Fundamentals of Bridge Design Lecture Notes

Fundamentals of Bridge Design Lecture Notes

Uploaded by

Sami IGCopyright:

Available Formats

Fundamentals of Bridge Design Lecture Notes

Fundamentals of Bridge Design Lecture Notes

Uploaded by

Sami IGOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Fundamentals of Bridge Design Lecture Notes

Fundamentals of Bridge Design Lecture Notes

Uploaded by

Sami IGCopyright:

Available Formats

Fundamentals of Bridge Design Lecture Notes 2019

CHAPTER 1

INVESTIGATION FOR BRIDGE

1.1) General Introduction

A bridge is a structure providing passage over an obstacle. The obstacle may be a river,

valley, road or railway. The passage may be for highway or railway traffic, pedestrian, canal

or pipeline.

As the saying “Build bridges and you will have a friend” goes, bridges have a unique

attribute of connecting different people. Rivers and mountains form physical barriers

between people to interact, trade with one another, live and work together.

Investment by both nationals and foreigners is crucial for economic development of a

country, and one of the criteria that foreign investors weigh in their investment decisions in a

country is the level of development of the transportation network. Bridges provide essential

links in highways and railways at obstacles. The cost of bridges and culverts is a significant

proportion of a highway project.

Bridges also have military strategic importance. The mobility of an army at war is often

affected by the availability of bridges to cross rivers. Military training puts

special emphasis on learning how to build new bridges quickly while advancing and destroy

bridges while retreating.

Bridge engineering is one of the fascinating fields in civil engineering calling for expertise in

many areas: structural analysis and design, geotechniques, traffic projection, surveying, runoff

calculation and methods of construction. A bridge engineer has to have an appreciation of

economics and aesthetics besides ability in analysis and design. The materials and procedures

involved in the construction of any sizable bridge are quite varied.

1.2) Bridge Terminologies

Superstructure: it comprises all the components of a bridge above the supports. The basic

superstructure components consist of the following:

Wearing Surface: is that portion of the deck cross section which resists traffic wear. In

some instances this is a separate layer made of bituminous material, while in some

other cases it is an integral part of concrete deck.

Deck: is the physical extension of the roadway across the obstruction to be bridged. The

main function of the deck is to distribute loads transversely along the bridge cross

section. The deck either rests on or is integrated with a frame or other structural system

designed to distribute loads longitudinally along the length of the bridge.

Primary members: distribute loads longitudinally and are usually designed principally to

resist flexure and shear. Beam type primary members are called stringers or girders. It is

By Abdusemed B. (MSc) Page 1

Fundamentals of Bridge Design Lecture Notes 2019

also possible for the bridge superstructure to be formed in the shape of a box (either

rectangular or trapezoidal). Box girder bridges can be constructed out of steel or

prestressed concrete and are used in situations where large span lengths are required

and for horizontally curved bridges.

Secondary members: are bracings between primary members designed to resist cross-

sectional deformation of the superstructure frame and help distribute part of the vertical

load between stringers. They are also used for the stability of the structure during

construction (diaphragms can be typical examples of these members.)

Substructure: consists of all elements required to support the superstructure and overpass

roadway. The basic substructure components consist:

Abutments: are earth-retaining structures which support the superstructure and

overpass roadway at the beginning and end of a bridge.

Piers: are structures which support the superstructure at intermediate points between

the end supports (abutments).

Bearings: are mechanical systems which transmit the vertical and horizontal loads of the

superstructure to the substructure, and accommodate movements between the

superstructure and the substructure. The use and functionality of bearings vary greatly

depending on the size and configuration of the bridge. Bearings allowing both rotation

and longitudinal translation are called expansion bearings, and those which allow

rotation only are called fixed bearings.

Pedestal: is a short column on an abutment or pier under a bearing which directly

supports a superstructure primary member. Normally pedestals are designed with

different heights to obtain the required bearing elevations.

Abutment and pier footings: transfer loads from the substructure to the subsoil or

piles. A footing supported by soil without piles is called a spread footing. A footing

supported by piles is known as a pile cap. When the soil under a footing cannot provide

adequate support for the substructure (in terms of bearing capacity, overall stability, or

settlement), support is obtained through the use of piles, which extend down from the

footing to a stronger soil layer or to bedrock. There are a variety of types of piles ranging

from concrete, which is cast in place (also called drilled shafts or caissons) or precast, to

steel H-sections driven to sound rock.

Wing Walls: is a wall constructed at both sides subjected side ways to lateral

earth pressures. Assist in confining the earth/backfill behind the abutment.

Free (clear) span: the face to face distance between supported components measured

perpendicular to the supports.

Span Length: is the distance between the centers of bearings.

Total width of a bridge: is defined as the distance between the inside of the railings including

walkways.

Waterway: area through which the water flows under the superstructure of the bridge.

By Abdusemed B. (MSc) Page 2

Fundamentals of Bridge Design Lecture Notes 2019

Natural waterway: unobstructed area of the river.

Linear waterway: the width of the water surface measured from edge to edge along the design

high flood level.

Waterway afflux: the vertical increase of water due to vertical supports.

Freeboard: The vertical distance between the crown and the level of the bottom of the girder

taking in to account the backwater effects.

Approach road way: The section of overpass roadway which leads up to and away

from the bridge abutments is called the approach or approach roadway. It can be either a part

of the bridge or a separated small bridge. To compensate for potential differential settlement at

the approaches, a reinforced concrete slab or approach slab is sometimes used for a given

distance back from the abutment. The approach slab helps to evenly distribute traffic loads on

the soil behind the abutment, and minimizes impact to the abutment which can result from

differential settlement between the abutment and the approach. An approach slab is typically

supported by the abutment at one end, and supported by the soil along its length.

Traffic Barriers: A traffic barrier is a protective device “used to shield vehicles from obstacles or

slope located along either side of roadway”. Traffic barriers can range from a guard rail made of

corrugated steel to reinforced concrete parapets. On bridges, they are usually called bridge

railings.

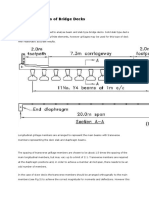

Figure 1.1 A typical single span slab-on-stringer bridge and its representative components

By Abdusemed B. (MSc) Page 3

Fundamentals of Bridge Design Lecture Notes 2019

1.3 ) Elements of Bridge Project

The design of bridges requires the collection of extensive data and from this the selection of

possible options. From such a review the choice is narrowed down to a shortlist of potential

bridge designs. A sensible work plan should be devised for the marshaling and deployment

of information throughout the project from conception to completion and through the design

period to the end of its life. Such a checklist will vary from project to project but a typical

example might be drawn along the following lines. Such a project list serves to highlight the

various requirements of a bridge project.

i) Feasibility Phase:

a) Data collection; b) Topographical and hydrographical surveys;

c) Hydrological information; d) Geological and geotechnical information;

e) Site investigation requirements for soil and f) Meteorological and aerodynamic data;

rock evaluation

g) Assembly of basic criteria; h) Likely budget

ii) Assembly of design criteria:

(a) data and properties on the material to be used (b) foundation considerations;

including steel, concrete, timber; (c) hydraulic considerations, flood, scour;

(d) loading and design criteria; (e) clearance height and width (such as

(f) criteria for gradients, alignment, etc.; for navigation or traffic);

(g) hazards such as impact, accident; (h) proximity to other engineering works

(i) functional requirements; (j) transportation and traffic planning;

(k) highway and/or railway engineering aspects; (l) drainage requirements;

(m)provision for services (water, sewage, power, (n) design life and durability

electricity, telephone, communications links) considerations.

iii) Design phase:

(a) choice of bridge: (b) detailed design of bridge including

(c) production of drawings and documentation, foundations, substructure and

(d) preparation of quality assurance plan; superstructure;

(e) estimation of cost and program.

iv) Construction phase:

(a) contractual matters; (b) construction methods;

(c) budget and financial control; (d) quality control;

(e) supervision of construction; (f) commissioning;

(g) operating, inspection and maintenance

schedules for each part of the work.

