Devcon Plastic Steel Putty A

Devcon Plastic Steel Putty A

Uploaded by

AZLAN ABDULLAICopyright:

Available Formats

Devcon Plastic Steel Putty A

Devcon Plastic Steel Putty A

Uploaded by

AZLAN ABDULLAIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Devcon Plastic Steel Putty A

Devcon Plastic Steel Putty A

Uploaded by

AZLAN ABDULLAICopyright:

Available Formats

Technical Data Sheet

11 November 2022

PLASTIC STEEL PUTTY (A)

Steel-Filled Epoxy Putty

Description: Plastic Steel Putty (A) is a steel-filled, epoxy putty that cures at room

temperature and is designed for filling, rebuilding and bonding metal surfaces.

Intended Use: • Patching and repairing areas where welding or brazing would be

undesirable or impossible

• Repair of worn or fatigued metals

• Patching of castings

• Rebuilding pump and valve bodies

• Rebuilding bearing journals and races

Product • Applies easily to vertical surfaces

features: • Bonds to aluminium, steel and many other metals, as well as

concrete

• Machinable to metallic finish

• Makes repairs that are non-rusting

• Resistant to chemicals and most acids, bases, solvents and alkalis

Chemical (Chemical resistance is calculated with a 7 day, room temperature cure (30 days immersion) @ 24°C)

Resistance:

1,1,1 Trichloroethane Very good Phosphoric 10% Very good

Ammonia Very good Potassium Hydroxide 20% Very good

Cutting Oil Very good Sodium Chloride Brine Very good

Petrol (unleaded) Very good Sodium Hydroxide 10% Very good

Hydrochloric 10% Very good Sulphuric 10% Very good

Methyl Ethyl Ketone Poor Sulphuric 50% Poor

Methylene Chloride Poor Trisodium Phosphate Very good

Kerosene Very Good Xylene Fair

Limitations: Not recommended for long term exposure to concentrated acids or to organic

solvents.

Typical Technical data should be considered representative or typical only and should not

Physical be used for specification purposes.

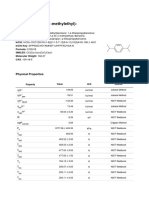

Properties: TEST METHOD

Colour Grey

Mix Ratio (Resin to Hardener) Weight 9:1

Volume 2.5:1

Mixed Viscosity Putty

Work Time of 500gms minutes @ 24°C 45

Cure Time 16 hours

Recoat Time 10 – 12 hours

% Solids by Volume 100

Specific Volume 430cm3/kg

Specific Gravity 2.33 gm/cm3

Cure Shrinkage 0.0006 cm/cm ASTM D2566

Hardness Shore D 85 ASTM D2240

Adhesive Tensile Shear 19.3 MPa ASTM D1002

Tensile Strength 22.2 MPa ASTM D638

Compressive Strength 57 MPa ASTM D695

Modulus of Elasticity 1896 MPa ASTM D695

AUSTRALIA NEW ZEALAND

ITW Polymers & Fluids ITW Polymers & Fluids

100 Hassall Street Unit 2 / 38 Trugood Drive

Wetherill Park NSW 2164 East Tamaki 2013, Auckland

Phone (02) 9757 8800 Phone (09) 272 1945

www.itwpf.com.au www.itwpf.co.nz

Page 1 of 3

Technical Data Sheet

Co-efficient of Thermal Expansion 86 x 10-6 °C-1 ASTM D696

Thermal Conductivity 1.37 x 10-3 cal.cm/sec/cm2.°C ASTM C177

Dielectric Strength 1181 volts/mm ASTM D149

Dielectric Constant 67.5 ASTM D150

Flexural Strength 38.6 MPa ASTM D790

Maximum Operating Temperature Wet 49˚C

Dry: 120°C

Coverage (per coat) 860cm2/kg @ 5mm

Surface Proper surface preparation is essential to the success of any epoxy application. In

Preparation: all cases the surface should be clean, dry, free from oils, and rough.

1. Remove all oils, dirt and grease by means of a strong cleaner/degreaser

(Devcon® Surface Cleaner is suitable for this process).

2. Roughen the surface by grit blasting (8-40 mesh grit) or grinding. A 75-125

micron profile is desired for most applications, including defined edges (do

not ‘feather edge’ epoxy).

