Professional Documents

Culture Documents

01 Introduction Bluevison NG V1 07

01 Introduction Bluevison NG V1 07

Uploaded by

Abdul MuksithCopyright:

Available Formats

You might also like

- MTU 4000 Maintenance ScheduleDocument35 pagesMTU 4000 Maintenance Schedulenereomad100% (8)

- Mtu Sam & Adec E532304 - 00eDocument216 pagesMtu Sam & Adec E532304 - 00ecampioed85% (13)

- MTU 4000 With MIP v1.8Document23 pagesMTU 4000 With MIP v1.8Aurelio Serrano100% (2)

- MtuDocument464 pagesMtuDarin Hood100% (13)

- Manual MTUDocument134 pagesManual MTUjuan pablo zuniga100% (2)

- System Documentation: Electronics Electronic Engine Control Unit Ecu 9 Application: Genset Series 2000 Gx6Document198 pagesSystem Documentation: Electronics Electronic Engine Control Unit Ecu 9 Application: Genset Series 2000 Gx6Minh Le100% (1)

- MDEC Stationary DieselDocument5 pagesMDEC Stationary DieselAhmad Shahrul Mohamed100% (2)

- E532284 - Funcional Descrition MtuDocument42 pagesE532284 - Funcional Descrition MtuNippur de Lagash100% (1)

- Field Automation Level Assembly CatalogDocument254 pagesField Automation Level Assembly CatalogAbdul Khaliq100% (1)

- Mtu 4000 Water Pump DismantleDocument93 pagesMtu 4000 Water Pump Dismantlesxturbo100% (1)

- Mtu 1600 1600G 00 Parts Catalog 154pagesDocument154 pagesMtu 1600 1600G 00 Parts Catalog 154pagesertl100% (1)

- Maintenance Schedule: Diesel Engine EPA V 4000 Mx3 V 4000 Mx3 X Application Group 1ADocument79 pagesMaintenance Schedule: Diesel Engine EPA V 4000 Mx3 V 4000 Mx3 X Application Group 1AshashirajNo ratings yet

- 4000 G OverhoolDocument745 pages4000 G Overhoolaup100% (2)

- MTU Technical DocumentationDocument157 pagesMTU Technical DocumentationAhmadTaufikMurad100% (3)

- E531827 00E CAN FieldbusDocument46 pagesE531827 00E CAN Fieldbusarcangel_pic100% (1)

- MTU Engine 4000-Series Functional DescriptionDocument42 pagesMTU Engine 4000-Series Functional DescriptionAlex100% (1)

- Mtu 1600 Operating InstructionsDocument134 pagesMtu 1600 Operating InstructionsGerman O.No ratings yet

- ADEC Advancet Diesel Engine Controller For BR 4000 and BR 2000 Generator Application MTU PDFDocument49 pagesADEC Advancet Diesel Engine Controller For BR 4000 and BR 2000 Generator Application MTU PDFaup100% (4)

- 12v2000 CR OperatingDocument170 pages12v2000 CR OperatingANDREA100% (4)

- Error Code ECU8Document16 pagesError Code ECU8Giang DoNo ratings yet

- Engine Control Unit Type ECU 4/G: MTU/DDC Series 4000 Genset ApplicationsDocument62 pagesEngine Control Unit Type ECU 4/G: MTU/DDC Series 4000 Genset ApplicationsGeorge Barsoum100% (3)

- PrachFreqAdjSwitch - Trial ReportDocument16 pagesPrachFreqAdjSwitch - Trial ReportMunir AlamNo ratings yet

- Day 1 - Chris Sivertz - S2C2 SatcomDocument55 pagesDay 1 - Chris Sivertz - S2C2 SatcomEkrem ErginNo ratings yet

- Farmers First FormatDocument9 pagesFarmers First FormatAkhil ANo ratings yet

- Adec Advanced Diesel Engine Controller For Genset Application 2007Document11 pagesAdec Advanced Diesel Engine Controller For Genset Application 2007Mauro Miranda Couto100% (2)

- Dvigatel Mtu 12v2000g65eDocument155 pagesDvigatel Mtu 12v2000g65eAziz Arrahal100% (2)

- MTU 12V4000M53 Spare Parts Catalog PDFDocument745 pagesMTU 12V4000M53 Spare Parts Catalog PDFkhaireddin100% (2)

- Installation and Commissioning InstructionsDocument170 pagesInstallation and Commissioning InstructionsvanduongNo ratings yet

- SensorsDocument9 pagesSensorsGiang DoNo ratings yet

- Mtu - Technical Documentation: ServiceDocument154 pagesMtu - Technical Documentation: Serviceabduh qaidNo ratings yet

- 1600 Series Parts and OverviewDocument94 pages1600 Series Parts and OverviewJorge Eraldo Albarran PoleoNo ratings yet

- Edoc - Pub E53173000eDocument64 pagesEdoc - Pub E53173000eBayanaka TehnikNo ratings yet

- Мануал L33 - new - MS50199 - 01EDocument16 pagesМануал L33 - new - MS50199 - 01EAleksey100% (1)

- Part Catalog 12V 4000 M93 LDocument847 pagesPart Catalog 12V 4000 M93 LDimas Destriyan100% (1)

- Plan de Manteniemiento m53 MtuDocument9 pagesPlan de Manteniemiento m53 MtuNippur de LagashNo ratings yet

- Series 8000 Diesel Engines For Marine ApplicationsDocument3 pagesSeries 8000 Diesel Engines For Marine ApplicationsMaurizioNo ratings yet