By Abdusemed B. (MSc) Page 4

Fundamentals of Bridge Design Lecture Notes 2019

iv) Performance phase:

(a) obligations of owner; (b) management of facility;

(c) inspection, maintenance and repair; (e) decommissioning and demolition

(d) rehabilitation and refurbishment requirements

(change of loading, widening, change of use and durability aspects);

1.4) Design Objectives

The objectives in a bridge design are safety, serviceability, economy, constructability and

aesthetics.

Safety – the primary responsibility of the engineer is to ensure public safety in the design by

ensuring adequate structural safety (minimum requirements to ensure the structural safety of

bridges can be obtained in different codes)

Serviceability – consists of satisfying requirements of deformation, durability, inspectability,

maintainability and rideability.

Deformation – Bridges should be designed to avoid excessive deformations that cause

undesirable structural or psychological effects. Limits on deflection or minimum depth

to consider are given in codes (AASHTO 98, Articles 2.5.2.6.2 and 2.5.2.6.3 respectively).

Durability – contract documents specify quality of materials to be used and standards of

fabrication and erection of elements to ensure durability.

Inspectability – inspection ladders, walkways, catwalks and covered access holes will be

provided where other means of inspection are not practical.

Maintainability - Structural systems whose maintenance is expected to be difficult

should be avoided.

Rideability – the deck of the bridge will be designed to permit smooth movement of

traffic. The number of deck joints will be kept to a practicable minimum.

Economy – structural types, span lengths and materials should be selected based on cost.

The cost of future expenditures during the projected service life of the bridge should be

considered.

Constructability – bridges should be designed in a manner such that fabrication and erection

can be performed without undue difficulty or distress and that construction force effects are

within tolerable limits.

Aesthetics - Bridges should complement their surroundings, be graceful in form and present an

appearance of adequate strength. Because the major structural components are the largest

parts of a bridge and are seen first, they determine the appearance of a bridge. Consequently,

By Abdusemed B. (MSc) Page 5

Fundamentals of Bridge Design Lecture Notes 2019

engineers should seek excellent appearance in bridge parts in the following order of

importance: Horizontal and vertical alignment and position in the environment; Superstructure

type, Pier placement; Abutment placement and height; Superstructure shape, i.e., haunched,

tapered, depth; Pier shape; Abutment shape; Parapet and railing details; Surface colors and

textures; and Ornament.

1.5) Site Selection and Data Collection

Preliminary Survey

The objective of the preliminary survey is to study more than one alternative bridge sites.

Usually the road plans are not prepared with contours at this early stage, which make it

necessary to use the topographic maps available in the country. Possible bridge sites are first

located on topographic maps. The Ethiopian Mapping Authority has prepared maps to scale

of 1:250,000 for the whole country. In addition there are also maps to scale of 1:50,000

available for large areas of the country shown in the current “Map Catalogue” published by

the Ethiopian Mapping Agency. These are especially suited for the planning stage to

calculate catchment areas, possible provisional road alignments, aggregate quarries, and other

uses. After locating the possible bridge sites on these maps, these sites are visited to collect

certain preliminary data required for thorough examination of alternative bridge sites from

which the final site shall be selected.

Selection of Bridge Site

For the bridge engineer, rivers are the most common obstructions needing to be bridged.

Occasionally the engineer may be called upon to design a rail or road grade separated crossing.

These are relatively simple compared to river crossings because they involve considerations

only of height and span. The design of a river crossing has to also take hydraulic requirements

into account. There are three initial considerations to bear in mind in selection of the site:

A bridge site must offer appropriate vertical and horizontal alignments (skew angle

above 20o should be avoided due to increased bridge costs).

Its soils must be of sufficient strength to ensure the stability of the structure (the site

selection should if possible be made together with a soils engineer to minimize costs

and select the best site).

The bridge and its associated works should not have an adverse impact on adjoining

land or buildings, or be susceptible to damage from/to the local environment.

For a river crossing it is important to identify the type of river to be crossed. There are two

types of rivers namely alluvial and incised.

By Abdusemed B. (MSc) Page 6

Fundamentals of Bridge Design Lecture Notes 2019

Alluvial rivers are winding and they erode their tanks and scour their beds; they have flood

plains on either side of the channel and the flow regularly overtops the channel banks to

spread across the flood plain. They are continually active, scouring and depositing materials

on the banks and transporting quantities of sediment. The main channels and any of the

minor channels can change position and islands can disappear in the course of a single major

flood.

Incised river: have relatively stable tanks and are generally narrower and deeper than alluvial

rivers. Some overtop their banks during flood, but the flow returns to the existing channel

when the flood subsides.

There is a wide range of sites for bridges in rural areas but the choice may be limited in urban

areas and for Passovers. An ideal site for bridge crossing is one that:

Is on a straight reach of the river. If the river is meandering the best crossing site will

be at the nodal points of the course, which are not affected by the meandering.

Is beyond the disturbing influence of large tributaries.

Has well defined banks

Has reasonably straight approach roads and permits as a perpendicular crossing as

possible. Curves should be avoided in the immediate approaches to the bridge.

Has a good foundation condition.

A bridge aligned at right angles to the river results in the shortest superstructure. A skewed

bridge requires more material and is more complicated to design and construct. If a skew is

unavoidable, the angle should preferably not exceed 20 O due to the increased cost. Bridge

crossings over alluvial rivers nearly always require training works to stabilize the channel flow

within the bridge waterway opening. The location of the bridge in relation to the alignment of

the approaches may be decided as below.

a) Total span <60m-The alignment of the approaches will govern.

b) 60m<Total span < 300m-Both the alignment and good bridge site govern.

c) Total span>300m-Good bridge site governs.

Selection of a suitable bridge site especially for major bridges is teamwork consisting of

highway engineer, bridge engineers, geologist and hydraulic engineer. It is most common that

two to five different alignments are compared and evaluated from technical, economical,

environmental, and other points of view, to select the most beneficial alignment(s). This may be

performed either by hand or by a computer program. The preliminary cost of the bridges may

be calculated by unit cost per m2 of bridge deck. Several computer programs are available. An

example is a computer program developed in 1993-98 by the Overseas Centre Transport

By Abdusemed B. (MSc) Page 7

Fundamentals of Bridge Design Lecture Notes 2019

Research Laboratory (TRL) in Berkshire, United Kingdom is “RTIM3-Road Transport Investment

Model”, which is widely used to carry out cost- benefit analysis on road construction, upgrading

and maintenance projects in developing countries. The program runs on a microcomputer and

operates as a series of linked compiled spreadsheets for traffic flow, road deterioration, and

vehicle operating costs and economic analysis.

1.6) Site Investigation

Once the engineer has identified a likely site for the bridge, he/she needs to obtain field

information on the catchment area and run off, local terrain, river conditions and water levels,

navigational and other clearance requirements, and soil information.

Factors that most often need to be confirmed by field inspection are:

High-water marks or profiles and related frequencies.

Selection of roughness coefficients,

Evaluation of apparent flow direction and diversions,

Flow concentration (main stream),

Observation of land use and related flood hazards, and

Geomorphic relationships and soil conditions

Catchment Area and Run off Data1

The extent of the river catchment area determines the area to be included in plans and

sections, and can be used to estimate flow volumes. Using maps or aerial photographs to an

appropriate scale, the catchment area can be marked and its size calculated, using transparent

squared graph paper or a planimeter. If soft copy of the topographic map is available, the

area can easily be calculated from this file. The information which is of interest are: catchment

size, catchment grade, catchment cover, presence of any artificial or natural storage such as

dams, lakes etc., possibility of any change in the nature of the catchment due to forestation or

deforestation, maximum recorded intensity and frequency of rainfall in the catchment.