Note: For metals exposed to sea water or other salt solution, grit blast and high

pressure water blast the area, then leave overnight to allow any salts in the metal

to ‘sweat’ to the surface. Repeat blasting to ‘sweat out’ all soluble salts. Perform

chloride contamination test to determine soluble salt content (should be no more

than 40ppm)

3. All abrasive preparation should be followed by another cleaning to remove

any remnants from that process.

4. Repair surface as soon as possible to eliminate any changes or surface

contaminants.

Mixing Ideal application temperature is 13ºC - 32ºC. Under cold conditions, heating the

Instructions: repair area to 38ºC - 43ºC is recommended to dry off any moisture, contamination,

or solvents, as well as to assist epoxy in achieving maximum adhesion properties.

Mix Ratio – Resin to hardener: Weight 9:1, Volume 2.5:1

It is strongly recommended that full units be mixed, as ratios are pre-measured.

1. Add hardener to resin.

2. Mix thoroughly with a putty knife or similar tool (continuously scrape

material away from sides and bottom of container) until a uniform, streak

free consistency is obtained.

Application Spread mixed material over the repair area and work firmly into the substrate to

Instructions: ensure maximum surface contact. Plastic Steel Putty (A) fully cures in 16 hours, at

which time it can be machined, drilled, or painted.

For Bridging Large Gaps or Holes

Place fibreglass sheet, expanded metal or mechanical fasteners between repair

area and Plastic Steel Putty (A) prior to application.

For Vertical Surface Applications

Plastic Steel Putty (A) can be trowelled up to 6mm thick without sagging.

AUSTRALIA NEW ZEALAND

ITW Polymers & Fluids ITW Polymers & Fluids

100 Hassall Street Unit 2 / 38 Trugood Drive

Wetherill Park NSW 2164 East Tamaki 2013, Auckland

Phone (02) 9757 8800 Phone (09) 272 1945

www.itwpf.com.au www.itwpf.co.nz

Page 2 of 3

Technical Data Sheet

For Maximum Physical Properties

Cure at room temperature for 2 ½ hours, then heat cure for 4 hours @ 100°C.

For +24°C Applications

Applying epoxy at temperatures below 24°C lengthens functional cure and pot life

times. Conversely, applying above 24°C shortens functional cure and pot life.

Machining

Allow material to cure for at least 16 hours before machining

• Lathe speed 46 m/minute

• Cut: Dry

• Tools: Carbide top rake 6º (+/- 2º) – Side/front 8º (+/- 2º)

• Feed rate (rough): Travel speed 0.50 mm Rough cut 0.50 mm – 1.5

mm/rev

• Feed rate (finishing): Travel speed 0.25 mm Finish cut 0.25 mm/rev

• Polishing: Use 400 to 650 emery paper wet. Material should polish to a 25-

50 micron finish

Storage: Store in dry conditions between 10°C and 40°C, away from sources of heat and

naked flames. Protect from frost. When stored in original sealed containers, the

minimum shelf life is five years.

Warranty: Devcon will replace any material found to be defective. Because the storage,

handling and application of this material is beyond our control, we can accept no

liability for the results obtained.

Disclaimer: All information on this data sheet is based on laboratory testing and is not intended

for design purposes. ITW Polymers & Fluids and Devcon makes no

representations or warranties of any kind concerning this data.

Order 500gm kit D10110

Information: 1.5kg kit D10120

Health &

For Health & Safety Information, refer to Safety Data sheet available from ITW

Safety Polymers & Fluids upon request on our website www.devcon.com.au or

Information: www.devcon.co.nz

AUSTRALIA NEW ZEALAND

ITW Polymers & Fluids ITW Polymers & Fluids

100 Hassall Street Unit 2 / 38 Trugood Drive

Wetherill Park NSW 2164 East Tamaki 2013, Auckland

Phone (02) 9757 8800 Phone (09) 272 1945

www.itwpf.com.au www.itwpf.co.nz

Page 3 of 3

You might also like

- Technical Data: Plastic Steel Putty (A)Document4 pagesTechnical Data: Plastic Steel Putty (A)francisNo ratings yet

- Technical Data: Plastic Steel 5-Minute Putty (SF)Document4 pagesTechnical Data: Plastic Steel 5-Minute Putty (SF)Hoàng DũngNo ratings yet

- DEVCON® Fasmetal 10 HVAC Repair (Special F)Document2 pagesDEVCON® Fasmetal 10 HVAC Repair (Special F)mohamed hamedNo ratings yet

