DuPont FilmTec Seamaxx 440 L

DuPont FilmTec Seamaxx 440 L

Uploaded by

ventas.benyiCopyright:

Available Formats

DuPont FilmTec Seamaxx 440 L

DuPont FilmTec Seamaxx 440 L

Uploaded by

ventas.benyiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

DuPont FilmTec Seamaxx 440 L

DuPont FilmTec Seamaxx 440 L

Uploaded by

ventas.benyiCopyright:

Available Formats

Product Data Sheet

FilmTec™ Seamaxx™-440 Element

Seawater Reverse Osmosis Element

Description DuPont Water Solutions offers various premium seawater reverse osmosis (SWRO)

elements designed to reduce capital and operation cost of desalination systems.

FilmTec™ Elements combine premium membrane quality with automated precision

fabrication resulting in outstanding performance, reliability and robustness.

FilmTec™ Seamaxx™-440 Elements are the choice for seawater systems operating at

low to medium levels of salinity and temperature, as well as for brackish water with

relatively high salinity. The element’s flowrate is significantly above flowrates of any

other SWRO element currently available in the market. This extraordinary high element

productivity leads to substantial savings, primarily in energy consumption when

compared to conventional low-energy SWRO products. In addition,

FilmTec™ Seamaxx™-440 includes the typical FilmTec™ Element features:

l The 28-mil feed spacer combines low differential pressure with low cleaning

frequency and high cleaning efficiency.

l The oxidative-free membrane manufacturing process results in high membrane

robustness and long-term stable performance.

l The widest pH range for cleanings (pH 1 – 13) allows effective cleanings even in

cases of severe fouling.

l The automated, precision fabrication gives a greater number of shorter membrane

leaves thus reducing fouling while maximizing element efficiency.

FilmTec™ Seamaxx™-440 Elements are tested on flow and rejection performance using

a standard test at 600 psi. Potential defects in element construction are detected and

elements which do not comply with the quality protocol are discarded. A 600-psi standard

test was introduced to specifically account for the high permeability of this seawater

element. The results of standard tests performed at 600 psi and 8% recovery are different

from the nominal performance condition of 800 psi and 8% recovery. The test conditions

for the Certificate of Analysis are defined in the table below.

Product Type Spiral-wound element with polyamide thin-film composite membrane.

Page 1 of 4 Form No. 45-D00689-en, Rev. 0

August 2019

Typical Properties of Standard Test performed at 600 psi (4.1 MPa)

Active

Area Feed Spacer Permeate Flowrate Stabilized Boron Stabilized Salt

FilmTec™ Element (ft 2) (m2) Thickness (mil) (gpd) (m3/d) Rejection Rejection (%)

Seamaxx™-440 440 41 28 9,050 34.2 81.8 99.47

1. The above values are based on the following test conditions: 32,000 ppm NaCl, 600 psi (4.1 MPa), 77°F

(25°C), pH 8, 8% recovery.

2. Permeate flows for individual elements may vary ± 15%.

3. Minimum Salt Rejection is 99.25%.

4. Stabilized salt rejection is generally achieved within 24 – 48 hours of continuous use; depending upon

feedwater characteristics and operating conditions.

5. Product specifications may vary slightly as improvements are implemented.

6. Specific boron stabilized rejection based on the following test conditions: 32,000 ppm NaCl, 5 ppm boron,

600 psi (4.1 MPa), 77°F (25°C), pH 8, 8% recovery.

7. Active area guaranteed ± 5%. Active area as stated by DuPont Water Solutions is not comparable to the

nominal membrane area figure often stated by some element suppliers.

Expected Properties and Performance at Common Standard Test Conditions:

800 psi (5.5 MPa)

Active

Area Feed Spacer Permeate Flowrate Stabilized Boron Stabilized Salt

FilmTec™ Element (ft 2) (m2) Thickness (mil) (gpd) (m3/d) Rejection (%) Rejection (%)

Seamaxx™-440 440 41 28 17,000 64.4 89 99.70

1. The above values are normalized from the 600-psi specification standard test to the following conditions:

32,000 ppm NaCl, 800 psi (5.5 MPa), 77°F (25°C), pH 8, 8% recovery. Due to the very high permeability of

FilmTec™ Seamaxx™-440 Elements, they are not tested at the typical feed pressure for standard test

conditions of 800 psi, but at a lower feed pressure of 600 psi. This allows to standard test the element

within its operating guidelines.

