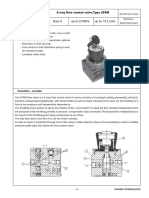

The open loop proportional flow regulator is 2 and 3 way compensated with priority function.

It is designed to regulate flow in proportion to an applied electrical current (REM or SE3AN

power amplifier). Flow regulation is load independent - B port. Load compensation is achieved

by a spool compensator which holds the pressure drop constant across the proportional spool.

Valves are available in the following versions

(see hydraulic symbol):

- 2 way pressure compensated - 3 way

XQP.3... pressure compensated with priority function.

STANDARD CONNECTORS CH. I PAGE 19 - 3 way pressure compensated with priority

and venting function.

"D15P" PROPORT. SOLENOIDS CH. VIII PAGE 21

REM.S.RA... CH. IX PAGE 4

SE.3.AN.21.00... CH. IX PAGE 11

BC.06.XQP3... CH. VII PAGE 13 • In order to obtain the 2 way pressure

compensated version the cavities P and T

HYDRAULIC SYMBOLS have be closed on the subplate.

ORDERING CODE

SIMPLIFIED TYPE

XQP Open loop 2/3 way

proportional compensated

flow regulator

• In order to obtain the 3 way pressure

3 CETOP 3/NG6 compensated version the cavity T have be

closed on the subplate.

C 2/3 way compensation

with priority function

DIAGRAMS

3 3 way version (standard) ΔP - FLOW RATE A → B ΔP - SECONDARY LINE FLOW

For to obtain 2-way version the P line (WITH 5 l/min TO P) (A → P FREE)

must be closed on the subplate

* Nominal flow rates

F = 6 l/min

Δp (bar)

Δp (bar)

G = 12 l/min

H = 22 l/min

I = 32 l/min

L = 40 l/min

* S = without decompression

8 *

D = with decompression

Max. current to solenoid

Q (l/min)

FLOW RATE

BACK PRESSURE ON PRIORITY LINE

Q (l/min)

FLOW RATE

BACK PRESSURE ON SECONDARY LINE

E = 2.35 A

F = 1.76 A

G = 0.88 A

Q (l/min)

Q (l/min)

** Variant (*):

S1 = No variant

P2 = Rotary emergency

R5 = Rotary emergency 180°

SV = Viton

2 Serial No. P (bar) P (bar)

INPUT SIGNAL 2 WAY COMPENSATION 2 WAY COMPENSATION

FLOW (A 270 bar - B VARIABLE) (A VARIABLE - B 30 bar)

(*) All variants

are considered

without connec-

tors. The connec-

Q (l/min)

Q (l/min)

Q (l/min)

tors must be order

separately.

See Ch. I Page 19

I (%) P (bar) P (bar)

The fluid used is a mineral based oil with a viscosity of 46 mm2/s at 40°C.

The tests have been carried out at with a fluid of a 40°C.

File: XQP3002_E VIII • 20 02 /2011/e

XQP.3... OPEN LOOP 2/3 WAY PROPORTIONAL

PRESSURE COMPENSATED FLOW REGULATORS

OPERATING SPECIFICATIONS

Max. operat. pressure ports A/B /P see note (*) With T port blocked on subplate 250 bar AMPLIFIER UNIT AND CONTROL

Regulated flow rate 6 / 12 / 22 / 32 / 40 l/min

REM.S.RA.*.*...

Decompression drain flow max 0,7 l/min

Electronic card for control single proportional

Relative duty cycle Continuous 100% ED

solenoid valve

Type of protection (in relation to the connector used) IP 65

Flow rate gain See diagram "Input signal flow"

Fluid viscosity 10 ÷ 500 mm2/s SE.3.AN.21.00...