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Protective & Marine Coatings: Galvite™ HsDocument4 pagesProtective & Marine Coatings: Galvite™ HsAna CabreraNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Titanium Putty HPDocument2 pagesTitanium Putty HPDivyanshu GuptaNo ratings yet

- Brushable Abrasion Resistant Composite Epigen 806BR: ProfileDocument2 pagesBrushable Abrasion Resistant Composite Epigen 806BR: Profileputra gradaxNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- LLDPE-218BJ EditDocument3 pagesLLDPE-218BJ EditChu ChuNo ratings yet

- HojaTecnica Heat Flex Hi Temp 1200Document4 pagesHojaTecnica Heat Flex Hi Temp 1200NANCY JASMIN MORENONo ratings yet

- Epoxy Backing Grout Epigen 0301: Typical Applications ProfileDocument2 pagesEpoxy Backing Grout Epigen 0301: Typical Applications ProfileDianWidodoNo ratings yet

- Ceramic Rebuild Putty: Technical Reference InformationDocument2 pagesCeramic Rebuild Putty: Technical Reference InformationAbdul Rafii100% (1)

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocument4 pagesProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNo ratings yet

- Sherwin Williams - Heatflex Hi-Temp 1200 DatasheetDocument4 pagesSherwin Williams - Heatflex Hi-Temp 1200 DatasheetAce AceNo ratings yet

- Brushable CeramicDocument2 pagesBrushable CeramicDivyanshu GuptaNo ratings yet

- Data Sheet PEEK Extruded 450CA30Document1 pageData Sheet PEEK Extruded 450CA30shakouri1370_8902064No ratings yet

- DuraplateDocument4 pagesDuraplatelovaldes62No ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- 1 Wa-Catalog13Document1 page1 Wa-Catalog13johnNo ratings yet

- 226NDocument2 pages226NUmaibalanNo ratings yet

- Plastic Steel Putty (A) : Technical Data SheetDocument3 pagesPlastic Steel Putty (A) : Technical Data SheetsanjayNo ratings yet

- Data Sheet PEEK Extruded HTDocument1 pageData Sheet PEEK Extruded HTmarkymarkNo ratings yet

- 107 Ps - rv3.13052019Document2 pages107 Ps - rv3.13052019LuckyNo ratings yet

- Sabic Fortify C5070D TDSDocument2 pagesSabic Fortify C5070D TDSmiya079127No ratings yet

- Industrial Aluminum Paint: Protective & Marine CoatingsDocument4 pagesIndustrial Aluminum Paint: Protective & Marine CoatingsAna CabreraNo ratings yet

- Ceramic Brush On - 95010K-1Document2 pagesCeramic Brush On - 95010K-1NazmiNo ratings yet

- BELZONA 1111 Product Specification SheetDocument2 pagesBELZONA 1111 Product Specification SheetMohamed NouzerNo ratings yet

- Belzona 1321: Product Specification SheetDocument2 pagesBelzona 1321: Product Specification Sheetmehdi kamaliNo ratings yet

- Belzona 1121: Product Specification SheetDocument2 pagesBelzona 1121: Product Specification SheetQuy RomNo ratings yet

- Epigen 0907: High Strength Epoxy AdhesiveDocument2 pagesEpigen 0907: High Strength Epoxy AdhesiveAfzal ImamNo ratings yet

- DTM Acrlylic CoatingDocument4 pagesDTM Acrlylic CoatingNestorNo ratings yet

- SABIC® LLDPE - 324CNJ - Global - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 324CNJ - Global - Technical - Data - Sheettechnical kmiNo ratings yet

- Brushable Ceramic Blue Red v4Document2 pagesBrushable Ceramic Blue Red v4abhishek raviNo ratings yet

- DTM Acrylic Coating: Protective & Marine CoatingsDocument4 pagesDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNo ratings yet

- Product Description: Properties Value Unit Test MethodDocument1 pageProduct Description: Properties Value Unit Test MethodRPM28XINo ratings yet

- ReportDocument21 pagesReportFaisal AkhterNo ratings yet

- High Performance Backing Compound: Technical Data SheetDocument2 pagesHigh Performance Backing Compound: Technical Data SheetNiku SamarthNo ratings yet

- Emsol MRP-1100 (English)Document2 pagesEmsol MRP-1100 (English)angirethmbarretomNo ratings yet