Drawings

a) Index Map – showing the proposed location of the bridge, the alternative bridge sites

investigated and rejected, towns and villages in the vicinity and the general topographic of the

area. Scale may be 1:50,000.

1

Catchment area same as catch basin. Catch basin A reservoir, esp. for catching and retaining surface drainage

over a large area, in which sediment may settle.

By Abdusemed B. (MSc) Page 8

Fundamentals of Bridge Design Lecture Notes 2019

b) Contour Survey Plan of the river- showing all topographic features for a sufficient

distance on either side of the site to give indication of the features, which would

influence the location, and the design of the bridge and its approaches. Distances to be

covered by contour plans are shown in Table 2.1.

c) Site plan – showing the details of the selected site and of the stream to a distance of 100

to 200m upstream and downstream of the selected site. This should show the crossing

point and alignment of approaches, location and reduced level of benchmark, location of

cross section and longitudinal sections of road and stream taken within area of the plan,

and location of buildings, rock outcrops and other possible obstructions to the road

alignment.

Table 1.1 Distance to be covered by contour plans

Catchment area (Sq.Km) Upstream Downstream

Up to 2.5 150m 150m

2.5 0 10.0 200 – 400m 150m

Over 10.0 400 – 500m 250m

d) Cross-section and longitudinal sections of the river – Cross-sections are taken at suitable

distances both upstream and downstream of the proposed bridge site. These should indicate

the distance from the centerline of the bridge and also the HFL, OFL, LWL and the bed levels at

suitable intervals along the centerline of the deep water channel.

e) Catchment area map – is prepared by tracing the ridge line of the water shed on the

topographic map of the area.

River Survey

Information required by the designer for analysis and design include not only the physical

characteristics of the land and channel, but all features that can affect the magnitude and

frequency of the flood flow which will pass the site under study. These data may include

climatological characteristics, land runoff characteristics, and stream gauging records, high

water marks and the sizes and past performances of existing structures in the vicinity. The

hydrologic characteristics of the basin or watershed of the stream under study are needed

for any predictive methods used to forecast flood flows. Although many of these characteristics

can be found from office studies, some are better found by a field survey of the basin. The size

and configuration of the watershed, the geometry of the stream network, storage, volumes of

ponds, lakes, reservoirs, and flood plains, and the general geology and soils of the basin can be

found from maps. Having determined these basin characteristics, runoff times, infiltration

By Abdusemed B. (MSc) Page 9

Fundamentals of Bridge Design Lecture Notes 2019

values, storage values, and runoff coefficients can be found and used in calculating flood flow

values using different methods such as Ryve‟s formula, Rational Formula and Area-Velocity

Method

Once the best site is selected, information is needed on the highest known flood level, the

ordinary flood level and the low water level at the proposed site. The design discharge also

needs to be determined.

The normal high water level, Ordinary Flood Level (OFL) – is the level to which the river

normally rises during the wettest season of the year.

The normal low water level, the Low Water Level (LWL) – is the level prevailing in the river

during dry weather. If there is little or no flow in dry weather, the period during which the

riverbed remains dry should be noted.

Highest know Flood Level (HFL) – is the highest level that the river is known to rise to

Soil Investigation

Soil investigation is required to get soil profile, engineering property of the foundation material

and foundation level for the abutments and piers for design of the foundations. This

information is obtained by analyzing samples taken from boreholes, test pits or geophysical

surveying. It is important to sample for soil, rock, stone, water, etc in co-operation with the soil

investigators. Samples of at least 2 kg each should be collected marking the station number

where they are collected.

1.7) Span Determination

Economical Span

For a given linear waterway the total cost of the superstructure increase and the total cost of

the substructure decrease with increase in span. The most economical span length is that for

which the cost of superstructure equals the cost of substructure, the point at which the total

cost is a minimum.

Hydraulic Requirements

Bridges are designed to accommodate design discharge at design flood. It is not economical

to build a bridge to clear a wide flood plain. So lineal waterway that passes the design discharge

should be provided (plus free board) and the bridge will be designed for the high flood. When a

river has a wide flood plain, the economical solution may be using short span bridge with proper

scour and erosion protection for the embankments, abutments and piers.

By Abdusemed B. (MSc) Page 10

Fundamentals of Bridge Design Lecture Notes 2019

Location of Piers

Piers should be located in such a manner that they can provide the required lineal waterway

and navigational clearance. The alignment of piers and abutments should, if possible, be set

parallel to the direction of flow during maximum flood even for skewed and curved bridges,

which may not be the same as during normal flow. Bridge crossings over alluvial rivers nearly

always require training works to stabilize the flow within the bridge water way opening.

Free Board

The waterway below the superstructure must be designed to pass the design flood and the

floating debris carried on it. This should apply even after several years of sedimentation.

The free board allows for uncertainty in determining DFL also. The minimum free board

above the design water level is given in table below unless a refined hydraulic have been

made.

Table 1.2 Free Bard

Discharge(m3/s) Free Board(m)

0-3 0.3

3-30 0.6

30-300 0.9

>300 1.2

These clearance measurements should be increased for backwater effects when the flow is

restricted by short span bridge or when the river has a history of unusual large floating items

or for navigational requirements. For arched structures the clearance will be measured at quarter

points of the span. The minimum clearance above roadways shall be at least 5.1m. Light

superstructures (timber, steel trusses, steel girders, etc) will have a minimum clearance height of

5.3m above roadways. Underpasses for pedestrian and bicycles should not be less than 2.4m. For

cattle and wildlife underpasses should be designed as the normal height of the actual kind of

animal plus 0.5m and for horse riding, the clear height should not be less than 3.4m. Bridges

above railways shall have a clearance height of at least 6.1m if not otherwise stated to facilitate

future electrification.

Grade Requirements

Often in mountainous areas the roadway grade is governed by capacity of heaviest vehicle to

climb, vertical curve and sight distance. These grade requirements may increase the bridge

span more than that required by hydraulic design.

By Abdusemed B. (MSc) Page 11

Fundamentals of Bridge Design Lecture Notes 2019

CHAPTER 2

BRIDGE TYPE AND SELECTION

2.1 Bridge Classification

Bridges can be classified in different ways:

(a) Traffic type/functionality

- Road bridge, Railway bridge, Pedestrian bridge, Aqueduct,2 Viaduct, Equipment bridge

(b) Life Span

- Temporary bridges, Permanent bridges, Semi-permanent bridges

(c) Horizontal Arrangement

- Straight/Normal bridge, Skewed bridge, Curved bridge

(d) Vertical Arrangement

- Horizontal/ Flat/ Normal, Inclined

(e) Span

- L ≤ 6m (Culvert)

- 7m < L ≤ 15m (Small span bridges)

- 16 ≤ L ≤ 50m (Medium span Bridges)

- 50 ≤ L≤ 150m (Large Span Bridges)

- L≥150m (Extra Large Span Bridges)

(f) Construction Materials

- Timber Bridges, Masonry Bridges, Reinforced Concrete Bridges, Prestressed Concrete Bridges,

Steel Bridges, Composite Bridges

(g) Span Arrangement

- Simply Supported, Continuous, Cantilever

2

aqueduct A channel for supplying water; often underground, but treated architecturally on high arches when

crossing valleys or low ground

By Abdusemed B. (MSc) Page 12

Fundamentals of Bridge Design Lecture Notes 2019

(h) Structural Arrangement

- Slab Bridges, Girder (Deck girder Bridges), Box Girder, Portal Frame Bridges, Arch Bridges

Truss Bridges, Plate Girder Bridges, Cable Stayed Bridges, Suspension Bridges, Box Cell/ Box

culvert

(i) Movements

- Movable Bridges, Fixed Bridges

Here we will discuss the classification of bridge types based on structural arrangement in more

detail.

2.2 Classification by Structural Form

Structural form refers to the load resisting mechanism of a bridge by which it transfers

gravity and lateral loads from the deck to the foundation. From this perspective bridges can be

classified as follows.

