1.method Statement - INSTALLATION OF GRP WATER TANKS

1.method Statement - INSTALLATION OF GRP WATER TANKS

Uploaded by

sarmad spectrumCopyright:

Available Formats

1.method Statement - INSTALLATION OF GRP WATER TANKS

1.method Statement - INSTALLATION OF GRP WATER TANKS

Uploaded by

sarmad spectrumOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

1.method Statement - INSTALLATION OF GRP WATER TANKS

1.method Statement - INSTALLATION OF GRP WATER TANKS

Uploaded by

sarmad spectrumCopyright:

Available Formats

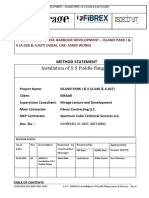

Plot Z02-B12 - PALACE BEACH RESIDENCE MAIN WORKS (LOA 6809)

CLIENT

CONSULTANT

CONTRACTOR MEP CONTRACTOR

METHOD STATEMENT FOR INSTALLATION OF GRP WATER STORAGE TANKS

Table of contents

1. Scope/Objectives

2. Reference

3. Access/Egress and Location

4. OHS Requirement

5. Health & Safety hazards

6. Definitions

7. Responsibilities/Supervision

8. Sequence/Method to be employed

9. Notification of Inspection

10. Witness Inspection/Check

10. Materials requirement

11. Records

12. Supporting documentation

13. Distribution

14. Other Information

15. Attachments

DOCUMENT NUMBER ISSUE PAGE NUMBER DATE

ABM-BME-MS-MEP-PL-009 Rev - 00 1 of 11 17/10/2022

Plot Z02-B12 - PALACE BEACH RESIDENCE MAIN WORKS (LOA 6809)

CLIENT

CONSULTANT

CONTRACTOR MEP CONTRACTOR

METHOD STATEMENT FOR INSTALLATION OF GRP WATER STORAGE TANKS

1. Scope/Objectives

Installation of GRP water storage tanks in accordance with the requirements specified in

the relevant specifications, procedures and drawings, considering safety and quality of the

work activities at palace beach residence by M/s Thermoset technologies & M/s Bilt Middle

East.

2. Reference

2.1. Contract Drawings

2.2. Specifications

2.3. Project Quality Plan Ref:

2.4. HSE Plan Ref:

2.5. Environmental Plan Ref: Shop drawings

2.6. Material Submittals

3. Access/Egress and Location

Access to the work place will be through designated and exit pathway.

4. OHS Requirements

4.1. HSE legal and contractual references

Dubai Municipality Code of Construction Safety Practice.

UAE Fire and Life Safety Code of Practice.

ABM HSE Management System.

Emaar- Project Health, Safety, Environment & Security Guidelines.

4.2. HSE Procedures/ Requirements specific to the activity.

Lift Plan based on the Lifting Operations Management Plan.

Job specific work permit system shall be followed as per scope of work prior to

the commencement of the activity.

Daily basic task briefing shall be carried out as per work permit system,

DOCUMENT NUMBER ISSUE PAGE NUMBER DATE

ABM-BME-MS-MEP-PL-009 Rev - 00 2 of 11 17/10/2022

Plot Z02-B12 - PALACE BEACH RESIDENCE MAIN WORKS (LOA 6809)

CLIENT

CONSULTANT

CONTRACTOR MEP CONTRACTOR

METHOD STATEMENT FOR INSTALLATION OF GRP WATER STORAGE TANKS

Skilled and competent workman shall be deployed, external training or third

party training shall be provided if required. MSRA Briefing to be done and

recorded.

4.3. Permit Systems for hazardous work / High Risk Activities.

Permit to work is mandatory for all activity and the same shall be enforced.

The Supervisor/ Foreman will inspect the work place physically and ensure the

permit to work conditions are compiled before requesting for the work permit;

the same shall be produced to the engineer in charge of the activity for

approval.

The Safe conditions mentioned in the work permit shall follow till the

completion of the said activity and the permit to be closed out immediately after

every activity completion.

4.4. Emergency procedure specific to the activity.

In case of any emergency, the emergency response procedure will be in effect.

