Steel Pipes (Ashrae) (Schedule 40)

Steel Pipes (Ashrae) (Schedule 40)

Uploaded by

Ahmed SherifCopyright:

Available Formats

Steel Pipes (Ashrae) (Schedule 40)

Steel Pipes (Ashrae) (Schedule 40)

Uploaded by

Ahmed SherifCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Steel Pipes (Ashrae) (Schedule 40)

Steel Pipes (Ashrae) (Schedule 40)

Uploaded by

Ahmed SherifCopyright:

Available Formats

Pipes, Tubes, and Fittings 45.

Table 2 Steel Pipe Data

U.S. Working Pressurec

Nominal Nominal Wall Inside Surface Area Cross Section Mass ASTM A53 B to 200°C

Size, Size, Thickness Diameter Outside, Inside, Metal Flow Area, Pipe, Water, Mfr. Joint kPa

in. mm Schedulea t, mm d, mm m2/m m2/m Area, mm2 mm2 kg/m kg/m Process Typeb (gage)

1/4 8 40 ST 2.24 9.25 0.043 0.029 80.6 67.1 0.631 0.067 CW T 1296

80 XS 3.02 7.67 0.043 0.024 101.5 46.2 0.796 0.046 CW T 6006

3/8 10 40 ST 2.31 12.52 0.054 0.039 107.7 123.2 0.844 0.123 CW T 1400

80 XS 3.20 10.74 0.054 0.034 140.2 90.7 1.098 0.091 CW T 5654

1/2 15 40 ST 2.77 15.80 0.067 0.050 161.5 196.0 1.265 0.196 CW T 1476

80 XS 3.73 13.87 0.067 0.044 206.5 151.1 1.618 0.151 CW T 5192

3/4 20 40 ST 2.87 20.93 0.084 0.066 214.6 344.0 1.68 0.344 CW T 1496

80 XS 3.91 18.85 0.084 0.059 279.7 279.0 2.19 0.279 CW T 4695

1 25 40 ST 3.38 26.64 0.105 0.084 318.6 557.6 2.50 0.558 CW T 1558

80 XS 4.55 24.31 0.105 0.076 412.1 464.1 3.23 0.464 CW T 4427

1-1/4 32 40 ST 3.56 35.05 0.132 0.110 431.3 965.0 3.38 0.965 CW T 1579

80 XS 4.85 32.46 0.132 0.102 568.7 827.6 4.45 0.828 CW T 4096

1-1/2 40 40 ST 3.68 40.89 0.152 0.128 515.5 1 313 4.05 1.313 CW T 1593

80 XS 5.08 38.10 0.152 0.120 689.0 1 140 5.40 1.140 CW T 3972

2 50 40 ST 3.91 52.50 0.190 0.165 690.3 2 165 5.43 2.165 CW T 1586

80 XS 5.54 49.25 0.190 0.155 953 1 905 7.47 1.905 CW T 3799

Licensed for single user. © 2008 ASHRAE, Inc.