2. Permeate flows for individual elements may vary ± 15%.

3. Minimum Salt Rejection is 99.58%.

4. Specific boron stabilized rejection based on the following normalization conditions: 32,000 ppm NaCl,

5 ppm boron, 800 psi (5.5 MPa), 77°F (25°C), pH 8, 8% recovery.

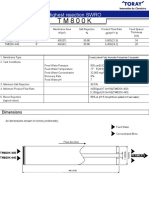

Element

Dimensions

Dimensions – inches (mm) 1 inch = 25.4 mm

A B C

FilmTec™ Element (in) (mm) (in) (mm) (in) (mm)

Seamaxx™-440 40.0 1,016 1.125 ID 29 ID 7.9 201

1. Refer to FilmTec™ Design Guidelines for multiple-element systems of 8-inch elements

(Form No. 45-D01695-en).

2. Element to fit nominal 8-inch (203-mm) I.D. pressure vessel.

Page 2 of 4 Form No. 45-D00689-en, Rev. 0

August 2019

Operating and Maximum Operating Pressure and Temperature a, b 1,000 psig (69 bar) at T < 35°C

900 psig (62 bar) at T = 35 – 45°C

Cleaning Limits

Maximum Element Pressure Drop 15 psig (1.0 bar)

pH Range

Continuous Operation c 2 – 11

Short-term Cleaning (30 min) d 1 – 13

Maximum Feed Silt Density Index (SDI) SDI 5

Free Chlorine Tolerance e < 0.1 ppm

a. The limits for feed pressure and temperature cover the typical operations.

b. Consult your DuPont representative for advice on applications above 95°F (35°C). Refer to FilmTec™

Elements Operating Limits (Form No. 45-D00691) for warranty-voiding conditions and additional

information.

c. Maximum temperature for continuous operation above pH 10 is 95°F (35°C).

d. Refer to guidelines in Cleaning Guidelines (Form No. 45-D01696-en) for more information.

e. Under certain conditions, the presence of free chlorine and other oxidizing agents will cause premature

membrane failure. Since oxidation damage is not covered under warranty, DuPont Water Solutions

recommends removing residual free chlorine by pretreatment prior to membrane exposure. Please refer to

Dechlorinating Feedwater (Form No. 45-D01569-en) for more information.

Additional Before use or storage, review these additional resources for important information:

Important l Usage Guidelines for FilmTec™ 8” Elements (Form No. 45-D01706-en)

l Start-Up Sequence (Form No. 45-D01609-en)

Information

l Storage and Shipping of New FilmTec™ Elements (Form No. 45-D01633-en)

Product DuPont has a fundamental concern for all who make, distribute, and use its products, and

Stewardship for the environment in which we live. This concern is the basis for our product stewardship

philosophy by which we assess the safety, health, and environmental information on our

products and then take appropriate steps to protect employee and public health and our

environment. The success of our product stewardship program rests with each and every

individual involved with DuPont products—from the initial concept and research, to

manufacture, use, sale, disposal, and recycle of each product.

Customer Notice DuPont strongly encourages its customers to review both their manufacturing processes

and their applications of DuPont products from the standpoint of human health and

environmental quality to ensure that DuPont products are not used in ways for which they

are not intended or tested. DuPont personnel are available to answer your questions and to

provide reasonable technical support. DuPont product literature, including safety data

sheets, should be consulted prior to use of DuPont products. Current safety data sheets are

available from DuPont.

Please be aware of the following:

l The use of this product in and of itself does not necessarily guarantee the removal

of cysts and pathogens from water. Effective cyst and pathogen reduction is

dependent on the complete system design and on the operation and maintenance

of the system.

l Permeate obtained from the first hour of operation should be discarded.

Regulatory Note This product may be subject to drinking water application restrictions in some countries;

please check the application status before use and sale.

Page 3 of 4 Form No. 45-D00689-en, Rev. 0

August 2019

Lenntech

info@lenntech.com

info@lenntech .com Tel. +31-152-610-900

Tel. +31-152-610-900

www.lenntech.com

www.lenntech.com Fax. +31-152-616-289

Fax. +31-152-616-289

Have a question? Contact us at: All information set forth herein is for informational purposes only. This information is general information and may differ from that based

on actual conditions. Customer is responsible for determining whether products and the information in this document are appropriate for

Customer's use and for ensuring that Customer's workplace and disposal practices are in compliance with applicable laws and other

government enactments. The product shown in this literature may not be available for sale and/or available in all geographies where

DuPont is represented. The claims made may not have been approved for use in all countries. Please note that physical properties may

vary depending on certain conditions and while operating conditions stated in this document are intended to lengthen product lifespan

and/or improve product performance, it will ultimately depend on actual circumstances and is in no event a guarantee of achieving any

specific results. DuPont assumes no obligation or liability for the information in this document. References to “DuPont” or the “Company”

mean the DuPont legal entity selling the products to Customer unless otherwise expressly noted. NO WARRANTIES ARE GIVEN; ALL

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED. No

freedom from infringement of any patent or trademark owned by DuPont or others is to be inferred.

