0 ratings0% found this document useful (0 votes)

17 viewsUS10301573蜡水分散

US10301573蜡水分散

Uploaded by

ivyhomeCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

US10301573蜡水分散

US10301573蜡水分散

Uploaded by

ivyhome0 ratings0% found this document useful (0 votes)

17 views5 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

17 views5 pagesUS10301573蜡水分散

US10301573蜡水分散

Uploaded by

ivyhomeCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

US010301573B2

(12) United States Patent (10 ) Patent No.: US 10 ,301,573 B2

Shoshany et al. (45) Date of Patent: May 28 , 2019

(54 ) CANDLE WITH WATER IN WAX 3 ,266 ,272 A *

3 ,660 , 128 A *

8/ 1966 Fredericks .................... 431/ 126

5 /1972 Sheldahl ......... 106 /271

(75 ) Inventors: Haggai Shoshany , Kfar Tavor (IL ); 3 ,677, 808 A * 7 /1972 Sheridan ... 106 /660

4 ,622, 118 A * 11/1986 Chimenti et al. ............. 204 / 562

Amnon Shoshani, Caesarea ( IL ) 6 , 066 ,186 A * 5 /2000 Matsumoto ................. ... 44 /301

6 ,864,349 B2 * 3/ 2005 Pavlin et al. ................ 528 /310

( 73 ) Assignee : Smartech Ltd ., Caesarea Industrial 2006 /0100696 A1 * 5 /2006 Atanasoska et al. ........ 623 / 1 .44

Park ( IL ) 2009 /0300969 A1 * 12 /2009 Martin ..... 44 / 301

2014 /0199646 A1* 7 /2014 Beadles .................. C11C 5 /002

( * ) Notice : Subject to any disclaimer, the term ofthis 431 / 288

patent is extended or adjusted under 35 FOREIGN PATENT DOCUMENTS

U . S . C . 154( b ) by 1260 days.

(21) Appl. No.: 12/424, 633 CN

DE

1238147

837916

12 / 1999

5 / 1952

EP 1518917 3 /2005

(22) Filed : Apr. 16 , 2009 58063798 4 / 1983

(65 ) Prior Publication Data OTHER PUBLICATIONS

US 2009/0263756 A1 Oct. 22 , 2009 W Liu , et al. Formation and stability of paraffin oil- in -water

Related U .S . Application Data nano -emulsions prepared by the emulsion inversion point method ,

(60 ) Provisional application No.61/045,329, filed on Apr. Jul. 26 , 2006 , Journal of Colloid and Interface Science , 303 (2006 ).*

16 , 2008 . PCT/GB2007000132: Martin , Water-In - Oil Emulsions, Methods,

and Uses of Emulsiifying Agents, Jan . 18 , 2007. *

(51) Int. Ci. * cited by examiner

F23D 3/ 16 ( 2006 .01)

C11C 5 /00 ( 2006 .01)

(52) CPC

U .S . CI............... C11C 5/ 002 (2013 .01); C11C 5/ 008

Primary Examiner — Avinash A Savani

(74 ) Attorney, Agent, or Firm - Dekel Patent Ltd .; David

(2013 .01) Klein

(58 ) Field of Classification Search

USPC ...... .......... 431/288 , 289; 44 /275 , 280 , 311 (57) ABSTRACT

See application file for complete search history.

(56) References Cited A method for producing a candle shaped from a wax ,

wherein a dispersion of water droplets is purposely added

U .S . PATENT DOCUMENTS within the wax .

2 ,892,732 A * 6 / 1959 Rockland 106 /277

3 , 000 ,753 A 9 / 1961 Rockland 18 Claims, No Drawings

US 10 ,301,573 B2

CANDLE WITH WATER IN WAX In addition , the present invention enables candle users to

reduce their wax consumption thus contributing to the global

CROSS -REFERENCE TO RELATED effort to reduce the emission of greenhouse gases.

APPLICATIONS There is thus provided in accordance with an embodiment

5 of the present invention a method for saving on wax used in

This application claims priority under 35 USC $ 119 to producing a candle, including producing a candle from a

U . S . Provisional Patent Application 61/045 , 329 , filed Apr. wax, wherein a dispersion of water droplets is purposely

16 , 2008 , incorporated herein by reference. added within the wax (e . g ., to replace candle wax by mass ).

