LED1550E Ultra Bright NIR LED: Specifications and Documentation

LED1550E Ultra Bright NIR LED: Specifications and Documentation

Uploaded by

Nicolás VásquezCopyright:

Available Formats

LED1550E Ultra Bright NIR LED: Specifications and Documentation

LED1550E Ultra Bright NIR LED: Specifications and Documentation

Uploaded by

Nicolás VásquezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

LED1550E Ultra Bright NIR LED: Specifications and Documentation

LED1550E Ultra Bright NIR LED: Specifications and Documentation

Uploaded by

Nicolás VásquezCopyright:

Available Formats

LED1550E

Ultra Bright NIR LED

Specifications and Documentation

LED1550E

Part 1. Introduction: LED1550E Ultra Bright NIR LED

The LED1550E emits light with a spectral output centered at 1500 nm. This LED is composed of

heterostructures (HS) grown on an InGaAsP substrate. The diode is encapsulated in a round clear epoxy

casing with a 5 mm diameter.

Part 2. Specifications for an LED1550E

2.1. Electrical Specifications

Typical Maximum Ratings

Power Dissipation 120 mW

Reverse Voltage 5.0 V

DC Forward Current 100 mA

Forward Voltage @ 20 mA 1.2 V 1.5 V

Reverse Current Vr = -5 V 10 µA

Pulsed Current (1 ms pulse with 10% duty cycle) 1000 mA

Operating Temperature -30 ºC to 85 ºC

Storage temperature Range -30 ºC to 100 ºC

Note: All maximum measurements specified are at 25 ºC.

2.2. Optical Specifications

Typical

Center Wavelength 1550 nm (±50 nm)

FWHM 100 nm

Half Viewing Angle 15º

Forward Optical Power 1.2 mW @ 20 mA

Total Optical Power 2.0 mW @ 20 mA

Rise (Fall) Time 10 (10) ns

2.3. Soldering Specifications

Conditions

Manual Soldering 295 ºC ± 5 ºC , for less than 3 seconds

Wave Soldering 260 ºC ± 5 ºC , for less than 5 seconds

Preheating: 70 ºC to 80 ºC , for 30 seconds

Reflow Soldering

Soldering: 245 ºC ± 5 ºC , for less than 5 seconds

2.4. Cleaning Solvents

Solvent Ethyl Alcohol Isopropyl Propanol Acetone Chloroseen Tricloroethylene MKS

Alcohol

Approved Yes Yes Yes No No No No

16392-S01 Rev. B, 06/04/2009 Page 2 www.thorlabs.com

LED1550E

2.5. Physical Specifications

Figure 1: LED1550E. The cathode is the short lead and the anode is the long lead.

2.6. Typical Spectral Intensity Distribution

1

Normalized Intensity

0.8

0.6

0.4

0.2

0

1400 1450 1500 1550 1600 1650 1700

Wavelength (nm)

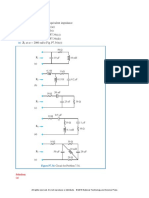

2.7. Typical Radial Intensity Distribution

16392-S01 Rev. B, 06/04/2009 Page 3 www.thorlabs.com

LED1550E

Part 3. Measurement Techniques

3.1. Measurement Technique for Spectral Distribution Plot and FWHM

Specification

A SP1-USB fiber based spectrometer connected to a computer is used to measure the spectral response

of each LED in the visible spectrum (390-810 nm). The LED is powered with a LD1255 laser diode

driver operating in a constant current mode. The light from the LED is focused by a ∅1″ Bi-convex

lens, f = 40 mm, into a multimode fiber, 50 um SMA patch cable, attached to the spectrometer, see

figure 2.

Spectrometer

LED Driver

LED

Multimode Fiber

Figure 2: Schematic of the setup used to measure the spectral emission of an LED.

Picture of Setup Depicted in Figure 2

16392-S01 Rev. B, 06/04/2009 Page 4 www.thorlabs.com

LED1550E

The spectral FWHM is measured using the SP1-USB software; see the screen shot in figure 3. The

spectral distribution of the LED is assumed to be Gaussian when determining the FWHM specification.

The data is also used to create a typical spectral distribution plot as shown in section 2.5. The central

wavelength and shape of the curve vary due to the uniqueness of each LED, as indicated by the

deviation column of the optical specifications table.