2 -1/2 65 40 ST 5.16 62.71 0.229 0.197 1 099 3 089 8.62 3.089 CW W 3675

80 XS 7.01 59.00 0.229 0.185 1 454 2 734 11.40 2.734 CW W 5757

3 80 40 ST 5.49 77.93 0.279 0.245 1 438 4 769 11.27 4.769 CW W 3323

80 XS 7.62 73.66 0.279 0.231 1 946 4 261 15.25 4.261 CW W 5288

4 100 40 ST 6.02 102.26 0.359 0.321 2 048 8 213 16.04 8.213 CW W 2965

80 XS 8.56 97.18 0.359 0.305 2 844 7 417 22.28 7.417 CW W 4792

6 150 40 ST 7.11 154.05 0.529 0.484 3 601 18 639 28.22 18.64 ERW W 4799

80 XS 10.97 146.33 0.529 0.460 5 423 16 817 42.49 16.82 ERW W 8336

8 200 30 7.04 205.0 0.688 0.644 4 687 33 000 36.73 33.01 ERW W 3627

40 ST 8.18 202.7 0.688 0.637 5 419 32 280 42.46 32.28 ERW W 4433

80 XS 12.70 193.7 0.688 0.608 8 234 29 460 64.51 29.46 ERW W 7626

10 250 30 7.80 257.5 0.858 0.809 6 498 52 060 50.91 52.06 ERW W 3344

40 ST 9.27 254.5 0.858 0.800 7 683 50 870 60.20 50.87 ERW W 4178

XS 12.70 247.7 0.858 0.778 10 388 48 170 81.39 48.17 ERW W 6116

80 15.06 242.9 0.858 0.763 12 208 46 350 95.66 46.35 ERW W 7453

12 300 30 8.38 307.1 1.017 0.965 8 307 74 060 65.09 74.06 ERW W 3096

ST 9.53 304.8 1.017 0.958 9 406 72 970 73.70 72.97 ERW W 3641

40 10.31 303.2 1.017 0.953 10 158 72 190 79.59 72.21 ERW W 4020

XS 12.70 298.5 1.017 0.938 12 414 69 940 97.28 69.96 ERW W 5157

80 17.45 289.0 1.017 0.908 16 797 65 550 131.62 65.57 ERW W 7419

14 350 30 ST 9.53 336.6 1.117 1.057 10 356 88 970 81.15 88.96 ERW W 3316

40 11.10 333.4 1.117 1.047 12 013 87 290 94.13 87.30 ERW W 3999

XS 12.70 330.2 1.117 1.037 13 681 85 610 107.21 85.63 ERW W 4695

80 19.05 317.5 1.117 0.997 20 142 79 160 157.82 79.17 ERW W 7453

16 400 30 ST 9.53 387.4 1.277 1.217 11 876 117 800 93.06 117.8 ERW W 2903

40 XS 12.70 381.0 1.277 1.197 15 708 114 000 123.09 114.0 ERW W 4109

18 450 ST 9.53 438.2 1.436 1.376 13 396 150 800 104.98 150.8 ERW W 2579

30 11.10 435.0 1.436 1.367 15 556 148 600 121.90 148.6 ERW W 3110

XS 12.70 431.8 1.436 1.357 17 735 146 450 138.97 146.4 ERW W 3654

40 14.27 428.7 1.436 1.347 19 863 144 300 155.65 144.3 ERW W 4185

20 500 20 ST 9.53 489.0 1.596 1.536 14 916 187 700 116.88 187.4 ERW W 2324

30 XS 12.70 482.6 1.596 1.516 19 762 182 900 154.85 182.9 ERW W 3289

40 15.06 477.9 1.596 1.501 23 325 179 400 182.78 179.4 ERW W 4006

aNumbers are schedule numbers per ASME Standard B36.10M; ST = Standard; XS = (2) An arbitrary corrosion allowance of 0.64 mm for pipe sizes through NPS 2 and

Extra Strong. 1.65 mm from NPS 2½ through 20, plus

bT = Thread; W = Weld (3) A thread cutting allowance for sizes through NPS 2.

cWorking pressures were calculated per ASME B31.9 using furnace butt-weld (contin-

uous weld, CW) pipe through 100 mm and electric resistance weld (ERW) thereafter. Because the pipe wall thickness of threaded standard pipe is so small after deducting the

The allowance A has been taken as allowance A, the mechanical strength of the pipe is impaired. It is good practice to limit

(1) 12.5% of t for mill tolerance on pipe wall thickness, plus standard threaded pipe pressure to 620 kPa (gage) for steam and 860 kPa (gage) for water.