Fluid temperature -20°C ÷ 75°C Electronic card format EUROCARD for control

Ambient temperature -20°C ÷ 70°C single proportional solenoid valve

Max. contamination level from class 7 to 9 in accordance

with NAS 1638 with filter ß10≥75

Weight 1,7 Kg

Max. current 2.33A 1.76 A 0.88 A

Solenoid coil resistance at 25°C (77°F) 2.25 Ohm 4.0 Ohm 16.0 Ohm

Hysteresis with Δp 7 bar ≤5% <5% <8%

Response to step Δp = 7 bar

0 ÷ 100% 32 ms 40 ms 85 ms

100% ÷ 0 33 ms 33 ms 33 ms

Frequency response -3db (Input signal 50% ± 25% Vmax.)

22Hz 22Hz 12Hz

(*) Pressure dynamic allowed for 2 millions of cycles

Operating specifications are valid for fluids with 46 mm2/s viscosity at 40°C, using

specified ARON electronic control units.

Performance data are carried out using the specified Aron power amplifier SE.3.AN...

powered to 24V.

OVERALL DIMENSIONS

P2 Rotary emergency 8

R5 Rotary emergency 180°

Fixing screws UNI 5931 M5x25 Support plane

(min. 8.8 material screws are recommended) specifications

Tightening torque 4 ÷ 5 Nm / 0.4 ÷ 0.5 Kgm

"D15P" PROPORTIONAL SOLENOIDS

Type of protection (in relation to connector used) IP 66

Duty cycle 100% ED

Insulation class wire H

Weight (coil) 0,354 Kg

Weight (solenoid) 0,608 Kg

ETD15P - 01/2002/e

File: XQP3002_E VIII • 21 02/2011/e

You might also like

- McCLOSKEY ST80-MANUAL-KUBOTADocument29 pagesMcCLOSKEY ST80-MANUAL-KUBOTAPitupy100% (1)

- 160.84 EG1 Engineering Guide Model YMC2 Magentic Bearing Centrifugal Liq...Document70 pages160.84 EG1 Engineering Guide Model YMC2 Magentic Bearing Centrifugal Liq...dszvNo ratings yet

- Spillback CompressorDocument3 pagesSpillback CompressorpsaradaNo ratings yet

- Pioneer XDJ-1000 PDFDocument41 pagesPioneer XDJ-1000 PDFboroda241050% (2)

- XQP5001 eDocument2 pagesXQP5001 enadmyrNo ratings yet

- XQP.5. O 2/3 C 5: PEN Loop WAY Proportional Pressure Compensated Flow Regulators EtopDocument2 pagesXQP.5. O 2/3 C 5: PEN Loop WAY Proportional Pressure Compensated Flow Regulators EtopPitupyNo ratings yet

- XDP.5.A... / XDP.5.C ... P: Roportional Directional Valves Open LoopDocument2 pagesXDP.5.A... / XDP.5.C ... P: Roportional Directional Valves Open LoopPitupyNo ratings yet

- Presentation On 3-Element Control and Surge Control SystemDocument11 pagesPresentation On 3-Element Control and Surge Control SystemriteshrishabhNo ratings yet

- XDP3002 eDocument2 pagesXDP3002 eEvgeni FrangovNo ratings yet

- Lecture-5 Drilling EngineeringDocument23 pagesLecture-5 Drilling Engineeringحيدر بادي - Haider BadiNo ratings yet

- XDP.3.A... / XDP.3.C ... P: Roportional Directional Valves Open LoopDocument2 pagesXDP.3.A... / XDP.3.C ... P: Roportional Directional Valves Open LoopAbddia SolennisNo ratings yet

- XEPV.3... P V E B: Roportional Alve With Lectronic ON OardDocument3 pagesXEPV.3... P V E B: Roportional Alve With Lectronic ON OardPitupyNo ratings yet

- A11v0 eDocument32 pagesA11v0 eDhanraj PatilNo ratings yet

- Basic Surge Control System: FCV CoolerDocument2 pagesBasic Surge Control System: FCV Coolerankur2061No ratings yet