Figure 3: Screen shot of the spectral emission of an LED471E LED measured using an SP1-USB

spectrometer.

Part List for Spectral Distribution Measurement

Quantity Part Description

1 SP1-USB 400-800 nm USB Spectrometer

1 M14L01 50 um Core SMA Multimode Patch Cable, 0.22 NA

2 UPH2 Swivel Base Post Holder (2″)

3 PH2-ST Post Holder

5 TR1.5 ∅1/2″ Posts 1.5″ Long

3 BA1 Base Plate

2 LMR1 Lens Mount

1 LMR05 Lens Mount

1 SM1SMA SM1 to SMA Connector Adapter Plate

1 SM1L05 Lens Tube

1 LB1027-B Bi-Convex Lens (f = 40 mm)

1 MB810 Solid Standard Aluminum Breadboard (8″ x 10″)

1 HW-KIT2 1/4-20 Cap Screw Kit

1 LEDMF LED Socket and Holder

*

Product in development.

16392-S01 Rev. B, 06/04/2009 Page 5 www.thorlabs.com

LED1550E

3.2. Measurement Technique for Radial Intensity Distribution Plot and the

Half Viewing Angle Specification

To make a measurement of the intensity pattern as a function of angle, the LED is rotated on an axis

perpendicular to the axis along which the emitted light intensity was the greatest. Goniometric rotation

of the LED is achieved by mounting the LED on a post attached to a motorized rotation stage (CR1-Z6)

so that the rotation axis goes through the light emitting surface of the LED. The CR1-Z6 is powered by

an APT TDC001 USB Motor Diver while the LED is powered by an LD1255 Laser Diode Driver. The

radiated light is detected using either a Si or InGaAs photodetector, DET100A or DET10C respectively,

located approximately 12 inches from the LED. To keep stray or scattered light from hitting the detector

a ∅1" lens tube is attached to the detector that extends to just short of the LED. Two iris apertures are

placed along the path from the LED to the detector. The iris closer to the LED has an aperture diameter

of 10 mm while the aperture nearest the detector has a diameter of 3 mm. The setup is shown in figure 4.

Figure 4: Schematic of the setup used to measure the radial power distribution. The drawing is not

to scale.

As the LED rotates, the output of the photodiode detector, which is proportional to the light intensity, is

recorded for each angular position using a NI data acquisition card. The LED is rotated from +90° to

−90° where 0° approximately corresponds to when the Axis of Maximum Intensity, see figure 5, is

parallel to the Detector Axis. The results are displayed in a plot similar to the one shown in figure 6. The

half viewing angle specification is determined by the angle that corresponds to a 50% drop in the

maximum detector output.

16392-S01 Rev. B, 06/04/2009 Page 6 www.thorlabs.com

LED1550E

Picture of Setup Depicted in Figure 4

Parts List for Radial Intensity Distribution Measurement

Quantity Part Description

DET100A Si Photodiode Detector

1 or or

DET10C InGaAs Photodiode Detector

1 CR1-Z6 Motorized Rotational Stage

1 CR1A CR1 to Post AdapterPlate

1 TDC001 T-Cube Single Channel USB DC Servo Controller/Driver

3 SM1L30 1″ Lens Tube 3″ Long

2 SM1D12C SM1 Lever Actuated Iris Diaphragm

2 UPH3 Swivel Base Post Holder

1 PH2-ST Post Holder

1 PH1-ST Post Holder

2 TR3 ∅1/2″ Post 3″ Long

2 TR1 ∅1/2″ Post 1″ Long

1 RLA0300 Dovetail Optical Rail 3″ Long

1 RC1 Rail Carrier

1 MB612 Solid Standard Aluminum Breadboard (6″ x 24″)

1 2249-C-36 BNC Coaxial Cable

1 HW-KIT2 1/4-20 Cap Screw Kit

1 LEDMF LED Socket and Holder

*

Product in development.

16392-S01 Rev. B, 06/04/2009 Page 7 www.thorlabs.com

LED1550E

3.3. Measurement Technique for Determining the Forward Radiated

Optical Power Specification

The total forward radiated power of the LED is measured using a PM120 with a S120B Power Head.

See the picture below.

Forward Radiating Power Setup

Parts List for the Forward Radiated Optical Power Measurement

Quantity Part Description

1 PM121 Digital Optical Power Meter with S121B optical sensor

2 UPH3 Swivel base post holder 3″ Long

2 TR2 ∅1/2″ Post 2″ Long

1 MB810 Solid Standard Aluminum Breadboard (8″ x 10″)

1 HW-KIT2 1/4-20 Cap Screw Kit

1 LEDMF LED Socket and Holder

*

Product in development.

