Fci Itp PDF

Fci Itp PDF

Uploaded by

Ilir DalipiCopyright:

Available Formats

Fci Itp PDF

Fci Itp PDF

Uploaded by

Ilir DalipiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fci Itp PDF

Fci Itp PDF

Uploaded by

Ilir DalipiCopyright:

Available Formats

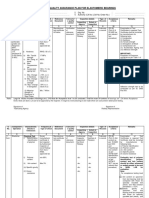

INSPECTION

AND TEST PLAN

for Composite Insulators

FCI Composite Insulator Ltd.

Relevant product standards: IEC 61109, IEC 61952, IEC 62231

Activity Method Equipment Frequency Inspected by

Dimensions Caliper, micrometer

Metal end fittings Galvanic layer Layer thickness tester

Brinell hardness Brinell hardness tester

Mechanical load Rubber tensile strength tester

Housing material Tracking and erosion Tracking and Leakage current tester

Sampling from

(slicone rubber) Shore hardness Shore A hardness tester

Quality control of every batch Quality

Density Precision balance

the raw materials (testing samples from Control

Density Densimeter (water displacement)

every packageing unit)

Dimensions Caliper, micrometer

Core (FRP rod)

Dye penetration Manual

Barcol hardness Barcol hardness tester

Protective devices, Sampling test of dimensions Caliper, micrometer

accessories Sampling test of galvanic layer Layer thickness tester

Crimping of Allocating the crimping parameters Crimping equipment Every time before Operators

end fittings Verifying the tensile strength Tensile strength tester equipment the production starts + Quality Control

Allocating the moulding parameters Moulding equipment additional allocations in Operators

Moulding

Trial casting, verifying the housing profile Moulding equipment, manual case of huge series Quality Control

Marking Compliance of the customer's requirements Manual First piece + sampling Quality Control, Operators

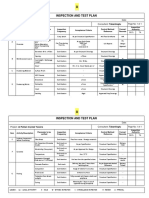

Checking of housing and shed profile

Checking of silicone filling at the location

of the concentricity positioning pins

Checking of elimination of air inclusions

and contaminations in the housing

Checking the homogeneity

of the housing color

Visual inspection Checking the appropriate burr removal Manual

Sampling acc. to the

Checking the geometry of the shed profile Quality

Sample Test above detailed relevant

Checking the appropriate location Control

product standards

and legibility of the markings

Checking the adhesion between

the end fittings and the housing

Checking the metal end fittings and the protective coating to

avoid any damage of them

Verification of dimensions (distances and diameters) Manual, caliper, measuring tape

Verification of SML (Specified Mechanical Load) or SCL (Specified Cantilever load) Tensile strength tester equipment

Test of galvanization Layer thickness tester

Measurement of the mounting length Measuring tape

Verification of RTL (Routine Test Load: min. 5kN tensile load) Tensile strength tester equipment

Routine Test Every pieces

Manual control of the adhesion of the housing Manual Quality Control, Operators

Manual control of the surface of the insulator Manual

Packing Final check, compliance of the customer's requirements Manual Every package

Quality

QC report Completing of the Quality Certificate report Manual Every pieces

Control

FCI COMPOSITE INSULATOR LTD. Phone:+36 29 889 200

2251 Tápiószecső, Pesti út 17 Fax: +36 29 889 204 e‐mail: euroins@fcicomposite.hu

You might also like

- JLL Quality Test Reports & Checklists - CivilDocument55 pagesJLL Quality Test Reports & Checklists - CivilN.PrabhuNo ratings yet

- Standard QA Plan (Elastomeric Bearings)Document8 pagesStandard QA Plan (Elastomeric Bearings)ghaghra bridgeNo ratings yet

- Derringer's Desirability FunctionDocument8 pagesDerringer's Desirability Functioniabureid7460No ratings yet

- Governor Actuator - Calibrate: Shutdown SIS Previous ScreenDocument16 pagesGovernor Actuator - Calibrate: Shutdown SIS Previous ScreenAdolfo MoscosoNo ratings yet

- Std. QAP of Expension Joints (March 16)Document6 pagesStd. QAP of Expension Joints (March 16)ghaghra bridgeNo ratings yet

- Supplier Standardised Process Guide: - Raw Material Testing - RM Processing - ForgingDocument22 pagesSupplier Standardised Process Guide: - Raw Material Testing - RM Processing - ForgingBhavna Acharya100% (1)

