0 ratings0% found this document useful (0 votes)

93 viewsX-Mix CableGrout Additive

X-Mix CableGrout Additive

Uploaded by

KRISHNA PRASATH SThis document provides information on X-Mix CableGrout Additive, a cementitious grout admixture for post-tensioned cables. It produces a free-flowing non-shrink grout when mixed with cement and water. Key features include controlled expansion to compensate for shrinkage, high early and ultimate strength, and low permeability. The additive is supplied as a dry powder in 12 kg bags and has a shelf life of 12 months. Detailed mixing and application instructions are provided.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

X-Mix CableGrout Additive

X-Mix CableGrout Additive

Uploaded by

KRISHNA PRASATH S0 ratings0% found this document useful (0 votes)

93 views2 pagesThis document provides information on X-Mix CableGrout Additive, a cementitious grout admixture for post-tensioned cables. It produces a free-flowing non-shrink grout when mixed with cement and water. Key features include controlled expansion to compensate for shrinkage, high early and ultimate strength, and low permeability. The additive is supplied as a dry powder in 12 kg bags and has a shelf life of 12 months. Detailed mixing and application instructions are provided.

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

This document provides information on X-Mix CableGrout Additive, a cementitious grout admixture for post-tensioned cables. It produces a free-flowing non-shrink grout when mixed with cement and water. Key features include controlled expansion to compensate for shrinkage, high early and ultimate strength, and low permeability. The additive is supplied as a dry powder in 12 kg bags and has a shelf life of 12 months. Detailed mixing and application instructions are provided.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

93 views2 pagesX-Mix CableGrout Additive

X-Mix CableGrout Additive

Uploaded by

KRISHNA PRASATH SThis document provides information on X-Mix CableGrout Additive, a cementitious grout admixture for post-tensioned cables. It produces a free-flowing non-shrink grout when mixed with cement and water. Key features include controlled expansion to compensate for shrinkage, high early and ultimate strength, and low permeability. The additive is supplied as a dry powder in 12 kg bags and has a shelf life of 12 months. Detailed mixing and application instructions are provided.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

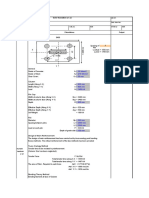

Technical Data Sheet

X-Mix CableGrout Additive

Cementitious grout admixture for post tensioned cables 80150515

Product Description Yield

X-Mix CableGrout Additive is supplied as a dry powder Approximately 140 liters when mixed with 200 kg

requiring only the addition of a controlled amount of clean cement, 84 liters of water and 12kg of X-Mix CableGrout

water and cement to produce a free flowing non-shrink Additive.

grout.

X-Mix CableGrout Additive is an all fines admixture which Packaging

imparts controlled expansion in the plastic state whilst 12 kg bags, can be altered to suit mixing volumes.

minimising water demand. The material is designed to

allow uniform mixing, and eliminates unwanted Shelf Life

segregation and bleeding. X-Mix CableGrout Additive has a shelf life of 12 months if

kept in a dry store in sealed bags. If stored in high

Advantages temperature and high humidity the shelf life will be

• Expansion system compensates for shrinkage and reduced.

settlement in the plastic state

• Develops high early strength Instruction for use

• High ultimate strength and low permeability ensure Preparation

the durability of the hardened grout Several hours prior to grouting, the area should be

• Compatible with ordinary Portland Cements complying flooded with fresh water. Immediately before grouting

to BS 12 and ASTM C150. remove any free water should be removed.

All cable ducts must be thoroughly cleaned. Those ducts

Uses formed without metal sheaths should be flushed with

For pumped or free flow grouting, it can be used in a wide water after which all surplus water must be removed.

range of applications: Cable anchorages should be sealed before the duct

• Post tensioned bridge deck ducts grouting is carried out.

• Prestressed structural element cables ducts

• Slip form silo tendon ducts Application

Mixing

Application Properties For best results a mechanically powered grout mixer

The following properties were achieved using 200 kg OPC, should be used. When quantities of up to 60 kg are

84 liters of water and 12kg of X-Mix CableGrout Additive. used, a slow speed drill fitted with a high shear mixer is

suitable. Larger quantities will require a high shear vane

Compressive strength 40 N/mm2 at 7 days

mixer. Do not use a colloidal impeller mixer, if sands/

55 N/mm2 at 28 days

aggregates are being utilised.

Flexural strength 7 N/mm2 at 7 days

To enable the grouting operation to be carried out

Fluidity Initial < 25sec continuously, it is essential that sufficient mixing capacity

Flow cone method 30 min < 25sec and labour are available. The use of a grout holding tank

with provision to gently agitate the grout may be

Bleeding Nil required.