3.4. Measurement Technique for Determining the Total Optical Power

Specification

The total optical output power of an Total Radiated Power Setup

LED is measured using an integrating

sphere. The radiated light is detected

using either a Si or InGaAs integrating

sphere, IS236A or IS210C

respectively. The sphere is calibrated

with a known laser power source such

as the Thorlabs CPS180 laser diode

module. The output of the integrating

sphere is digitized using our PDA200C

benchtop photodiode amplifier.

16392-S01 Rev. B, 06/04/2009 Page 8 www.thorlabs.com

LED1550E

Part List for the Total Radiated Optical Power Measurement

Quantity Part Description

IS236A 2″ Integrating Sphere with a Si Detector

1 or or

IS210C 2″ Integrating Sphere with a InGaAs Detector

1 PDA200C Benchtop Photodiode Amplifier

2 UPH3 Swivel Base Post Holder 3″ Long

2 TR2 ∅1/2″ Post 2″ Long

1 HW-KIT2 1/4-20 Cap Screw Kit

1 LEDMF LED Socket and Holder

*

Product in development.

Part 4. Precautions and Warranty Information

These products are ESD (electro static discharge) sensitive and as a result are not covered under warranty. In

order to ensure the proper functioning of an LED care must be given to maintain the highest standards of

compliance to the maximum electrical specifications when handling such devices. The LEDs are

particularly sensitive to any voltage that exceeds the absolute maximum ratings of the product. Any

applied voltage in excess of the maximum specification will cause damage and possible complete failure

to the product. The user must use handling procedures that prevent any electro static discharges or other

voltage surges when handling or using these devices.

Thorlabs, Inc. Life Support and Military Use Application Policy is stated below:

THORLABS’ PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN

LIFE SUPPORT DEVICES OR SYSTEMS OR IN ANY MILITARY APPLICATION WITHOUT

THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF THORLABS, INC. As used

herein:

1. Life support devices or systems are devices or systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and whose failure to perform, when properly used in

accordance with instructions for use provided in the labeling, can be reasonably expected to result in a

significant injury to the user.

2. A critical component is any component in a life support device or system whose failure to perform can

be reasonably expected to cause the failure of the life support device or system or to affect its safety or

effectiveness.

3. The Thorlabs products described in this document are not intended nor warranted for usage in

Military Applications.

16392-S01 Rev. B, 06/04/2009 Page 9 www.thorlabs.com

LED1550E

Part 5. Contact Information

USA, Canada, and South America Japan and Asia Scandinavia

Thorlabs, Inc. Thorlabs Japan Inc. Thorlabs Sweden AB

56 Sparta Ave 3-6-3, Kitamachi Bergfotsgatan 7

Newton, NJ 078600 Nerima-ku, Tokyo 179-0081 431 35 Mölndal

USA Japan Sweden

Tel: 973-300-3000 Tel: 81-3-6915-7701 Tel: +46-31-733-30-00

Fax: 973-300-3600 Fax: 81-3-6915-7716 Fax: +46-31-703-40-45

www.thorlabs.com www.thorlabs.jp www.thorlabs.com

email: sales@thorlabs.com email: sales@thorlabs.jp email: scandinavia@thorlabs.com

Europe UK and Ireland

Thorlabs GmbH Thorlabs LTD.

Hans-Böckler-Str. 6 1 Saint Thomas Place, Ely

85221 Dachau Cambridgeshire CB7 4EX

Germany Great Britain

Tel: +49-(0)8131-5956-0 Tel: +44 (0)1353-654440

Fax: +49-(0)8131-5956-99 Fax: +44 (0)1353-654444

www.thorlabs.com www.thorlabs.com

email: Europe@thorlabs.com email: sales.uk@thorlabs.com

16392-S01 Rev. B, 06/04/2009 Page 10 www.thorlabs.com

You might also like

- Panasonic PT-VZ570 PDFDocument108 pagesPanasonic PT-VZ570 PDFboroda2410No ratings yet

- A Guide to Electronic Maintenance and RepairsFrom EverandA Guide to Electronic Maintenance and RepairsRating: 4.5 out of 5 stars4.5/5 (7)