- Material Integrity Testing MISTDocument2 pagesMaterial Integrity Testing MISTsyafiqNo ratings yet

- Determining The Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and RivetsDocument15 pagesDetermining The Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and RivetsILSEN N. DAETNo ratings yet

- Scope of Work of Non IBR Boiler InspectionDocument1 pageScope of Work of Non IBR Boiler InspectionShailendra BoroleNo ratings yet

- FM-QMS-13-REV01-01092023 Quality Risk Assessment MatrixDocument1 pageFM-QMS-13-REV01-01092023 Quality Risk Assessment MatrixAice LuzadaNo ratings yet

- ASTM F606 - 05 Fastener Test MethodsDocument15 pagesASTM F606 - 05 Fastener Test MethodsFernado RinconNo ratings yet

- Unit 3b Welding InspectionDocument11 pagesUnit 3b Welding InspectionMarcell John TamioNo ratings yet

- FAT LIST-CLD Station Post InsulatorDocument1 pageFAT LIST-CLD Station Post InsulatorFacturas SempsaNo ratings yet

- Inspection MatrixDocument2 pagesInspection MatrixFabian BellNo ratings yet

- Civil and Construction: Strong Foundation Builds TrustDocument2 pagesCivil and Construction: Strong Foundation Builds TrustazhaniNo ratings yet

- Test Procedure and MethodDocument1 pageTest Procedure and MethodkmiqdNo ratings yet

- Advait Panels QAPDocument1 pageAdvait Panels QAPrinkukachhelaNo ratings yet

- Inspection and Test Plan ConcreteDocument2 pagesInspection and Test Plan Concreteavikshit yNo ratings yet

- Quality Control of Work 1601 Quality Control Plan: or Part Thereof For Which Minimum One Test Set To Be Carried OutDocument2 pagesQuality Control of Work 1601 Quality Control Plan: or Part Thereof For Which Minimum One Test Set To Be Carried OutSABEASNNo ratings yet

- Concrete Crack Meter - Crack Monitoring Equipment - PCTEDocument2 pagesConcrete Crack Meter - Crack Monitoring Equipment - PCTEPrajakta RahateNo ratings yet

- Manufacturing QP For Bathroom OrganizersDocument1 pageManufacturing QP For Bathroom OrganizersHossam ElagamyNo ratings yet

- Itp For Structural Steel WorkDocument12 pagesItp For Structural Steel Worknguyen thangNo ratings yet

- 2.3 - Mr. Methsara Lokuge - Material Engineer (Matara) PDFDocument22 pages2.3 - Mr. Methsara Lokuge - Material Engineer (Matara) PDFmpchanakaNo ratings yet

- TATA Painting Specification 40Document1 pageTATA Painting Specification 40Suleman KhanNo ratings yet

- Quality Assurance Plan For PEBDocument2 pagesQuality Assurance Plan For PEBBipin Vihari DasNo ratings yet

- Ductile Iron (DI) Pipes - Quality StandardsDocument3 pagesDuctile Iron (DI) Pipes - Quality StandardsKalpana KrishnaNo ratings yet

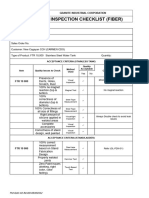

- FG Inspection For FiberDocument2 pagesFG Inspection For FiberAice LuzadaNo ratings yet

- Q A P - Coco BogieDocument2 pagesQ A P - Coco BogieANIRBANNo ratings yet

- Quality Management PlanDocument14 pagesQuality Management PlanrabiaNo ratings yet

- F 606 - 00 - Rjywni0wmaDocument14 pagesF 606 - 00 - Rjywni0wmaEYBER ALEXANDER GARNICA TRUJILLONo ratings yet

- Road Embankment ITPDocument6 pagesRoad Embankment ITPMahendraSinghNo ratings yet

- Purchase Policies 3Document5 pagesPurchase Policies 3jatinNo ratings yet

- Itp For Structural Steel Work 4 PDF FreeDocument12 pagesItp For Structural Steel Work 4 PDF FreemahmoudNo ratings yet

- Azerian PipeDocument3 pagesAzerian PipeHadad KarimiNo ratings yet

- Manufacturing QP For Dish DrainersDocument1 pageManufacturing QP For Dish DrainersHossam ElagamyNo ratings yet

- ValveDocument6 pagesValvetharmarajuNo ratings yet

- Standard Operation ProcedureDocument3 pagesStandard Operation ProcedureAnand KesarkarNo ratings yet

