Scope Jufra Project 14.12

Scope Jufra Project 14.12

Uploaded by

Mohammad ShublaqCopyright:

Available Formats

Scope Jufra Project 14.12

Scope Jufra Project 14.12

Uploaded by

Mohammad ShublaqCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Scope Jufra Project 14.12

Scope Jufra Project 14.12

Uploaded by

Mohammad ShublaqCopyright:

Available Formats

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

CERT

STD

ENG'G

MAA

SCOPE OF WORK

DESCRIPTION

ISSUED FOR CONSTRUCTION

LSPB SCOPE OF WORK

JAFURAH MAINTAIN POTENTAIL WELL TIE-INS

11-21034-1001

EAST REMOTE MANIFOLD (ERM)

JO/EWO

30-NOV-22

DATE

REV. NO.

00

DISCIPLINE

ENGINEER

MAH

DATE 30 NOV 22

PROJECT

ENGINEER

ali.alghafli

SAA

DATE 30 NOV 22

CERTIFIED

stuart.dixon

STD

DATE 30 NOV 22

CONSTRUCTION

AGENCY

HMYM GCP-4

DATE 01 DEC 22

JAFURAH

OPERATIONS

MIH

DATE 05 DEC 22

___________

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

EDSD

APPROVAL/CERTIFICATION REQUIREMENTS,

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

THIS INDICATES THAT REV. NO. 00

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 1

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

CERT

TABLE OF CONTENTS

STD

ENG'G

MAA

1. INTRODUCTION 6

1.1 PROJECT OVERVIEW 6

1.1.1 GAS GATHERING WELL PADS SYSTEM 6

1.2 LOCATION ANALYSIS 7

2. SAFETY 8

DESCRIPTION

2.1

ISSUED FOR CONSTRUCTION

GENERAL 8

2.2 PERSONNEL SAFETY 8

2.3 MAINTENANCE SAFETY 8

3. OVERALL SCOPE OF WORK 9

3.1 GENERAL 9

3.2 HIGH LEVEL SUMMARY 10

11-21034-1001

JO/EWO

3.3 INTERFACES 10

3.4 CATHODIC PROTECTION 10

30-NOV-22

4. PERMITS 10

DATE

4.1 LAND USE PERMITS (LUPS) 10

REV. NO.

00

4.2 PERMIT TO WORK 10

DISCIPLINE

ENGINEER

4.3 OTHER PERMITS 11

MAH

DATE 30 NOV 22 5. DRAWINGS 11

PROJECT

ENGINEER 5.1 PROJECT DRAWINGS 11

SAA

DATE 30 NOV 22

5.2 AS-BUILT DRAWINGS 11

CERTIFIED 6. CODES AND STANDARDS 11

STD

6.1 INDUSTRY CODES, STANDARDS AND SPECIFICATIONS 13

DATE 30 NOV 22

7. PROCESS 14

CONSTRUCTION

AGENCY

7.1 DETAILED SCOPE OF WORK 14

DATE 01 DEC 22

8. PIPING 16

OPERATIONS

MIH

8.1 DETAILED SCOPE OF WORK 16

DATE 05 DEC 22

___________ 8.2 GENERAL 16

8.3 PIPE MATERIAL 17

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

8.4

EDSD

POSITIVE MATERIAL IDENTIFICATION 17

8.5 WELDING 17

8.6 INSTALLATION & PRESERVATION 18

APPROVAL/CERTIFICATION REQUIREMENTS,

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

8.7 PAINTING, COATING 18

REVISION CERTIFICATE

THIS INDICATES THAT REV. NO. 00

8.8 HYDROTESTING 19

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 2

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

8.9 CHOKE VALVE SKID 19

CERT

STD

9. MECHANICAL 20

ENG'G

9.1

MAA

GENERAL 20

9.2 DETAILED SCOPE OF WORK 20

10. CONTROL & INSTRUMENTATION 20

10.1 DETAILED SCOPE OF WORK 20

10.2 GENERAL 21

DESCRIPTION

10.3 SYSTEM INTERFACES 22

ISSUED FOR CONSTRUCTION

10.4 DOCUMENTATION 22

10.5 SITE ACTIVITIES 22

11. ELECTRICAL 23

11.1 GENERAL 23

11.2 REFERENCE DOCUMENT LIST 24

11-21034-1001

11.3 WELL HEADS SCOPE OF WORK 25

JO/EWO

12. TELECOM 26

12.1 DETAILED SCOPE OF WORK 26

30-NOV-22

DATE

12.2 TELECOM INTERFACE 31

12.3 REFERENCE DOCUMENT LIST 32

REV. NO.

00

DISCIPLINE 13. CIVIL 34

ENGINEER

13.1 GENERAL 34

MAH

DATE 30 NOV 22

13.2 DETAILED SCOPE OF WORK 36

PROJECT

13.3

ENGINEER

CONCRETE WORKS 36

SAA

DATE 30 NOV 22 13.4 STRUCTURAL STEEL 36

14.

CERTIFIED

PIPELINES 37

STD

DATE 30 NOV 22

14.1 DETAILED SCOPE OF WORK 37

CONSTRUCTION

AGENCY

14.2 GENERAL 37

14.3 PRELIMINARY WORKS ALONG THE ROUTE OF FLOWLINES 38

DATE 01 DEC 22

OPERATIONS

14.4 TEMPORARY CROSSINGS 39

MIH 14.5 REQUIREMENT FOR CROSSING EXISTING SERVICES 40

DATE 05 DEC 22

___________

14.6 CONSTRUCTION PROCEDURES 40

CONTROL NUMBER

DATE _____________

BY: ______________

14.7 RIGHT OF WAY PREPERATION 41

VERIFICATION

EDSD

14.8 EXCAVATION AND TRENCHING 42

14.9 BEDDING, BACKFILLING AND STABILISED BERMS 43

14.10 CROSSINGS 44

APPROVAL/CERTIFICATION REQUIREMENTS,

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

14.11 SIGNS AND MARKERS 45

THIS INDICATES THAT REV. NO. 00

14.12 CORROSION CONTROL 46

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 3

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

14.13 HYDROSTATIC TESTING & DEWATERING 46

CERT

STD

15. CONTRACTOR’S RESPONSIBILITIES WHILE EXECUTING THE WORK 46

ENG'G

15.1

MAA

PROJECT MANAGEMENT 46

15.2 SITE VERIFICATION 46

15.3 PROCUREMENT REQUIREMENTS 47

15.4 FREE ISSUED MATERIALS 47

15.5 CONTRACTOR’S RESOURCES 47

DESCRIPTION

15.6 TRANSPORT 47

ISSUED FOR CONSTRUCTION

15.7 JOBSITE SECURITY 48

15.8 HYDROSTATIC TESTING 48

15.9 PRE-COMMISSIONING AND COMMISSIONING 49

15.10 QUALITY ASSURANCE / QUALITY CONTROL 49

15.11 WASTE MATERIALS 49

11-21034-1001

JO/EWO

30-NOV-22

DATE

REV. NO.