Expansion characteristics 0 to 4%

8 to 8.5 litres of clean water (depending on nature of

Chloride content Nil to BS5075 cement) and 20 kg of cement are required to be added

per 1.2 kg of X-Mix CableGrout Additive to achieve the

Note: It is recommended that trials be conducted prior to correct consistency. The water should be accurately

use, to ascertain the best source of OPC for the measured into the mixer then X-Mix CableGrout Additive

application. OPC varies in quality and consistency. slowly added with the cement and continuous mixing

should take place for 5 minutes. This will ensure that the

grout has a smooth even consistency. Authorized Technical Specialist

Please note that only X-Calibur Authorized Technical

Placing Specialists (‘ATSs’) are permitted to change any of the

Place the grout within 20 minutes of mixing. X-Mix information in this data sheet or to provide written

CableGrout Additive can be placed in annular gaps of up recommendations concerning the use of this product.

to 60mm in thickness. Visit www.x-calibur.us for a full list of X-Calibur ATSs.

Pumping should be from a single point to eliminate any Datasheet Validity

air or water entrapment. A heavy duty diaphragm pump X-Calibur makes modifications to its product datasheets

is recommended for pumping. Screw feed and piston on a continuous basis. Please check the datasheet

pumps may also be suitable. update section on www.x-calibur.us to ensure you have

the latest version.

Curing

Any exposed areas should be thoroughly cured. This Warranties

should be done by the use of X-Cure WB curing X-Calibur supplies products that comply with the

membrane. properties shown on the current datasheets. In the

unlikely event that products supplied are proved not to

Clean Up comply with these properties, then we will replace the

X-Mix CableGrout Additive should be removed from tools non-compliant product or refund the purchase price.

and equipment with clean water immediately after use. X-Calibur does not warrant or guarantee the installation

Cured material can be removed mechanically. of the products as it does not have control over the

installation or end use of the products. Any suspected

Limitations defects must be reported to X-Calibur in writing within

Low temperature working five working days of being detected. X-Calibur

For ambient temperatures below 10oC the formwork Construction Chemistry Inc. makes no warranty as to

should be kept in place for at least 36 hours. merchantability or fitness for a particular purpose

When the air or contact surface temperatures are 5°C or and this warranty is in lieu of all other warranties

below on a falling thermometer, warm water express or implied. X-Calibur Construction Chemistry

(30 to 40°C) is recommended to accelerate strength Inc. shall not be liable for damages of any sort including

development. Normal precautions for winter working remote or consequential damages, down time, or delay.

with cementitious materials should then be adopted.

High temperature working

It is suggested that, for temperatures above 35°C, the

following guidelines are adopted as good working

practice:

(i) Store unmixed material in a shaded location avoiding

exposure to direct sunlight.

(ii) Keep equipment cool, arranging shade protection if

necessary. It is especially important to keep cool those

surfaces of the equipment which will come into direct

contact with the material itself.

(iii) Try to eliminate application during the hottest times

of the day.

(iv) Make sufficient material, plant and labour available

to ensure that application is a continuous process.

(v) Water (below 20°C) should be used for mixing the

grout prior to placement.

Health and Safety

This product is for industrial use only by trained

operatives. It is potentially hazardous if not used

correctly. Please refer to the Material Safety Data

Sheet (MSDS) prior to the purchase and use of

this product. The MSDS can be obtained via our

website www.x-calibur.us.

www.x-calibur.us

You might also like

- Memo - 11 - Save ElectricityDocument1 pageMemo - 11 - Save ElectricityKRISHNA PRASATH S100% (8)

- X-Tite Construction GroutDocument2 pagesX-Tite Construction GroutEndayenewMollaNo ratings yet

- Cebex Cable Grout - FosrocDocument4 pagesCebex Cable Grout - FosrocIrshadYasinNo ratings yet

- Accogrout: Description AdvantagesDocument2 pagesAccogrout: Description AdvantagesrajupetalokeshNo ratings yet

- Masterflow 810: Non-Shrink, Precision Cementitious Grout For Use in General Civil Engineering WorksDocument2 pagesMasterflow 810: Non-Shrink, Precision Cementitious Grout For Use in General Civil Engineering WorksPradeep KumaraNo ratings yet

- Flo-Add C.Document2 pagesFlo-Add C.tuski24No ratings yet

- MasterFlow810 TDSDocument2 pagesMasterFlow810 TDSPT PP BIH SanurNo ratings yet

- Conbextra Cable GroutDocument4 pagesConbextra Cable GroutVenkata RaoNo ratings yet