Table 2.1 Span lengths for various types of superstructures

Structural Maximum span in

Material Spans (m) Rang of

Type service

Slab Concrete 0-12

240, Hamana-Ko Lane

Concrete 12-250

Girder 261, Sava I,

Steel 30-260

Yugoslavia

235, Maracaibo,

Concrete girder

Cable-stayed <250 Venezuela 856,

Steel girder

Normandy

550, Quebec, Canada

Truss Steel 90-550

(rail)

304, Gladsvile

90-300

510, New River

Arch Concrete 240-500

Gorge, USA

120-360

365, Port Mann

1990 main span, 3910

Suspension Steel 300-1400 total span,

Akashi-Kaiko, Japan

a) Slab bridges: The simplest type of bridge to construct and design and is perhaps the most

common bridge. Is a bridge in which the structural deck slab itself represents the

superstructure (i.e., there are no supporting primary and secondary members).

By Abdusemed B. (MSc) Page 13

Fundamentals of Bridge Design Lecture Notes 2019

Fig. 2.1 Slab bridge

b) Girder Bridges: In girder bridges, the deck is supported on girders that are in turn supported

on abutments for single span or abutment and piers for continuous and multi-span bridges.

Girders are classified into T-Girder (cast-insitu), concrete Box-Girder (RC or Prestressed) and

steel plate Girder. T – Girder is usually used for a single span bridge spanning between 12-20m.

Box Girder is used for span length of between 30-90m, especially if a slender structure is

desired or for curved bridges with small horizontal curves where a great resistance to torsion is

required with no loss of strength in bending and shear. Steel girder bridges are most favorable

over deep or muddy waters since scaffolding from the ground is not necessary.

Steel girder and T-Girder bridges Box-Girder bridge

Fig. 2.2 Girder bridges

By Abdusemed B. (MSc) Page 14

Fundamentals of Bridge Design Lecture Notes 2019

c) Truss Bridges: Truss bridges are used for larger spans for which the depth of girder bridges is

not practical due to fabrication, erection and transportation limitation or due to economy in the

case of concrete girders. The maximum practical length of plate girders is in the 45m range.

Truss bridges provide the answer when a girder of large depth is required. By virtue of truss

action, members are primarily subjected to direct stresses only. Thus, they can carry large

amounts of force with small amount of steel. Trusses are hardly economical for spans less than

92m.

d) Rigid Frame Bridges: Rigid frame bridges consist of superstructures supported on vertical or

slanted monolithic legs (columns), and are economically suitable for moderate medium – span

lengths. Both steel and concrete is used to construct this type of bridge, the girder being T-or

box – girder. A slant – legged pre stressed concrete box girder bridge Spanning Gouritz River

was completed in 1977 with total span of 265m.

Fig. 2.3 Through truss bridge

i) rigid frame (two hinged) ii) inclined leg frame

Fig. 2.4 Rigid frame bridge

By Abdusemed B. (MSc) Page 15

Fundamentals of Bridge Design Lecture Notes 2019

e) Arch Bridges: Arch bridges are the oldest types of bridges ever built. A true arch transfers

loads to its foundation by pure compression, however, the variable position of the live load

always causes super imposed bending. Arches can be classified in different ways

From design stand point – nature of their ribs as trussed arch or solid – ribbed arch (rib

consists of a girder)

Analytically – by degree of articulation as two-hinged or three-hinged arch

Position of deck – Deck – arch bridge – arch is below deck. This is the most usual type of arch

bridges. Load transfer from deck to arch is by struts (or columns). These may be open or solid

spandrel arch types. Through arch – arch is above deck (also called bowstring girders or langer

girders) and the load is transferred from deck to arch by tension hangers.

Half – through arches_ - are those for which some part of the deck is hanging under the arch

and some portion of the deck is above the arch. Materials used may be concrete or steel. Arch

bridges are economical for medium and long spans.

Fig. 2.5 Arch bridges

f) Cable-stayed bridge: represent the most innovative and dramatic development of the post –

World War II period. These bridges are very competitive economically for medium and long

spans. They can be built with girders of either steel or prestessed concrete. A cable stayed

bridge hangs the girders by diagonal cables that are tensioned from the tower. The cables of

cable-stayed bridges are anchored in the girders. The girders are most often supported by

movable or fixed hinges. Due to the diagonally tensioned cables, axial forces and bending

By Abdusemed B. (MSc) Page 16

Fundamentals of Bridge Design Lecture Notes 2019

moments are imposed on the girder and the tower. For long span bridges, stability under strong

wind currents should be carefully considered in the design.

Longitudinal cable arrangement

I. Radiating (converging)-Fan: because the cables are at maximum angle of inclination

to the girders, the cables take maximum component of DL & LL loads. Therefore, the

axial loads in the girders are minimal. (fig.a)

II. Harp: it causes bending moment in the tower. The harp pattern is not the best from

economic point of views. It is superior aesthetically. (fig. b)

III. Fan/Modified fan: combination of radiating and harp types and combining the

advantages of both. Large numbers of cable-stayed bridges have been built using

this. (fig. c)

This type of bridge is recommended to be economical over the range 100-350m, but the

maximum span used is 890m of the Tatarn Bridge in Japan.

Fig. 2.6 Cable stayed bridges

By Abdusemed B. (MSc) Page 17

Fundamentals of Bridge Design Lecture Notes 2019

g) Suspension Bridges: Suspension bridges are recognized for spanning the longest distances

and for their superior aesthetics. Suspension bridges use two main cables suspended between

two towers and anchored to blocks at the ends. Stiffening girders are either truss or box type

and hung from the main cables using hangers.

Flow of forces in a suspension bridge: The load on the girder is transmitted to the towers

through the hangers and the main cables, and then to the anchor blocks. It can be seen that

anchor blocks are essential to take the horizontal reaction force from the cables. The gravity of

the anchor blocks resists the upward component of the cable tension force and the shear force

between the anchor blocks and the foundation resists the horizontal component. Unlike the

cable-stayed bridge, no axial force is induced in the girders of a suspension bridge.

The sag in the main cable affects the structural behavior of the suspension bridge: the smaller

the sag, the larger the stiffness of the bridge and thereby large horizontal forces are applied to

anchor blocks. In general the ratio of the sag to the main span is selected to about 1:10. The

suspension bridge is most suitable for long spans. The longest is the Akashi Kaikyo Bridge, which

has the main span of 1908.8m in Japan.

2.7 Suspension bridges

The distinction between cable-stayed and suspension bridges is the profile of the cable. In

suspension bridges the main cables are curved and continuous between the towers. The deck

and other vertical loading are suspended from these cables at relatively short intervals. Being

relatively flexible, the main cable develops funicular shape, which is a function of the

magnitude and position of the loading. On the other hand, in cable-stayed bridges, the cables

are straight and extend from one tower and connected to the deck directly at discrete points.

By Abdusemed B. (MSc) Page 18

Fundamentals of Bridge Design Lecture Notes 2019

Being, taut, they furnish relatively inflexible support along the span at several points and

provide a bridge with relatively greater stiffness than that achievable in suspension bridges.

Bridges data in Ethiopia

2.8) bridges data in Ethiopia

2.3 Selection of Bridge Type

In selection of a bridge type, there is no unique answer. For each span length range there is

more than one bridge type that will satisfy the design criteria. Generally the following factors

should be considered.

Geometric Condition of the Site: The type of bridge selected will often depend on the

horizontal and vertical alignment of the highway route and on the clearances above and below

the road way. E.g. If the alignment is on a curve, box and slab type bridges are best options.

By Abdusemed B. (MSc) Page 19

Fundamentals of Bridge Design Lecture Notes 2019

Subsurface Conditions of the Site: The foundation soils at a site will determine whether

abutments and piers can be founded on spread footings, driven piles and etc. The potential for

seismic activity at a site should be a part of the subsurface investigation because this will

change details of the substructure. For example, rigid frame bridge requires strong foundation

material that can resist both horizontal and vertical thrust. If the foundation material is weak,

then another bridge type is more appropriate.