00

DISCIPLINE

ENGINEER

MAH

DATE 30 NOV 22

PROJECT

ENGINEER

SAA

DATE 30 NOV 22

CERTIFIED

STD

DATE 30 NOV 22

CONSTRUCTION

AGENCY

DATE 01 DEC 22

OPERATIONS

MIH

DATE 05 DEC 22

___________

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

EDSD

APPROVAL/CERTIFICATION REQUIREMENTS,

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

THIS INDICATES THAT REV. NO. 00

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 4

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

ABBREVIATIONS

CERT

STD

A/G (a/g) Above Ground

ENG'G

MAA

API Application Programming Interface

CCA Casing/Casing Annulus

EMS Electronic Marker System

EPC Engineering, Procurement, Construction

FA Flow Assurance

FBE Fusion Bond Epoxy

DESCRIPTION

HDPE High Density Polyethylene

ISSUED FOR CONSTRUCTION

HD High Definition

IES Industrial Ethernet Switch

IOM Installation, Operation and Maintenance

IP Internet Protocol

LEL Lower Explosive Limit

LUP Land Use Permit

MCC Mechanical Completion Certificate

11-21034-1001

MSDS Material Safety Data Sheets

JO/EWO

MTO Material Take Off

NEMA National Electrical Manufacturers Association

NDT Non-Destructive Testing

30-NOV-22

DATE

O&M Operation and Maintenance

OSB Operation Support Building

REV. NO.

00

OSP Outside Plant

DISCIPLINE

ENGINEER PCCTV Process CCTV

MAH PoE Power over Ethernet

DATE 30 NOV 22

PTZ Pan, Tilt, Zoom

PROJECT

ENGINEER PVC Polyvinyl Chloride

SAA

QA Quality Assurance

DATE 30 NOV 22

QC Quality Control

CERTIFIED

ROW Right Of Way

STD

DATE 30 NOV 22

RSC Rigid Steel Conduit

CONSTRUCTION

RTP Reinforced Thermosetting Plastic

AGENCY

RTU Remote Terminal Unit

DATE 01 DEC 22

RVL Regulated Vendor List

OPERATIONS

SAES SAUDI ARAMCO Engineering Standards

MIH SAPMT SAUDI ARAMCO Project Management Team

DATE 05 DEC 22

___________ SAT Site Acceptance Tests

SPF Satellite Processing Facility

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

TCA Tubing/Casing Annulus

EDSD

U/G Under Ground

CCTV Closed-Circuit Television

FOC Fibre Optic Cable

APPROVAL/CERTIFICATION REQUIREMENTS,

HCIS High Commission of Industrial Security

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

UTP Unshielded Twisted Pair

THIS INDICATES THAT REV. NO. 00

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 5

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

1. INTRODUCTION

CERT

STD

1.1 PROJECT OVERVIEW

ENG'G

MAA

This document provides an overarching narrative of the technical requirements

and scope definition for CONTRACTOR’s scope of WORK within this Package

The JAFURAH FACILITIES to be provided by the CONTRACTOR as part of

Maintain Potential Well Tie-in scope comprises of the Pipelines and Well Tie-

Ins located at Jafurah Gas Development block, HMYM-4 East inclusive of the

following 4-Well Configuration wellpads:

DESCRIPTION

ISSUED FOR CONSTRUCTION

# Well-Pad

1 HMYM-4621

2 HMYM-4623

3 HMYM-4625

4 HMYM-4627

5 HMYM-4629

11-21034-1001

6 HMYM-4325

JO/EWO

7 HMYM-4327

8 HMYM-4329

9 HMYM-4331

30-NOV-22

DATE

10 HMYM-4333

11 HMYM-4335

REV. NO.

00

The Engineering documents for the wellpads included in this package are for

DISCIPLINE

ENGINEER al wellpads indicated in the above table.

MAH

DATE 30 NOV 22 Each wellpad will feature;

PROJECT

•

ENGINEER

SAA

Gas Gathering Wellpad / Wellhead System

DATE 30 NOV 22

CERTIFIED

• Burn Pits

STD

• Gas Gathering Flowlines from Well pads to Remote Manifolds

DATE 30 NOV 22

CONSTRUCTION

AGENCY

• Corrosion and Scale Inhibition lines from Remote manifolds to each

Wellpad.

DATE 01 DEC 22

OPERATIONS

1.1.1 GAS GATHERING WELL PADS SYSTEM

MIH

DATE 05 DEC 22

The main function of the well pad in the Gas Gathering System is to control

___________

production fluids. Each typical Well pad has the following facilities:

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

• Choke Valve Skid: One skid per wellhead; Well pad piping

EDSD

connected to a dedicated choke valve and an automated spec

break valve on a combined skid.

• Control Skid: One Control Skid per well pad shall be provided for

APPROVAL/CERTIFICATION REQUIREMENTS,

the Hydraulic Power Unit and Panels for the electrical systems and

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

controls.

THIS INDICATES THAT REV. NO. 00

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 6

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

• Corrosion Inhibitor Injection facilities with a dedicated Chemical

CERT

STD

Throttle valve at each wellhead, distributed from the Centralized

Corrosion inhibitor Injection Skids (Skids by Others) located at each

ENG'G

MAA

remote manifold (by Others).

• Scale Inhibitor Injection facilities with a dedicated Chemical Throttle

valve at each wellhead, distributed from the Centralized Scale

Inhibitor Injection Skids (Skids by Others) located at each remote

manifold (by Others).

• MEG (Mono Ethylene Glycol) injection facilities upstream of the

DESCRIPTION

Choke valve at each wellhead MEG being supplied by Mobile Skid

(By Others).

ISSUED FOR CONSTRUCTION

• One Burn Pit shall be provided for each Well pad, with production

fluids being depressurised through the Well pad Burn Pit.

1.2 LOCATION ANALYSIS

The JFGP location is approximately 60km East of the centre of the major

urban area of Al-Hofuf.

11-21034-1001

JO/EWO

Development Block, HMYM-4 (below) is located approx. 35Kms North of the

JFGP location.

30-NOV-22

DATE

REV. NO.

00

DISCIPLINE

ENGINEER

MAH

DATE 30 NOV 22

PROJECT

ENGINEER

SAA

DATE 30 NOV 22

CERTIFIED

STD

DATE 30 NOV 22

CONSTRUCTION

AGENCY

DATE 01 DEC 22

OPERATIONS

MIH

DATE 05 DEC 22

___________

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

EDSD

APPROVAL/CERTIFICATION REQUIREMENTS,

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

THIS INDICATES THAT REV. NO. 00

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 7

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

2. SAFETY

CERT

STD

2.1 GENERAL

ENG'G

MAA

During the performance of the work, CONTRACTOR shall comply with all SAUDI

ARAMCO construction safety manual and engineering standards including SAES-

B-062, SAES-B-064, security directives for industrial facilities and Saudi Arabian

government safety regulations

2.2 PERSONNEL SAFETY

DESCRIPTION

CONTRACTOR shall note that the process fluid is flammable multiphase

ISSUED FOR CONSTRUCTION

hydrocarbons (HC gas and associated water).

CONTRACTOR shall provide fire and gas detection and monitoring system as per

the design document and ensure free HC environment before commencing any hot

work.

CONTRACTOR shall ensure adequate PPE is always worn specially when handling

11-21034-1001

hazardous fluids such as corrosion inhibitors chemicals.

JO/EWO

Toolbox talks shall be held at the beginning on any hazardous activities to ensure

personnel are aware of any potential hazards and are able to carry out work in safe

30-NOV-22

manner.

DATE

CONTRACTOR shall ensure the site is kept tidy and exempt of unnecessary

REV. NO.

00

obstructions to prevent the occurrence of slips and trips.

DISCIPLINE

ENGINEER

MAH

CONTRACTOR shall maintain and regularly update a log of site incidents and near

DATE 30 NOV 22

misses.