- Macropoxy 646 FF 2022Document4 pagesMacropoxy 646 FF 2022nellyNo ratings yet

- Carboguard 1207 PDSDocument4 pagesCarboguard 1207 PDSmartinbeyerNo ratings yet

- Fluteck P7500 CA v01.19Document2 pagesFluteck P7500 CA v01.19fprovitaliNo ratings yet

- Ceramic Brush On: Technical Reference InformationDocument2 pagesCeramic Brush On: Technical Reference InformationAbdul RafiiNo ratings yet

- LR-C-VentureClad Catalogue 01Document16 pagesLR-C-VentureClad Catalogue 01himanshu desaiNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNo ratings yet

- Trowellable Abrasion Resistant Composite Epigen 806: ProfileDocument2 pagesTrowellable Abrasion Resistant Composite Epigen 806: ProfileDedika MulyanaNo ratings yet

- Technical Information: (BR) (WR-2) (Special F)Document1 pageTechnical Information: (BR) (WR-2) (Special F)johnNo ratings yet

- Especificaciones Pintura Macropoxi NavalDocument4 pagesEspecificaciones Pintura Macropoxi NavalVicenteRojasLeonNo ratings yet

- Innoplus HD8100M & HD8100MBDocument1 pageInnoplus HD8100M & HD8100MBgovind.sNo ratings yet

- Ajedium Films (Solvay)Document3 pagesAjedium Films (Solvay)hyper meshNo ratings yet

- Material Spec For 6600Document1 pageMaterial Spec For 6600Namelezz ShadowwNo ratings yet

- UHMW-PE Tivar 1000Document2 pagesUHMW-PE Tivar 1000centurion2988No ratings yet

- En 2Document2 pagesEn 2Kirolos NabilNo ratings yet

- Protective & Marine Coatings: Pro-Cryl Universal PrimerDocument4 pagesProtective & Marine Coatings: Pro-Cryl Universal PrimerAna CabreraNo ratings yet

- 1838B (DatasheetDocument6 pages1838B (Datasheetpoyrazatmaca069No ratings yet

- SBN Cat FamilyOfQtyDocument4 pagesSBN Cat FamilyOfQtyAZLAN ABDULLAINo ratings yet

- Long Form Certificate of Accuracy For Elcometer 456 ProbeDocument2 pagesLong Form Certificate of Accuracy For Elcometer 456 ProbeAZLAN ABDULLAINo ratings yet

- SMART by GEP® Supplier User Guide v2.0Document76 pagesSMART by GEP® Supplier User Guide v2.0AZLAN ABDULLAINo ratings yet

- Msds SIGMATHERM 540 (ENG) (sk-19-07-07leg-MT)Document8 pagesMsds SIGMATHERM 540 (ENG) (sk-19-07-07leg-MT)AZLAN ABDULLAINo ratings yet

- Product OverviewDocument1 pageProduct OverviewAZLAN ABDULLAINo ratings yet

- This Crawler Crane Will Be Tighten With Sea Fastening. Therefore, Crane Will Be Fixed Position On The Barge DeckDocument12 pagesThis Crawler Crane Will Be Tighten With Sea Fastening. Therefore, Crane Will Be Fixed Position On The Barge DeckAZLAN ABDULLAINo ratings yet

- Kanon Green Binder Rev 2Document202 pagesKanon Green Binder Rev 2AZLAN ABDULLAINo ratings yet

- MEC - SVS - 204488 Pre-Qualification - Provision of Infrastructure Services For Labuan OperationsDocument18 pagesMEC - SVS - 204488 Pre-Qualification - Provision of Infrastructure Services For Labuan OperationsAZLAN ABDULLAINo ratings yet

- Flat Bar 3mm 4.5Document1 pageFlat Bar 3mm 4.5AZLAN ABDULLAINo ratings yet

- Hi-Force Product Catalogue - HFM1911EN (Page 93)Document1 pageHi-Force Product Catalogue - HFM1911EN (Page 93)AZLAN ABDULLAINo ratings yet

- 2015 StoneAge - LowresDocument51 pages2015 StoneAge - LowresAZLAN ABDULLAINo ratings yet

- Bristle Blaster BrochureDocument12 pagesBristle Blaster BrochureAZLAN ABDULLAINo ratings yet

- TMI Imperial Catalogue 2013Document364 pagesTMI Imperial Catalogue 2013AZLAN ABDULLAINo ratings yet

- Gasket No 1Document1 pageGasket No 1AZLAN ABDULLAINo ratings yet

- Assignment 2 AST-451 PDFDocument8 pagesAssignment 2 AST-451 PDFPriya SinghNo ratings yet