In accordance with an embodiment of the present inven

FIELD OF THE INVENTION 10 tion a reference candle is defined as a candle produced from

the wax without addition of water droplets , and wherein the

The present invention relates generally to wax candle candle produced with the water droplets and the reference

manufacture, and particularly to a method formanufacturing candle burn at approximately equal burn rates , burn rate

candles from wax dispersed with water. being defined as total mass loss of candle divided by burn

15 time. (“ Approximately equal” is preferably within a range of

BACKGROUND OF THE INVENTION + 40 % ,preferably + 30 % , more preferably - 20 % ,more pref

erably + 10 % , more preferably 5 % .)

In accordance with an embodiment of the present inven

As is well known in the art , wax, especially paraffin wax , tion a reference candle is defined as a candle produced from

is the main constituent in most candles .

From ancient times, wax has been melted and poured into 20 the wax without addition of water droplets , and wherein

grade points are allotted to the reference and water - contain

molds where it cools and hardens to a desired solid candle ing candles as a function of burn rate, flame size , sputtering,

form . During the 20th century , extrusion and /or press mold flickering, excess smoke , wick clogging , and wick drown

ing of solid wax particles below their melt temperature have ing, and wherein the grade points of the candle produced

become additional major production methods for making 25 with the water droplets differ from the grade points of the

candles. reference candle in a range of 0 - 40 % (or alternatively 0 - 20 %

From the start of the 21st century , due to steep rises in or 0 - 10 % ).

crude oil prices, the cost of paraffin wax has soared . Prices

of all waxes and wax -like products , such as fossil, synthetic DETAILED DESCRIPTION OF EMBODIMENTS

plant and animal waxes, have also soared . There is thus a 30

need in the candle industry to significantly decrease raw It was surprisingly found that one can deliberately add a

material costs . dispersion of small or minutely divided water droplets

One obvious way of decreasing raw material costs is to within the wax and form a candle with consumer - acceptable

reduce the size of the candle. However, there is a relation properties , that is, properties that are not noticeable different

ship between parameters, such as but not limited to , the size 35 from prior art candles that have no water content.

of flame, the type and size of wick , the rate the wax burns, Without limitation , the minutely divided droplets can be

and candle weight which determine the length of time the of a droplet size smaller than 500 microns, preferably

candle burns. Accordingly, reducing the size of the candle smaller than 100 microns , preferably smaller than 50

forces the manufacturer to take steps, such as adjusting the microns, preferably smaller than 25 microns, preferably

properties of the wick and /or flame, in order to maintain the 40 smaller than 10 microns, preferably smaller than 5 microns,

same length of time that the candle burns . In addition , the and preferably smaller than 1 micron , all of which provide

candle manufacturer must take into account various satisfactory results . The water added to the wax can be in the

demands of the consumer, such as but not limited to , size , form of , without limitation , water in wax suspension , emul

weight, burn time, flame properties, etc . There are no easy sion , dispersion , etc . The added water still allows forming a

or obvious solutions to the problems faced by the candle 45 candle with consumer- acceptable properties , such as accept

manufacturer to reduce costs without compromising candle ably low levels of sputtering and /or flickering (or possibly

properties. even no noticeable sputtering and /or flickering ), and enables

A known problem in the prior art is keeping water from manufacturers to maintain desirable candle characteristics ,

being mixed with the wax in the candle manufacture , such such as appearance , volume, weight, flame size and burn

as water that can get trapped in the vicinity of the wick . It 50 time, etc ., while using less wax .

is well known in the prior art that water in the candle wax It was found that up to 50 % water can be incorporated

is undesired and can result in phenomena , such as flame within the wax ; however, best results were achieved using

flickering or sputtering, wick clogging , smoking or others. 0 . 1 - 25 % water (other embodiments use 0 . 1 to 20 % or 30 % ).

Other advantages for incorporation of water in the wax

SUMMARY OF THE INVENTION 55 were noticed . Water dispersed in wax (as a suspension ,

emulsion , dispersion among others ) may enable manufac

The present invention seeks to provide a novelmethod for turers to use higher oil content waxes ( slack waxes, scale

manufacturing candles from wax dispersed with water drop - waxes and/ or blends thereof), thus further reducing raw

lets, as is described more in detail hereinbelow . In direct material costs. Water dispersed in wax enables manufactur

contradistinction to the accepted norms of the prior art, in 60 ers to add water soluble additives in the manufacturing

the present invention water droplets are deliberately added process instead of wax soluble additives . The term “ adding”

to the wax raw material without compromising the quality of encompasses mixing , coating, dissolving , pouring , or any

the candle . Without being limited to any theory of how the other action to make the additive part of the finished candle

invention works , it is believed that the invention succeeds in product.