PROJECT

ENGINEER

SAA

2.3 MAINTENANCE SAFETY

DATE 30 NOV 22

CERTIFIED

The safety of any CONTRACTOR personnel and the roving maintenance operatives

visiting the well sites shall be considered and provisions made for depressurizing

STD

and purging instrumentation equipment prior to opening process connections. The

DATE 30 NOV 22

depressurising and purging facilities shall be fully tested by the CONTRACTOR

CONSTRUCTION

AGENCY

before ‘Hydrocarbon In’.

DATE 01 DEC 22 Since the process fluids are flammable hydrocarbons at elevated pressures, the

OPERATIONS

CONTRACTOR shall test the installations to ensure that the following features are

MIH

provided:

DATE 05 DEC 22

___________

• Proper, verifiable process isolations at piping interface Bleed/Test/Purge

CONTROL NUMBER

DATE _____________

valving as required for higher pressure rating service, as indicated on the

BY: ______________

VERIFICATION

P&IDs

EDSD

• Facilities to vent only to safe locations

• Facilities to introduce N2 purging to the vent system to remove the flammable

hydrocarbons prior to opening / removing instrumentation equipment

APPROVAL/CERTIFICATION REQUIREMENTS,

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

THIS INDICATES THAT REV. NO. 00

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 8

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

3. OVERALL SCOPE OF WORK

CERT

STD

3.1 GENERAL

ENG'G

MAA

The facilities shall be constructed / installed in accordance with this scope of work,

standards and drawings referenced herein.

The work includes but is not limited to the following:

• Field verification before execution of the scope of work

DESCRIPTION

• Supply and installation of all Carbon steel metallic underground flowlines ,

ISSUED FOR CONSTRUCTION

underground Duplex Stainless steel Centralized Corrosion Inhibition and

Scale Inhibition lines in Jafurah field

• Cross check all materials and quantities from construction drawings.

• Excavation of sand, marl and rock as required for the concrete foundations

and underground piping works

• Sand padding, backfilling, compacting, forming, and stabilizing of berm for

flowlines and construction of road, camel crossings, finalising pipeline

11-21034-1001

JO/EWO

access road

• Supply and Installation of pipe sleepers/foundations for equipment, platforms

and pipe supports, etc.

30-NOV-22

DATE

• Picking up, offloading and handling of COMPANY supplied material (if any)

• Procurement, testing and commissioning of Mechanical Equipment.

REV. NO.

00

DISCIPLINE • Storage and preservation of equipment prior to commissioning and spare

ENGINEER

components

MAH

DATE 30 NOV 22

• Supply, testing and installation of all materials required for the scope

PROJECT

ENGINEER • Fabrication and installation of all steel structures (pipe supports, platforms,

SAA

etc.)

DATE 30 NOV 22

CERTIFIED

• Re-route the existing pipeline access roads where required as per the project

drawings

STD

DATE 30 NOV 22 • Restore marl borrow pits areas and return them to the original contour upon

CONSTRUCTION

project completion

AGENCY

• Supply, transport and disposal of hydrotest water for piping

•

DATE 01 DEC 22

Installation of all signs as shown on the drawings including but not limited to

OPERATIONS

flowline signs and all type of markers, personnel warning signs, safety signs,

MIH

DATE 05 DEC 22

etc

___________

• Painting and coating of all piping

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

• All other work required to provide a complete, safe and operational facility

EDSD

• Co-ordination with other parties working in the same area

• Assistance with commissioning of all piping, flowlines and instrumentation

APPROVAL/CERTIFICATION REQUIREMENTS,

• Preparation of consolidated As-Built red line mark-up drawings

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

• Site clean-up

THIS INDICATES THAT REV. NO. 00

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 9

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

3.2 HIGH LEVEL SUMMARY

CERT

STD

Overall scope of work to be completed for Jafurah Field is noted below and detailed

ENG'G

MAA

in the respective sections.

All works shall be performed in accordance with the project drawings and

specifications and all applicable Industry and International Standards and

Specifications.

• Supply and installation of Interconnecting above ground Piping

• Supply and construction of foundations and supports

DESCRIPTION

• Supply and installation of field instruments

ISSUED FOR CONSTRUCTION

• Supply and Installation of metallic Pipelines

• Supply and Installation of Corrosion Inhibition and Scale Inhibition lines

3.3 INTERFACES

CONTRACTOR shall refer to all interfaces listed in Interface Points Register

11-21034-1001

Document TD-053401 All interfaces shall be confirmed and verified by all

JO/EWO

interfacing parties as required.

30-NOV-22

DATE

3.4 CATHODIC PROTECTION

REV. NO.

00

CONATRCTOR shall be responsible for the engineering design, supply, installation

DISCIPLINE

ENGINEER

and commissioning of Cathodic Protection System by COMPANY approved 3rd

party Sub-Contractor.

MAH

DATE 30 NOV 22

PROJECT

CONTRACTOR shall refer to TE-903858 REV.00 for the engineering requirements

ENGINEER

of the Cathodic Protection System. All detailed engineering for the Cathodic

SAA

Protection System shall be carried out by COMPANY approved 3rd party.

DATE 30 NOV 22

CERTIFIED

STD

DATE 30 NOV 22 4. PERMITS

CONSTRUCTION

AGENCY

4.1 LAND USE PERMITS (LUPS)

DATE 01 DEC 22

CONTRACTOR shall be responsible for reviewing the validity of project specific

OPERATIONS LUPs as advised by COMPANY.

MIH

DATE 05 DEC 22

___________ 4.2 PERMIT TO WORK

CONTROL NUMBER

DATE _____________

BY: ______________

CONTRACTOR shall obtain work permits before commencement of any work.

VERIFICATION

EDSD

CONTRACTOR shall develop Permitting Matrix for any work to be carried out

involving interfaces with any 3rd parties (e.g., all other contractors associated with

the project and existing facilities). This system shall be subject to the approval of the

APPROVAL/CERTIFICATION REQUIREMENTS,

COMPANY. No work shall be carried out in areas where interfacing is an issue

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

without a valid permit. CONTRACTOR shall obtain work permits before

THIS INDICATES THAT REV. NO. 00

commencement of any work.

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 10

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

4.3 OTHER PERMITS

CERT

STD

CONTRACTOR shall secure all official permits, forms and approvals, relevant to the

ENG'G

MAA

construction work, including permits necessary for the transportation of pipe and

other materials, permits for crossing of roads watercourses and all other permits that

may be required in connection with the construction works.

CONTRACTOR shall ensure that such permits, forms and approvals are valid for

the duration of the project contract and maintenance period. Copies of these shall

be provided to COMPANY.

DESCRIPTION

No construction works shall commence until all requirements in respect of

ISSUED FOR CONSTRUCTION

indemnities, bonds and agreements have been secured and all official forms duly

stamped, signed, and authenticated.

5. DRAWINGS

5.1 PROJECT DRAWINGS

11-21034-1001

JO/EWO

The drawings that are issued with, and form part of this Scope of Work are listed in

the Document Control List TD-905419

30-NOV-22

5.2

DATE

AS-BUILT DRAWINGS

The CONTRACTOR shall be responsible for maintaining a robust QA system for

REV. NO.

00

completion of all red line marked-up as-built drawings for all completed works within

DISCIPLINE

ENGINEER his scope of supply.

MAH

DATE 30 NOV 22 The As-built drawings should include traceability of all agreed changes where

PROJECT applicable and shall be available at site for review by COMPANY representatives

ENGINEER

during all stages of construction.

SAA

DATE 30 NOV 22

Following completion of construction activities, 3 hard copies plus 1 electronic pdf

CERTIFIED

copy of all As-built drawings shall be sent to COMPANY.

