Skill Developement Format

Skill Developement Format

Uploaded by

00083583rfCopyright:

Available Formats

Skill Developement Format

Skill Developement Format

Uploaded by

00083583rfCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Skill Developement Format

Skill Developement Format

Uploaded by

00083583rfCopyright:

Available Formats

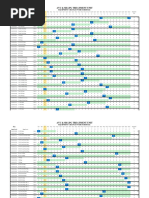

AVU & SR-LPG Treatment Unit

Paradip Refinery

DATED:06.08.2023

Topic Covered: “SOP: Emergency procedure in case of CW failure.”

Faculty: MD ARIF

Training Session Attended By:

Sl. Sl.

No Name Signature/Date No. Name Signature/Date

.

GAUTAM Gurunath

1 8

I P SINGH Jagdish

2 9

ANIL KR

3 10

RAJESH

4 11

AVNISH

5 12

RAKESH

6 13

7 14

Discussion Points:

AVU receives Cooling Water from CT-3. Cooling Water Failure can occur when all the operating pumps

in CT-3 fail to supply water. However, this is a rare phenomenon as there are 3 steam & 2 motor driven

pumps out of 5.

Water supply to pumps, compressors, for cooling of bearings, seals etc. will be stopped and will

tend to overheat & damage the running equipments.

Loss of vacuum in vacuum column due to unavailability of Cooling Water in surface condensers.

Loss of cooling water will lose the condensing ability on stabilizer, de ethanizer & de propanizer

overhead, with resultant loss of reflux and column pressure control.

Loss of product trim cooling will result in higher run down temperature.

Loss of liquid level in hot well drum due to vaporization of water/hydrocarbons.

If the cooling water failure is ‘TOTAL’ and not resumed for long time, the unit will be brought down

urgently in the same way as in the case of ‘TOTAL’ power failure. (except all running

pumps/compressors which are to be stopped manually). If the cooling water failure is ‘PARTIAL’

following actions to be taken.

1. Contact UCR for low flow/pressure of cooling water and advise them to start the pumps

AVU & SRLPG Treatment Unit - Skill DevelopmentPage 1 of 2

immediately.

2. Inform RSM, Shift-in-Charge, JEAs/EAs and Unit-in-Charge for cooling water pump failure.

3. Reduce crude through Put & if required throttle water to cooler & condensers.

4. Keep close watch in vacuum column top pressure and top temperature, vacuum column draw tray

level etc.

5. Keep close watch in Stabilizer, De Ethanizer, De Propaniser overhead temperature & pressure

Suggestions for Improvement of the Content:

AVU & SRLPG Treatment Unit - Skill DevelopmentPage 2 of 2

You might also like

- BMW 2 - M5 - Engine - S62B50 PDFDocument26 pagesBMW 2 - M5 - Engine - S62B50 PDFkukumarcic50% (2)

- Refrigeration NotesDocument4 pagesRefrigeration NotesWai Phyo AungNo ratings yet

- OM&S-R - UpdatedDocument229 pagesOM&S-R - UpdatedTITU V100% (2)

- APH Water Washing ProcedureDocument4 pagesAPH Water Washing ProcedureKarthick Velayutham100% (1)

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreFrom EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreRating: 3 out of 5 stars3/5 (2)

- Practical Booklet 2019Document118 pagesPractical Booklet 2019Kenneth Knight100% (1)

- The Psychrometric Chart: Theory and Application: Perry Peralta NC State UniversityDocument50 pagesThe Psychrometric Chart: Theory and Application: Perry Peralta NC State UniversityAlaeddin Guner RodopNo ratings yet

- Skill Developement - CW FAILDocument3 pagesSkill Developement - CW FAIL00083583rfNo ratings yet

- Skill Developement On Total Steam FailureDocument2 pagesSkill Developement On Total Steam Failure00083583rfNo ratings yet

- Skill Developement On K3AB Start UpDocument2 pagesSkill Developement On K3AB Start Up00083583rfNo ratings yet

- Skill Developement On Rain Time ActionDocument4 pagesSkill Developement On Rain Time Action00083583rfNo ratings yet

- Naphtha To Storage Line LeakDocument3 pagesNaphtha To Storage Line Leak00083583rfNo ratings yet

- CEP Isolation & Normalisation ProcedureDocument2 pagesCEP Isolation & Normalisation ProcedureVishal GuptaNo ratings yet

- Skill Developement On Cdu Anypass Flow LossDocument3 pagesSkill Developement On Cdu Anypass Flow Loss00083583rfNo ratings yet

- Training ReportDocument21 pagesTraining ReportPiyush Khandait0% (1)