Functional Requirements: The bridge must function to carry not only present but also future

volumes of traffic. Decision must be made on the number of lanes of traffic to accommodate

present and future volumes of traffic, inclusion of sidewalks, future wearing surface, possibility

of future widening and the like. In the case of stream and flood plain crossings, the bridge must

continue to function during flood and should not impose constriction to water or debris.

Satisfaction of these requirements will suggest some type of bridge over others.

Aesthetics: It is necessary to understand what qualities and features of a bridge tend to make

that aesthetics statement a good one. This understanding requires training and time.

When a bridge is placed across a relatively shallow valley, the most pleasing appearance

occurs when there are an odd number of spans with span lengths that decrease going

up the side of the valley.

Harmony between the whole structure and its surrounding needed to be addressed.

Repeating similar spans too many times can become monotonous and can be

uncomfortable.

Economics and ease of maintenance: In comparison of the economics of different bridge types,

the construction cost and maintenance cost should be taken together. A general rule is that the

bridge with minimum number of spans, fewest deck joints and widest spacing of girders will be

the most economical. By reducing the number of spans, the construction cost of one pier is

eliminated. Deck joints are a high maintenance cost item, so minimizing their number will

reduce the life cycle cost of the bridge. Generally, concrete structures require less maintenance

than steel structures.

Construction and erection considerations: The selection of the bridge type to be built is often

governed by construction and erection considerations. In general, the larger the prefabricated

or precast member, the shorter the construction time. However, the larger the members, the

more difficult they are to transport and lift into place. The availability of skilled labor and

specified materials will also influence the choice of a particular bridge type.

Legal Considerations: Applicable laws like environmental laws also govern the type of bridge.

By Abdusemed B. (MSc) Page 20

Fundamentals of Bridge Design Lecture Notes 2019

CHAPTER 3

BRIDGE LOADING AND DESIGN METHODS

3.1) Types of loads

The following permanent and transient loads and forces shall be considered for design of

bridges where applicable. The load provisions may also be applied to the structural evaluation

of existing bridges.

Permanent Loads

Permanent loads are those that remain on the bridge for an extended period of time, perhaps

for the entire service life. Such loads include:

DC = dead load of structural components and nonstructural attachments

DD = down drag

DW = dead load of wearing surfaces and utilities

EH = horizontal earth pressure load

EL = accumulated locked-in effects resulting from the construction process

ES = earth surcharge load

EV = vertical pressure from dead load of earth fill

Transient Loads

Transient loads, as the name implies, change with time and may be applied from several

directions and/or locations. Typically, such loads are highly variable.

BR = vehicular braking force

CE = vehicular centrifugal force

CR = creep

CT = vehicular collision force

EQ = earthquake

FR = friction

IM = vehicular dynamic load allowance

By Abdusemed B. (MSc) Page 21

Fundamentals of Bridge Design Lecture Notes 2019

LL = vehicular live load

LS = live load surcharge

PL = pedestrian live load

SE = settlement

SH = shrinkage

TG = temperature gradient

TU = uniform temperature

WA = water load and stream pressure

WL = wind on live load

WS = wind load on structure

3.2) Dead Loads

Dead load shall include the weight of all components of the structure, appurtenances and

utilities attached thereto, earth cover, wearing surface, future overlays, and planned widening.

In the absence of more precise information, the densities, specified in table below, shall be

used for dead loads.

Table 3.1 Densities and Force Effects of Different Materials

MATERIAL DENSITY (kg/m3) Force effect (kN/m3)

Bituminous Wearing Surfaces 2250 22.5

Cast Iron 7200 72

Cinder (volcanic stone) Filling 960 9.6

Compacted Sand, silt, or Clay 1925 19.3

Normal concrete 2400 24

Loose Sand, Silt, or Gravel 1800 18

Soft Clay 1700 17

Rolled Gravel or Ballast 2250 22.5

Steel 7850 79

Stone Masonry 2725 27.3

Hard wood 960 9.6

Soft wood 800 8

Fresh water 1000 10

3.3) Live Loads

Number of Design Lanes: Generally, the number of design lanes should be determined by

taking the integer part of the ratio w/3600, where w is the clear roadway width in mm between

curbs and/or barriers. In cases where the traffic lanes are less than 3600 mm wide, the number

By Abdusemed B. (MSc) Page 22

Fundamentals of Bridge Design Lecture Notes 2019

of design lanes shall be equal to the number of traffic lanes, and the width of the design lane is

taken as the width of traffic lanes. For roadway widths from 6000 to 7200 mm, two design lanes

should be used, and the design lane width should be one-half the roadway width.

Multiple Presence of Live Load: The provisions of this subchapter shall not be applied to the

fatigue limit state for which one design truck is used, regardless of the number of design lanes.

Trucks will be present in adjacent lanes on roadways with multiple design lanes but this is

unlikely that all adjacent lanes will be loaded simultaneously. This will be considered by the

multiple presence factors. When the loading condition includes the pedestrian loads combined

with one or more lanes of the vehicular live load, the pedestrian loads shall be taken to be one

loaded lane.

Table 3.2 Multiple presence factors

Number of Loaded Lanes 1 2 3 >3

Multiple Presence Factors “m” 1.20 1.0 0.85 0.65

Dynamic Load Allowance

Vehicular Dynamic Load Allowance (IM): Dynamic effects due to moving vehicles shall

be attributed to two sources:

1) Hammering effect: is the dynamic response of the wheel assembly to riding surface

discontinuities, such as deck joints, cracks, potholes and the likes.

2) Dynamic response of the bridge as a whole to passing vehicles, which shall be due to

long undulations in the roadway pavement, such as those caused by settlement of fill, or

to resonant excitation as a result of similar frequencies of vibration between bridge and

vehicle. The frequency of vibration of any bridge should not exceed 3 Hz.

Dynamic load allowance need not be applied to:

Retaining walls not subject to vertical reactions from the superstructure, and

Foundation components that are entirely below ground level.

The dynamic load allowance shall not be applied to pedestrian loads or to the design lane load.

The factor to be applied to the static load shall be taken as: (1 + IM/100).

Table 3.3 Dynamic Load Allowance, IM

Component IM

Deck Joints – All Limit States 75%

By Abdusemed B. (MSc) Page 23

Fundamentals of Bridge Design Lecture Notes 2019

All Other Components

15%

Fatigue and Fracture Limit State

33%

All Other Limit States

The dynamic load allowance for culverts and other buried structures, in %, shall be taken as:

IM = 33 (1.0 - 4.1*10-4 DE) > 0%

Where: DE = the minimum depth of earth cover above the structure (mm)

3.3.1) Vehicular Live Loads

Vehicular live loading on the roadways of bridges structures, designated HL-93, and shall

consist of a combination of the:

Design truck or design tandem, and

Design lane load

Consideration should be given to site-specific modifications to the design truck, design tandem,

and/or the design lane load under the following conditions:

The roadway is expected to carry unusually high percentages of truck traffic;

Flow control, such as a stop sign, traffic signal, or control booth, causes trucks to collect

on certain areas of a bridge or to not be interrupted by light traffic; or

Special industrial loads are common due to the location of the bridge.

The live load model, consisting of either a truck or tandem coincident with a uniformly

distributed load, was developed as a notional representation of shear and moment produced

by a group of vehicles routinely permitted on highways under exclusions to weight laws. The

vehicles considered to be representative of these exclusions are called exclusion vehicles. The

load model is called "notional" because it is not intended to represent any particular truck. The

exclusion load is the load produced by an exclusion vehicle. Each design lane under

consideration shall be occupied by either the design truck or tandem, coincident with the lane

load, where applicable. The loads shall be assumed to occupy 3 m transversely within a design

lane.

Design truck: The weights and spacing of axles and wheels for the design truck shall be as

specified in Figure below.