You might also like

- Project FeasibilityDocument5 pagesProject FeasibilityShahrooz Leo Qureshi100% (2)

- Clarke 100e Mig WelderDocument18 pagesClarke 100e Mig WelderplainmanNo ratings yet

- Havc Underground Piping MosDocument5 pagesHavc Underground Piping MosYusuf Ziya DilbazNo ratings yet

- Astm C 1290 - Fibrous Glass Balnket For DuctsDocument4 pagesAstm C 1290 - Fibrous Glass Balnket For DuctsleandroschroederNo ratings yet

- Air Volumes in Ducts in Cubic Feet Per Minute (CFM)Document1 pageAir Volumes in Ducts in Cubic Feet Per Minute (CFM)mahaveenNo ratings yet

- LPG Handbook PDFDocument50 pagesLPG Handbook PDFAhmed Sherif100% (2)

- Hvac For Clean Rooms FacilitiesDocument54 pagesHvac For Clean Rooms FacilitiesAhmed Sherif100% (3)

- Corridoio 8 Strade CompletoDocument177 pagesCorridoio 8 Strade Completocvijica635No ratings yet

- Extreme Project ManagementDocument20 pagesExtreme Project ManagementSiddique SattarNo ratings yet

- Data Structures Using CDocument7 pagesData Structures Using CVikram Rao0% (1)

- Diamond Walraven Product Catalog PDFDocument218 pagesDiamond Walraven Product Catalog PDFKABIR CHOPRANo ratings yet

- Pagine Da DW144 Sheet Metal DuctworkDocument2 pagesPagine Da DW144 Sheet Metal DuctworkscacchiNo ratings yet

- Technical Data Sheet - Round & Oval Ducts..Document13 pagesTechnical Data Sheet - Round & Oval Ducts..Sandeep GalhotraNo ratings yet

- Data Sheet Ironman Water Flow DetectorDocument2 pagesData Sheet Ironman Water Flow DetectorsalesNo ratings yet

- Checklist QualityDocument14 pagesChecklist QualityCheeragNo ratings yet

- Table Equivalent Schedule 40 Steel PipeDocument1 pageTable Equivalent Schedule 40 Steel PipeorisNo ratings yet

- Chilled Water Piping System: SECTION 15/1/6Document9 pagesChilled Water Piping System: SECTION 15/1/6Ahmed Yousri AhmedNo ratings yet

- ISL G.I SheetDocument3 pagesISL G.I Sheetmalik hafeezNo ratings yet

- Hunter GP100 08-2003 PDFDocument1 pageHunter GP100 08-2003 PDFaymanmkNo ratings yet

- Chiller Fire Fighting: Flow Range (GPM) Pipe Size (Inch) Pressure Drop Range (Of Water / 100 FT)Document2 pagesChiller Fire Fighting: Flow Range (GPM) Pipe Size (Inch) Pressure Drop Range (Of Water / 100 FT)raifaisalNo ratings yet

- NRV - IntervalveDocument2 pagesNRV - IntervalveRajkishorNo ratings yet

- EN 253 Pre-InsulatedDocument4 pagesEN 253 Pre-Insulatedlela84kNo ratings yet

- Disc Valves PDFDocument7 pagesDisc Valves PDFMUHAMMED SHAFEEQNo ratings yet

- Zeus Acds Series BrochureDocument40 pagesZeus Acds Series BrochureAntonio Osante LeyvaNo ratings yet

- DIamond Walraven New CatalogueDocument225 pagesDIamond Walraven New Cataloguegk80823No ratings yet

- CHECKLSITDocument2 pagesCHECKLSITaboobacker siddiqueNo ratings yet

- Fripex-San Export Englisch Druckbogen 08-2015 75dpi PDFDocument5 pagesFripex-San Export Englisch Druckbogen 08-2015 75dpi PDFMuhammad ArslanNo ratings yet

- Copper Pipe Friction Loss Chart MetricDocument1 pageCopper Pipe Friction Loss Chart Metricahmed aliNo ratings yet