- SCP 35 SpecDocument3 pagesSCP 35 SpecTeoNo ratings yet

- Manual de Armado KIT Detector de Metal MDS 60Document2 pagesManual de Armado KIT Detector de Metal MDS 60Gil VelascoNo ratings yet

- 10 1016-j Rser 2014 02 032Document16 pages10 1016-j Rser 2014 02 032yasamanasadianNo ratings yet

- (Physics) R Gupta's Popular Master Guide 2022Document150 pages(Physics) R Gupta's Popular Master Guide 2022beniiiNo ratings yet

- Introduction To 3 Phase AC SystemsDocument5 pagesIntroduction To 3 Phase AC SystemsJohannah Crystal ModinaNo ratings yet

- Anticipated Overfiring in Porcelain Tiles: Effects of The Firing Cycle and Green Bulk DensityDocument9 pagesAnticipated Overfiring in Porcelain Tiles: Effects of The Firing Cycle and Green Bulk Densitymap vitcoNo ratings yet

- OscillatorDocument7 pagesOscillatorHemantha DalugamaNo ratings yet

- Drilling GeomechanicsDocument32 pagesDrilling Geomechanicsjsever1No ratings yet

- Surface and Interfacial Phnomenppt-DeSKTOP-RVOK5TMDocument27 pagesSurface and Interfacial Phnomenppt-DeSKTOP-RVOK5TMAman KumarNo ratings yet

- B A S Ket Strainer Pressure Drop-LiquidsDocument4 pagesB A S Ket Strainer Pressure Drop-LiquidsguillemaraNo ratings yet

- App 10093Document9 pagesApp 10093Omkar BordeNo ratings yet

- Chapter 5 - Section B - Non-Numerical SolutionsDocument9 pagesChapter 5 - Section B - Non-Numerical Solutionslight2618No ratings yet

- Sectional MCQDocument8 pagesSectional MCQsayanchatterjee098No ratings yet

- Thermodynamics Fundamentales Morales RodriguezDocument553 pagesThermodynamics Fundamentales Morales RodriguezJorge Cronwell Montaño VásquezNo ratings yet

- TransformerDocument18 pagesTransformerEid MohamedNo ratings yet

- Capacitance (George Ricarrson - 2501987261)Document12 pagesCapacitance (George Ricarrson - 2501987261)George RYNo ratings yet

- I N F O R M A T I O N: Drop Volume Tensiometer DVT50Document4 pagesI N F O R M A T I O N: Drop Volume Tensiometer DVT50MiguelNo ratings yet

- Structural TUBES PDFDocument56 pagesStructural TUBES PDFvegamasterinNo ratings yet

- Tribology ProjectDocument14 pagesTribology ProjectTanuja SachanNo ratings yet

- ASTM B987 1424135-1 - Published VersionDocument5 pagesASTM B987 1424135-1 - Published VersionTran Tuan Tu0% (1)

- Lecture 9Document10 pagesLecture 9Michael Conan MaglaqueNo ratings yet

- Cáp Treo Tokyo RopeDocument18 pagesCáp Treo Tokyo RopeAnonymous DNb6yWERfBNo ratings yet

- 90CA085 SkyCiv ReportDocument6 pages90CA085 SkyCiv ReportFrancisco BurgosNo ratings yet

- Phyy 4Document78 pagesPhyy 4Sajjad FaisalNo ratings yet

- Viscoelastic Properties of The Human Medial Collateral Ligament Under Longitudinal, Transverse and Shear LoadingDocument10 pagesViscoelastic Properties of The Human Medial Collateral Ligament Under Longitudinal, Transverse and Shear LoadingBruno MelloNo ratings yet

- Thermal Management of Cree Xlamp LedsDocument19 pagesThermal Management of Cree Xlamp LedsEsen DilerNo ratings yet

- Friction. Classification of Friction. Coefficient of Friction. İntroduction and ClassificationDocument7 pagesFriction. Classification of Friction. Coefficient of Friction. İntroduction and ClassificationAbdulla CamalNo ratings yet

- ASTM For Bend TestingDocument16 pagesASTM For Bend TestingMaha LingamNo ratings yet

- Benzene, 1,4-Bis (1-Methylethyl) - : Physical PropertiesDocument3 pagesBenzene, 1,4-Bis (1-Methylethyl) - : Physical PropertiesLAURA LUC�A ATENCIA CASTILLONo ratings yet