By Abdusemed B. (MSc) Page 24

Fundamentals of Bridge Design Lecture Notes 2019

Except on the application of Design Vehicular Live Loads and Fatigue Loads, the spacing

between the two 145 KN axles shall be varied between 4.3 and 9.0 m to produce extreme force

effects.

Fig. 3.1 Characteristics of the Design Truck

Design Tandem: The design tandem used for Strategic Bridges shall consist of a pair of 110

kN axles spaced 1.2 m apart. The transverse spacing of wheels shall be taken as 1.8 m. See

below.

Fig. 3.2 Design Tandem Load

Design Lane Load: The design lane load shall consist of a load of 9.3 KN/m, uniformly

distributed in the longitudinal direction. Transversely, the design lane load shall be assumed

to be uniformly distributed over a 3.0-m width. The force effects from the design lane load

shall not be subject to a dynamic load allowance.

By Abdusemed B. (MSc) Page 25

Fundamentals of Bridge Design Lecture Notes 2019

3.3.2) Centrifugal forces (CE= Vehicular Centrifugal Force)3

Centrifugal force is due to inertia force of vehicles on curved bridges at speed. Centrifugal

forces shall be applied horizontally at a distance 1.8 m above the roadway surface.

Centrifugal forces shall be taken as the product of the axle weights of the design truck or

tandem and the factor C, taken as:

Where: v = highway design speed (m/s)

g = gravitational acceleration: 9.81 (m/s2)

R = radius of curvature of traffic lane (m)

3.3.3) Breaking Force (BR= Vehicular Braking Force)4

From AASHTO Commentary 3.6.4 Based on energy principles, and assuming uniform

deceleration (retardation), the braking force determined as a fraction "b" of vehicle weight is:

Where a = the length of uniform deceleration.

From AASHTO Article 3.6.4 Braking forces shall be taken as 25 % of the axle weights of the

design truck or tandem per lane placed in all design lanes headed in the same direction.

3

Acceleration is the time derivative of the velocity vector and as such results from either a change of magnitude or

direction of velocity. A truck can increase speed, decrease speed, and/or change directions as it moves along a

curvilinear path. All of these effects require an acceleration of the vehicle that causes a force between the deck

and the truck. As a truck moves along a curvilinear path, the change in direction of the velocity causes a centrifugal

acceleration in the radial direction.

4

A decrease in speed due to braking can create a significant acceleration (deceleration) that causes large forces on

the bridge in the direction of the truck movement. Such forces are transmitted to the deck and must be taken into

the substructure at the fixed bearings or supports. It is quite probable that all truck operators on a bridge will

observe an event that causes the operators to apply the brakes. Thus, loading of multiple lanes should be

considered in the design. Again, it is unlikely that all the trucks in all lanes will be at the maximum design level,

therefore the multiple presence factors outlined previously may be applied

By Abdusemed B. (MSc) Page 26

Fundamentals of Bridge Design Lecture Notes 2019

These forces shall be assumed to act horizontally at a distance of 1800 mm above the roadway

surface in either longitudinal direction to cause extreme force effects.

3.3.4) Vehicular Collision (CT= Vehicular Collision Force):

Unless protections are provided a horizontal force of 1800KN applied at 1.2m above the ground

should be considered.

3.3.5) Pedestrian Loads

A pedestrian load of 3.6 KPa (kN/m2) shall be applied to all sidewalks wider than 0.6 m and

considered simultaneously with the vehicular design live load.

3.3.6) Water Loads (WA= Water Load and Stream Pressure)

Static Pressure: Static pressure of water shall be assumed to act perpendicular to the surface

that is retaining the water. Pressure shall be calculated as the product of height of water

above the point of consideration, the density of water, and "g" (the acceleration of gravity =

9.81 m/s2).

p = * g * z * 10-9

Where p = static pressure (Mpa)

= density of water (kg/m3)

z = height of water above the point of consideration (mm)

g = Gravitational acceleration (m/s2)

3.3.7) Buoyancy

Buoyancy shall be considered an uplift force, taken as the sum of the vertical components of

static pressures, acting on all components below design water level.

3.3.8) Stream Pressure

Longitudinal: The longitudinal drag force shall be taken as the product of longitudinal

stream pressure and the projected surface exposed thereto. The pressure of flowing water

acting in the longitudinal direction of substructures will be taken as:

p = 5.14*10-4 CDV2

Where: p = pressure of flowing water (MPa)

CD = drag coefficient for piers as specified in Table below

By Abdusemed B. (MSc) Page 27

Fundamentals of Bridge Design Lecture Notes 2019

V = design velocity in m/s of water for the design flood in strength and service limit states and

for the check flood in the extreme event limit state

Table 3.4 Drag Coefficient

Type CD

Semicircular-nosed pier 0.7

Square-ended pier 1.4

Debris lodged against the pier 1.4

Wedged-nosed pier with nose angle 90 or less

o

0.8

Lateral: The lateral, uniformly distributed pressure on substructure due to water flowing at an

angle, , to the longitudinal axis of the pier (see Figure below) shall be taken as:

PL = 5.14 x 10-4CLV2

Where: PL = lateral pressure (MPa)

CL = lateral drag coefficient specified in Table below.

Fig. 3.3 Plan View of Pier Showing Stream Flow Pressure

Table 3.5 Lateral Drag Coefficient

Angle, , between direction of flow and

CL

longitudinal axis of the pier

0o 0.0

1o 0.5

10o 0.7

20o 0.9

30o 1.0

The lateral drag force shall be taken as the product of the lateral stream pressure and the

surface exposed thereto.

3.3.9) Wind Loads (WL= Wind on Live load; WS= Wind load on Structure)

By Abdusemed B. (MSc) Page 28

Fundamentals of Bridge Design Lecture Notes 2019

Wind Pressure on Structures, (WS): For small and medium sized concrete bridges below

50m length the wind load on structures shall be neglected.

In the absence of more precise data, design wind pressure, PD in KPa, shall be determined as:

Where PB = base wind pressure specified in Table below

VDZ = design velocity of wind at design elevation, Z (Km/hr)

VB= Base wind velocity (Km/hr)

Table 3.6 Base Pressures, PB Corresponding to VB = 160 km/h (45 m/s)

STRUCTURAL COMPONENT WINDWARD LOAD, KPa LEEWARD LOAD, KPa

Trusses, Columns, and Arches 2.4 1.2

Beams 2.4 Not applicable

Large Flat Surfaces 1.9 Not applicable

The wind loading shall not be taken less than 4.4 kN/m2 in the plane of a windward chord and

2.2 kN/m2 in the plane of a leeward chord on truss and arch components, and not less than 4.4

kN/m2 on beam or girder components.

Wind Pressure on Vehicles, (WL): When vehicles are present, the design wind pressure shall be

applied to both structure and vehicles. Wind pressure on vehicles shall be represented by an

interruptible moving force of 1.46 KN/m acting normal to and 1.8 m above the roadway and

shall be transmitted to the structure.

Aeroelastic Instability: Many bridges, decks, or individual structural components have been

shown to be aeroelastically insensitive if their length-to-width or length-to-depth ratios are

under about 30.0. Wind tunnel testing of bridges and other civil engineering structures is a

highly developed technology, which shall be used to study the wind response characteristics of

a structural model or to verify the results of analysis. This is especially applicable to long spans.

3.3.10) Earthquake Effects (EQ= Earthquake)

Earthquake loads are given by the product of the elastic seismic response coefficient C sm and

the equivalent weight of the superstructure. These are inertia forces due to mass of the bridge

when a sudden shaking of the ground occurs. Minimum seat width requirements shall be at

By Abdusemed B. (MSc) Page 29

Fundamentals of Bridge Design Lecture Notes 2019

least 500 mm at each abutment. For multispan structures, the minimum analysis requirements

shall be as specified below:

Note: Essential bridges in the following table are generally those that should, as a minimum, be

open to emergency vehicles and for security/defense purposes immediately after the design

earthquake, i.e., a 475-year return period event. However, some bridges must remain open to

all traffic after the design earthquake and be usable by emergency vehicles and for

security/defense purposes immediately after a large earthquake, e.g., a 2500 year return period

event. These bridges should be regarded as critical structures.