STD

DATE 30 NOV 22

CONSTRUCTION 6. CODES AND STANDARDS

AGENCY

DATE 01 DEC 22

CONTRACTOR shall complete all Works, under this contract, in accordance with the

OPERATIONS

applicable SAUDI ARAMCO Standards, Specifications, General Instructions (GI’s),

MIH

DATE 05 DEC 22

Procedures, Library Drawings, Reports, International Industry Codes, Standards and

___________ Recommended Practices.

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

This shall include but is not limited to the following:

EDSD

• SAUDI ARAMCO Engineering Standards (SAES)

• SAUDI ARAMCO Safety and Security Standards (SAES-O-Series)

• SAUDI ARAMCO Material Systems Specifications (SAMSS)

APPROVAL/CERTIFICATION REQUIREMENTS,

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

•

REVISION CERTIFICATE

SAUDI ARAMCO Standard Library Drawings (SASD)

• SAUDI ARAMCO Engineering Procedures (SAEP)

THIS INDICATES THAT REV. NO. 00

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 11

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

• SAUDI ARAMCO GIs and Procedures

CERT

•

STD

SAUDI ARAMCO Engineering Reports

• SAUDI ARAMCO Best Practices

ENG'G

MAA

• SAUDI ARAMCO Inspection Requirement

• SAUDI ARAMCO Pre-Commissioning Forms, Industry Codes and Standards

• SAUDI ARAMCO Environmental Health Code (SAEHC)

• Saudi Arabian Standards Organization Documents (SASO)

• SAUDI ARAMCO Construction Safety Manual (SACSM)

• SAUDI ARAMCO Safety Management Guide (SASMG)

• SAUDI ARAMCO Safety and Security Directives

DESCRIPTION

• American National Standards Institute (ANSI)

ISSUED FOR CONSTRUCTION

• American Society of Mechanical Engineers (ASME)

• American Society of Testing & Materials (ASTM)

• American Concrete Institute (ACI)

• American Institute of Steel Construction (AISC)

• National Electrical Manufacturers Association (NEMA)

• National Electrical Code (NEC)

• National Fire Protection Association (NFPA)

• Instrument, Systems & Automation Society (ISA)

11-21034-1001

JO/EWO

• International Fire Code (IFC)

• International Organization for Standardization (ISO)

• International Electro-Technical Commissions (IEC)

•

30-NOV-22

Internal Electro-Technical Commission (IEC)

DATE

• Welding Research Council (WRC)

• International Building Code.

REV. NO.

00

• Library drawings

•

DISCIPLINE

ENGINEER Other Industry Codes & Standards

MAH

• Building Service Industry Consulting International (BICSI)

DATE 30 NOV 22

• High Commission of Industrial Security (HCIS)

PROJECT

ENGINEER

SAA

CONTRACTOR shall note that any Deviation from above SAUDI ARAMCO or

DATE 30 NOV 22 International Standards/Specifications/Procedures etc. shall be approved by the

CERTIFIED

responsible SAUDI ARAMCO Dept. in writing.

STD All work shall be carried out in accordance with the SAUDI ARAMCO Construction

DATE 30 NOV 22

Safety Manual and the minimum behavioural safety standards detailed in the SAUDI

CONSTRUCTION

AGENCY

ARAMCO Safety Handbook. Further the project shall provide site specific Safety

Plan and Hazard Identification Plan (HIP) for Loss Prevention approval.

DATE 01 DEC 22

OPERATIONS After Procurement, and Construction, CONTRACTOR shall test and pre-commission

MIH all systems, equipment, and instruments in accordance with SAUDI ARAMCO

DATE 05 DEC 22 applicable standards and specifications.

___________

CONTROL NUMBER

DATE _____________

March 2021 shall be considered as the SAUDI ARAMCO Standards (Other than

BY: ______________

VERIFICATION

Safety) cut-off date for procurement, construction, testing, pre-commissioning, and

EDSD

commissioning phases.

The latest available / published SAUDI ARAMCO Safety & Security Standards shall

APPROVAL/CERTIFICATION REQUIREMENTS,

be complied with, irrespective of cut-off date.

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

THIS INDICATES THAT REV. NO. 00

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 12

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

6.1 INDUSTRY CODES, STANDARDS AND SPECIFICATIONS

CERT

STD

CONTRACTOR shall carry out all work in accordance with the following Industry

ENG'G

MAA

Codes, Standards and Specifications. The edition of any standard listed shall be that

in effect as of the date that the construction contract is awarded.

Code Title

API 5L Specification for Line Pipe

API-6D Specification for Pipeline Valves

API-6F A Specification for Fire Test for Valves

DESCRIPTION

Recommended Practice, Steel Pipelines crossing Railroads

API-RP-1102

ISSUED FOR CONSTRUCTION

and Highways

API RP 1110 Pressure testing of Steel Pipelines for the Transportation of

Gas, Petroleum Gas, Hazardous Liquids, Highly Volatile

Liquids or Carbon Dioxide

API-STD-598 Valve Inspection and Testing

API STD 1104 Welding of Pipelines and related facilities

Metallic gaskets for Pipe flanges, Ring joint, Spiral wound and

ASME B16.20

Jacketed

11-21034-1001

ASME B16.5 Standard for Pipe Flanges and Flanged Fittings

JO/EWO

ASME B31.3 Process Piping

ASME B31.8 Gas Transmission and Distribution Piping System

ASME B31.4 Pipeline Transportation Systems for Liquids and Slurries

30-NOV-22

DATE

ASME B36.10M Welded and Seamless Wrought Steel Pipe

ASME B36.19M Stainless Steel Pipe

REV. NO.

00

NACE SP-0286 The Electrical Isolation of Cathodically Protected Pipelines.

DISCIPLINE

ENGINEER NACE RP 0402 Field Applied FBE pipe coating system for girth weld joints –

Application performance and quality control

MAH

DATE 30 NOV 22

PROJECT

ENGINEER

SAA

DATE 30 NOV 22

CERTIFIED

STD

DATE 30 NOV 22

CONSTRUCTION

AGENCY

DATE 01 DEC 22

OPERATIONS

MIH

DATE 05 DEC 22

___________

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

EDSD

APPROVAL/CERTIFICATION REQUIREMENTS,

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

THIS INDICATES THAT REV. NO. 00

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 13

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

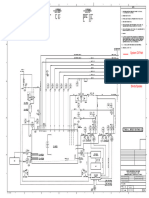

7. PROCESS

CERT

STD

7.1 DETAILED SCOPE OF WORK

ENG'G

MAA

- Contractor shall include all piping, instrumentation and material works

necessary to wellhead tie-in (typical for all well pads). This scope of work shall

be read in conjunction with the technical P&ID drawings provided in document

control list Doc. no. TD-905419

- The scope of the typical upstream fluid gathering system consists of the

following:

DESCRIPTION

ISSUED FOR CONSTRUCTION

▪ Well pad system

▪ Dedicated choke valve skid for each well head piping system which

comprises choke valve, automated spec break valve, annuli piping with

pressure transmitters.

▪ The choke skid package consists of two units, one for the choke valve and

second for the chemical injection instruments.

▪ Common one manifold for well pad which combines the flow from typically

four operating wellheads arrangement.

11-21034-1001

▪ Flowline from well pad common manifold for four wells arrangement to the

JO/EWO

respective remote manifold

▪ Wet gas flow meter with multivariable measuring capability (it shall be

installed after well dewatering when advised by Company’s production

30-NOV-22

DATE

engineering team).