- Skill Developement On Vgo HDT TripDocument2 pagesSkill Developement On Vgo HDT Trip00083583rfNo ratings yet

- Description: 2009 Dodge Journey SE 2009 Dodge Journey SEDocument129 pagesDescription: 2009 Dodge Journey SE 2009 Dodge Journey SERodrigoAntonioRoblesSantosNo ratings yet

- Engine: Cooling SystemDocument26 pagesEngine: Cooling Systemdmitry esaulkovNo ratings yet

- Cep Startup and ShutdownDocument5 pagesCep Startup and ShutdownAnonymous W9VINoTzaNo ratings yet

- 615DT - ManualDocument16 pages615DT - ManualMatheus Ferreira PeresNo ratings yet

- Skill Development On P25ABC LOSES DIS FLOW.Document5 pagesSkill Development On P25ABC LOSES DIS FLOW.00083583rfNo ratings yet

- CBEX Elite 100-1200 Operation and Maintenance ManualDocument146 pagesCBEX Elite 100-1200 Operation and Maintenance Manualfauzi endra100% (1)

- 14 CoolingDocument20 pages14 CoolingconsultasNo ratings yet

- WAG Dulang FieldDocument9 pagesWAG Dulang FieldfrhslmnNo ratings yet

- Southwest ResearchDocument6 pagesSouthwest ResearchGerman Assencio JeresNo ratings yet

- Skill Developement On Mathura Ref Incident On 27.05.2023Document7 pagesSkill Developement On Mathura Ref Incident On 27.05.202300083583rfNo ratings yet

- PP Aaa PP1 148Document14 pagesPP Aaa PP1 148Rabah Amidi100% (1)

- Proton Arena Engine Cooling 1.5 1.8 Service ManualDocument16 pagesProton Arena Engine Cooling 1.5 1.8 Service ManualchipestNo ratings yet

- Event Ana U#7,2006 - CompletedDocument31 pagesEvent Ana U#7,2006 - CompletedGajanan JagtapNo ratings yet

- Btg-Sop035 Stator Water SystemDocument5 pagesBtg-Sop035 Stator Water Systemarunrajmech09No ratings yet

- Lantai 6 DAK: NO Lokasi Alat Pendingin Tipe Kapasitas KontrakDocument32 pagesLantai 6 DAK: NO Lokasi Alat Pendingin Tipe Kapasitas KontrakBayu GustiNo ratings yet

- Samsung RA20VHSW Service ManualDocument32 pagesSamsung RA20VHSW Service Manualnuk1doe50% (2)

- Skill Developement On Mathura Ref Incident On 27.05.2023 e ShiftDocument7 pagesSkill Developement On Mathura Ref Incident On 27.05.2023 e Shift00083583rfNo ratings yet

- Instructions & Guidelines On Sampling of Oil From Oil Filled Electrical EquipmentDocument13 pagesInstructions & Guidelines On Sampling of Oil From Oil Filled Electrical EquipmentsorabhNo ratings yet

- Shell and Tube Heat Exchangers Using Cooling WaterDocument20 pagesShell and Tube Heat Exchangers Using Cooling WaterslowsilverhopeNo ratings yet

- Cold Start Up SalayaDocument28 pagesCold Start Up SalayaShambhu MehtaNo ratings yet

- Multiple Aligned Cooling System: PART NO. 1568204 700 SRM 1159Document16 pagesMultiple Aligned Cooling System: PART NO. 1568204 700 SRM 1159Juanjo Garcia JimenezNo ratings yet

- 3.E Hand Over Report - THAI GIANG NAMDocument7 pages3.E Hand Over Report - THAI GIANG NAMHien CaoNo ratings yet

- BR gen inf 14Document16 pagesBR gen inf 14Chirayu ShahNo ratings yet

- Loading PlanDocument6 pagesLoading PlanIordache Dumitru100% (1)

- Condensate Extraction Pump (CEP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantDocument8 pagesCondensate Extraction Pump (CEP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantSaravanan Sundararaj100% (1)

- Closed Drain SystemDocument6 pagesClosed Drain SystemRicardo NapitupuluNo ratings yet

- Opgs 0 BLR Opn 19-29-00 Sop For CCCW SystemDocument7 pagesOpgs 0 BLR Opn 19-29-00 Sop For CCCW SystemAnbu MathiNo ratings yet

- Why Cooling Is Essential For Long TDocument10 pagesWhy Cooling Is Essential For Long TNepoliyanNo ratings yet

- Cargo Plant GuidelinesDocument93 pagesCargo Plant GuidelinesPhani PrahladNo ratings yet