Table 3.7 Minimum Analysis Requirements for Seismic Effects

In which

* = no seismic analysis required (Zone 1-3)

UL = uniform load elastic method

SM = single-mode elastic method

MM = multimode elastic method

The selection of the method of analysis depends on seismic zone, regularity, and importance of

the bridge.

3.3.11) Earth Pressure (EH = Horizontal Earth Pressure; ES = Earth Surcharge; LS = Live Load

Surcharge; DD = Down drag)

Earth pressure shall be considered as a function of the:

- Type and density of earth - Location of groundwater table

- Water content - Earth-structure interaction

- Soil creep characteristics - Amount of surcharge and

- Degree of compaction - Earthquake effects

Walls that can tolerate little or no movement should be designed for at-rest earth pressure.

Walls that can move away from the soil mass should be designed for pressures between active

and at rest conditions, depending on the magnitude of the tolerable movements. Movement

required to reach the minimum active pressure or the maximum passive pressure is a function

By Abdusemed B. (MSc) Page 30

Fundamentals of Bridge Design Lecture Notes 2019

of the wall height and the soil type. Some typical values of these mobilizing movements,

relative to wall height, are given in Table 3.8.

EH = Horizontal Earth Pressure

There are two earth pressure theories used. These are Rankin and Coulomb Earth Pressure

theories. Coulomb theory is recommended by AASHTO for masonry and RC abutment since this

theory holds better for the actual situation. Basic earth pressure (p, in MPa) shall be assumed to

be linearly proportional to the depth of earth and taken as:

p = kh*s*g*z *10-9

Where: kh = coefficient of lateral earth pressure taken as ko, from table 3.9 for walls that do

not deflect or move

s = density of soil (kg/m3), z = depth below the surface of earth (mm), g = Gravitational

acceleration (m/s2)

Table 3.8 Approximate Values of Relative Movements Required to Reach Minimum Active or

Maximum Passive Earth Pressure Conditions

Type of backfill (Value of /H) Active (Value of /H) Passive

Dense sand 0.001 0.01

Medium-dense sand 0.002 0.02

Loose sand 0.004 0.04

Compacted silt 0.002 0.02

Compacted lean clay 0.01 0.05

Compacted fat clay 0.01 0.05

Where: = movement of top of wall required to reach minimum active or maximum passive

pressure by tilting or lateral translation (mm)

H = height of wall (mm)

Table 3.9 Typical Coefficients of Lateral Earth Pressure At-Rest (ko), where: OCR = over

consolidation ratio

Soil type Coefficient of Lateral Earth Pressure, ko

OCR = 1 OCR = 2 OCR = 5 OCR = 10

Loose sand 0.45 0.65 1.1 1.6

Medium Sand 0.4 0.6 1.05 1.55

Dense Sand 0.35 0.55 1 1.5

Silt (ML) 0.5 0.7 1.1 1.6

By Abdusemed B. (MSc) Page 31

Fundamentals of Bridge Design Lecture Notes 2019

Lean Clay (CL) 0.6 0.8 1.2 1.65

Highly Plastic Clay (CH) 0.65 0.8 1.1 1.4

Values for the coefficient of active pressure shall be taken as:

In which

Where: = friction angle between fill and wall

= angle of fill to the horizontal

= angle of backfill of wall to the vertical

/ = effective angle of internal friction ()

Fig. 3.4 Notation for Coulomb at Earth Pressure

ES = Earth Surcharge

Where a uniform surcharge is present, a constant horizontal earth pressure, p (MPa), shall be

added to the basic earth pressure. This constant earth pressure shall be taken as:

p = ks qs

Where: ks = coefficient of earth pressure due to surcharge, qs = uniform surcharge applied to

the upper surface of the active earth wedge (MPa)

LS = Live Load Surcharge

By Abdusemed B. (MSc) Page 32

Fundamentals of Bridge Design Lecture Notes 2019

Live load surcharge shall be applied where vehicular load is expected to act on the surface of

the backfill within a distance equal to the wall height behind the back face of the wall.

The increase in horizontal pressure due to live load surcharge shall be estimated as:

p = k*s*g*heq *10-9

Where: p = constant horizontal earth pressure due to uniform surcharge (MPa), s = density of

soil (kg /m3), k = coefficient of earth pressure, heq = equivalent height of soil for the design truck

(mm)

Equivalent heights of soil, heq, for highway loadings shall be taken from Table below. Linear

interpolation shall be used for intermediate wall heights. The “Wall Height” shall be taken as

the distance between the surface of the backfill and the bottom of the footing.

Table 3.10 Equivalent Height of Soil, heq for Different Wall Heights Due to Vehicular Loading

Wall Height (mm) heq (mm)

1500 1700

3000 1200

6000 760

9000 610

N.B If the vehicular loading is transmitted through a structural slab, which is also supported by

means other than earth, an appropriate reduction in the surcharge loads shall be permitted.

Down Drag (DD)

When soil surrounding piles settle, it applies a downward force. In this case, the force should be

considered.

3.3.12) Force Effects Due to Superimposed Deformations: TU, TG, SH, CR, SE

Uniform temperature (TU): Bridge materials expand and contract in response to rise and fall of

temperature. The difference between the lowest or the highest temperature and the base

construction temperature assumed in design shall be used to calculate thermal deformation

effects.

Temperature Gradient (TG): Temperature rise can differ on the top and bottom surfaces of

abridge because the top surface is subjected to direct solar radiation.

Differential Shrinkage (SH): Where appropriate, differential shrinkage strains between

concretes of different age and composition, and between concrete and steel or wood, shall be

By Abdusemed B. (MSc) Page 33

Fundamentals of Bridge Design Lecture Notes 2019

determined. The designer may specify timing and sequence of construction in order to

minimize stresses due to differential shrinkage between components.

Creep (CR): In determining force effects and deformations due to creep, dependence on time

and changes in compressive stresses shall be taken into account.

Settlement (SE): This will cause internal forces in continues structures. Force effects due to

extreme values of differential settlements among substructures and within individual

substructure units shall be considered.

3.4) Design Philosophy

In engineering design the general principle is that the resistance of a cross section has to

exceed the effects come from the applied loads. That is

Resistance ≥Effect of Loads

When a particular loading condition reaches and just exceeds the resistance capacity of the

provided section failure is the result. Such a condition is referred to as a Limit State. A limit

state is a condition beyond which a bridge system or bridge component ceases to full fill the

function for which it is designed. Preventing a limit state from being reached is the central goal

of design of bridges. In addition to this function, appearance and economy must get due

attention. Safety is achieved by using reasonable margin of safety factors. These factors are

results of collective experience and judgment of qualified group of engineers and officials.

In Highway Bridge design AASHTO LRFD provision is used for bridge design. The resistance

side of the inequality of Equation above is multiplied by a statistically based resistance factor,

whose value is usually less than one, and the load side is multiplied by a statistically based load

factor, whose value is usually greater than one.

The load effect at a particular limit state involves a combination of a different load types (Qi)

that have different degrees of predictability. Due to this reason the load effect side is written in

a summation form. The equation is

And this equation involves both load factors and resistance factor due to this the design

method is called load and resistance factor design method. In AASHTO LRFD bridge design

specification the equation is given by

By Abdusemed B. (MSc) Page 34

Fundamentals of Bridge Design Lecture Notes 2019

Where

i= load modifier

Qi = force effects from loads specified herein

i = load factors specified in Tables B and C below

Rn= resistance

The additional parameter η is known as load modifier which is incorporated to consider

ductility, redundancy and operational importance of the bridge. Under the umbrella of the

LRFD the strength limit state, extreme event limit state, service limit state and fatigue and

fracture limit state exist.