maintaining candle quality because the water is added as 65 Wax herein encompasses tallow and /or wax of fossil

droplets (small drops ). The small drops blend sufficiently origin , such as but not limited to , paraffin wax ,montan wax ,

well with the wax so as to maintain candle quality. etc ., or of plant origin , such as but not limited to , soy wax,

US 10 ,301,573 B2

etc., or of animal origin , such as but not limited to , bee wax , means that the water-containing candle burns less wax since

fat wax , etc ., or synthetic wax , such as but not limited to , its mass comprises water that has replaced wax .

fisher tropsch wax , polyethylene wax , polypropylene wax , Generally a grade of 6 or higher is acceptable by the

sterine wax , stearic wax , etc . or any other wax - likematerial

consumers of the candle industry .

Without derogating from the aforesaid , wax herein may 5

encompass , without limitation , soft wax , slack wax , scale Example 1

wax , partially refined wax , fully refined wax , oxidized wax ,

bleached wax , unbleached wax , macrocrystalline wax , Tap water was added to molten paraffin wax ( congealing

microcrystalline wax and others. point 58° C .) using a batch high shear mixer ( Ystral equip

Wax blend herein may encompass any combination of at 10 ment ) The water containing wax was poured into tea -lights

least two types of waxes , or any combination of wax and and cooled to room temperatures within about 10 minutes.

other constituents such as but not limited to , oil, etc . Grade results are shown in Table 1 .

The term dispersion is used in the specification and claims TABLE 1

to encompass suspension , emulsion and dispersion, among

other types ofmixtures. 15 Mixing time

" Solution ” herein is defined as a homogenous liquid of Candle Number Mixer RPM [seconds] % water Candle grade

miscible materials in which wax is dissolved in a solvent. 300 reference

The wax is in its molecular or ion form . It is noted that the 301 24000 60 10

weight or volume ratio of the solvent may be 0 . 1 - 99 . 9 % of

the solution . It is also noted that a solution may be formed 20

at an elevated temperature in which the wax is in liquid form Table 1 shows that candles of equivalent performance can

and then used as a solid at room temperature . be achieved in water -containing candles under these terms.

“ Emulsion ” herein is defined as a stable dispersion of Example 2

immiscible materials . It is noted that some water in wax

emulsionsmay require emulsifiers to maintain stability . The 25 Tap water and alcoholic additive was mixed forming a

emulsifiers prevent the water particles from adhering to or solution . The alcohol containing solution was mixed with

merging with themselves. It is noted that an emulsion may molten paraffin wax (congealing point 55° C .) using a batch

be formed at an elevated temperature in which wax is in high sheer mixer ( Ystral Equipment) at various solution

liquid form and then used as a solid at room temperature . loads. The mixing was operated for 45 seconds within a 600

“ Suspension ” herein is defined as a buoyant dispersion of 30 ml candle jar. The mixing was stopped after 45 seconds, a

immiscible materials . It is noted that water in wax suspen - wick was inserted , and the candle jar cooled below the wax ' s

sions may require constant agitation during the manufactur freezing temperature within 20 minutes .

ing process and during storage in order to prevent improper Grade results of the candles are shown in Table 2 :

inclusion such as but not limited to merging, immersion ,

floatage, of the water in the wax . It is noted that a water - 35 TABLE 2

in -wax suspension may be formed at an elevated tempera % alcohol

ture in which wax is in liquid form and then used as a solid Candle Mixing time in the % Candle

at room temperature . Number Mixer RPM [seconds] water water grade

It was surprisingly found that water dispersed in the wax 498 24000 452 10 8

may reduce the wick drowning phenomenon , wherein the 40 499 200451 10

wick leans or falls to drown in the pool of molten wax 500 reference 0 8

resulting in premature extinguishing of the candle flame.

The invention enables the wax candle manufacturer to

manufacture candles at lower costs , using less wax , and still Table 2 shows that water containing candles achieved

maintain quality and standards expected by the consumer 45 equivalent performance to regular candles and that candles

and industry . For example , tea light candles made according with an alcoholic additive improves candle 's performance

to the invention will contain less wax than prior art tea light compared to under these terms.

candles , yet will exhibit qualities expected and accepted by Example 3

the consumer, such as but not limited to , appearance , vol

ume, weight, burn time, and flame size . As another example , 50

candles that are sold by weight ( colored or non - colored , Tap water and wax were mixed using a batch ultrasonic

scented or non -scented , etc . ) and which are made according horn (COLE PALMER Equipment). The ultrasonic horn was

to the invention will contain less wax than their prior art operated at 100 % amplitude for 45 seconds creating sus

counterparts, yet will exhibit qualities expected and pensions . The suspensions were cooled below the wax

congealing point within 30 seconds. The cold suspension

accepted by the consumer, such as but not limited to , 55 and reference candle material were pressed into tea -light

appearance , volume, weight, burn time, and flame size .