- NGL1 V1 Sec 7Document203 pagesNGL1 V1 Sec 7varatharajan g rNo ratings yet

- Cooling System Recom Gas EngineDocument13 pagesCooling System Recom Gas Enginebambang eengNo ratings yet

- Fridge Shop CERA (Workshop Practice Refrigeration& Air Condition)Document48 pagesFridge Shop CERA (Workshop Practice Refrigeration& Air Condition)Md ZakariaNo ratings yet

- Experimental Advanced Flow Channel: Operation ManualDocument51 pagesExperimental Advanced Flow Channel: Operation ManualUzair BukhariNo ratings yet

- GSP Process PatentDocument22 pagesGSP Process PatentSuleman AhmadNo ratings yet

- Chilled Water Plant Saving Cost July 07Document10 pagesChilled Water Plant Saving Cost July 07ceo123456No ratings yet

- Design and Select PumpsDocument50 pagesDesign and Select Pumpsgeotherm100% (1)

- PR Ec Sio N: Owner'S GuideDocument13 pagesPR Ec Sio N: Owner'S GuideHencheal AtangaNo ratings yet

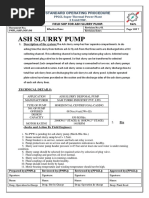

- 08-SOP of ASH SLURRY PUMPDocument5 pages08-SOP of ASH SLURRY PUMPMithun Singh Rajput100% (1)

- Grundfos GuideDocument8 pagesGrundfos GuideIsmael Llamelo PerezNo ratings yet

- 1B 40208-2 ChargingDocument5 pages1B 40208-2 Chargingravi kalariaNo ratings yet

- Qatar Petroleum Ngl-1 Operating Manual: 1. GeneralDocument49 pagesQatar Petroleum Ngl-1 Operating Manual: 1. Generalvaratharajan g rNo ratings yet

- 1.8 Gas Well Testing PDFDocument3 pages1.8 Gas Well Testing PDFHATEMNo ratings yet

- Ongc Report-1Document35 pagesOngc Report-1Saransh GoyalNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- E360 QuestionsDocument3 pagesE360 Questions00083583rfNo ratings yet

- Equipment Change Over Schedule AVU-2022-23Document3 pagesEquipment Change Over Schedule AVU-2022-2300083583rfNo ratings yet

- VGOHVGO ROuting To Crude Tank - Nov2022Document6 pagesVGOHVGO ROuting To Crude Tank - Nov202200083583rfNo ratings yet

- Skill Cdu Pass Flo LossDocument2 pagesSkill Cdu Pass Flo Loss00083583rfNo ratings yet

- Skill DevDocument3 pagesSkill Dev00083583rfNo ratings yet

- 2 Avu&Srlpg - Sop - f101 - 201 Failure of 1 Passflow CVDocument3 pages2 Avu&Srlpg - Sop - f101 - 201 Failure of 1 Passflow CV00083583rfNo ratings yet

- 1 Avu&Srlpg - Sop - f002 Failure of 1 Passflow CVDocument3 pages1 Avu&Srlpg - Sop - f002 Failure of 1 Passflow CV00083583rfNo ratings yet

- Skill Developement On Cdu Anypass Flow LossDocument3 pagesSkill Developement On Cdu Anypass Flow Loss00083583rfNo ratings yet

- p7 Failure 29.01.2023Document2 pagesp7 Failure 29.01.202300083583rfNo ratings yet

- 3 Avu&Srlpg Sop P-003abc FailureDocument5 pages3 Avu&Srlpg Sop P-003abc Failure00083583rfNo ratings yet

- 1 of ANYPASS - MergedDocument2 pages1 of ANYPASS - Merged00083583rfNo ratings yet

- PM DecDocument1 pagePM Dec00083583rfNo ratings yet

- AVU Operating Manual Rev. 07Document965 pagesAVU Operating Manual Rev. 0700083583rfNo ratings yet

- Skill Development p7Document1 pageSkill Development p700083583rfNo ratings yet

- Skill Developement On p07 FailureDocument3 pagesSkill Developement On p07 Failure00083583rfNo ratings yet

- Nalco Hac ReportDocument81 pagesNalco Hac Report00083583rf100% (1)

- Skill D FurnaceDocument1 pageSkill D Furnace00083583rfNo ratings yet

- Mock Drill Report IA FAILUREDocument4 pagesMock Drill Report IA FAILURE00083583rfNo ratings yet

- Mockdrill Power Failure 11.05.2023 NightDocument5 pagesMockdrill Power Failure 11.05.2023 Night00083583rfNo ratings yet