- Logsheet 3hrDocument11 pagesLogsheet 3hrfaiz budiNo ratings yet

- Terminology and Performance Features of Proportional Valve and ServovalveDocument21 pagesTerminology and Performance Features of Proportional Valve and ServovalvenarimeneNo ratings yet

- Log Sheet Engineering Gumaya Tower Hotel Semarang Water Storage & Pool Treatment B2 Month Of: 2018Document11 pagesLog Sheet Engineering Gumaya Tower Hotel Semarang Water Storage & Pool Treatment B2 Month Of: 2018faiz budi0% (1)

- Mech. Equip. Hyd. & Pneumatic SysDocument25 pagesMech. Equip. Hyd. & Pneumatic Syshema_1959No ratings yet

- Equipos de CalderaDocument1 pageEquipos de Calderaevawali0002No ratings yet

- Chapter_5_2021 (1)Document9 pagesChapter_5_2021 (1)khangthanh1911No ratings yet

- Fluid Mechanics Day 9 Chapter5 Long Mar 2024Document22 pagesFluid Mechanics Day 9 Chapter5 Long Mar 2024Đại Quý NgôNo ratings yet

- XECV.3... C L P V E B: Losed OOP Roportional Alve With Lectronic ON OardDocument3 pagesXECV.3... C L P V E B: Losed OOP Roportional Alve With Lectronic ON OardPitupyNo ratings yet

- D7765N enDocument13 pagesD7765N enli geneNo ratings yet

- Z2FS 6, 16, 22 Modular Throttle Check ValveDocument6 pagesZ2FS 6, 16, 22 Modular Throttle Check Valvenemi90No ratings yet

- 1260709146e - Hydraulics PDFDocument9 pages1260709146e - Hydraulics PDFAbdul Hameed OmarNo ratings yet

- PMCC (TB11) - Part-1Document30 pagesPMCC (TB11) - Part-1sanjay kumar sikdarNo ratings yet

- Operaciones de Transferencia de Calor Examen # 2Document19 pagesOperaciones de Transferencia de Calor Examen # 2Estefanía Angel ClavijoNo ratings yet

- HANDBOOK_FOR_CONTROL_VALVE_SIZING_PARCOLDocument21 pagesHANDBOOK_FOR_CONTROL_VALVE_SIZING_PARCOLhanfeng.zouNo ratings yet

- Control Valve SizingDocument21 pagesControl Valve Sizingtiwarishailendra2198100% (1)

- 2FRM 6Document6 pages2FRM 6Romly MechNo ratings yet

- Procidia Control Solutions Compressor Surge Control: Application DataDocument3 pagesProcidia Control Solutions Compressor Surge Control: Application DataAto AnsoriNo ratings yet

- Fundamentals of Compressible Flows in Pipelines: Dr. Ahmed Elmekawy Fall 2018Document74 pagesFundamentals of Compressible Flows in Pipelines: Dr. Ahmed Elmekawy Fall 2018Tamunoiboumie ElijahNo ratings yet

- Variable Displacement Vane Pump Variable Displacement Vane PumpDocument4 pagesVariable Displacement Vane Pump Variable Displacement Vane PumpRonaldNo ratings yet

- XDC.3... P: Roportional Directional Valves Closed Loop Position ControlDocument2 pagesXDC.3... P: Roportional Directional Valves Closed Loop Position ControlPitupyNo ratings yet

- AM3 3 QF Flow-Regulator-Cetop-3Document1 pageAM3 3 QF Flow-Regulator-Cetop-3PitupyNo ratings yet

- Datenblatt PDFDocument6 pagesDatenblatt PDFsabouni1970No ratings yet

- Info On DRS, MRS, SRDocument23 pagesInfo On DRS, MRS, SRsushant shirsatNo ratings yet