The Emergency response team comprises of the Project Manager,

Construction Manager, Project Engineer, the Logistics Engineer, the HSE

Engineer, the Safety Officer and the Male Nurse.

Emergency rescue shall be carried out as per approved emergency plan,

adequate first aid facility provided as per DM requirement.

In case of any emergency all employees are advised to communicate the same

through the Emergency Hot Line Number

4.5. Environmental procedure, waste management arrangements.

All waste shall be disposed as per Approved CEMP with proper segregation.

Segregation of waste shall be marked with proper signs. Regular removal of

waste from site shall be planned and executed.

All chemical storage shall be deployed as per approved HSE standard

requirements, paints shall be used & returned back to COSSH store on daily

basis.

DOCUMENT NUMBER ISSUE PAGE NUMBER DATE

ABM-BME-MS-MEP-PL-009 Rev - 00 3 of 11 17/10/2022

Plot Z02-B12 - PALACE BEACH RESIDENCE MAIN WORKS (LOA 6809)

CLIENT

CONSULTANT

CONTRACTOR MEP CONTRACTOR

METHOD STATEMENT FOR INSTALLATION OF GRP WATER STORAGE TANKS

Detailed procedure will be documented in the CEM Plan

4.6. Job specific PPE requirement

Mandatory PPE include coverall (Workers), Hard Hat, Visibility Vest, Safety

Shoes and Goggles.

Task specific PPE includes Hand Gloves, Safety Harness, fall arrestors, etc.

The Supervisor shall ensure his team wears PPE in 100% compliance to

project requirements and to Safe guard themselves.

4.7. Night work and loan working

Night work shall be carried out with approved DDA night work permit, loan

work is prohibited in palace beach residence.

5. Health & safety hazards.

5.1. Contractor will comply with all safety measures as applicable to project safety

requirement.

5.2. Fall of men &material:

5.3. Unskilled work force

5.4. Work at height.

6. Definitions

BILT-Bilt Middle East LLC

MS-Method Statements

QCP-Quality Control Procedures

PPE-Personnel Protective Equipment

QA/QC-Quality Assurance/Quality Control

ITP – Inspection Test Plan

WIR – Work Inspection Request

7. Responsibilities/Supervision

7.1. Project Manager:

DOCUMENT NUMBER ISSUE PAGE NUMBER DATE

ABM-BME-MS-MEP-PL-009 Rev - 00 4 of 11 17/10/2022

Plot Z02-B12 - PALACE BEACH RESIDENCE MAIN WORKS (LOA 6809)

CLIENT

CONSULTANT

CONTRACTOR MEP CONTRACTOR

METHOD STATEMENT FOR INSTALLATION OF GRP WATER STORAGE TANKS

Shall direct responsible to carry out the works as per approved Method Statement

and Risk Assessment.

Responsible to prepare method statement and risk assessment for all critical

operation in the project and the same is approved, communicated and followed.

Directly responsible for ensuring the completion of works as per approved MSRA.

Ensure welfare arrangements are provided and maintained as per the

requirements.

7.2. Project Engineer:

Shall be responsible to organize required machinery, material, manpower to

engineers& foreman for effectively executing the work in a safe manner.

To clarify any discrepancies in the work.

7.3. Foreman:

To execute the work as per Project Engineers instructions with the right

methodology & in a safe manner.

Make sure that all the works are completed prior to offering for inspections.

To execute the works as per approved method statements.

To ensure all equipments inspection by third party and certificate is displayed.

To attend all the comments made by Consultant at the time of inspection.

Ensure the workers PPE, sufficient lighting.

7.4. QA / QC Engineer:

To check the work is carried out as per the approved method statement.

To ensure all approved materials are being used.

Verify whether suitability of ambient temperature for casting concrete.

7.5. HSE Staff Responsibilities:

To advice Project Manager, Construction Manager, Engineers & Supervisor/ Foreman

regarding the Safety precautions to be taken and monitor for the safety implementations to

execute the work.

Monitor the lifting plan and work permits procedure is complied with and the safe

conditions are in place.