- Roll Grooved Anti-Vortex Plate - Hot Dipped GalvanisedDocument1 pageRoll Grooved Anti-Vortex Plate - Hot Dipped GalvanisedNikhil RajanNo ratings yet

- Aleem CV Mechanic EXPDocument3 pagesAleem CV Mechanic EXPmohd nadeem ahmedNo ratings yet

- Water Parameters NeededDocument1 pageWater Parameters Neededafraz_xecNo ratings yet

- Fittings Catalogue: Celebrating Sixty Years in BusinessDocument27 pagesFittings Catalogue: Celebrating Sixty Years in BusinessrenramaNo ratings yet

- Hvac-Question & AnswerDocument4 pagesHvac-Question & AnswerKkrkollam KrishnaKumarNo ratings yet

- HVAC Design Project PlanningDocument2 pagesHVAC Design Project PlanningAlison LewisNo ratings yet

- VRF Outdoor Unit InstallationDocument25 pagesVRF Outdoor Unit Installationtyberius7No ratings yet

- Duct Weight EstimatingDocument16 pagesDuct Weight EstimatingfghabboonNo ratings yet

- Weicco - Flexible Connector PDFDocument2 pagesWeicco - Flexible Connector PDFmsmrizhwanNo ratings yet

- Friction Loss ChartDocument1 pageFriction Loss ChartShahrizal SharifNo ratings yet

- Puddle FlangeDocument1 pagePuddle FlangeWaqar KhanNo ratings yet

- Material Submittal For Chilled Water Valves (Gala)Document1 pageMaterial Submittal For Chilled Water Valves (Gala)carloNo ratings yet

- FormulasDocument4 pagesFormulascristiamhiguita6No ratings yet

- Technical Submittal For Pipes (Interpipe)Document18 pagesTechnical Submittal For Pipes (Interpipe)ahsan100% (1)

- Pipe Schudle ChartDocument2 pagesPipe Schudle Chartsachinshirnath100% (1)

- Vent BoqDocument2 pagesVent BoqAndrew Awad AdlyNo ratings yet

- E Ductulator09Document9 pagesE Ductulator09Carlos SamaniegoNo ratings yet

- Calorifier ManualDocument27 pagesCalorifier ManualPaul KwongNo ratings yet

- Welding of Austenitic Stainless Steel - Part 2 - TWIDocument6 pagesWelding of Austenitic Stainless Steel - Part 2 - TWISumantaNo ratings yet

- Test and Drain PDFDocument8 pagesTest and Drain PDFPARIETALNo ratings yet

- Handbook Chapter9 MixingVentilationDocument44 pagesHandbook Chapter9 MixingVentilationJoao SousaNo ratings yet

- WPS and MOS For Welder TestDocument8 pagesWPS and MOS For Welder TestDo Van HUNGNo ratings yet

- 220 Tig Ac/Dc Welder Operating Manual: FeaturesDocument24 pages220 Tig Ac/Dc Welder Operating Manual: FeaturesAlejandro CKNo ratings yet

- Steel Tubes Bs 1387 en 10255pdfDocument6 pagesSteel Tubes Bs 1387 en 10255pdfMuhammad Mahbub HussainNo ratings yet

- LOFICA Brochure 2017Document4 pagesLOFICA Brochure 2017main mydriveNo ratings yet

- S/A 106 Spec Sheet A106 Pipe Specifications: ScopeDocument7 pagesS/A 106 Spec Sheet A106 Pipe Specifications: ScopeyanurarzaqaNo ratings yet

- Dasco 1-9Document9 pagesDasco 1-9Ahmed AzadNo ratings yet

- Technical Data Sheet: Complete Solution For InsulationsDocument1 pageTechnical Data Sheet: Complete Solution For InsulationsjaganNo ratings yet

- Duct Weight With InsulationDocument16 pagesDuct Weight With Insulationhasanadel88100% (1)