DuPont™, the DuPont Oval Logo, and all trademarks and service marks denoted with ™, ℠ or ® are owned by affiliates of DuPont de

Nemours Inc. unless otherwise noted. © 2020 DuPont.

Page 4 of 4 Form No. 45-D00689-en, Rev. 0

August 2019

You might also like

- Brine Calculator User ManualDocument20 pagesBrine Calculator User Manualankitsaxena123100% (2)

- Filmtec Hsro 390 FF Pds 45 d01701 enDocument3 pagesFilmtec Hsro 390 FF Pds 45 d01701 enGunwant VarmaNo ratings yet

- Membrana Filmtec Sw30xle-400iDocument3 pagesMembrana Filmtec Sw30xle-400iBuenaventura Jose Huamani TalaveranoNo ratings yet

- DOW FILMTEC™ ECO Line RO Elements: Product DatasheetDocument2 pagesDOW FILMTEC™ ECO Line RO Elements: Product DatasheetakbarNo ratings yet

- FilmTec Hypershell Dairy Membranes PDS 45 D00720 enDocument4 pagesFilmTec Hypershell Dairy Membranes PDS 45 D00720 enMauricio ChiNo ratings yet

- Hsro 390 FFDocument3 pagesHsro 390 FFAlejandro OdioNo ratings yet

- FILMTEC™ MembranesDocument2 pagesFILMTEC™ MembranesSamir BensitouahNo ratings yet

- Membrane SW30XLE-440iDocument3 pagesMembrane SW30XLE-440iecrNo ratings yet

- Ag HR Seri S: High Rejection Brackish Water RO ElementsDocument2 pagesAg HR Seri S: High Rejection Brackish Water RO ElementsPraveen KumarNo ratings yet

- FilmTec BW30XHR PRO 440 PDS 45 D03750 enDocument2 pagesFilmTec BW30XHR PRO 440 PDS 45 D03750 enMasoud AmirzadehfardNo ratings yet

- TM 800 ADocument2 pagesTM 800 Ama_princess7840No ratings yet

- Datasheet LG SW 400 SR G2 ENGDocument1 pageDatasheet LG SW 400 SR G2 ENGMohamed MotaweaNo ratings yet

- Datasheet SWRO 01.10.20Document6 pagesDatasheet SWRO 01.10.20marioNo ratings yet

- Hydranautics SWC5-LD (PW)Document1 pageHydranautics SWC5-LD (PW)mahdi rasoulianNo ratings yet

- Toray TM820V 400 Sea Water RO Element LDocument2 pagesToray TM820V 400 Sea Water RO Element LLuzmaNo ratings yet

- Microdyn Ro SWLDocument2 pagesMicrodyn Ro SWLgulfengsolutionsNo ratings yet

- Swro TM800KDocument2 pagesSwro TM800KthanhhuyenNo ratings yet

- AP Seri S: Extreme Low Pressure Brackish Water RO ElementsDocument1 pageAP Seri S: Extreme Low Pressure Brackish Water RO ElementshermanNo ratings yet

- 1.14 SW30HR-LE400iDocument2 pages1.14 SW30HR-LE400iMed Ait MndNo ratings yet

- Hsro 4040 FFDocument3 pagesHsro 4040 FFAlejandro OdioNo ratings yet

- CRP 100NDocument2 pagesCRP 100NbaharehestekiNo ratings yet

- FilmTec SW30XHR 440 PDS 45 D00970 enDocument2 pagesFilmTec SW30XHR 440 PDS 45 D00970 enAndri Sanjaya SembiringNo ratings yet

- SWC4 LDDocument1 pageSWC4 LDJUANNo ratings yet

- 700 Series Portable: Reverse Osmosis System 650 To 2600 Ml/minDocument2 pages700 Series Portable: Reverse Osmosis System 650 To 2600 Ml/mineduardoNo ratings yet

- Filmtec™ Soar 7000I Element: Product Data SheetDocument3 pagesFilmtec™ Soar 7000I Element: Product Data Sheetali jafNo ratings yet