DOCUMENT NUMBER ISSUE PAGE NUMBER DATE

ABM-BME-MS-MEP-PL-009 Rev - 00 5 of 11 17/10/2022

Plot Z02-B12 - PALACE BEACH RESIDENCE MAIN WORKS (LOA 6809)

CLIENT

CONSULTANT

CONTRACTOR MEP CONTRACTOR

METHOD STATEMENT FOR INSTALLATION OF GRP WATER STORAGE TANKS

All employees involved in the activity should be Safety Inducted by safety department

before allowing working at site.

Monitor HSE safe working procedures and cross check control measures mentioned in

Risk assessment is implemented for the activity.

Monitor the use of task based PPE for the activity.

DOCUMENT NUMBER ISSUE PAGE NUMBER DATE

ABM-BME-MS-MEP-PL-009 Rev - 00 6 of 11 17/10/2022

Plot Z02-B12 - PALACE BEACH RESIDENCE MAIN WORKS (LOA 6809)

CLIENT

CONSULTANT

CONTRACTOR MEP CONTRACTOR

METHOD STATEMENT FOR INSTALLATION OF GRP WATER STORAGE TANKS

8. Sequence/Method to be Employed

8.1. Material

8.1.1. Insulated panels

8.1.2. Upvc fittings

8.1.3. Stainless steel ties rod, nut bolt & washer.

8.1.4. Ladder

8.1.5. Tube level gauge

8.1.6. Hot dipped galvanized skid base

8.1.7. Internal roof support

8.2. Tools for GRP water storage tanks installation and testing.

8.2.1. Pipe Fitter Tool Box

8.2.2. Drilling Machine

8.2.3. Cleaning Clothes

8.2.4. Hole saw cutting machine

8.2.5. Scaffolding

8.2.6. Electrician Hand Tools

8.2.7. Hand Tools including ratchet spanner

8.2.8. Torque wrench

8.3. Installation Procedure

The following stages are applicable for the Installation of GRP water tank as per schedule

below.

DOCUMENT NUMBER ISSUE PAGE NUMBER DATE

ABM-BME-MS-MEP-PL-009 Rev - 00 7 of 11 17/10/2022

Plot Z02-B12 - PALACE BEACH RESIDENCE MAIN WORKS (LOA 6809)

CLIENT

CONSULTANT

CONTRACTOR MEP CONTRACTOR

METHOD STATEMENT FOR INSTALLATION OF GRP WATER STORAGE TANKS

8.3.1. Pre-Installation Check:

8.3.1.1. Refer to Approved shop drawing and specification.

8.3.1.2. “Toolbox talk” to be given before activity starts. Required number of panels and

accessories required for installation to be kept ready.

8.3.1.3. Ensure that the notification to start activity has been issued.

8.3.1.4. Ensure that materials are as per approved material submittal.

8.3.1.5. Ensure that the area is safe to carry out the work and is clean from debris and foreign

matters.

8.3.2. Installation of GRP Water storage tank

The following stages are applicable for the Installation of GRP water storage tank.

8.3.2.1. Approved Builders work drawing and approved shop drawing to be checked for setting

out dimensions for the concrete base to be made for installation of GRP water tanks. Any

deviations to be brought to consultant’s notice for approval.

8.3.2.2. GRP panels shall be assembled by the specialist supplier / contractor with gaskets and

stainless steel bolts as per sizes indicated on the approved shop drawings. Torque

DOCUMENT NUMBER ISSUE PAGE NUMBER DATE

ABM-BME-MS-MEP-PL-009 Rev - 00 8 of 11 17/10/2022

Plot Z02-B12 - PALACE BEACH RESIDENCE MAIN WORKS (LOA 6809)

CLIENT

CONSULTANT

CONTRACTOR MEP CONTRACTOR

METHOD STATEMENT FOR INSTALLATION OF GRP WATER STORAGE TANKS

wrench shall be used for tightening of assembly bolts as per manufacturer’s

recommendation to avoid over tightening.