- Datasheet File - Conbextra GPDocument3 pagesDatasheet File - Conbextra GPmuraliNo ratings yet

- X-Pruf Crystal Mix PowderDocument2 pagesX-Pruf Crystal Mix PowderVenkat Uday KiranNo ratings yet

- X-Tech CrystalClear 3Document2 pagesX-Tech CrystalClear 3EGO AnimationNo ratings yet

- X-Tech Primer FillerDocument2 pagesX-Tech Primer FillersamerNo ratings yet

- Flo-Grout 60 - TDSDocument2 pagesFlo-Grout 60 - TDSOption HunterNo ratings yet

- Flo-Grout BP800Document26 pagesFlo-Grout BP800qasim078100% (1)

- Blucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Document4 pagesBlucem Hb55: Product Code Bc-20-00-000S R01/2017 Page 1 of 4Rajiv SingalNo ratings yet

- Cementitious-Grout MasterFlow 718Document2 pagesCementitious-Grout MasterFlow 718Abhi MitraNo ratings yet

- Ds Plastacryl 85Document1 pageDs Plastacryl 85faridNo ratings yet

- X-Roc Epoxybond: Technical Data SheetDocument2 pagesX-Roc Epoxybond: Technical Data SheetJanaka Dinesh100% (1)

- Fosroc Cebex Cable Grout: Pre-Bagged, Non-Shrink Cementitious Grout Admixture For Post Tensioned CablesDocument3 pagesFosroc Cebex Cable Grout: Pre-Bagged, Non-Shrink Cementitious Grout Admixture For Post Tensioned CablesKRISHNA PRASATH SNo ratings yet

- Conbextra BB80: Non-Shrink Cementitious Bridge Bearing GroutDocument3 pagesConbextra BB80: Non-Shrink Cementitious Bridge Bearing GroutTori Small100% (1)

- Sika PDS - E - SikaGrout - 214-11 HF2 PDFDocument4 pagesSika PDS - E - SikaGrout - 214-11 HF2 PDFlwin_oo2435No ratings yet

- Furan C - Product Information Sheet PDFDocument2 pagesFuran C - Product Information Sheet PDFAnuradhaPatraNo ratings yet

- Cebex Cable Grout-1Document4 pagesCebex Cable Grout-1depi_rachmanNo ratings yet

- X-Pruf Crystalcoat: Cementitious Crystalline Waterproof Coating For ConcreteDocument2 pagesX-Pruf Crystalcoat: Cementitious Crystalline Waterproof Coating For ConcreteAmr RagabNo ratings yet

- Manhole-Bench Mix DesignDocument5 pagesManhole-Bench Mix DesignAhmadNo ratings yet

- X-Cure 111 PDFDocument2 pagesX-Cure 111 PDFKarim Boulos100% (1)

- Conbextra 621: Constructive SolutionsDocument4 pagesConbextra 621: Constructive SolutionsTori SmallNo ratings yet

- Sikagrout®-200 PT Id: Product Data SheetDocument3 pagesSikagrout®-200 PT Id: Product Data SheetCbeztNo ratings yet

- Conbextra Cable GroutDocument4 pagesConbextra Cable Groutm.elsanee.cubicNo ratings yet

- Tds Aqualoc Tp60Document1 pageTds Aqualoc Tp60Vikram ManeNo ratings yet

- Conbextra Cable Grout : Constructive SolutionsDocument4 pagesConbextra Cable Grout : Constructive SolutionsAnonymous uNhWGqNzNo ratings yet

- TDS - Conbextra BB72 IN - IndiaDocument2 pagesTDS - Conbextra BB72 IN - IndiaVikas Singh ChandelNo ratings yet

- X-Shield AcrylCoatDocument2 pagesX-Shield AcrylCoatEGO AnimationNo ratings yet

- Conbextra HFDocument4 pagesConbextra HFUbaid Mazhar Abidi SyedNo ratings yet

- Egrout S50Document2 pagesEgrout S50m.elsanee.cubicNo ratings yet

- X-Shield SF PrimerDocument2 pagesX-Shield SF Primernader enanyNo ratings yet

- Conbextra GP2Document4 pagesConbextra GP2Sikander GirgoukarNo ratings yet

- X-Tite Finegrout: Technical Data SheetDocument2 pagesX-Tite Finegrout: Technical Data SheetdeshapriyaedsNo ratings yet

- TDS of CAC-Hyperfluid R100Document2 pagesTDS of CAC-Hyperfluid R100Prashant MankarNo ratings yet