- BreatheDocument9 pagesBreatheMohammad Arshad KamarNo ratings yet

- Jet DiffuserDocument146 pagesJet DiffuserPrabu YadavNo ratings yet

- Condensate Recovery and Return Systems Sdi / SDS: Data SheetDocument4 pagesCondensate Recovery and Return Systems Sdi / SDS: Data Sheetqdod_waffiNo ratings yet

- BS 10 Table Flange Dimensions PDFDocument5 pagesBS 10 Table Flange Dimensions PDFvishwas salunkhe100% (1)

- Bottomgrass Engineering & HVAC Services: Indoor Section Coompressor SectionDocument1 pageBottomgrass Engineering & HVAC Services: Indoor Section Coompressor SectionSubodh Murkewar0% (1)

- Systech Duct FactoryDocument14 pagesSystech Duct Factoryمحمد عبداللهNo ratings yet

- Steel Pipe Data Pipe ODDocument2 pagesSteel Pipe Data Pipe ODMuhammad Arief RamdhaniNo ratings yet

- Working Pressure PDFDocument11 pagesWorking Pressure PDFAPGENCO EENo ratings yet

- Calculator NEWDocument8 pagesCalculator NEWJohn Eric OliverNo ratings yet

- Ariston Dish Washer Manual (English)Document8 pagesAriston Dish Washer Manual (English)Ahmed SherifNo ratings yet

- Steel Pipes (Carrier)Document1 pageSteel Pipes (Carrier)Ahmed SherifNo ratings yet

- Conditioning Air Into The Human Comfort ZoneDocument4 pagesConditioning Air Into The Human Comfort ZoneAhmed SherifNo ratings yet

- Miniature Circuit BreakersDocument24 pagesMiniature Circuit BreakersAhmed SherifNo ratings yet

- BerryFloor 2010Document12 pagesBerryFloor 2010Ahmed SherifNo ratings yet

- Chenille Warp / Flash Back Glasbac® TileDocument2 pagesChenille Warp / Flash Back Glasbac® TileAhmed SherifNo ratings yet

- FM200Document23 pagesFM200Ahmed SherifNo ratings yet

- TRANE Airside EconomizerDocument8 pagesTRANE Airside EconomizerAhmed SherifNo ratings yet

- Measurement and Verification Hand Book PDFDocument278 pagesMeasurement and Verification Hand Book PDFAhmed SherifNo ratings yet

- 13-Acoustics - NOISE (Compatibility Mode)Document84 pages13-Acoustics - NOISE (Compatibility Mode)Ahmed SherifNo ratings yet

- Velocity PressureDocument1 pageVelocity PressureAhmed SherifNo ratings yet

- Air Filters: Dr. Ahmed Elsafty yDocument55 pagesAir Filters: Dr. Ahmed Elsafty yAhmed Sherif100% (1)

- 6-AirHandling UnitsDocument37 pages6-AirHandling UnitsAhmed SherifNo ratings yet

- AC Systems Lectures ModDocument38 pagesAC Systems Lectures ModAhmed SherifNo ratings yet

- 1-HVAC Load Explorer V1Document34 pages1-HVAC Load Explorer V1Ahmed SherifNo ratings yet

- List of AbbreviationsDocument1 pageList of AbbreviationsAhmed SherifNo ratings yet

- Ventilation Strategies in Case of Fire in Longitudinally Ventilated Two-Way TunnelsDocument11 pagesVentilation Strategies in Case of Fire in Longitudinally Ventilated Two-Way TunnelsAhmed SherifNo ratings yet

- 9 AC Air - OutletsDocument48 pages9 AC Air - OutletsAhmed SherifNo ratings yet

- 307 161-02 Ta-Cmi GBDocument21 pages307 161-02 Ta-Cmi GBAhmed SherifNo ratings yet