- Steam Load Shedding SequenceDocument3 pagesSteam Load Shedding Sequence00083583rfNo ratings yet

- Avu&Srlpg - SRN Leak Over CreekDocument9 pagesAvu&Srlpg - SRN Leak Over Creek00083583rfNo ratings yet

- High TAN Study SummuaryDocument3 pagesHigh TAN Study Summuary00083583rfNo ratings yet

- Cdu Furnace Mock Drill DraftDocument8 pagesCdu Furnace Mock Drill Draft00083583rfNo ratings yet

- Avu&Srlpg SopsDocument732 pagesAvu&Srlpg Sops00083583rfNo ratings yet

- Mock Drill 24th July On Furnace Trip Due To Hi Arch PRDocument5 pagesMock Drill 24th July On Furnace Trip Due To Hi Arch PR00083583rfNo ratings yet

- Accuracy of First - and Second-Order Tetrahedral ElementsDocument8 pagesAccuracy of First - and Second-Order Tetrahedral ElementsKillgusNo ratings yet

- NABIC+Safety ValveDocument58 pagesNABIC+Safety Valvept tabNo ratings yet

- Introduction To Surface EngineeringDocument31 pagesIntroduction To Surface Engineeringlogeshboy007No ratings yet

- Factors Affecting To Compression TestDocument18 pagesFactors Affecting To Compression TestAmila LiyanaarachchiNo ratings yet

- Ficha Técnica Estibador Hyster b60zDocument8 pagesFicha Técnica Estibador Hyster b60zAndrey Fernando Luque SeguraNo ratings yet

- LIMIT STATE DESIGN A Text Book ofDocument1,058 pagesLIMIT STATE DESIGN A Text Book ofYlber Jashari100% (1)

- Fluid Mechanics I (MEng 2306)Document2 pagesFluid Mechanics I (MEng 2306)addisudagneNo ratings yet

- 150.75 NM2 YdajDocument100 pages150.75 NM2 YdajMohammed SafiuddinNo ratings yet

- 5edb8bdcc6a0b PDFDocument185 pages5edb8bdcc6a0b PDFRodrigo VinhoNo ratings yet

- Citroen c4 Handbook 119480Document188 pagesCitroen c4 Handbook 119480Asif Jownally100% (1)

- Brake Design AnalysisDocument16 pagesBrake Design AnalysisBalkrishna ChaudharyNo ratings yet

- Himalayan 2 PDFDocument20 pagesHimalayan 2 PDFJulian GallegoNo ratings yet

- Homelite String Trimmer Parts Manual HTC12 Tiller UT 22089Document9 pagesHomelite String Trimmer Parts Manual HTC12 Tiller UT 22089Anonymous hIS9O1m26MNo ratings yet

- Aib-Fd160 1998-12-01Document16 pagesAib-Fd160 1998-12-01Filipe GuaranyNo ratings yet

- Lista de Refaccion: Modelo Hr2810Document3 pagesLista de Refaccion: Modelo Hr2810Yohan FranciscoNo ratings yet

- EEUDocument250 pagesEEUujjal deyNo ratings yet

- Nonlinear Magnetostrictive Transducer Using ComsolDocument40 pagesNonlinear Magnetostrictive Transducer Using Comsolsajan100% (1)

- Belt Conveyor DesignDocument61 pagesBelt Conveyor Designaerryawan100% (2)

- Building Name: Office Building / Structure: RC Construction / Building Scale: Multiple StoreyDocument4 pagesBuilding Name: Office Building / Structure: RC Construction / Building Scale: Multiple StoreyFaquruddin AliNo ratings yet

- 97537xuerfkdujhuv &rpsuhvvruvlghehdulqjv: NjurxqgDocument1 page97537xuerfkdujhuv &rpsuhvvruvlghehdulqjv: NjurxqgAlexanderNo ratings yet

- TUYORIAL Units and Measwurements 1Document15 pagesTUYORIAL Units and Measwurements 1SUNILNo ratings yet

- 556099d1570488268 Timing Procedure Help 2017 3 5 Turbo Timing ChainDocument18 pages556099d1570488268 Timing Procedure Help 2017 3 5 Turbo Timing ChainRickNo ratings yet

- Problem CollectDocument18 pagesProblem CollectreflectiondarkNo ratings yet

- Hump Hydraulics CalculationsDocument13 pagesHump Hydraulics CalculationsrutujaNo ratings yet

- Monopitch Roof Steel Truss (Ware House) 12345Document5 pagesMonopitch Roof Steel Truss (Ware House) 12345FatihNo ratings yet

- Met302 ADocument4 pagesMet302 AVenkitaraj K PNo ratings yet