- Microdyn Ro XleDocument2 pagesMicrodyn Ro XlegulfengsolutionsNo ratings yet

- FilmTec BW30XHR PRO 400 34 PDS 45 D03749 enDocument2 pagesFilmTec BW30XHR PRO 400 34 PDS 45 D03749 enmshahid305655No ratings yet

- TM700D Series: High-Rejection Brackish Water Reverse Osmosis Membrane Element With Enhanced Chemical ToleranceDocument2 pagesTM700D Series: High-Rejection Brackish Water Reverse Osmosis Membrane Element With Enhanced Chemical ToleranceKeily VilcarromeroNo ratings yet

- Microdyn Ro BWDocument2 pagesMicrodyn Ro BWgulfengsolutionsNo ratings yet

- Dairy Pro Ro and NF Polishing Elements PDFDocument2 pagesDairy Pro Ro and NF Polishing Elements PDFAsepNo ratings yet

- Toray TM820M 440 - Spec - SheetDocument2 pagesToray TM820M 440 - Spec - SheetJoselito CortesNo ratings yet

- BW30HR-440i - MembranaDocument2 pagesBW30HR-440i - Membranaclaudia gonzalesNo ratings yet

- hp228 Series Element Upgrade DatasheetDocument2 pageshp228 Series Element Upgrade DatasheetJovMac ManzanoNo ratings yet

- Membrana RO Industrial 4x40 y 8x40Document2 pagesMembrana RO Industrial 4x40 y 8x40luisNo ratings yet

- Data Sheet - BW30-PRO-400Document2 pagesData Sheet - BW30-PRO-400satheesh kumarNo ratings yet

- Lfc3-Ld: Specified PerformanceDocument1 pageLfc3-Ld: Specified PerformanceLuqmanNo ratings yet

- Swc5-Ld: Specified PerformanceDocument1 pageSwc5-Ld: Specified PerformanceBenjamin MillerNo ratings yet

- SWC5 LDDocument1 pageSWC5 LDAhmed AzabNo ratings yet

- Hydranautics Cpa6-Ld (DW)Document1 pageHydranautics Cpa6-Ld (DW)mahdi rasoulianNo ratings yet

- Hsro 390 FFDocument3 pagesHsro 390 FFsales.dowtecindonesiaNo ratings yet

- Filmtec SW30-8040Document2 pagesFilmtec SW30-8040PT Deltapuro IndonesiaNo ratings yet

- System ManualDocument14 pagesSystem ManualCareers SSPNo ratings yet

- CPA3Document1 pageCPA3Imran Ahmed KhanNo ratings yet

- HF 760 - HF 761 Series: in Line High Pressure FiltersDocument28 pagesHF 760 - HF 761 Series: in Line High Pressure FilterssitnikovsNo ratings yet

- Transaqua - HT2 TDSDocument6 pagesTransaqua - HT2 TDSFerri AguswanNo ratings yet

- Filmtec SW30HRLE-400Document3 pagesFilmtec SW30HRLE-400PT Deltapuro IndonesiaNo ratings yet

- DOW FILMTEC™ SW30HRLE-400 Element: DescriptionDocument3 pagesDOW FILMTEC™ SW30HRLE-400 Element: Descriptiongvnks90No ratings yet

- FSsmEGGSeries ENDocument1 pageFSsmEGGSeries ENivanyanez0709No ratings yet

- ChemflakeDocument5 pagesChemflakeManohar SeetharamNo ratings yet

- Brayco Micronic™ SV/B: DescriptionDocument5 pagesBrayco Micronic™ SV/B: DescriptionAlfonsus W.M.No ratings yet

- Espa1: Specified PerformanceDocument1 pageEspa1: Specified PerformanceBerlin TirtaNo ratings yet

- Cpa5 LDDocument1 pageCpa5 LDleisurely.dpgNo ratings yet

- Espa2-Ld Max: Specified PerformanceDocument1 pageEspa2-Ld Max: Specified PerformanceHaseebNo ratings yet

- Eccoh 5836 TDS01 2018-10Document2 pagesEccoh 5836 TDS01 2018-10bobNo ratings yet

- DOW FILMTEC™ SW30HR-380 Element: DescriptionDocument3 pagesDOW FILMTEC™ SW30HR-380 Element: DescriptionAnonymous zUsOCUNo ratings yet

- FilmTec Heat Sanitizable PDS 45 D01511 enDocument4 pagesFilmTec Heat Sanitizable PDS 45 D01511 enali jafNo ratings yet

- Mar Cor: 700 Series Portable Medical DeviceDocument2 pagesMar Cor: 700 Series Portable Medical Deviceعايد التعزيNo ratings yet