The invention may be better understood by the following candles .

non limiting examples : Grade results of the candles are shown in Table 3 :

Grading of candles performance was done comparatively TABLE 3

with reference candles of the same wax composition and 60

similar shape and weight. Maximum grade is 10 . Grade Ultrasonic Mixing Wax

points are lowered if there is someadverse effect as regards amplitude time congealing % Candle

burn rate , sputtering, flickering, flame size , excess smoke , Candle Number [% ] [seconds] point [° C.] water grade

wick clogging, wick drowning, and more . Burn rate is 334 1004555209

calculated as the total mass loss of a candle divided by burn 65 351 reference 5509

time. Therefore , when a water - containing candle and a

reference candle without water burn at the same rate it

US 10 ,301,573 B2

Table 3 shows that ultrasonic mixing produces equivalent Table 6 it shows that fatty acid derivative emulsifier may

performance candles at water content of 20 % under these improve candle performance under these terms.

terms.

Example 7

Example 4

Tap water and wax were mixed using a continuous high

De- ionized water and wax were mixed using a continuous sheer homogenizer (ROSS rotor -stator equipment). The

flow and ultrasonic device (Hielscher Equipment). The made suspensions, and the reference were poured into

ultrasonic device was operated at 100 % amplitude with a tea -light candles, which cooled below their congealing point

booster. The suspensions and reference were poured into 10 within about 10 minutes .

tea -light candles , which cooled below their congealing point Grade results of the candles are shown in Table 7 :

within about 10 minutes .

Grade results of the candles are shown in Table 4 : TABLE 7

TABLE 4 15 Wax congealing point

Candle Number [°C.] % water Candle grade

Ultrasonic Wax congealing Candle 1325 reference 58

Candle Number amplitude [ % ] point [° C . ] % water grade 1332

539 100 + booster 58 15

578 reference 100 + booster 58 09

- 20 Table 7 shows that rotor - stator equipment enables the

production of equivalent candles under these terms.

Table 4 shows that Ultrasonic mixer can continuously It will be appreciated by persons skilled in the art that the

produce water containing waxes of equivalent quality under present invention is not limited by what has been particu

these terms. larly shown and described hereinabove . Rather the scope of

25 the present invention includes both combinations and sub

Example 5 combinations of the features described hereinabove as well

as modifications and variations thereof which would occur

Emulsifiers of the type GMS (Glycerin monostearate ) to a person of skill in the art upon reading the foregoing

were added to molten paraffin waxes using a batch stirrer description and which are not in the prior art .

(Ika Equipment) forming a solution . The emulsifier -contain - 30

ing waxes were mixed with distilled water using a batch What is claimed is :

ultrasonic device (Hielscher equipment) at 45 seconds mix 1. A method for saving on wax used in producing and

ing time. The water-wax emulsions and reference were burning a candle , comprising :

poured to tea -lights which cooled below their congealing producing a candle from a wax , wherein a dispersion of

point within about 10 minutes . water droplets is purposely added within the wax as a

Grade results of the candles are shown in Table 5 : replacement ofwax by mass thereby saving on the wax

TABLE 5 used in producing the candle , wherein a reference

candle is defined as a candle produced from the wax

Wax congealing Emulsifier Candle without addition of water droplets as a replacement of

Candle Number point [ ° C . ) Tuisiner

content [ % ] % water grade 40 wax by mass , and wherein the candle produced with the

1101 reference 56 0 water droplets and the reference candle burn at approxi

1111 56 0.5 10 mately equal burn rates, burn rate being defined as total

1105 56 1.0 10 mass loss of candle divided by burn time, and the

candle produced with the water droplets burns less wax

Table 5 shows thatGMS emulsifier has positive influence to

45 than the reference candle by an amount equal to said

on candle performance under these terms. water droplets .

2 . The method according to claim 1 , wherein the disper

Example 6 sion of water droplets is purposely added within the candle

wax to replace candle wax by mass .