- Pums Paht G 256Document24 pagesPums Paht G 256Jhonathan CanzarioNo ratings yet

- Alkyl Halide PDFDocument29 pagesAlkyl Halide PDFSantosh Potdar100% (2)

- Revenue Cycle-Chapter 12Document35 pagesRevenue Cycle-Chapter 12XiangLiNo ratings yet

- Auto Car Lock Using Cell PhoneDocument25 pagesAuto Car Lock Using Cell PhoneAmadi E. UchennaNo ratings yet

- Top DBA Shell Scripts For Monitoring The DatabaseDocument9 pagesTop DBA Shell Scripts For Monitoring The DatabaseIan HughesNo ratings yet

- CE 262 - Civil and Construction Engineering Materials Lab ReportDocument13 pagesCE 262 - Civil and Construction Engineering Materials Lab ReportMuhammad Noman SaeedNo ratings yet

- Understanding The Early EffectDocument4 pagesUnderstanding The Early Effectabirami sNo ratings yet

- Technology of Building: I3-GCI (GROUP 01) 12 JUNE 2017Document43 pagesTechnology of Building: I3-GCI (GROUP 01) 12 JUNE 2017ChhengnguonNo ratings yet

- Impact Hardness TestDocument7 pagesImpact Hardness TestAse Sharew100% (1)

- EatonDocument157 pagesEatonMauro MonsalveNo ratings yet

- WLTC Retrievable Bridge Plug One PagerDocument1 pageWLTC Retrievable Bridge Plug One PagerPrakhil BilayeNo ratings yet

- GIS Client GIS Capabilities Review Project - Kickoff MeetingDocument17 pagesGIS Client GIS Capabilities Review Project - Kickoff MeetingMohamad AldadaNo ratings yet

- مطلوب مواصفة لوحة توزيع ضغط منخفض رئيسية لمبنيDocument21 pagesمطلوب مواصفة لوحة توزيع ضغط منخفض رئيسية لمبنيAsma ElsaftyNo ratings yet

- Panasonic KX Td1232Document6 pagesPanasonic KX Td1232suwandi76No ratings yet

- Data Sheet Lfbo 00 b1 Ds 001Document10 pagesData Sheet Lfbo 00 b1 Ds 001Agung SugiwantoNo ratings yet

- Triple-DES VHDL ProjectDocument57 pagesTriple-DES VHDL ProjectRamanaButterflyNo ratings yet

- 2021 - SM - LC - 60r410a - 3D Inverter - S - Us - C1 - 211018Document352 pages2021 - SM - LC - 60r410a - 3D Inverter - S - Us - C1 - 211018Técnico ElectrónicoNo ratings yet

- IRF630Document10 pagesIRF630Jose M PeresNo ratings yet

- Turbo Generator & Its AuxiliariesDocument89 pagesTurbo Generator & Its AuxiliariesPapun Scribd100% (1)

- TCG 2015, BA, enDocument175 pagesTCG 2015, BA, enmarcusa85No ratings yet

- Data Warehousing ConceptsDocument50 pagesData Warehousing ConceptsSandeep KumarNo ratings yet

- What Is Summation Current Transformer - Definition & Types - Circuit GlobeDocument4 pagesWhat Is Summation Current Transformer - Definition & Types - Circuit Globem kh100% (1)

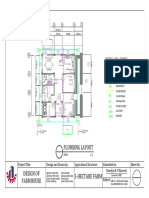

- Catch Basin and Septic TankDocument1 pageCatch Basin and Septic Tankguerrerobeverly35No ratings yet

- Intel Corporation: 1. 1971-4004 MicroprocessorDocument2 pagesIntel Corporation: 1. 1971-4004 MicroprocessorR-MarufNo ratings yet

- Sample Session PlanDocument7 pagesSample Session PlanNorvie Marie Tutor OmandamNo ratings yet

- Jery Pondaag CV 2018Document10 pagesJery Pondaag CV 2018Anonymous Z1lKhYNo ratings yet