8.3.2.3. Co-ordinate with main contractor for required civil activities.

8.3.2.4. All civil activities to be checked for completion (i.e. Block work, Plaster, screed, flooring,

painting etc.) prior to shifting of GRP panels to the service floor.

8.3.2.5. Check the concrete plinths if the location size and finishing are correct as per approved /

latest shop drawing.

8.3.2.6. Ensure the top surface of all the plinths is uniform at the same level.

8.3.2.7. Install galvanized steel skid base on the concrete plinths.

8.3.2.8. Install the base panels.

8.3.2.9. Install the side panels using support and corner bracket with stainless steel nut, bolt and

washer.

8.3.2.10. Knock outs for Tanks provisions shall be made as per approved drawing and filling

strategy.

8.3.2.11. Inlet and outlet pipes are connected to water tanks by using flanges and valves as per the

approved shop drawings.

8.3.2.12. After the tank is assembled it will be cleaned of any dust or dirt inside and outside.

8.3.2.13. In elevated positions external tank ladder will be fitted without hoops.

8.3.2.14. Approved sealant/gasket to be used at joints.

8.3.2.15. Installation of all accessories, such as level switches, float valves, control wiring etc to be

completed after hydro testing.

8.3.2.16. Install inlet, outlet, over flow and drain nozzles and air vent.

8.3.2.17. Tank shall have adequate drain and over flow pipes routed to nearest drainage system

8.3.2.18. Ensure proper clearance is provided around the GRP water tank as specified.

8.4. Testing Procedure:

The installation to be tested shall be inspected for compliance with the drawings and

specifications.

DOCUMENT NUMBER ISSUE PAGE NUMBER DATE

ABM-BME-MS-MEP-PL-009 Rev - 00 9 of 11 17/10/2022

Plot Z02-B12 - PALACE BEACH RESIDENCE MAIN WORKS (LOA 6809)

CLIENT

CONSULTANT

CONTRACTOR MEP CONTRACTOR

METHOD STATEMENT FOR INSTALLATION OF GRP WATER STORAGE TANKS

8.4.1. The water tanks as assembled above are filled with water to its full capacity upto the over

flow outlet. All outlets from the tanks are closed by closing the gate valves.

8.4.2. Allow water to stand for at least 24 hours and inspect the tank thoroughly for leaks.

8.4.3. Rectify leaks if any, and check again after 24 hours.

8.4.4. Repeat this exercise until no leak is observed in any part of the tank and the water tank is

scheduled for inspection by the Consultant.

8.4.5. Once the inspection is approved, the water tank is covered with tarpaulin till the handing

over of the project/commissioning of the system so that it is not damaged.

9. Notification of Inspection

9.1. Engineer to inspect delivered material / installations at site as per attached check

lists, prior to notifying consultant for inspection.

9.2. Bilt shall notify the Consultant with relevant transmittal form for all material

inspection (Material Inspection Check list attached)

10. Witness Inspection/Check

10.1. Bilt will follow the approved check list/inspection checklist test plan for witnessing

inspection/check, as applicable.

10.2. Rectification of any defect /damages, found during inspection is to be rectified by

responsible Site Engineer and QA/QC to check & confirm the same to consultant for

his approval.

11. Records:

11.1. Prepare work inspection request (WIR) along with check list and have them signed

by Consultant.

12. SUPPORTING DOCUMENTATION

This MS to be read in conjunction with the below referenced documents

Contract Drawings and specifications

Project Quality Plan

Project HSE Plan

13. DISTRIBUTION

DOCUMENT NUMBER ISSUE PAGE NUMBER DATE

ABM-BME-MS-MEP-PL-009 Rev - 00 10 of 11 17/10/2022

Plot Z02-B12 - PALACE BEACH RESIDENCE MAIN WORKS (LOA 6809)

CLIENT

CONSULTANT

CONTRACTOR MEP CONTRACTOR

METHOD STATEMENT FOR INSTALLATION OF GRP WATER STORAGE TANKS

Copies of this MS will be circulated to the following for Information & action

Project Manager

Construction Manager

Site Engineer

QA/QC Engineer

HSE Engineer

Subcontractor Engineer

14. OTHER INFORMATION

Ensure that all the activities have been carried out to suit the site conditions and involved

with Site in Charge.