- Week 6 NotesDocument2 pagesWeek 6 NotesBowei ZhangNo ratings yet

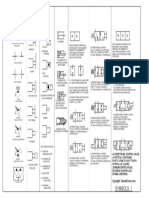

- Symbols 1Document1 pageSymbols 1KOWSHIK 4310No ratings yet

- Re28164 2011-05Document8 pagesRe28164 2011-05Daniel GómezNo ratings yet

- Fans and Blowers Ygmelliza PDFDocument22 pagesFans and Blowers Ygmelliza PDFtristan calaraNo ratings yet

- 2FRM 5Document5 pages2FRM 5Romly MechNo ratings yet

- Boiler Controls: Low Water Cut-Offs - Mechanical For Steam BoilersDocument1 pageBoiler Controls: Low Water Cut-Offs - Mechanical For Steam BoilersAlfredo Mitzi HernandezNo ratings yet

- bucher-mtkavd-2m22-018178-flow-control-valve-560687Document6 pagesbucher-mtkavd-2m22-018178-flow-control-valve-560687Marusya KlimovaNo ratings yet

- Load Test Single Phase TransformerDocument8 pagesLoad Test Single Phase Transformerrakshnaanachiyar.sureshNo ratings yet

- Amca L Mov e 06 02Document2 pagesAmca L Mov e 06 02manjappahNo ratings yet

- Van Nap LT06Document3 pagesVan Nap LT06hoiNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- AX152886482331en-US0502 JDocument408 pagesAX152886482331en-US0502 JPitupyNo ratings yet

- Catalogo Poly 2Document4 pagesCatalogo Poly 2PitupyNo ratings yet

- Doc.i NRB Cat1 Gba WebDocument84 pagesDoc.i NRB Cat1 Gba WebPitupyNo ratings yet

- 2020 North American Customer Training CatalogDocument30 pages2020 North American Customer Training CatalogPitupyNo ratings yet

- Service Tool Screens: JS1 PVE JoystickDocument20 pagesService Tool Screens: JS1 PVE JoystickPitupyNo ratings yet

- Service Manual PVG32 - 16Document28 pagesService Manual PVG32 - 16PitupyNo ratings yet

- 02B PVG Specsheet Field HelpDocument4 pages02B PVG Specsheet Field HelpPitupyNo ratings yet

- XECV.3... C L P V E B: Losed OOP Roportional Alve With Lectronic ON OardDocument3 pagesXECV.3... C L P V E B: Losed OOP Roportional Alve With Lectronic ON OardPitupyNo ratings yet

- XEPV.3... P V E B: Roportional Alve With Lectronic ON OardDocument3 pagesXEPV.3... P V E B: Roportional Alve With Lectronic ON OardPitupyNo ratings yet

- XDC.3... P: Roportional Directional Valves Closed Loop Position ControlDocument2 pagesXDC.3... P: Roportional Directional Valves Closed Loop Position ControlPitupyNo ratings yet

- AM3 3 QF Flow-Regulator-Cetop-3Document1 pageAM3 3 QF Flow-Regulator-Cetop-3PitupyNo ratings yet

- Hydraulic Motor Type Mhl... : Max. Speed (RPM)Document9 pagesHydraulic Motor Type Mhl... : Max. Speed (RPM)PitupyNo ratings yet

- DSG 03 PDFDocument17 pagesDSG 03 PDFPitupyNo ratings yet

- 9970 Hall Effect Sensor: Mechanical Specifications Electrical Specifications Environmental SpecificationsDocument2 pages9970 Hall Effect Sensor: Mechanical Specifications Electrical Specifications Environmental SpecificationsPitupyNo ratings yet

- Pressure and Flow Control System Type SYDFE1-2X, SYDFEE-2X, SYDFEC-2X, Sydfen-2X, Sydfed-2XDocument40 pagesPressure and Flow Control System Type SYDFE1-2X, SYDFEE-2X, SYDFEC-2X, Sydfen-2X, Sydfed-2XPitupyNo ratings yet