▪ Well pad utilities – electric power, hydraulic fluid system, provision for

REV. NO.

corrosion inhibitor, scale inhibitor and MEG injection

00

DISCIPLINE

▪ A tube kill line with local pressure gauge is provided for each well head for

ENGINEER

well suppression and de-sanding operation.

MAH ▪ Well pad

DATE 30 NOV 22

▪ Burn pit (HOLD: Size to be confirmed by Saudi Aramco)

PROJECT

ENGINEER

SAA

- The remote headers/manifolds and trunklines design are not part of the

DATE 30 NOV 22 subject design basis and detailed engineering shall be performed by others.

CERTIFIED

- MEG (Mono Ethylene Glycol) injection facilities upstream of the Choke valve

STD at each wellhead MEG being supplied by Mobile Skid. Three portable skids

DATE 30 NOV 22

per block shall be provided. For HMYM-4, the skids will be provided by

CONSTRUCTION

AGENCY

Others.

DATE 01 DEC 22 - In Jafurah block, each well pad contains typically four producing wells that

OPERATIONS

produce gas, HC condensate, and water.

MIH

DATE 05 DEC 22 - Burn pit is provided at each well pad where all the blowdown wet hydrocarbon

___________

inventory from the well pad

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

- No scraper launchers and receivers are required for wells flow line however

EDSD

provision for temporary scraping shall be provided.

- There are no permanent process utilities required at the Well pad. The

wellhead area shall be backfilled, and no air blower shall be needed to ensure

APPROVAL/CERTIFICATION REQUIREMENTS,

safe access to the wellhead area.

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

- No test separator facilities are required as part of this project. Portable MEG

THIS INDICATES THAT REV. NO. 00

injection skid (by others)shall comprise of MEG storage tank, MEG injection

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 14

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

pumps, instrumentation and local panel, and associated piping with valves as

CERT

minimum.

STD

- Hydraulic fluid system for wellhead valves operation

ENG'G

MAA

- Electric Power

- Fire and Gas detection

- Instrument air is not included in the well pad design as the project philosophy

is to use electric motor operated and hydraulic operated valves where

possible. Hence Instrument Air shall not be available at the well pads; the

choke valve, SSVs and SBV actuators shall use hydraulic fluid provided by a

DESCRIPTION

local HPU system.

ISSUED FOR CONSTRUCTION

- The design life for all surface facilities i.e., wellhead and burn pit shall be 20

years.

- The design life for all pipelines shall be 25 years.

- The electric heat tracing is applied for following wellhead instrumentation,

PIT-0132/0133/0134/0135/0175 and FIT-0102.

11-21034-1001

JO/EWO

Note: For more details,refer to below documents:

1. Process Design Basis Doc. noTE-683188

2. Process Description Doc. no TE-683189

30-NOV-22

DATE

REV. NO.

00

DISCIPLINE

ENGINEER

MAH

DATE 30 NOV 22

PROJECT

ENGINEER

SAA

DATE 30 NOV 22

CERTIFIED

STD

DATE 30 NOV 22

CONSTRUCTION

AGENCY

DATE 01 DEC 22

OPERATIONS

MIH

DATE 05 DEC 22

___________

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

EDSD

APPROVAL/CERTIFICATION REQUIREMENTS,

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

THIS INDICATES THAT REV. NO. 00

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 15

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

8. PIPING

CERT

STD

8.1 DETAILED SCOPE OF WORK

ENG'G

MAA

The work shall, include but not limited to installation of pipework, pipe supports,

anchor blocks (if required), painting/coating, installation of all piping work,

valves, fittings, mounting of all instruments, making all piping, electrical &

instrumentation connections, and final hook-up to wellhead and skids.

CONTRACTOR shall refer to Piping Basis of Design Doc# TE-681683 Rev. 00

for further Details

DESCRIPTION

ISSUED FOR CONSTRUCTION

8.2 GENERAL

a. CONTRACTOR scope shall include design, supply, transportation, installation,

testing and commissioning of the Piping Systems for this Project, including all

Piping skids, Valves and Actuators, Piping Specials, Utility Piping items and

Pipe Supports etc., and comply in accordance with SAEP-35.

b. CONTRACTOR shall fabricate and install all pipe works for the wellhead piping

11-21034-1001

in accordance with the approved drawings, specification, and Saudi Aramco

JO/EWO

standard. It shall be CONTRACTOR’s responsibility to complete all activities

associated with the assembly, testing and functional checking of all pipework,

equipment and instrumentation etc. installed on the wellhead piping.

30-NOV-22

DATE

c. CONTRACTOR shall ensure integrity of the Piping System and shall ensure

REV. NO.

proper maintenance access for all equipment, piping, and accessories.

00

DISCIPLINE

ENGINEER d. All Piping material classes shall comply with SAES-L-105 and within skid piping

MAH

shall be per 01-SAMSS-010. CONTRACTOR shall be fully responsible for

DATE 30 NOV 22 installation of all pipes supports, pipe support details, pipe support attachments

PROJECT on equipment and, any special pipe support required

ENGINEER

SAA

DATE 30 NOV 22

e. CONTRACTOR shall ensure that the piping assemblies are not under strain

prior to final bolting or welding. CONTRACTOR shall also ensure that all

CERTIFIED

equipment and piping is thoroughly swabbed clean of dust, debris, welding-

STD

spatter, scale, or any potentially detachable matter prior to final tie-in or closure

DATE 30 NOV 22

bolting.

CONSTRUCTION

AGENCY

f. Necessary platforms shall be provided for all equipment, valves, and

DATE 01 DEC 22

instruments for proper access for operation and maintenance. Crossovers shall

OPERATIONS

be provided for proper movement in accessing the equipment / skids.

MIH

DATE 05 DEC 22

g. On completion of the Work, all elements for each installation, shall be inspected

___________

and tested for complete and correct functional operation in the presence of, and

to the satisfaction of COMPANY. All Work shall be carried out strictly in

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

accordance with company specification requirements.

EDSD

h. CONTRACTOR shall take all necessary actions to prevent entry of sand

particles into delicate parts of equipment (Skids and valves) during

transportation, storage, assembly, and installation.

APPROVAL/CERTIFICATION REQUIREMENTS,

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

i. CONTRACTOR shall carry out all piping work in close liaison with the

THIS INDICATES THAT REV. NO. 00

COMPANY representative to meet the project requirements.

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 16

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

j. CONTRACTOR shall follow all safety precautions required by SAUDI ARAMCO

CERT

Standards and those suggested by the Loss Prevention Engineer to ensure safe

STD

construction works

ENG'G

MAA

k. CONTRACTOR shall be responsible for valves handling, hauling, receipt,

testing and storage in accordance with SAEP-35

l. CONTRACTOR to provide all work procedures prior to start of work for

COMPANY approval.

m. CONTRACTOR shall be responsible for the return of any excess materials upon

DESCRIPTION

completion of work to a point designated by Client.

ISSUED FOR CONSTRUCTION

n. Any activities not specifically mentioned above but necessary to achieve

completion of the work shall be part of CONTRACTOR’s scope.

8.3 PIPE MATERIAL

CONTRACTOR shall comply to Material Specification document number TE-

681684, and Corrosion Management Program document number TE-906131,

11-21034-1001

Saudi Aramco Standards SAES-L-105 and applicable international standard as

JO/EWO

following:

a. Material procurement of pipes, fittings, valves and gaskets shall be in

30-NOV-22

DATE

accordance with Saudi Aramco Regulated Vendor List.

b. Material selection for line pipes and components shall be in accordance with

REV. NO.