- TDS of CAC-Hyperfluid R100 PDFDocument2 pagesTDS of CAC-Hyperfluid R100 PDFPrashant MankarNo ratings yet

- X - Pruf RBEDocument2 pagesX - Pruf RBEAmr RagabNo ratings yet

- X-Tite EpoxyGrout 150Document2 pagesX-Tite EpoxyGrout 150jasonNo ratings yet

- CIKO FloGroutDocument3 pagesCIKO FloGroutAbdul YaskarNo ratings yet

- Antistatic SLEDocument51 pagesAntistatic SLEhodido2006No ratings yet

- Conbextra GP 1011Document4 pagesConbextra GP 1011Srinivasan ReddyNo ratings yet

- Conbextra HTDocument3 pagesConbextra HTTori SmallNo ratings yet

- Conbextra GPIDocument4 pagesConbextra GPIVenkata Raju KalidindiNo ratings yet

- X - Pruf CrystalCoatDocument2 pagesX - Pruf CrystalCoatSanjay ChopraNo ratings yet

- Sikagrout - 200 PtidDocument3 pagesSikagrout - 200 Ptidfandy sipataNo ratings yet

- Expangrout GP: General Purpose Non-Shrink Cementitious Grout UsesDocument4 pagesExpangrout GP: General Purpose Non-Shrink Cementitious Grout UsesZaid AhmedNo ratings yet

- Masterflow 544Document3 pagesMasterflow 544Raed BeetawiNo ratings yet

- X Roc RushCoatDocument2 pagesX Roc RushCoatAK DESIGNNo ratings yet

- Alccofine 1108SR : Description Typical PropertiesDocument2 pagesAlccofine 1108SR : Description Typical Propertiesravi100% (1)

- Accogrout - MC 547: Microconcrete - Non ShrinkDocument4 pagesAccogrout - MC 547: Microconcrete - Non Shrinkshahid shaikhNo ratings yet

- ElastocemDocument2 pagesElastocemEGO AnimationNo ratings yet

- Flo-Grout PC100 - TDSDocument2 pagesFlo-Grout PC100 - TDSAhmed AbuoelnagaNo ratings yet

- Conbextra STDDocument2 pagesConbextra STDm.elsanee.cubicNo ratings yet

- CONBEXTRA GP - JordanDocument4 pagesCONBEXTRA GP - JordanShabbir HussainNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Decothane Root Resistant Top Coat: Product Data SheetDocument4 pagesDecothane Root Resistant Top Coat: Product Data SheetKRISHNA PRASATH SNo ratings yet

- Sarnacol 2142S PDS Sika SarnafilDocument3 pagesSarnacol 2142S PDS Sika SarnafilKRISHNA PRASATH SNo ratings yet

- Fosroc Cebex Cable Grout: Pre-Bagged, Non-Shrink Cementitious Grout Admixture For Post Tensioned CablesDocument3 pagesFosroc Cebex Cable Grout: Pre-Bagged, Non-Shrink Cementitious Grout Admixture For Post Tensioned CablesKRISHNA PRASATH SNo ratings yet

- Igasol Liquid®Document2 pagesIgasol Liquid®KRISHNA PRASATH SNo ratings yet

- Hy-Rib Permanet Formwork - TDSDocument20 pagesHy-Rib Permanet Formwork - TDSKRISHNA PRASATH SNo ratings yet

- Safe Concrete Cutting and Drilling: Industry StandardDocument19 pagesSafe Concrete Cutting and Drilling: Industry StandardKRISHNA PRASATH SNo ratings yet

- Normal DistributionDocument1 pageNormal DistributionKRISHNA PRASATH SNo ratings yet

- The History of The QFD MethodDocument13 pagesThe History of The QFD MethodKRISHNA PRASATH SNo ratings yet

- Dissertation OrientationDocument22 pagesDissertation OrientationKRISHNA PRASATH SNo ratings yet

- (Dis) Trust, Control, and Project Success: From A Chinese Project Owner's PerspectiveDocument16 pages(Dis) Trust, Control, and Project Success: From A Chinese Project Owner's PerspectiveKRISHNA PRASATH SNo ratings yet

- Ehs Organization Chart For Jewel of Creek ProjectDocument1 pageEhs Organization Chart For Jewel of Creek ProjectKRISHNA PRASATH SNo ratings yet

- Attentive Driving Policy: SAMPLE Memo To Employees RegardingDocument1 pageAttentive Driving Policy: SAMPLE Memo To Employees RegardingKRISHNA PRASATH SNo ratings yet

- Memo - 10 - Petty Cash Approval For Material RequestDocument1 pageMemo - 10 - Petty Cash Approval For Material RequestKRISHNA PRASATH S50% (2)