15. ATTACHMENTS

Risk Assessment

Checklist

ITP

DOCUMENT NUMBER ISSUE PAGE NUMBER DATE

ABM-BME-MS-MEP-PL-009 Rev - 00 11 of 11 17/10/2022

You might also like

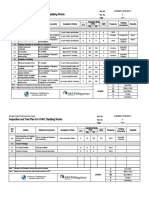

- Inspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0Document3 pagesInspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0Researcher67% (3)

- Method Statement For Testing and Commissioning of Water Supply Pipes Including ChlorinationDocument11 pagesMethod Statement For Testing and Commissioning of Water Supply Pipes Including Chlorinationfidgety100% (1)

- Method Statement Form - HDPE PN10,16 PipeDocument22 pagesMethod Statement Form - HDPE PN10,16 PipeSmith SuwanNo ratings yet

- Gravity Test Report Water SupplyDocument1 pageGravity Test Report Water SupplygaineyskNo ratings yet

- Method Statement Water Supply Line Tie in Point Re-RoutingDocument17 pagesMethod Statement Water Supply Line Tie in Point Re-RoutingShyju Melepurath83% (6)

- (Barash) Clinical Anesthesia (6th Ed.)Document3,968 pages(Barash) Clinical Anesthesia (6th Ed.)menocide_ss67% (3)

- ITP For Cleaning Flushing & Chemical Dosing SystemDocument1 pageITP For Cleaning Flushing & Chemical Dosing SystemDong Vanra100% (1)

- Method of Statement For Pressure Test PDFDocument2 pagesMethod of Statement For Pressure Test PDFBen Lim0% (1)

- Method Statement For Gi Puddle Flanges InstallationDocument1 pageMethod Statement For Gi Puddle Flanges InstallationSanto E0% (1)

- The Method Statement of The Sand FilterDocument6 pagesThe Method Statement of The Sand FilterJeffrey Wey100% (1)

- NEW TEMPLATE-Method Statement - Smoke CurtainDocument13 pagesNEW TEMPLATE-Method Statement - Smoke CurtainJuwe PkdoNo ratings yet

- Method Statement - Air Terminal Devices Installation - R0Document13 pagesMethod Statement - Air Terminal Devices Installation - R0Anish Kumar100% (1)

- Method Statement For Pipe Flushing and Internal Cleaning (SAMPLE)Document7 pagesMethod Statement For Pipe Flushing and Internal Cleaning (SAMPLE)Hasann MaawiaNo ratings yet

- CGC-ITP-MECH-002-Irrigation SystemDocument6 pagesCGC-ITP-MECH-002-Irrigation SystemSajad Pk100% (1)

- SA04C2-MS-MET-AAG-00018 Method Statement For HDPE Pipe InstallationDocument13 pagesSA04C2-MS-MET-AAG-00018 Method Statement For HDPE Pipe InstallationABAID ULLAHNo ratings yet

- Method Statement For Leak Rectification WorksDocument7 pagesMethod Statement For Leak Rectification Worksgiri943No ratings yet

- GRP TANK Installation Method StatementDocument2 pagesGRP TANK Installation Method StatementQasim Khan82% (11)

- Method Statement Ductile Iron Flange Type Joint Pipe LTESTDocument8 pagesMethod Statement Ductile Iron Flange Type Joint Pipe LTESTmuhammad syauqi shaidanNo ratings yet

- Method Statement For Installation of FansDocument5 pagesMethod Statement For Installation of FansBinod Davis50% (2)

- MS For Deflection Test-Rev.03Document9 pagesMS For Deflection Test-Rev.03anishdev6100% (1)

- Form Leak Test Report DD 101005Document5 pagesForm Leak Test Report DD 101005Thiri HtetNo ratings yet

- Method Statement Machnical, Electrical PlumbingDocument11 pagesMethod Statement Machnical, Electrical Plumbingmangeshshinde124No ratings yet

- Method Statement - DisinfectionDocument3 pagesMethod Statement - DisinfectionSharon50% (2)