Emulsifiers of fatty acids derivatives type were added to 50 3 . The method according to claim 1 , wherein a reference

molten paraffin waxes using a batch stirrer ( Ika Equipment) candle is defined as a candle produced from the wax without

forming a solution . The emulsifier - containing waxes were addition of water droplets , and wherein grade points are

mixed with tap water using a batch ultrasonic device (Hiel- allotted to the reference and water- containing candles as a

scher Equipment) for 45 seconds mixing time, forming an function of burn rate , flame size, sputtering, flickering ,

emulsion . The water in wax emulsion and the reference were 55 excess smoke , wick clogging, and wick drowning, and

poured into tea-lights which cooled below their congealing wherein the grade points of the candle produced with the

point within about 10 minutes . water droplets differ from the grade points of the reference

Grade results of the candles are shown in Table 6 : candle in a range of 0 - 40 % .

TABLE 6 4 . The method according to claim 1, wherein a reference

60 candle is defined as a candle produced from the wax without

Wax congealing Wax emulsifier Candle addition of water droplets , and wherein grade points are

Candle Number point [°C.] content [% ] % water grade allotted to the reference and water- containing candles as a

1234 0 .5 10 function of burn rate , flame size , sputtering, flickering ,

1237 5610108 excess smoke , wick clogging, and wick drowning , and

1240 reference 56 0 .0 10 ? 65 wherein the grade points of the candle produced with the

water droplets differ from the grade points of the reference

candle in a range of 0 -20 % .

US 10 ,301,573 B2

5 . The method according to claim 1 , wherein a reference 11 . The method according to claim 1, wherein said water

candle is defined as a candle produced from the wax without droplets are smaller than 5 microns.

addition of water droplets, and wherein grade points are 12 . The method according to claim 1 , wherein said water

allotted to the reference and water -containing candles as a

function of burn rate , flame size , sputtering, flickering, 55 droplets are smaller than 1 micron .

13 . The method according to claim 1 , wherein said water

excess smoke, wick clogging , and wick drowning , and droplets are added to the wax as a water-in -wax suspension .

wherein the grade points of the candle produced with the

water droplets differ from the grade points of the reference 14 . The method according to claim 1 , wherein said water

candle in a range of 0 - 10 % . droplets are added to the wax as a water- in -wax emulsion .

6 . The method according to claim 1 , wherein said water 15 . The method according to claim 1, wherein said water

droplets are smaller than 500 microns. droplets are added to the wax as a water-in -wax dispersion .

7 . The method according to claim 1 , wherein said water 16 . The method according to claim 1 , wherein said candle

droplets are smaller than 100 microns. comprises 0 . 1 - 50 % water .

8 . The method according to claim 1, wherein said water 17 . The method according to claim 1 , wherein said candle

droplets are smaller than 50 microns. 15 comprises 0 . 1 - 30 % water.

9. The method according to claim 1, wherein said water 15 18 . The method according to claim 1, wherein said candle

droplets are smaller than 25 microns.

10 . The method according to claim 1 , wherein said water comprises 0 .1 -20 % water.

droplets are smaller than 10 microns.

You might also like

- Handbook of Applied Surface and Colloid Chemistry - Volume 2Document505 pagesHandbook of Applied Surface and Colloid Chemistry - Volume 2Alex Flores Pardo100% (4)

- G-ENPMD318 - Hot Melt Extrusion With BASF Pharma Polymers - Book v2 PDFDocument201 pagesG-ENPMD318 - Hot Melt Extrusion With BASF Pharma Polymers - Book v2 PDFSantosh Kumar Tata100% (1)

- Us8316665 PDFDocument9 pagesUs8316665 PDFnangkarak8201No ratings yet

- United States Patent: Caro Et AlDocument13 pagesUnited States Patent: Caro Et AlmaaathanNo ratings yet

- Us 7112559Document15 pagesUs 7112559Raphael RegaladoNo ratings yet

- United States Patent: Cartier Et AlDocument17 pagesUnited States Patent: Cartier Et AlChoo Wei shengNo ratings yet

- Us 6214778Document9 pagesUs 6214778Andre SantillanaNo ratings yet

- US7968110Document25 pagesUS7968110Rhelvis1No ratings yet

- United States Patent (10) Patent No.: US 7,188.478 B2: Bourgeois (45) Date of Patent: Mar. 13, 2007Document10 pagesUnited States Patent (10) Patent No.: US 7,188.478 B2: Bourgeois (45) Date of Patent: Mar. 13, 2007Mateus GaygerNo ratings yet