- Pro XP1Document2 pagesPro XP1sunil patelNo ratings yet

- Hsro-390-Ff & Hsro-4040-FfDocument2 pagesHsro-390-Ff & Hsro-4040-FfYasser Mahmoud ZiadaNo ratings yet

- Filmtec BW30-400-IGDocument2 pagesFilmtec BW30-400-IGPT Deltapuro IndonesiaNo ratings yet

- Double Pass Operating ManualDocument12 pagesDouble Pass Operating ManualNorrelle Joy MagbanuaNo ratings yet

- Conducting A Water QualityDocument10 pagesConducting A Water QualityPrashansa ShresthaNo ratings yet

- GVT-ODIS-SWRO For PBMC PDFDocument35 pagesGVT-ODIS-SWRO For PBMC PDFSwati BhattacharyyaNo ratings yet

- Automation and Controls Engineer or Electrical EngineerDocument4 pagesAutomation and Controls Engineer or Electrical Engineerapi-121402780No ratings yet

- Water Treatment For HemodialysisDocument8 pagesWater Treatment For HemodialysisCristian FarinaNo ratings yet

- Water Desalination 2016/2017: For 3 Grade, Mechanical Power EngineeringDocument7 pagesWater Desalination 2016/2017: For 3 Grade, Mechanical Power EngineeringAhmed Mohamed GadoNo ratings yet

- Biofilm RemovalDocument5 pagesBiofilm Removaledo wijayantoNo ratings yet

- Pursuit Manual RO + UVDocument8 pagesPursuit Manual RO + UVOvee Maidul IslamNo ratings yet

- Pilot StudyDocument10 pagesPilot StudyNorsiah ShukeriNo ratings yet

- Momentum Transfer FiltrationDocument76 pagesMomentum Transfer FiltrationMinjdeDiosNo ratings yet

- AXEON WaterDocument2 pagesAXEON WaterJoannaNo ratings yet

- 07 Unit Operations in Food ProcessingDocument36 pages07 Unit Operations in Food ProcessingAlex Samuel Silva75% (4)

- CSM-CV Single and Multistage PumpsDocument20 pagesCSM-CV Single and Multistage PumpsNavinNo ratings yet

- Senior Process Engineer - IDE NoidaDocument3 pagesSenior Process Engineer - IDE NoidamaniyarasanNo ratings yet

- Internship Report..Muhammad Musaddaq MasoodDocument46 pagesInternship Report..Muhammad Musaddaq MasoodMusaddiq Masood83% (6)

- Water Treatment For Green Hydrogen What You Need To Know 1672466456Document16 pagesWater Treatment For Green Hydrogen What You Need To Know 1672466456Alexander FuglesangNo ratings yet

- Babcock EICDocument2 pagesBabcock EICsl73No ratings yet

- Laboratory Manual For WastewaterDocument385 pagesLaboratory Manual For Wastewaterabulyalee50% (2)

- OJT Case StudyDocument17 pagesOJT Case StudyClaudine Cabico ValdezNo ratings yet

- UF and RO For Recovery and Reuse of Wastewater in Thermal Power Project... by Bhaskar Sengupta, Development Consultants (DC)Document4 pagesUF and RO For Recovery and Reuse of Wastewater in Thermal Power Project... by Bhaskar Sengupta, Development Consultants (DC)Mayur SharmaNo ratings yet

- Project ReportDocument64 pagesProject ReportNavdeep Khokhar100% (1)

- Ultra Tec Water Technologies L.L.C Dubai (Profile)Document16 pagesUltra Tec Water Technologies L.L.C Dubai (Profile)Anonymous yElIOalbNo ratings yet

- Us20090050558a1-Process For Producing CompositeDocument13 pagesUs20090050558a1-Process For Producing Compositesahar vahdatifarNo ratings yet

- Index Practical Guide To Thermal Power Station ChemistryDocument21 pagesIndex Practical Guide To Thermal Power Station ChemistrysoumitrabanNo ratings yet

- Ion Exchange (India) Ltd. (IEIL) - Detailed ReportDocument46 pagesIon Exchange (India) Ltd. (IEIL) - Detailed Reportsujal jhaNo ratings yet

- D17384 2Document116 pagesD17384 2Brandon ArceNo ratings yet

- Present and Future. Water InternationalDocument13 pagesPresent and Future. Water Internationalvictoroliveirah2o2No ratings yet

- Maintenance of Water SystemDocument0 pagesMaintenance of Water SystemPanchai PanjindaNo ratings yet

- Drinking Water SolutionsDocument16 pagesDrinking Water SolutionsLiviu SomesanNo ratings yet