00

SAES-L-132 and SAES-L-136 requirements.

DISCIPLINE

ENGINEER

MAH

c. Valves selection for piping systems shall be in accordance with SAES-L-108

DATE 30 NOV 22 requirements. CONTRACTOR shall refer to valve data sheet Document

PROJECT number TE-681685.

ENGINEER

SAA

DATE 30 NOV 22

d. Flanges, bolts, and gasket shall be in accordance with SAES-L-109

requirements. CONTRACTOR shall refer to Speciality Item Data sheet

CERTIFIED

Document number TE-681693.

STD

DATE 30 NOV 22 e. Pipe mill tolerance shall be based on the requirements given in ASME

CONSTRUCTION B36.10 or API 5L as applicable. CONTRACTOR shall refer to Pipe Wall

AGENCY

Thickness Calculation Document number TE-681697.

DATE 01 DEC 22

f. All non-metallic piping system shall be designed and constructed in

OPERATIONS

MIH

accordance with SAES-L-610 in addition to the applicable ASME B31 Code.

DATE 05 DEC 22

___________ 8.4 POSITIVE MATERIAL IDENTIFICATION

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

PMI shall be in accordance with SAES-A-206 shall be undertaken during

EDSD

fabrication or immediately prior to fabrication. The PMI testing will be undertaken

by the fabricator under the supervision of SAUDI ARAMCO representative.

8.5 WELDING

APPROVAL/CERTIFICATION REQUIREMENTS,

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

CONTRACTOR Shall submit welding procedures as a complete package to

THIS INDICATES THAT REV. NO. 00

Saudi Aramco for technical approval prior to the start of work (refer to SAEP-352

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 17

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

for details). Welding and weld inspection shall be in accordance with SAES-W-

CERT

011 and SAES-W-012.

STD

ENG'G

MAA

All welding procedures shall include the Welding Procedure Request Form

(Refer to SAES-W-011), Welding Procedure Specifications (WPS), Qualification

Test Records (PQR), and Weld and Line Description Tables.

Welding Procedure Specifications (WPS) and Procedure Qualification Records

(PQRs) shall be prepared as per the suggested format of ASME SEC IX.

CONTRACTOR is permitted to use any welding procedure previously approved

DESCRIPTION

by Saudi Aramco without CSD re-review. However, the assigned inspector and

ISSUED FOR CONSTRUCTION

the contractor welding engineer/representative must verify that the welding

procedure is within the welding parameters qualification range (e.g., diameter,

thickness, material grade, etc.) for the new job.

CONTRACTOR shall conform all WPSs and PQRs are complying with the latest

edition of the ASME SEC IX and the additional requirements of Saudi Aramco

standard.

11-21034-1001

8.6 INSTALLATION & PRESERVATION

JO/EWO

Fabrication, installation, and coating shall be in accordance with SAES-L-350

and SAES-L-450.

30-NOV-22

DATE

All openings on completed pipe sections and fabricated spools shall be protected

REV. NO.

with end caps when work is not being performed to prevent the entry of foreign

00

matter.

DISCIPLINE

ENGINEER

MAH

8.7 PAINTING, COATING

DATE 30 NOV 22

PROJECT CONTRACTOR shall clean and prepare piping for painting per SAES-H-001 and

ENGINEER

SAA

SAES-H-002.

DATE 30 NOV 22

CONTRACTOR shall provide Safety Identification and Safety Coloration to the

CERTIFIED

pipe, valves, fittings, and equipment as per SAES-B-067. The expired and/or

STD

discarded paint during/after Construction shall be considered as hazardous

DATE 30 NOV 22 waste and handled accordingly by the CONTRACTOR.

CONSTRUCTION

AGENCY

CONTRACTOR shall supply and apply painting and coating material in

DATE 01 DEC 22

accordance with SAES-H-002.

OPERATIONS

MIH

CONTRACTOR shall externally coat transition areas (buried to above ground

DATE 05 DEC 22

pipe sections), including field joints as per the requirements specified in SAES-

___________

H-002. And shall be protected with the buried service coating and supplemented

with an approved protective system such as APCS-113A or APCS-113C (with

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

UV resistant outer wrap). This system shall start at least 1m below ground and

EDSD

extend above ground as per the requirement of SAES-H-002.

CONTRACTOR shall be responsible for proper storage, handling and installation

of externally coated pipework in accordance with SAES-H-200.

APPROVAL/CERTIFICATION REQUIREMENTS,

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

CONTRACTOR shall refer to Coating map Doc.# TE-681686 Rev.00 for more

THIS INDICATES THAT REV. NO. 00

details

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 18

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

8.8 HYDROTESTING

CERT

STD

CONTRACTOR shall perform Hydrostatic Testing Plan as per the requirements

ENG'G

MAA

of SAES-A-004, SAES-A-007, and SAES-L-150.

CONTRACTOR Shall verify all high and low points on the line and install 1”

welding boss & temporary vent or drain valves. After the Hydrotest

CONTRACTOR shall remove all temporary connections and install plugs and

seal weld all threaded connection as per SAES-L-110

CONTRACTOR Shall provide all necessary equipment, inline materials and

DESCRIPTION

tools required for the Hydrotest.

ISSUED FOR CONSTRUCTION

CONTRACTOR shall comply with SAES-A-004, SAES-A-007 and SAES-L-150

requirements regarding hydrotesting.

CONTRACTOR shall follow SAES-A-104 for water disposal requirements. The

disposal sites for the test fluids shall be reviewed and approved by SAUDI

ARAMCO prior to hydrostatic testing, per SAEP-327.

11-21034-1001

CONTRACTOR Shall conduct Hydrostatic Testing as per Hydrostatic Testing

JO/EWO

diagrams included part of this package.

8.9 CHOKE VALVE SKID

30-NOV-22

DATE

The skid will be fabricated and supplied by the skid CONTRACTOR as part of

the Maintained Potential Well Tie-ins.

REV. NO.

00

DISCIPLINE

ENGINEER Choke Valve Skid controls the well flow using several valves configuration.

MAH

One skid per wellhead that comprises the following;

DATE 30 NOV 22

PROJECT • Well pad piping connected to a dedicated choke valve and an

ENGINEER

SAA

automated specs break valve.

DATE 30 NOV 22

• Mono Ethylene Glycol (MEG) piping including its valves and fittings.

CERTIFIED

• Scale Inhibitor (SI) piping including its valves and fittings.

STD

DATE 30 NOV 22 • Corrosion Inhibitor (CI) piping including its valve and fittings

CONSTRUCTION

AGENCY CONTRACTOR shall refer to Technical Specification of Choke Valve Skid Doc.#

TE-681692 Rev. 00 and Skid details drawing # TA-681690 Rev.00 for further

DATE 01 DEC 22

information

OPERATIONS

MIH

DATE 05 DEC 22

___________

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

EDSD

APPROVAL/CERTIFICATION REQUIREMENTS,

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

THIS INDICATES THAT REV. NO. 00

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 19

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

9. MECHANICAL

CERT

STD

9.1 GENERAL

ENG'G

MAA

9.1.1 CONTRACTOR shall procure receive, store and maintain the Burn Pit

Portable Ignitor Package including portable and permanent components.

9.1.2 CONTRACTOR shall instal all permanent of components of the Portable

Ignitor Package at each of of the burn pit locations. This shall include but not

be limited to the pilot pipe, guide pipe, ignition cables and junction boxes.