- Double PointersDocument21 pagesDouble PointersMahbub PatwariNo ratings yet

- Sample Daily Checklists For Powered Industrial Trucks: OSHA-ITA AllianceDocument4 pagesSample Daily Checklists For Powered Industrial Trucks: OSHA-ITA Alliancetemter gandaNo ratings yet

- HVAC Exam AnswersDocument10 pagesHVAC Exam Answersakshay kanadeNo ratings yet

- 1.3 StorageDocument55 pages1.3 StorageAnbarNo ratings yet

- 3 - What Is NonceDocument3 pages3 - What Is NonceprathamNo ratings yet

- TheEtsySuccessRoadmap LoveLissyDocument6 pagesTheEtsySuccessRoadmap LoveLissyPhát Nguyễn LýNo ratings yet

- Fuhrer A OpDocument116 pagesFuhrer A OpampueroromoNo ratings yet

- 18 IBCAST-2021: Important Important Dates DatesDocument14 pages18 IBCAST-2021: Important Important Dates DatesAsad MianNo ratings yet

- Cisco SD AccessDocument10 pagesCisco SD Accessjim1234uNo ratings yet

- OCW SKN3022 Instrumentation CH 3Document31 pagesOCW SKN3022 Instrumentation CH 3ramajaxNo ratings yet

- Installation Instruction No. 132101F/02.2008 Seik 14, 24, 34Document5 pagesInstallation Instruction No. 132101F/02.2008 Seik 14, 24, 34Sonia Noval LlorianNo ratings yet

- GCS 54 Cutover PlanDocument62 pagesGCS 54 Cutover PlanДашенька Большерёва-Рыкова100% (1)

- ET 7255 DatasheetDocument2 pagesET 7255 Datasheetliew kai huNo ratings yet

- SQL ExamplesDocument4 pagesSQL ExamplesCRONOQUILL OFFICIALNo ratings yet

- 1st Sem SKED 22 231st 5thMAS OFFICIAL PAblankBIENDocument11 pages1st Sem SKED 22 231st 5thMAS OFFICIAL PAblankBIENIzzah LNo ratings yet

- LTE Link BudgetDocument30 pagesLTE Link BudgetChandra GalajuNo ratings yet

- SAP Purchase Requisition ProcessDocument33 pagesSAP Purchase Requisition Processmario.netoNo ratings yet

- NAPIX LGD API Consumer Guidelines v1.1Document14 pagesNAPIX LGD API Consumer Guidelines v1.1mihirmddNo ratings yet

- ST14 V1.2 Electrical SystemDocument24 pagesST14 V1.2 Electrical SystemDugao Aya-os100% (1)

- Ict Introduction 103Document4 pagesIct Introduction 103Leah LabelleNo ratings yet

- Understanding DatabasesDocument50 pagesUnderstanding DatabasesAlexander Reyes QuinteroNo ratings yet

- WP 8 Climate Energy and Mobility Horizon 2021 2022 enDocument496 pagesWP 8 Climate Energy and Mobility Horizon 2021 2022 enThierry GailletNo ratings yet

- RGH41 Series Readhead Installation GuideDocument9 pagesRGH41 Series Readhead Installation GuideJohan LoockNo ratings yet

- ! SCM Chopra Chapters 1-17Document406 pages! SCM Chopra Chapters 1-17Bibekananda Panda43% (7)

- MIL 1ST QUARTER REVIEWERDocument11 pagesMIL 1ST QUARTER REVIEWERoliveNo ratings yet

- Pallavi Sagar: ObjectiveDocument2 pagesPallavi Sagar: ObjectivePallavi SagarNo ratings yet

- Register FormateDocument2 pagesRegister FormateDhruvi PatadiaNo ratings yet

- Building Drawing Sangita SahuDocument15 pagesBuilding Drawing Sangita SahuKavya Engineering ConsultancyNo ratings yet

- Research Paper On Augmented RealityDocument6 pagesResearch Paper On Augmented RealityHarshit RajNo ratings yet