- Electronic Devices and Circuits Lab NewDocument86 pagesElectronic Devices and Circuits Lab NewleevasusanNo ratings yet

- GP PSLM31.14 - enDocument22 pagesGP PSLM31.14 - enzebusNo ratings yet

- Led VermelhoDocument4 pagesLed Vermelhocaio felipeNo ratings yet

- Grandway Fhs2q01f Light SourceDocument2 pagesGrandway Fhs2q01f Light SourceCarbon Nano TubeNo ratings yet

- GW PSLM31.FM - enDocument22 pagesGW PSLM31.FM - enzebusNo ratings yet

- Circuito EL357N Optoacoplador PDFDocument11 pagesCircuito EL357N Optoacoplador PDFcastellano_rNo ratings yet

- Panasonic Pt-Ew540 Ew540l Ew540d Ew540ld Pt-Ex510 Ex510l Ex510d Ex510ld SMDocument125 pagesPanasonic Pt-Ew540 Ew540l Ew540d Ew540ld Pt-Ex510 Ex510l Ex510d Ex510ld SMTung NguyenNo ratings yet

- SR3411 / SR3411 - (B) : FeaturesDocument3 pagesSR3411 / SR3411 - (B) : FeaturesMauricio BalletNo ratings yet

- Laboratory Manual: Tester Lps04: DC Characteristics of Fiber Optic Leds, Pin Photodiode and PhototransistorDocument17 pagesLaboratory Manual: Tester Lps04: DC Characteristics of Fiber Optic Leds, Pin Photodiode and Phototransistorramakris79No ratings yet

- Tester LPS04 LabManualDocument17 pagesTester LPS04 LabManualSaravana KumarNo ratings yet

- Technology Corporation: FeaturesDocument13 pagesTechnology Corporation: Featuresosmanandac1No ratings yet

- Global Radiometers: "C511R, C102R, C502R Special Band Radiometers: "C502LUX, C502UVA, C502UVB, C502PAR, C502VIR" Instructions ManualDocument16 pagesGlobal Radiometers: "C511R, C102R, C502R Special Band Radiometers: "C502LUX, C502UVA, C502UVB, C502PAR, C502VIR" Instructions ManualGilmar RibeiroNo ratings yet

- QDD 400G DR4 AR C - Datasheets - ENDocument10 pagesQDD 400G DR4 AR C - Datasheets - ENobamab69No ratings yet

- BL B5141 LDocument5 pagesBL B5141 Lferda.siska1No ratings yet

- SPB2302010xx SFP+ Single Fibre: TX 1270nm RX 1330nm / 20km / 10x Gigabit EthernetDocument4 pagesSPB2302010xx SFP+ Single Fibre: TX 1270nm RX 1330nm / 20km / 10x Gigabit EthernetJose JaramilloNo ratings yet

- DS.1.7735.021Document2 pagesDS.1.7735.021Naveen KumarNo ratings yet

- Miniature Photoelectric SensorsDocument8 pagesMiniature Photoelectric SensorsoscarNo ratings yet

- SR 3411Document3 pagesSR 3411Mauricio BalletNo ratings yet

- El 357 NG ComDocument11 pagesEl 357 NG ComAnonymous oEoCVNhu7HNo ratings yet

- Datasheet PC13Document11 pagesDatasheet PC13Cuong TranNo ratings yet

- GF HRTDocument9 pagesGF HRTpanamedeboyoNo ratings yet

- LDR Project XII Physics Investigatory ProjectDocument16 pagesLDR Project XII Physics Investigatory ProjectAditya FarswanNo ratings yet

- PS2701Document11 pagesPS2701Leonel cadenas hernandezNo ratings yet

- FDS015 SpecSheetDocument4 pagesFDS015 SpecSheetg3188605831No ratings yet

- 39408, CP25QXVT80 Wengler Level SensorDocument19 pages39408, CP25QXVT80 Wengler Level SensorVigneshkumar JagannathanNo ratings yet

- Installation Manual TL Line-2Document4 pagesInstallation Manual TL Line-2hicham boutoucheNo ratings yet

- Description: Si PhotodiodeDocument4 pagesDescription: Si PhotodiodebobbbNo ratings yet

- LR6 Series - Specifications - AC Type (En)Document10 pagesLR6 Series - Specifications - AC Type (En)Nguyễn Văn ĐịnhNo ratings yet