- Masjid Sahabat - Testing PlanDocument14 pagesMasjid Sahabat - Testing PlanDinn NsNo ratings yet

- (2.3) Drilling & CementingDocument36 pages(2.3) Drilling & CementingDivyansh Singh ChauhanNo ratings yet

- Automatic Compression MachinesDocument7 pagesAutomatic Compression MachinesHumam SaifulNo ratings yet

- Determining The Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and RivetsDocument16 pagesDetermining The Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and RivetsSebastián SilvaNo ratings yet

- Application Note Hardness TestingDocument12 pagesApplication Note Hardness TestingJonathan FloresNo ratings yet

- Duties of Welding ManagerDocument3 pagesDuties of Welding ManagerBalkishan DyavanapellyNo ratings yet

- QAP - Rubber liningBORLDocument1 pageQAP - Rubber liningBORLdada shaikNo ratings yet

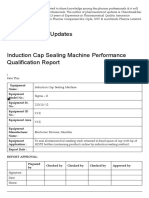

- Induction Cap Sealing Machine Performance Qualification Report - Pharmaceutical UpdatesDocument5 pagesInduction Cap Sealing Machine Performance Qualification Report - Pharmaceutical UpdatesChetan Ganesh RautNo ratings yet

- Module Details Ultrasonic Testing Methods: Name Nominal DurationDocument6 pagesModule Details Ultrasonic Testing Methods: Name Nominal Durationlamia97No ratings yet

- Durocrete Presentation NEW - 1Document31 pagesDurocrete Presentation NEW - 1rakesh.baviskar2009No ratings yet

- Modelquality Assuranceplanforpot 1Document8 pagesModelquality Assuranceplanforpot 1mouni9301997No ratings yet

- Astm F606-11Document16 pagesAstm F606-11oslatNo ratings yet

- Model Quality Assurance Plan For Pot-Ptfe BearingsDocument8 pagesModel Quality Assurance Plan For Pot-Ptfe Bearingsghaghra bridgeNo ratings yet

- F 606 - 02 - RjywngDocument15 pagesF 606 - 02 - RjywngkrutikNo ratings yet

- Not Destruction ProvesDocument6 pagesNot Destruction ProvesXheko Kalaka MendoskakoreNo ratings yet

- Astm F606Document18 pagesAstm F606dennisNo ratings yet

- PTE Catalogue 2021Document28 pagesPTE Catalogue 2021PP043No ratings yet

- Inspection and Testing Plan (Itp)Document2 pagesInspection and Testing Plan (Itp)kwameasembintiNo ratings yet

- NDT Testing of ConcreteDocument55 pagesNDT Testing of ConcreteHVRANANo ratings yet

- Reviewer Chapter 9-10Document2 pagesReviewer Chapter 9-10Kyle BullandayNo ratings yet

- ServicesDocument2 pagesServicesSecretario SigmaNo ratings yet

- Pdo - Instrument StatusDocument12 pagesPdo - Instrument StatusanandNo ratings yet

- Plastics Testing and Characterization: Industrial ApplicationsFrom EverandPlastics Testing and Characterization: Industrial ApplicationsNo ratings yet

- 7.0. Insulators and Acsr - Opgw FittingDocument20 pages7.0. Insulators and Acsr - Opgw FittingIlir DalipiNo ratings yet

- ESM AD Elektrani RMDocument3 pagesESM AD Elektrani RMIlir DalipiNo ratings yet

- 4293 PDFDocument16 pages4293 PDFIlir DalipiNo ratings yet

- 20.4.1-SPECIFICATION FOR HORIZONTAL INSTALLATION DISCONNECTOR 20 KV 630 ADocument2 pages20.4.1-SPECIFICATION FOR HORIZONTAL INSTALLATION DISCONNECTOR 20 KV 630 AIlir DalipiNo ratings yet

- MT Land Cruiser S 7 Extended Wheelbase PDFDocument1 pageMT Land Cruiser S 7 Extended Wheelbase PDFIlir DalipiNo ratings yet

- MT Land Cruiser S 7 Troopy PDFDocument1 pageMT Land Cruiser S 7 Troopy PDFIlir DalipiNo ratings yet

- 03091SzSzE PDFDocument1 page03091SzSzE PDFIlir DalipiNo ratings yet

- DCA-150 - 2 X 20 KV FOUNDATIONDocument1 pageDCA-150 - 2 X 20 KV FOUNDATIONIlir DalipiNo ratings yet