Load Factors and Load Combinations

Components and connections of a bridge shall satisfy the above equation for the applicable

combinations of factored extreme force effects as specified at each of the limit states

presented in Table 3.11

Table 3.11 Limit States

Basic load combination relating to the normal vehicular use of the bridge without

wind.

A reduced value of 0.50, applicable to all strength load combinations, specified for

STRENGTH uniform temperature (TU), creep (CR), and shrinkage (SH), used when calculating force

I effects other than displacements at the strength limit state, represents an expected reduction

of these force effects in conjunction with the inelastic response of the structure. The

calculation of displacements for these loads utilizes a factor greater than 1.0 to avoid

undersized joints and bearings.

Load combination relating to the use of the bridge by ERA-specified special design or

permit vehicles, without wind.

The permit vehicle should not be assumed to be the only vehicle on the bridge unless so

STRENGTH

assured by traffic control. Otherwise, the other lanes should be assumed to be occupied by

II the vehicular live load as specified herein. For bridges longer than the permit vehicle, the

presence of the design lane load, preceding and following the permit load in its lane, should

be considered.

Load combination relating to the bridge exposed to wind velocity exceeding 90 km/h.

STRENGTH

Vehicles become unstable at higher wind velocities. Therefore, high winds prevent the

III presence of significant live load on the bridge.

By Abdusemed B. (MSc) Page 35

Fundamentals of Bridge Design Lecture Notes 2019

Load combination relating to very high dead load to live load force effect ratios.

The standard calibration process for the strength limit state consists of trying out

various combinations of load and resistance factors on a number of bridges and their

components. Combinations that yield a safety index close to the target value of = 3.5 are

retained for potential application. From these are selected constant load factors and

corresponding resistance factors for each type of structural component reflecting its use.

This calibration process had been carried out for a large number of bridges with spans not

STRENGTH

exceeding 60 m. For the primary components of large bridges, the ratio of dead and live

IV load force effects is rather high, and could result in a set of resistance factors different from

those found acceptable for small- and medium-span bridges. It is believed to be more

practical to investigate one additional load case than to require the use of two sets of

resistance factors with the load factors provided in Strength Load Combination I, depending

on other permanent loads present. For bridges with up to 180 m spans, Load Combination

IV will govern where the dead load to live load force effect ratio exceeds 7.0

STRENGTH Load combination relating to normal vehicular use of the bridge with wind of 90 km/h (25

V m/s) velocity

Load combination including earthquake

This limit state includes water loads, WA. The probability of a major flood and an

EXTREME

earthquake occurring at the same time is very small. Therefore, consideration of basing

EVENT I water loads and scour depths on mean discharges shall be warranted. Live load coincident

with an earthquake is discussed elsewhere in this chapter.

Load combination relating to the normal operational use of the bridge with a 90 km/h

(25 m/s) wind and all loads taken at their nominal values. Also related to deflection

control in buried metal structures, tunnel liner plate, and thermoplastic pipe and to

control crack width in reinforced concrete structures. This load combination should also be

SERVICE I used for the investigation of slope stability.

Compression in prestressed concrete components is investigated using this load

combination. Service III is used to investigate tensile stresses in prestressed concrete

components.

Load combination intended to control yielding of steel structures and slip of slip critical

connections due to vehicular live load.

This load combination corresponds to the overload provision for steel structures, and it is

SERVICE II applicable only to steel structures. From the point of view of load level, this

combination is approximately halfway between that used for Service I and Strength I

Limit States.

Load combination relating only to tension in prestressed concrete structures with the

objective of crack control.

SERVICE The live load specified in these Specifications reflects, among other things, exclusion

III weight limits. The statistical significance of the 0.80 factor on live load is that the event is

expected to occur about once a year for bridges with two traffic lanes, less often for bridges

with more than two traffic lanes, and about once a day for bridges with a single traffic lane.

Fatigue and fracture load combination relating to repetitive gravitational vehicular live load

and dynamic responses under a single design truck having a constant axle spacing of 9.0 m

between 145 kN axles.

FATIGUE The load factor, applied to a single design truck, reflects a load level found to be

representative of the truck population with respect to a large number of return cycles of

stresses and to their cumulative effects in steel elements, components, and connections.

By Abdusemed B. (MSc) Page 36

Fundamentals of Bridge Design Lecture Notes 2019

The load factors for various loads comprising a design load combination shall be taken as

specified in Table 3.12 and 3.13. All relevant subsets of the load combinations shall be

investigated.

Table 3.12 Load Combinations and Load Factors

For each load combination, every load that is indicated to be taken into account and that is

germane to the component being designed, including all significant effects due to distortion,

shall be multiplied by the appropriate load factor and multiple presence factor specified in, if

applicable. The factors shall be selected to produce the total extreme factored force effect. For

each load combination, both positive and negative extremes shall be investigated.

In load combinations where one force effect decreases another effect, the minimum value shall

be applied to the load reducing the force effect. For permanent force effects, the load factor

that produces the more critical combination shall be selected from Table 3.13. Where the

permanent load increases the stability or load-carrying capacity of a component or

bridge, the minimum value of the load factor for that permanent load shall also be investigated.

The larger of the two values provided for load factors of Uniform Temperature (TU), Creep

(CR), and Shrinkage (SH) shall be used for deformations and the smaller values for all other

effects.

For example, at Strength I Limit State where the permanent load reaction is positive and live

load can cause a negative reaction, the load combination would be:

By Abdusemed B. (MSc) Page 37

Fundamentals of Bridge Design Lecture Notes 2019

0.9DC + 0.65DW + 1.75(LL+IM)

If both reactions were negative, the load combination would be:

1.25DC + 1.50DW + 1.75(LL+IM)

Table 3.13 Load Factors for Permanent Loads

Where the abbreviations are as defined in sec 3.1

Load Modifiers, i = D R I

D = a factor relating to ductility, as specified below

R = a factor relating to redundancy as specified below

I = a factor relating to operational importance as specified below

Ductility, redundancy, and operational importance are significant aspects affecting the margin

of safety of bridges.

Ductility: The structural system of a bridge shall be proportioned and detailed to ensure the

development of significant and visible inelastic deformations at the strength and extreme event

limit states prior to failure.

By Abdusemed B. (MSc) Page 38

Fundamentals of Bridge Design Lecture Notes 2019

For the strength limit state:

D 1.05 for non-ductile components and connections

D = 1.00 for conventional designs and details complying with these Specifications

D 0.95 for components and connections for which additional ductility-enhancing measures

have been specified beyond those required by these Specifications

For all other limit states:

D = 1.00

Redundancy: Multiple load-path structures should be used unless there are compelling reasons

not to use them.

For the strength limit state:

R 1.05 for nonredundant members

=1.00 for conventional levels of redundancy

0.95 For exceptional levels of redundancy

For all other limit states:

R = 1.00

Operational importance: This definition shall apply to the strength and extreme event limit

states only. Some bridges or structural components and connections shall be declared to be of

operational importance. Such classification should be based on social/survival and/or

security/defense requirements.

For the strength limit state:

l 1.05 for important bridges

= 1.00 for typical bridges

0.95 For relatively less important bridges

For all other limit states:

l = 1.00

For Conventional Construction, Resistance Factors Ф shall be taken as

For flexure and tension of RC = 0.9

For flexure and tension of PSC = 1.0

For shear and torsion = 0.9

For bearing on concrete = 0.7

For compression in strut-and-tie model = 0.7

For compression in anchorage zones = 0.8

By Abdusemed B. (MSc) Page 39

Fundamentals of Bridge Design Lecture Notes 2019

For tension in steel in anchorage zones = 1.0

For resistance during pile driving = 1.0

By Abdusemed B. (MSc) Page 40

You might also like

- T-Roff Girder DesignDocument41 pagesT-Roff Girder Designlinda100% (1)

- Design of Deck SlabDocument8 pagesDesign of Deck SlabHussein AlkafajiNo ratings yet