- Deodorizing Composition and Method of Forming ThereofDocument5 pagesDeodorizing Composition and Method of Forming Thereofazzrizalz1470No ratings yet

- Us9366187 PDFDocument12 pagesUs9366187 PDFFernando TaleroNo ratings yet

- US7743601Document4 pagesUS7743601Alien GmpNo ratings yet

- Bolas Ver VerDocument6 pagesBolas Ver VerpatgabrielNo ratings yet

- Us 7908972Document23 pagesUs 7908972Abas NjarkhatirNo ratings yet

- US7094341Document31 pagesUS7094341Diego RossoNo ratings yet

- United States Patent: (10) Patent No.: US 8,846,787 B2Document7 pagesUnited States Patent: (10) Patent No.: US 8,846,787 B2marcela walterosNo ratings yet

- United States Patent (10) Patent No.: US 8,102,071 B2Document52 pagesUnited States Patent (10) Patent No.: US 8,102,071 B2Marlon MataNo ratings yet

- Mold CastingDocument22 pagesMold CastingDicky MadikatamaNo ratings yet

- US7381250Document17 pagesUS7381250indoarmy145No ratings yet

- Rheo Diecasting of Al Si PB Immiscible AlloysDocument16 pagesRheo Diecasting of Al Si PB Immiscible AlloysHERNANDEZ1010No ratings yet

- Is So: (12) United States PatentDocument20 pagesIs So: (12) United States PatentСлэйтер Строительная компания100% (1)

- Film ExtrusionDocument16 pagesFilm ExtrusionhatharasingheNo ratings yet

- Silvering ActivatorDocument11 pagesSilvering ActivatorIwan Tejasukmana100% (1)

- United States Patent: Martens Et Al. (45) Date of Patent: Sep. 28, 2004Document13 pagesUnited States Patent: Martens Et Al. (45) Date of Patent: Sep. 28, 2004Sri NurNo ratings yet

- United States Patent (10) Patent No.: US 7.282,100 B1: Schouest Et Al. (45) Date of Patent: Oct. 16, 2007Document15 pagesUnited States Patent (10) Patent No.: US 7.282,100 B1: Schouest Et Al. (45) Date of Patent: Oct. 16, 2007opik24No ratings yet

- US9470251 - Water Activation - SchaubergerDocument12 pagesUS9470251 - Water Activation - SchaubergerZoran ConstantinescuNo ratings yet

- US8628609 Hydrogen Storage TankDocument12 pagesUS8628609 Hydrogen Storage TanksusanNo ratings yet

- US Patent PackingDocument9 pagesUS Patent Packingeng ahmedNo ratings yet

- United States Patent (10) Patent No.: US 7,759,419 B2: Stoffer Et Al. (45) Date of Patent: Jul. 20, 2010Document24 pagesUnited States Patent (10) Patent No.: US 7,759,419 B2: Stoffer Et Al. (45) Date of Patent: Jul. 20, 2010Alexander Franco CastrillonNo ratings yet

- US7255776使用熔融蜡悬浮液的纸制品及其方法Document6 pagesUS7255776使用熔融蜡悬浮液的纸制品及其方法ivyhomeNo ratings yet

- United States Patent (10) Patent No.: US 8.263,231 B2Document13 pagesUnited States Patent (10) Patent No.: US 8.263,231 B2Alexander Franco CastrillonNo ratings yet

- Slurry Reaction AgitatorsDocument10 pagesSlurry Reaction AgitatorsManoj BNo ratings yet

- 1986 - US6536700 - Device For Controlling Optical Fiber Twist On A BobbinDocument13 pages1986 - US6536700 - Device For Controlling Optical Fiber Twist On A Bobbinpgp39262No ratings yet

- US6169135Document13 pagesUS6169135NidaNo ratings yet

- US6200692 (Container)Document8 pagesUS6200692 (Container)cliff hsuNo ratings yet

- US6699426Document16 pagesUS6699426Muhammed BALIKÇINo ratings yet

- Wear TestDocument8 pagesWear TestHussain AgaNo ratings yet

- US99254019 (US Patent - Cold Spill Protection - Catch Basin Fire Suppersion - FOAMGLAS)Document12 pagesUS99254019 (US Patent - Cold Spill Protection - Catch Basin Fire Suppersion - FOAMGLAS)a.h.saberbaghban001No ratings yet