- Capstone ProjectDocument6 pagesCapstone Projectstephen njuku0% (1)

- 100 Quotes From The Movie "The Secret"Document17 pages100 Quotes From The Movie "The Secret"Elmer GatchalianNo ratings yet

- Method Statement of Installation of SS Puddle FlangesDocument7 pagesMethod Statement of Installation of SS Puddle Flangessarmad spectrum100% (2)

- Method Statement For Installation of Puddle Flange DN 500Document8 pagesMethod Statement For Installation of Puddle Flange DN 500Ahmed ImranNo ratings yet

- Method Statement For Cooling TowerDocument5 pagesMethod Statement For Cooling TowerWASIM MAKANDAR0% (1)

- Method Statement For Installation of VAV BoxDocument3 pagesMethod Statement For Installation of VAV BoxRamakrishnan100% (1)

- Method Statement of Installation of Ductile Iron FlangeDocument10 pagesMethod Statement of Installation of Ductile Iron Flangemuhammad syauqi shaidan50% (2)

- Method Statement HDPE PDFDocument1 pageMethod Statement HDPE PDFshameemNo ratings yet

- Installation Checklist For Fire PumpsDocument1 pageInstallation Checklist For Fire PumpsAmie GTunedNo ratings yet

- Inspection Checklist For Installation of Duct Hangers and Supports For HVAC Ductwork SystemDocument2 pagesInspection Checklist For Installation of Duct Hangers and Supports For HVAC Ductwork SystemBabar ShehzadNo ratings yet

- Method Statement For Firefighting Piping Equipment and Accessories InstallationDocument12 pagesMethod Statement For Firefighting Piping Equipment and Accessories InstallationMohamedNo ratings yet

- Sewerage SystemDocument9 pagesSewerage Systemhajjiyare2016No ratings yet

- Method Statement Submission: For: LPG System Work Installation, Testing & CommissioningDocument5 pagesMethod Statement Submission: For: LPG System Work Installation, Testing & CommissioningMd ShahinNo ratings yet

- Method Statement Pipe Re-Routing Saudi BinladinDocument11 pagesMethod Statement Pipe Re-Routing Saudi BinladinShyju MelepurathNo ratings yet

- Method Statement For Installation of PVC PipesDocument23 pagesMethod Statement For Installation of PVC Pipeschathura dharmasenaNo ratings yet

- Method Statement Installation of PPR Water SupplyFINALDocument5 pagesMethod Statement Installation of PPR Water SupplyFINALmengineering75% (4)

- MS A. Method Statement of UPVC Pipe Installation & Testing For Soil Waste Vent & Rain 29.06.23Document19 pagesMS A. Method Statement of UPVC Pipe Installation & Testing For Soil Waste Vent & Rain 29.06.23Rashmiranjan SamalNo ratings yet

- Method Statement For The Testing of Domestic PumpDocument11 pagesMethod Statement For The Testing of Domestic Pumpa100% (1)

- Ms-Black Steel PipeDocument4 pagesMs-Black Steel PipeYusufNo ratings yet

- Method of Statement Shutdown Water LineDocument10 pagesMethod of Statement Shutdown Water LineFrancis Mier SereñoNo ratings yet

- Method Statement For Pipe Sleeve InstallationDocument7 pagesMethod Statement For Pipe Sleeve InstallationmieadidassNo ratings yet

- Method Statement For Leakage Testing of Gravity Sewer LineDocument3 pagesMethod Statement For Leakage Testing of Gravity Sewer LinePrem Kumar100% (2)

- Gravity Test Report Water SupplyDocument1 pageGravity Test Report Water SupplygaineyskNo ratings yet

- Checklist Mechanical Block-Outs and Pipe SleevesDocument2 pagesChecklist Mechanical Block-Outs and Pipe SleevesImho Tep100% (1)

- Chilled Water Pipe Insulation Method Statement - Method Statement HQDocument3 pagesChilled Water Pipe Insulation Method Statement - Method Statement HQابوزيد عبد الجوادNo ratings yet