DESCRIPTION

9.1.3 CONTRACTOR shall have adequate technical resources and its personnel

ISSUED FOR CONSTRUCTION

shall have proven experience and capability in package equipment, piping,

and all associated mechanical installation procedures.

9.2 DETAILED SCOPE OF WORK

9.2.1 CONTRACTOR shall inspect equipment upon receipt for, as a minimum,

completeness, and condition to ensure all shipped items are received and

not damaged.

11-21034-1001

JO/EWO

9.2.2 CONTRACTOR shall, as a minimum, follow installation, preservation and

maintenance instructions supplied by Vendors.

30-NOV-22

DATE

9.2.3 Preservation and maintenance of equipment shall continue during all phases

from receipt through to hand-over to COMPANY.

REV. NO.

00

9.2.4 CONTRACTOR shall ensure equipment instrumentation and field wiring do

DISCIPLINE

ENGINEER not obstruct the operation and maintenance of equipment parts.

MAH

DATE 30 NOV 22 9.2.5 CONTRACTOR shall be responsible for compilation of all required

PROJECT certification data (Material Certificates, ATEX Certificates, test records, etc.)

ENGINEER

as required to enable verification and sign-off of installation, pre-

SAA

DATE 30 NOV 22

commissioning, and commissioning activities prior to Mechanical Completion

handover to COMPANY.

CERTIFIED

STD

9.2.6 CONTRACTOR shall also be responsible for the compilation of the IOM

DATE 30 NOV 22 manuals from the vendors.

CONSTRUCTION

AGENCY

9.2.7 CONTRACTOR shall maintain an up-to-date materials inventory list and

DATE 01 DEC 22

shall properly label and store all capital spares, commissioning / start up

spares and all special tools in suitable storage locations that is in line

OPERATIONS

MIH

environmentally with OEM recommended storage requirements.

DATE 05 DEC 22

___________ CONTRACTOR shall comply with the requiremetns of SAEP-385 regarding

Preservation of Projects Materials and Equipment.

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

EDSD

10. CONTROL & INSTRUMENTATION

10.1 DETAILED SCOPE OF WORK

APPROVAL/CERTIFICATION REQUIREMENTS,

CONTRACTOR shall perform all Instrumentation works in accordance with Project

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

Drawings and Documents as specified in section 10.4, including but not limited to

THIS INDICATES THAT REV. NO. 00

procurement of all instruments, package equipment, vendor services, installation,

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 20

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

construction, testing and pre-commissioning based on provided Specifications ,

CERT

Datasheets, Instrument Block Diagrams, Instrument Installation Schedules, Instrument

STD

Cable & Conduit Plans, Fire & Gas Layout Drawings, Interconnection Diagrams, Loop

ENG'G

MAA

Drawings, Instrument Support/Installation Details, and Instrument Hook-up Drawings,

etc.

CONTRACTOR shall perform all instrumentation works related and/or associated with

the following new instrumentation, packaged equipment skids and interfaces:

a) Supply & Installation of Control Skid at each well pad, comprising of Remote

Terminal Unit (RTU), Wellhead Shutdown Hydraulic Control Panel (WHCP) and

DESCRIPTION

hydraulic ancillaries, Telecom / Electrical panels.

ISSUED FOR CONSTRUCTION

b) RTU interface with GCP SCADA and GCP SCADA modifications to incorporate

the new well remote operation, engineering and maintenance requirements.

c) Wellhead choke valve, spec break valve, flowmeter, and pressure and

temperature instruments.

d) Pressure monitoring instruments for the inner, middle, and outer annuli.

e) Chemical Injection instruments flow throttle valves, pressure and on-off valves.

f) Gas detectors, beacons and sounders and fusible plug valves

g) Burried hydraulic tubing connection to wellhead safety valves, spec break

11-21034-1001

JO/EWO

valves and fusible plug valves

h) Burried home run cables

i) Sun shades for panels and field transmitters

30-NOV-22

DATE

10.2 GENERAL

REV. NO.

CONTRACTOR shall perform all Instrumentation works in accordance with referenced

00

DISCIPLINE

COMPANY Standards and Specifications.

ENGINEER

MAH All instrument selection, design, application, and documentation shall comply with

“SAES-J-003 Instrumentation and Control Buildings - Basic Design Criteria” and its

DATE 30 NOV 22

PROJECT

ENGINEER referenced COMPANY Standards and Specifications.

SAA

DATE 30 NOV 22 CONTRACTOR shall be responsible for the complete installation, testing and pre-

CERTIFIED commissioning of controls and instrumentation scope, including but not limited to the

following:

STD

DATE 30 NOV 22

1) CONTRACTOR shall verify the project documentation is fit for purpose and

CONSTRUCTION

AGENCY shall update the documents and drawings where required to incorporate

existing site conditions and final vendor design data.

DATE 01 DEC 22 2) CONTRACTOR shall field verify the design information relating to the

OPERATIONS Instrumentation scope of work for all well sites and tie-ins prior to fabrication

MIH and installation. Consideration shall be given to the installation design allowing

DATE 05 DEC 22

___________

for future removal of the choke valve skid , leaving the

3) CONTRACTOR shall be responsible for the supply of all materials and

CONTROL NUMBER

DATE _____________

BY: ______________

consumables as needed, whether these are shown on the drawings, apart from

VERIFICATION

EDSD

free issue materials by SAUDI ARAMCO (if any). All instrumentation and

installation necessary for successful project completion is within the scope of

the CONTRACTOR.

4) CONTRACTOR shall ensure that all sensitive items of electronic equipment are

APPROVAL/CERTIFICATION REQUIREMENTS,

appropriately packed and protected for their journey to site and the residence

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

time at site awaiting installation. CONTRACTOR shall provide storage indoors

THIS INDICATES THAT REV. NO. 00

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 21

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

for all instrumentation and valves, suitably protected against the ingress of sand

and moisture, in accordance with the manufacturer’s requirements for storage.

CERT

STD

5) CONTRACTOR shall carry out all civil works associated with Instrumentation

ENG'G

MAA

including foundation support for junction box and field transmitters, and cable

trenching for instrument cables where necessary.

6) CONTRACTOR shall fabricate necessary frames/stands, supports for

installation of Instruments and Junction Boxes, etc.

7) CONTRACTOR shall carry out testing, calibration, loop checking,

precommissioning and commissioning of all instruments, controls, systems,

data links and packages relevant to project scope. CONTRACTOR shall

provide all test equipment suitably calibrated, within date, traceable to national

DESCRIPTION

standards.

ISSUED FOR CONSTRUCTION

8) CONTRACTOR shall provide nameplates for field instruments, control

panels/enclosures and junction boxes.

9) CONTRACTOR shall paint support stands for instruments and junction boxes

as per SAES-H-101V.

10.3 SYSTEM INTERFACES

10.3.1 Software configuration and interface at GCP SCADA

11-21034-1001

JO/EWO

CONTRACTOR shall be responsible for requisitioning the SCADA Vendor materials

and services and shall render all required engineering deliverables to SCADA Vendor

30-NOV-22

DATE

and provide technical support and assistance for seamless integration of the wells into

the SCADA system at HMYM-4 GCP (SIB) and also at the JFGP Central Control

REV. NO.

Building.

00

DISCIPLINE

ENGINEER

Wellhead RTU interface with SCADA include networking, configuration, graphics

MAH development, database creation for the new wells for remote monitoring, control,

DATE 30 NOV 22

engineering and maintenance.