- United States Patent: GuirgisDocument11 pagesUnited States Patent: Guirgisamd mhmNo ratings yet

- US8574476Document11 pagesUS8574476王雪梅No ratings yet

- United States Patent: (12) (10) Patent No.: US 9,605,188 B2Document10 pagesUnited States Patent: (12) (10) Patent No.: US 9,605,188 B2peter shiNo ratings yet

- Us 9050873Document24 pagesUs 9050873Julius RojoNo ratings yet

- US7837970Document24 pagesUS7837970Shoot DieselNo ratings yet

- SKX (E.g. As: (12) United States Patent (10) Patent No.: US 6,626,712 B1Document9 pagesSKX (E.g. As: (12) United States Patent (10) Patent No.: US 6,626,712 B1shruti kapseNo ratings yet

- US8069593Document9 pagesUS8069593PUVAN TSTNo ratings yet

- US6982072 Patent H2o2Document9 pagesUS6982072 Patent H2o2zibaNo ratings yet

- US8663343 - Method For Manufacturing An Emulsified FuelDocument9 pagesUS8663343 - Method For Manufacturing An Emulsified FuelMichael MedinaNo ratings yet

- United States Patent (10) Patent No.: US 7,939.469 B2Document6 pagesUnited States Patent (10) Patent No.: US 7,939.469 B2live streamNo ratings yet

- United States Patent (10) Patent No.: US 8,584,752 B2Document17 pagesUnited States Patent (10) Patent No.: US 8,584,752 B2M FNo ratings yet

- United States Patent (10) Patent N6. US 8,117,852 B2Document7 pagesUnited States Patent (10) Patent N6. US 8,117,852 B2digecaNo ratings yet

- US6602404Document15 pagesUS6602404victor japposanNo ratings yet

- US8034246 PatentDocument9 pagesUS8034246 PatentCatalina SarriaNo ratings yet

- United States Patent (10) Patent No.: US 6,685,832 B2: Mahendran Et Al. (45) Date of Patent: Feb. 3, 2004Document31 pagesUnited States Patent (10) Patent No.: US 6,685,832 B2: Mahendran Et Al. (45) Date of Patent: Feb. 3, 2004Vansala GanesanNo ratings yet

- US11311473Document49 pagesUS11311473JayNo ratings yet

- Grenzebach Patent 2005Document8 pagesGrenzebach Patent 2005Muhammed BALIKÇINo ratings yet

- Adsorption 5ADocument9 pagesAdsorption 5ANguyễn Thị Kim PhượngNo ratings yet

- Hot-Melt Adhesive That Has Good Open Time at Room Temperature and Can Form Creep-Resistant BondsDocument8 pagesHot-Melt Adhesive That Has Good Open Time at Room Temperature and Can Form Creep-Resistant BondsCaio OliveiraNo ratings yet

- Us Patent SPRFDocument19 pagesUs Patent SPRFAbhishek DubeyNo ratings yet

- APEX US9049942 Movable BedDocument12 pagesAPEX US9049942 Movable BedbudituxNo ratings yet

- Fast Demould Extended Cream Time Pu Formulations US8618014Document9 pagesFast Demould Extended Cream Time Pu Formulations US8618014Gagan JainNo ratings yet

- United States Patent (10) Patent No.: Us 7,806,624 B2: Mclean Et Al. (45) Date of Patent: Oct. 5, 2010Document22 pagesUnited States Patent (10) Patent No.: Us 7,806,624 B2: Mclean Et Al. (45) Date of Patent: Oct. 5, 2010George ClooneyNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic Ceramics IIFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic Ceramics IIMihails KusnezoffNo ratings yet

- US7144454防水蜡悬浮液配方Document4 pagesUS7144454防水蜡悬浮液配方ivyhomeNo ratings yet

- US20160168439A1蜡基胶体分散体的相变材料及其制备方法Document27 pagesUS20160168439A1蜡基胶体分散体的相变材料及其制备方法ivyhomeNo ratings yet

- US7255776使用熔融蜡悬浮液的纸制品及其方法Document6 pagesUS7255776使用熔融蜡悬浮液的纸制品及其方法ivyhomeNo ratings yet

- US8834623木制品防水蜡配方Document4 pagesUS8834623木制品防水蜡配方ivyhomeNo ratings yet

- US8912275Document4 pagesUS8912275ivyhomeNo ratings yet

- US8663385防水蜡配方Document4 pagesUS8663385防水蜡配方ivyhomeNo ratings yet

- Classification of ColloidsDocument5 pagesClassification of ColloidsSaria JabeenNo ratings yet