- Katalog Wood New Line 2019 VintageDocument27 pagesKatalog Wood New Line 2019 VintageIlir DalipiNo ratings yet

- 120kN SevesDocument1 page120kN SevesIlir DalipiNo ratings yet

- HE24 NoDocument1 pageHE24 NoIlir DalipiNo ratings yet

- Tech - Spec.ACSR 95.15Document1 pageTech - Spec.ACSR 95.15Ilir DalipiNo ratings yet

- Notes For C ProgrammingDocument476 pagesNotes For C Programmingbindur87No ratings yet

- PLC Programming Language - ST1Document38 pagesPLC Programming Language - ST1Hardik LanghnojaNo ratings yet

- STABILITAS PENYIMPANAN (PERBEDAAN TITIK LEMBEK) ASTM D 5976 PART 6.1 - MarkingDocument3 pagesSTABILITAS PENYIMPANAN (PERBEDAAN TITIK LEMBEK) ASTM D 5976 PART 6.1 - Markingkomang bellaNo ratings yet

- Green ComputingDocument24 pagesGreen ComputingSunil Vicky VohraNo ratings yet

- CV AfonsoDocument3 pagesCV Afonsoapi-310378470No ratings yet

- Sekolah Menengah Jenis Kebangsaan Yok Bin Semester 1 2019Document8 pagesSekolah Menengah Jenis Kebangsaan Yok Bin Semester 1 2019Catherina LeelamNo ratings yet

- Attachment 4 DDocument3 pagesAttachment 4 DannisaNo ratings yet

- ReportDocument2 pagesReportKéssia SilvaNo ratings yet

- Shearail Punching Shear Reinforcement BS8110 Design Manual SO GBGBDocument10 pagesShearail Punching Shear Reinforcement BS8110 Design Manual SO GBGBNaziemi AhmadNo ratings yet

- Magnetic Materials and Their TypesDocument9 pagesMagnetic Materials and Their TypesRahul YadavNo ratings yet

- AITS Schedule 2023Document2 pagesAITS Schedule 2023Satyam KumarNo ratings yet

- Introduction To Linguistics & Linguistic Meaning: Dr. Alla Baksh Mohd Ayub Khan Ext: 3991Document43 pagesIntroduction To Linguistics & Linguistic Meaning: Dr. Alla Baksh Mohd Ayub Khan Ext: 3991Hanifu ImuranNo ratings yet

- Rtl8192ce GR RealtekDocument18 pagesRtl8192ce GR RealtekJorge Armando LaiNo ratings yet

- 6 8051 IO InterfacingDocument66 pages6 8051 IO InterfacingSahilYadavNo ratings yet

- Cummins ISM 11 425hp Engine Spec SheetDocument2 pagesCummins ISM 11 425hp Engine Spec SheetFranklin Boada0% (1)

- International Review of Financial AnalysisDocument12 pagesInternational Review of Financial AnalysisahmedNo ratings yet

- Decs 200 Davr2Document4 pagesDecs 200 Davr2ththeeNo ratings yet

- Cat VibroDocument16 pagesCat Vibrojheaszh100% (1)

- Engine Construction 1Document11 pagesEngine Construction 1collins arogoNo ratings yet

- Fundamentals of Surveying By: Engr. Sebastian Seth S. CabahugDocument24 pagesFundamentals of Surveying By: Engr. Sebastian Seth S. CabahugSebastian Seth Santos CabahugNo ratings yet

- 3102354-EN R015 VS Series Compatibility ListDocument20 pages3102354-EN R015 VS Series Compatibility ListFrancisco CanoNo ratings yet

- Parte Numero JGK-JGTDocument81 pagesParte Numero JGK-JGTdiego yecid millan mendoza100% (1)

- Experiment 06Document4 pagesExperiment 06DikshitNo ratings yet

- Loan Setup in Oracle PayrollDocument14 pagesLoan Setup in Oracle Payrollmohamedn_1567% (3)

- Escorts Agri Machinery Group Industrial ProjectDocument29 pagesEscorts Agri Machinery Group Industrial Projectmalik_poojaNo ratings yet

- R12.2 Installation DocumentDocument211 pagesR12.2 Installation DocumentraviNo ratings yet

- Intro To HDL MidtermDocument4 pagesIntro To HDL MidtermRALPH LAURENCE VISAYANo ratings yet

- Physics ProjectDocument9 pagesPhysics ProjectSoumya RamaiyaNo ratings yet