- HONYS01733_1-3070803Document5 pagesHONYS01733_1-3070803Roy MathewNo ratings yet

- RSL-3100 Xenon Light Source DatasheetDocument4 pagesRSL-3100 Xenon Light Source DatasheetIvanVolkovNo ratings yet

- SC1088 SilanMicroelectronicsDocument7 pagesSC1088 SilanMicroelectronicssoheil.zhalepouya1383No ratings yet

- PWM Type DC/DC Converter IC Included 650V MOSFET: DatasheetDocument23 pagesPWM Type DC/DC Converter IC Included 650V MOSFET: DatasheetDaiverJuarezNo ratings yet

- JaphDocument15 pagesJaphsandhysandhya12345No ratings yet

- Datasheet KT5W-2N1116D 1026540 enDocument8 pagesDatasheet KT5W-2N1116D 1026540 enBrahim RebaouiNo ratings yet

- PHYSICS RemovedDocument18 pagesPHYSICS RemovedRahul MetaNo ratings yet

- Datasheet WT12L-2B530 1018250 enDocument8 pagesDatasheet WT12L-2B530 1018250 enMuhammad SumeetNo ratings yet

- Led VerdeDocument4 pagesLed Verdecaio felipeNo ratings yet

- Model 851 Mark-2 Marine Radar Sme 34900a 58Document58 pagesModel 851 Mark-2 Marine Radar Sme 34900a 58gitlatsubNo ratings yet

- Penta Band W1910 - W1911Document4 pagesPenta Band W1910 - W1911Miguel Andres VanegasNo ratings yet

- Data Sheet: LR ZB250CPDocument2 pagesData Sheet: LR ZB250CPjulio perezNo ratings yet

- 83055-10,-20 Service ManualDocument36 pages83055-10,-20 Service ManualBijan AmiriNo ratings yet

- Ambient Light DocumentDocument15 pagesAmbient Light DocumentSimone GhirardinNo ratings yet

- Data Sheet: LR ZB250CNDocument2 pagesData Sheet: LR ZB250CNDanielNo ratings yet

- Throw Beem Sensor PDFDocument7 pagesThrow Beem Sensor PDFNiHAD OFFiCiALNo ratings yet

- Ml1Xx27 Series: Type NameDocument3 pagesMl1Xx27 Series: Type NameAbdalhakeem Al turkyNo ratings yet

- Experiment No.2Document10 pagesExperiment No.2Pankaj GargNo ratings yet

- MouseSensor MCS 12086 DatasheetDocument7 pagesMouseSensor MCS 12086 Datasheetpourya amiriNo ratings yet

- MMS4X00-NS400-C Datasheets ENDocument8 pagesMMS4X00-NS400-C Datasheets ENobamab69No ratings yet

- SFH 235 Fa - enDocument15 pagesSFH 235 Fa - enbarisNo ratings yet

- DSH 518-075 1Document4 pagesDSH 518-075 1ferda.siska1No ratings yet

- El3h7 GDocument11 pagesEl3h7 GAthiwa RuantoNo ratings yet

- Tda1572t CNV 2Document20 pagesTda1572t CNV 2István HorváthNo ratings yet

- NSI300D25DDocument20 pagesNSI300D25D3109828876No ratings yet

- 795nm 40W Laser Diode Bar Modulight-1416531703Document2 pages795nm 40W Laser Diode Bar Modulight-1416531703IvanNo ratings yet

- Light SensorDocument7 pagesLight Sensorمصطفى رواسNo ratings yet

- 2.5 Amp Output Current IGBT Gate Drive Optocoupler With Rail-to-Rail Output Voltage, High CMRDocument14 pages2.5 Amp Output Current IGBT Gate Drive Optocoupler With Rail-to-Rail Output Voltage, High CMRNae CarNo ratings yet

- Ifm PK6520 Pressure Sensor Pressure Switch Compact Pressure Sensor - Spec SheetDocument2 pagesIfm PK6520 Pressure Sensor Pressure Switch Compact Pressure Sensor - Spec SheetCleiton De oliveira limaNo ratings yet

- Flatron L1750S - L1950S - CL-82Document27 pagesFlatron L1750S - L1950S - CL-82Stefan BogdanNo ratings yet

- Electrical Characterization of Organic Electronic Materials and DevicesFrom EverandElectrical Characterization of Organic Electronic Materials and DevicesNo ratings yet