- Carbon Black Fundamentals 041206Document8 pagesCarbon Black Fundamentals 041206gems_gce074325No ratings yet

- Milk Powder IIDocument25 pagesMilk Powder IINamraNo ratings yet

- Guo Et Al 2024 Chitin Nanofibers Enable The Colloidal Dispersion of Carbon Nanomaterials in Aqueous Phase and HybridDocument14 pagesGuo Et Al 2024 Chitin Nanofibers Enable The Colloidal Dispersion of Carbon Nanomaterials in Aqueous Phase and HybridJean JeanoNo ratings yet

- Experiment 4:5 Lab ReportDocument6 pagesExperiment 4:5 Lab ReportHannah GonzalesNo ratings yet

- Applied Auditing Solution Manual Ngina Escala AsuncionDocument10 pagesApplied Auditing Solution Manual Ngina Escala Asuncionariolacharmaine06No ratings yet

- Unit 1 Physical Pharmaceutics 4th Sem MCQDocument37 pagesUnit 1 Physical Pharmaceutics 4th Sem MCQPankaj Chaurasiya50% (2)

- Wet Compounding With Pyrolytic Carbon Black From Waste Tyre For Manufacture of New TyDocument11 pagesWet Compounding With Pyrolytic Carbon Black From Waste Tyre For Manufacture of New TyDimpi PatelNo ratings yet

- Surface Chemistry Final RevisionDocument3 pagesSurface Chemistry Final RevisionROWA new year CelebrationNo ratings yet

- Surface Chemistry-01-Theory-1Document29 pagesSurface Chemistry-01-Theory-1Raju SinghNo ratings yet

- Pigment DisperDocument11 pagesPigment Disperalfosoa5505100% (1)

- Ferrofluids. Magnetically Controllable Fluids and Their Applications S. OdenbachDocument255 pagesFerrofluids. Magnetically Controllable Fluids and Their Applications S. OdenbachrobertNo ratings yet

- Dispersion and AggregationDocument17 pagesDispersion and AggregationDuc Anh NguyenNo ratings yet

- Application of ColliodsDocument19 pagesApplication of ColliodsCeya JoseNo ratings yet

- 12th Lab Manual Chem - 230126 - 105102Document145 pages12th Lab Manual Chem - 230126 - 105102Tarun SamantaNo ratings yet

- Martins Physical Pharmacy and Pharmaceutical Sciences, 6th Edition (Kazirhut - Com) - 420-429Document10 pagesMartins Physical Pharmacy and Pharmaceutical Sciences, 6th Edition (Kazirhut - Com) - 420-429Amna HamidNo ratings yet

- NASA Test6Document11 pagesNASA Test6孔祥宇No ratings yet

- Lesson-08 ColloidsDocument20 pagesLesson-08 ColloidsTeachingTrainingCoaching KnowledgeSharingSessionNo ratings yet

- COARSE DISPERSIONS ReviewedDocument80 pagesCOARSE DISPERSIONS ReviewedThando ComeNo ratings yet

- Colloids - Class 12 Chemistry Investigatory Project Free PDF DownloadDocument8 pagesColloids - Class 12 Chemistry Investigatory Project Free PDF DownloadtharunNo ratings yet

- AGITATORS Brochure TacminaDocument12 pagesAGITATORS Brochure TacminaSantoshkota123No ratings yet

- QuizletDocument2 pagesQuizletAngel GoNo ratings yet

- Boxall Et Al - 2010Document7 pagesBoxall Et Al - 2010suzannypaivaNo ratings yet

- XiGo Note 112 Pharma and The Acorn AreaDocument3 pagesXiGo Note 112 Pharma and The Acorn Areaprakush01975225403No ratings yet

- Hydrothermal SynthesisDocument10 pagesHydrothermal SynthesisPam S. PowellNo ratings yet

- Use Pharmaceutical Calculation Techniques and TerminologiesDocument62 pagesUse Pharmaceutical Calculation Techniques and TerminologiesKena Samuel86% (7)

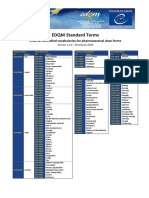

- Standard Terms Internal Vocabularies For Pharmaceutical Dose FormsDocument7 pagesStandard Terms Internal Vocabularies For Pharmaceutical Dose FormsJose De La Cruz De La ONo ratings yet