- Method Statement For Installation of PVC uPVC Drainage Piping Under Above GroundDocument9 pagesMethod Statement For Installation of PVC uPVC Drainage Piping Under Above Groundanver.yusifNo ratings yet

- Hume Pipe Method StatementDocument2 pagesHume Pipe Method StatementDurgawati Mishra67% (3)

- Installation of Chilled Water PumpsDocument1 pageInstallation of Chilled Water Pumpsmohamed farook0% (1)

- Sadara MFC Inspection Checklist: Copper Pipe Installation SMIC-S-4050 PlumbingDocument1 pageSadara MFC Inspection Checklist: Copper Pipe Installation SMIC-S-4050 PlumbingSiddiqui Abdul KhaliqNo ratings yet

- ITP For Firefighting SystemDocument31 pagesITP For Firefighting SystemDong Vanra100% (3)

- Method Statement For HVAC Ductwork Insulation and Acoustic LiningDocument4 pagesMethod Statement For HVAC Ductwork Insulation and Acoustic Liningrakeshamech100% (1)

- Method of Statement For Mechanical Works PDFDocument17 pagesMethod of Statement For Mechanical Works PDFJR De Leon100% (1)

- Method Statement Duct InstallationDocument5 pagesMethod Statement Duct Installationcharles d100% (1)

- Sump Pump Method of StatementDocument10 pagesSump Pump Method of StatementKhaled NaguibNo ratings yet

- PPRDocument10 pagesPPRachusanachuNo ratings yet

- Method Statement For Application of GRP Lining Inside Water TankDocument5 pagesMethod Statement For Application of GRP Lining Inside Water TankNaveed Ahmed Get-InfoNo ratings yet

- Mandrelling Test / Checklist: Pmqs Construction Solutions, IncDocument1 pageMandrelling Test / Checklist: Pmqs Construction Solutions, IncAbnar KumplishaNo ratings yet

- 1.method Statement - Aboveground Drainage PipeDocument11 pages1.method Statement - Aboveground Drainage Pipesarmad spectrumNo ratings yet

- 1.method Statement - INSTALLATION OF WATER SUPPLY PIPES & FITTINGSDocument16 pages1.method Statement - INSTALLATION OF WATER SUPPLY PIPES & FITTINGSsarmad spectrumNo ratings yet

- Method Statement - Installation of Domestic PumpsDocument12 pagesMethod Statement - Installation of Domestic Pumpssarmad spectrumNo ratings yet

- ITP Inspection and Testing Plan For Above Ground Water Supply PipesDocument1 pageITP Inspection and Testing Plan For Above Ground Water Supply Pipessarmad spectrumNo ratings yet

- Method Statement For Installtion & Testing of Above Ground Drainage SystemdocxDocument13 pagesMethod Statement For Installtion & Testing of Above Ground Drainage Systemdocxsarmad spectrum100% (1)

- Compliance Above Ground DrainageDocument1 pageCompliance Above Ground Drainagesarmad spectrumNo ratings yet

- 1.method Statement - INSTALLATION OF WATER SUPPLY PIPES & FITTINGSDocument16 pages1.method Statement - INSTALLATION OF WATER SUPPLY PIPES & FITTINGSsarmad spectrumNo ratings yet

- 3.ITP-Above Ground Draiange PipeDocument3 pages3.ITP-Above Ground Draiange Pipesarmad spectrumNo ratings yet

- 3.itp-Installation of GRP Water TanksDocument2 pages3.itp-Installation of GRP Water Tankssarmad spectrum100% (2)

- Method Statement - Installation of Domestic PumpsDocument12 pagesMethod Statement - Installation of Domestic Pumpssarmad spectrumNo ratings yet

- Sand Trap Bucket SizeDocument1 pageSand Trap Bucket Sizesarmad spectrumNo ratings yet

- GreenBuildingRegulation 3Document20 pagesGreenBuildingRegulation 3sarmad spectrumNo ratings yet

- Soya Bean FiberDocument12 pagesSoya Bean FiberAnonymous wA6NGuyklDNo ratings yet