- 3D Printing in Construction PresentationDocument18 pages3D Printing in Construction PresentationLucky 230503100% (2)

- Self Machining STANDOFFDocument12 pagesSelf Machining STANDOFFaldiNo ratings yet

- Name of The Project: Avigna Industrial Park, Nagondapalli Village, Hosur, Tamil NaduDocument4 pagesName of The Project: Avigna Industrial Park, Nagondapalli Village, Hosur, Tamil Nadua paul jayakumarNo ratings yet

- 5 PilecapDocument6 pages5 PilecapMaheshNo ratings yet

- Tempress PyrometerDocument3 pagesTempress PyrometerJesse GuoNo ratings yet

- Raj Abhishekfirst DoorDocument1 pageRaj Abhishekfirst DoorOMESH KUMAWATNo ratings yet

- Case StudyDocument116 pagesCase StudyJimmy Wangmo DorjiNo ratings yet

- DATA - SHEET-Polyurethane Construction Adhesive 9902-10Document2 pagesDATA - SHEET-Polyurethane Construction Adhesive 9902-10Adhika ADhiknyaNo ratings yet

- Air Conditioning Principles and Systems An Energy Approach (4th Edition)Document544 pagesAir Conditioning Principles and Systems An Energy Approach (4th Edition)Ira Martiani85% (20)

- Inspection ReportDocument45 pagesInspection Reportgav_sharma50% (2)

- Balconies MaastrichtDocument6 pagesBalconies MaastrichtAbubakar MusaNo ratings yet

- About RandDocument9 pagesAbout Randreloaded63No ratings yet

- Company Profile PT DSI 2022Document26 pagesCompany Profile PT DSI 2022gung tikkNo ratings yet

- Paper: by Rishabh GuptaDocument18 pagesPaper: by Rishabh GuptaSaif AzharNo ratings yet

- Gutter Repairs BizHouse - UkDocument2 pagesGutter Repairs BizHouse - UkAlex BekeNo ratings yet

- Deadman Anchor Quick Guide Low ResDocument2 pagesDeadman Anchor Quick Guide Low ResmohsenNo ratings yet

- RACOLD Domestic Solar PresentationDocument14 pagesRACOLD Domestic Solar PresentationnagtummalaNo ratings yet

- FORM 524: (To Be Filled For Each Lightning Arrester in Every Array)Document1 pageFORM 524: (To Be Filled For Each Lightning Arrester in Every Array)Bhalsingh JangraNo ratings yet

- Reconfirmation Notice: AS 1012.3.2-1998 (Reconfirmed) 2014-10-24Document9 pagesReconfirmation Notice: AS 1012.3.2-1998 (Reconfirmed) 2014-10-24heyh jdjNo ratings yet

- Asco Series 042 Gas Shutoff CatalogDocument4 pagesAsco Series 042 Gas Shutoff CatalogRoqueNetNo ratings yet

- PDF - 16012777053 SABIT PRIMER D-41Document1 pagePDF - 16012777053 SABIT PRIMER D-41MohamedNo ratings yet

- LEFT ELEVATION (Scale1:100) FRONT ELEVATION (Scale1:100) RIGHT ELEVATION (Scale1:100)Document1 pageLEFT ELEVATION (Scale1:100) FRONT ELEVATION (Scale1:100) RIGHT ELEVATION (Scale1:100)Ogulo JamesNo ratings yet

- Sub-Contractor Comments Response Sheet: Ain Tsila DevelopmentDocument23 pagesSub-Contractor Comments Response Sheet: Ain Tsila DevelopmentZaidi0% (1)

- TIAC SolutionsDocument29 pagesTIAC SolutionsJan JanssonNo ratings yet

- Bhavikatti S S - Design of RCC Structural Elements (RCC Volume-I) 3eDocument17 pagesBhavikatti S S - Design of RCC Structural Elements (RCC Volume-I) 3eeasy Books100% (1)

- Footing IsolatedDocument97 pagesFooting Isolatedpoliman2017No ratings yet

- 37-Infracon 2017 R L Wankhade Track 4 PDFDocument9 pages37-Infracon 2017 R L Wankhade Track 4 PDFHansV.HuamaníCamargoNo ratings yet

- 16.1 - Bearing Capacity - TerzaghiDocument4 pages16.1 - Bearing Capacity - TerzaghihiyeonNo ratings yet

- Key Plan: Section of A-RMG Track BeamDocument1 pageKey Plan: Section of A-RMG Track BeamJoel MontoyaNo ratings yet