- Guia de Onda para Antena KP PerformanceDocument2 pagesGuia de Onda para Antena KP PerformanceJose Danilo Caldera SaballosNo ratings yet

- Xii-Phy Sir Irfan Sanjrani Final-Terms 2023-24Document12 pagesXii-Phy Sir Irfan Sanjrani Final-Terms 2023-24jaipal singhNo ratings yet

- DC Motors and TypesDocument13 pagesDC Motors and TypesLjubisa RaimovicNo ratings yet

- 1985 Electronic Engineers Master Vol 2Document1,250 pages1985 Electronic Engineers Master Vol 2clkent2022No ratings yet

- Compass Stainer HologicDocument52 pagesCompass Stainer Hologicadcamara1No ratings yet

- Free Access To Solution Manual For VHDL For Engineers Kenneth L. Short Chapter AnswersDocument51 pagesFree Access To Solution Manual For VHDL For Engineers Kenneth L. Short Chapter AnswerskroflntereNo ratings yet

- Ars-404-21 en HS PDFDocument3 pagesArs-404-21 en HS PDFKlever MoralesNo ratings yet

- E5 PDFDocument5 pagesE5 PDFYip DavidNo ratings yet

- 2.3.7. PGM1 and PGM2 (Programmable) Output ConnectionsDocument15 pages2.3.7. PGM1 and PGM2 (Programmable) Output ConnectionsSuperNova xNo ratings yet

- Xenta Initial Service ProcedureDocument9 pagesXenta Initial Service Procedureperyats100% (1)

- National Instruments 187252 01 DatasheetDocument5 pagesNational Instruments 187252 01 Datasheetaime-desire.bikoliNo ratings yet

- JUI-RPWI-ESA-EBOX-RP-Mechanical Analysis Report RPWI - Issue - 2 - Rev - 0 - SignedDocument134 pagesJUI-RPWI-ESA-EBOX-RP-Mechanical Analysis Report RPWI - Issue - 2 - Rev - 0 - SignedAdamDNo ratings yet

- Problem 7.34 (A) (B) (C) (D) (E)Document5 pagesProblem 7.34 (A) (B) (C) (D) (E)Mohammad Haroon WaseemNo ratings yet

- Low Power Low Cost Compact Transceivers For IoTDocument2 pagesLow Power Low Cost Compact Transceivers For IoTSofia FENNINo ratings yet

- Data Sheet Sim 900Document6 pagesData Sheet Sim 900Felipe Rodrigo Campos MenaresNo ratings yet

- 2010 FHD Plasma TV G20 G25 Series Troubleshooting HandbookDocument62 pages2010 FHD Plasma TV G20 G25 Series Troubleshooting Handbookjay1988j50% (2)

- Data SheetDocument2 pagesData SheetsswahyudiNo ratings yet

- Duncan VCAs Part 2Document5 pagesDuncan VCAs Part 2Ian PressNo ratings yet

- 840 Ventilator Service ManualDocument674 pages840 Ventilator Service Manualchris100% (1)

- 900 X 600 Metrotrak Electrical 2Document3 pages900 X 600 Metrotrak Electrical 2Benjamin MurphyNo ratings yet

- Techstream Ecu Flash Reprogramming Procedure - SS002-07Document23 pagesTechstream Ecu Flash Reprogramming Procedure - SS002-07tyleung100% (3)

- Ringamp SurveyDocument20 pagesRingamp SurveyJack KangNo ratings yet

- Eng Sicor Catalogue GearlessDocument52 pagesEng Sicor Catalogue GearlessEmeka Pius OramunwaNo ratings yet

- Ijsrp p1613 PDFDocument3 pagesIjsrp p1613 PDFAnonymous BrUMhCjbiBNo ratings yet

- Light Operated RelayDocument19 pagesLight Operated RelayBARUN SINGHNo ratings yet

- Conventional Audible Visual Devices: Sounders With Supplementary Light IndicatorDocument2 pagesConventional Audible Visual Devices: Sounders With Supplementary Light IndicatorFlorin FlorinNo ratings yet

- Lab No 2 (VLSI Design)Document4 pagesLab No 2 (VLSI Design)Zahid Ul HassanNo ratings yet

- Protection BESSDocument8 pagesProtection BESSPratikKumarNo ratings yet

- Datasheet 5E-5Document8 pagesDatasheet 5E-5mikeNo ratings yet