- Anesthesia NutshellDocument388 pagesAnesthesia NutshellMuhammad UmerNo ratings yet

- Desalting Process in GOSP1 - ٠٤١٩٣١Document13 pagesDesalting Process in GOSP1 - ٠٤١٩٣١elkasehoNo ratings yet

- Asia-Pacific Shopping Center Definition Standard - ProposalDocument18 pagesAsia-Pacific Shopping Center Definition Standard - ProposalHari AdhariNo ratings yet

- ABB Conduit, Fittings and Glands Catalog For Hazardous LocationsDocument96 pagesABB Conduit, Fittings and Glands Catalog For Hazardous Locationseduardozapata20903No ratings yet

- Consumer Perception Towards Swiggy Digital Food Application Service: A Analytical Study With Special Reference To Ernakulam CityDocument7 pagesConsumer Perception Towards Swiggy Digital Food Application Service: A Analytical Study With Special Reference To Ernakulam CityAshutosh sonkarNo ratings yet

- Ats2m1 1 16a 230VDocument2 pagesAts2m1 1 16a 230Vmariam fekiNo ratings yet

- Specific Provisions For Rigid Geo-CellDocument1 pageSpecific Provisions For Rigid Geo-Cellvenkateswara rao PothinaNo ratings yet

- Ebn Presentation 1Document28 pagesEbn Presentation 1api-241721769No ratings yet

- Final Project 1Document17 pagesFinal Project 1api-295579805No ratings yet

- Home Economics-Bread and Pastry ProductionDocument6 pagesHome Economics-Bread and Pastry ProductionJuan L. CruzNo ratings yet

- Mechanical Engineering Applied-Thermodynamics Refrigeration NotesDocument24 pagesMechanical Engineering Applied-Thermodynamics Refrigeration Notesminesh.manu6531No ratings yet

- Catlow Fuel Nozzle CatalogDocument38 pagesCatlow Fuel Nozzle CatalogRosario Calisaya CastilloNo ratings yet

- Design and Costing of Drainage Network For Unilorin Lake ResortDocument15 pagesDesign and Costing of Drainage Network For Unilorin Lake ResortDr Olayinka Okeola100% (1)

- Flood ReportDocument20 pagesFlood ReportMehtab MirNo ratings yet

- Foxboro Eckardt Valve Pos e (HA031644 Issue 3)Document28 pagesFoxboro Eckardt Valve Pos e (HA031644 Issue 3)islamooov0% (1)

- Epas 10 Lecture Maintain and Repair Flat IronDocument2 pagesEpas 10 Lecture Maintain and Repair Flat IronRap PerezNo ratings yet

- Phuket TripDocument6 pagesPhuket TripabishekksivarajNo ratings yet

- Poster Scientifique 800x1200mm - Innra70ansDocument2 pagesPoster Scientifique 800x1200mm - Innra70ansfeghbalibNo ratings yet

- Hempel's Curing Agent 95040 PDFDocument12 pagesHempel's Curing Agent 95040 PDFeternalkhut0% (1)

- Miner Project Report Madhuri Verma ..Document35 pagesMiner Project Report Madhuri Verma ..Deep ChoudharyNo ratings yet

- Jaw Relation in Complete DentureDocument29 pagesJaw Relation in Complete DentureBharanija100% (1)

- Sa103s 2011Document2 pagesSa103s 2011iurm28No ratings yet

- Member Booklets Pmi Ia Medical Global Plan Lta 1120 PDFDocument12 pagesMember Booklets Pmi Ia Medical Global Plan Lta 1120 PDFbkourfatima8No ratings yet

- Advance Accounting Materials 2Document4 pagesAdvance Accounting Materials 2Andrea Lyn Salonga CacayNo ratings yet

- Gingival Retraction Techniques: A Review: Dental Update April 2018Document10 pagesGingival Retraction Techniques: A Review: Dental Update April 2018Varun bharathiNo ratings yet

- PFI-ES-05 (Cleaning 2006) PDFDocument2 pagesPFI-ES-05 (Cleaning 2006) PDFRamesh Kumar RamisettiNo ratings yet