PROJECT

ENGINEER

SAA

DATE 30 NOV 22 10.4 DOCUMENTATION

CERTIFIED

Refer to Document Cotrol List TD-905419 for all Control and Instrumentation

STD engineering, procurement and construction documentation.

DATE 30 NOV 22

CONSTRUCTION

AGENCY CONTRACTOR shall manage all Vendor Non Material Requirements (NMR) and

update all engineering and construction documents to incorporate Vendor data prior to

DATE 01 DEC 22 final installation and comissioning.

OPERATIONS

MIH

DATE 05 DEC 22 10.5 SITE ACTIVITIES

___________

CONTROL NUMBER

DATE _____________

CONTRACTOR shall implement a comprehensive QA/QC system during the site

BY: ______________

VERIFICATION

receiving inspection and calibration, installation, testing, loop checking, function

EDSD

checking and commissioning phases and maintain and provide full loop-by-loop-based

records and loop packs to continuously monitor and demonstrate the quality of the work

performed.

APPROVAL/CERTIFICATION REQUIREMENTS,

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

CONTRACTOR shall allow COMPANY overview and witnessing of all installation and

testing work.

THIS INDICATES THAT REV. NO. 00

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 22

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

CERT

STD

11. ELECTRICAL

ENG'G

MAA

11.1 GENERAL

1. CONTRACTOR shall perform all electrical work in accordance with SAES-P-

100, SAES-P-104, SAES-P-111, SAES-P-116, SAES-P-123, SAES-P-128 and

all other applicable SAUDI ARAMCO Standards, SAUDI ARAMCO Material

Specifications and International Codes and Standards etc.

DESCRIPTION

2. The cable routing proposed is indicative only and CONTRACTOR shall

ISSUED FOR CONSTRUCTION

undertake site verification before finalizing cable installation during

Construction. The cables routed through Fire Hazardous zone(s) shall meet the

requirements of SAES-B-006 & SAES-P-104.

3. The CONTRACTOR shall install power cables in accordance with SAES-P-104.

Instrument cables shall run in a separate trench and shall not be mixed with

electrical power & control cables. Wherever electrical and instrument cables are

routed in the same trench, cable separation requirement between power,

11-21034-1001

control and instrument cables shall be maintained as per SAES-J-902. All

JO/EWO

Underground cable and conduits shall be installed and marked per SAUDI

ARAMCO Standard Drawings AD-036874, AB-036273, AB-036326 and

insulation resistance testing.

30-NOV-22

DATE

4. CONTRACTOR is responsible for complete design of layouts of accessories for

REV. NO.

the cable tray system and conduits. CONTRACTOR shall note that the design

00

DISCIPLINE

does not necessary indicate all required fittings, bends, supports and other

ENGINEER

similar items required for a complete installation.The CONTRACTOR will

MAH finalise the cable tray system design during installation on site

DATE 30 NOV 22

PROJECT

ENGINEER

5. CONTRACTOR shall verify Area Classification Drawings and Schedules during

SAA Construction and install Electrical equipment according to the area

DATE 30 NOV 22 classification.

CERTIFIED

6. CONTRACTOR shall ensure the selected Luminaires are marked, listed or

STD labelled by an independent third-party laboratory while meeting all requirements

DATE 30 NOV 22

of SAUDI ARAMCO Standards.

CONSTRUCTION

AGENCY

7. CONTRACTOR shall provide all the safety precautions for DC UPS Battery and

DATE 01 DEC 22 Battery charger as per SAES-P-103.

OPERATIONS

MIH 8. CONTRACTOR shall comply with the requirements of SAES-P-104, SAES-J-

DATE 05 DEC 22

___________

902, NEC, NEMA, ICS 6, NEMA 250 and IEC 144 for any electrical and/or

electronics equipment installation in hazardous areas.

CONTROL NUMBER

DATE _____________

BY: ______________

VERIFICATION

9. CONTRACTOR shall use single door NEMA Type 4 or IEC 60529 type IP 66

EDSD

Junction Boxes for Class I, Zone 2 locations. CONTRACTOR shall ensure that

all cables are direct buried except entry/exit points of field junction boxes,

panels etc. All conduits shall be galvanized steel with PVC coating or armoured

APPROVAL/CERTIFICATION REQUIREMENTS,

(as required). CONTRACTOR shall carry out all cable/conduit installation work

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

REVISION CERTIFICATE

per National Electrical Code (NEC), SAES-P-104 and SAES-J-902. All non-

THIS INDICATES THAT REV. NO. 00

metallic underground conduits shall have a minimum bending radius

(DCC)NO. 11-21034-1001-001

SCOPE OF WORK DWG.TYPE PLANT .NO INDEX DRAWING NO. SHT. NO. REV. NO.

LSPB SCOPE OF WORK – EAST REMOTE MANIFOLD (ERM) DOC 23

752 A TE-905420

HMYM GCP-4 OF 00

JAFURAH SAUDI ARABIA JO / EWO: 11-21034-1001 49

Rev: R1 DOC CLASS: 4B DSN: 15717

Saudi Aramco 2616-ENG (10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

MIH

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

PMT

conforming to NEC Art 354, Sec. 354.24 and/or as per Vendor cable bending

CERT

radius requirements (most stringent shall apply).

STD

ENG'G

MAA

10. CONTRACTOR shall install lighting as per SAES-P-123.

11. CONTRACTOR shall, supply and install grounding system in accordance with

IEEE80, IEEE 142, ANSI/NFPA 70 (NEC), ANSI C2 and as supplemented or

amended by SAES-P-111, SAES-P-104 and SAES-J-902. SAUDI ARAMCO

Standard Drawing No. DD-950022 Sheet 1/12 shall be used for installation of

DESCRIPTION

grounding rods and necessary inspection points. CONTRACTOR shall test all

the grounding connections for verification of metallic path between all electrical

ISSUED FOR CONSTRUCTION

equipment and ground.

12. All underground cables shall be armoured unless otherwise specified on the

drawings. Care shall be taken to avoid damage to existing underground

facilities during excavation work. If during excavation CONTRACTOR

encounters any pipes, cables, concrete, or other obstructions not indicated on

the drawings, he shall then continue in accordance with subsequent instructions

from the SAUDI ARAMCO representative.

11-21034-1001

JO/EWO

13. CONTRACTOR shall have at the jobsite a responsible Electrical Supervisor,

who is skilled in installation, calibration, pre-commissioning, and commissioning

work.

30-NOV-22

DATE

REV. NO.

14. CONTRACTOR shall be responsible for receiving, transporting, unloading,

00

DISCIPLINE storing, and safeguarding all materials and equipment. He shall provide an

ENGINEER

efficient stock record system to prevent losses. Any damage to equipment

MAH

DATE 30 NOV 22

caused by the CONTRACTOR shall be replaced at the CONTRACTOR’s own

expenses. The CONTRACTOR shall ensure that all materials are stored in a

PROJECT

ENGINEER suitable, secure, dry, and weatherproof structure.

SAA

DATE 30 NOV 22

CERTIFIED

15. CONTRACTOR shall carry out Testing, Pre-commissioning, and

Commissioning of all electrical equipment duly witnessed by Saudi Aramco.

STD

DATE 30 NOV 22

CONSTRUCTION

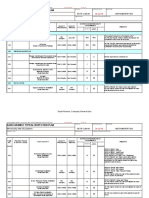

11.2

AGENCY

REFERENCE DOCUMENT LIST

DATE 01 DEC 22

OPERATIONS

Document Number Title

MIH

DATE 05 DEC 22

COMMON DOCUMENTS

___________