- MTU 12 V 4000M Main Engine Workshop ManualDocument1,922 pagesMTU 12 V 4000M Main Engine Workshop ManualSavindu Nanayakkara100% (2)

- MTUDocument7 pagesMTUGerman O.No ratings yet

- ADEC Genset Functions and ParameterDocument52 pagesADEC Genset Functions and ParameterRizki Heru Hermawan83% (23)

- MTU 16V 2000 M93 Brochure SpecificationDocument2 pagesMTU 16V 2000 M93 Brochure SpecificationPedro Mas0% (1)

- Series 2000 For Power GenerationDocument6 pagesSeries 2000 For Power GenerationBarham Gen Barham100% (2)

- MTU Gendrive SalesProgramDocument55 pagesMTU Gendrive SalesProgramEdutamNo ratings yet

- Diesel Engines 8V/10V 2000 M72: For Vessels With High Load Factors (1B)Document2 pagesDiesel Engines 8V/10V 2000 M72: For Vessels With High Load Factors (1B)zaki100% (1)

- MTUDocument7 pagesMTUABOUDH60% (5)

- 16 V 4000Document4 pages16 V 4000aup0% (1)

- Part Catalog MTU 12V 4000 M73, M73L PDFDocument813 pagesPart Catalog MTU 12V 4000 M73, M73L PDFDimas Saputro100% (2)

- MS15018 01eDocument162 pagesMS15018 01eاشرينكيل مسونكيلNo ratings yet

- Adec 1600Document84 pagesAdec 1600Sudiono Ajb50% (2)

- MTU Marine SalesProgramDocument49 pagesMTU Marine SalesProgramselleriverket100% (1)

- MTU BLUE VISION AdVANCED PDFDocument8 pagesMTU BLUE VISION AdVANCED PDFomar alayash100% (1)

- Operating Instructions: Diesel Engine 12V2000G65, G65-TB 16V2000G65, G65-TB 18V2000G65, G65-TB Application Group 3ADocument155 pagesOperating Instructions: Diesel Engine 12V2000G65, G65-TB 16V2000G65, G65-TB 18V2000G65, G65-TB Application Group 3APetrus GunturNo ratings yet

- Operating Instructions: Diesel Engine 16 V 1163 Mx4 20 V 1163 Mx4Document280 pagesOperating Instructions: Diesel Engine 16 V 1163 Mx4 20 V 1163 Mx4AGugerNo ratings yet

- 12V Mtu 4000Document248 pages12V Mtu 4000Mig Vazq100% (5)

- Mtu PDFDocument170 pagesMtu PDFjeferson de castro souza100% (1)

- DD TurbosDocument245 pagesDD TurbosAHMED MAHMOUDNo ratings yet

- MTU 2000 M94 OperationDocument153 pagesMTU 2000 M94 OperationDimas Saputro100% (1)

- Modelo 1Document74 pagesModelo 1lfrn2004No ratings yet

- DAVE Quick Start PresentationTutorial v2-1 PDFDocument39 pagesDAVE Quick Start PresentationTutorial v2-1 PDFAndrei LavricNo ratings yet

- Storage Configuration: HK902S E.00Document27 pagesStorage Configuration: HK902S E.00itnetmanNo ratings yet

- SOG QuickStartGuide v4.00Document172 pagesSOG QuickStartGuide v4.00Himansu Sekhar PradhanNo ratings yet

- Floor Plan Manager Learning & ExercisesDocument44 pagesFloor Plan Manager Learning & ExercisestopankajNo ratings yet

- CES Wrong Answer SummaryDocument3 pagesCES Wrong Answer SummaryAbdul Muksith100% (1)

- Klein KCHIRP 3310 SBP 1217Document2 pagesKlein KCHIRP 3310 SBP 1217Abdul MuksithNo ratings yet

- Mag Log ManualDocument345 pagesMag Log ManualAbdul MuksithNo ratings yet

- Data Sheet US - K3G310PV6905 KM218409 44d9e0c5-3ed1-4493-8787-1e907d8f04...Document7 pagesData Sheet US - K3G310PV6905 KM218409 44d9e0c5-3ed1-4493-8787-1e907d8f04...Abdul MuksithNo ratings yet

- 2021 Guidelines For Remuneration of Group Executive Board and Board Members in YaraDocument6 pages2021 Guidelines For Remuneration of Group Executive Board and Board Members in YaraAbdul MuksithNo ratings yet

- Data Analysis To Evaluate Reliability of A Main EngineDocument5 pagesData Analysis To Evaluate Reliability of A Main EngineAbdul MuksithNo ratings yet

- Spares ManagemtDocument13 pagesSpares ManagemtAbdul MuksithNo ratings yet

- Using Reliability Block Diagrams and Fault Tree Circuits, To Develop A Condition Based Maintenance Model For A Vessel's Main Propulsion System and Related SubsystemsDocument5 pagesUsing Reliability Block Diagrams and Fault Tree Circuits, To Develop A Condition Based Maintenance Model For A Vessel's Main Propulsion System and Related SubsystemsAbdul MuksithNo ratings yet

- Alarm and Monitoring System Wärtsilä SAM Electronics MCS Platinum Training Vigo 26.09.2018Document2 pagesAlarm and Monitoring System Wärtsilä SAM Electronics MCS Platinum Training Vigo 26.09.2018Abdul MuksithNo ratings yet

- Lambda VegaDocument6 pagesLambda VegaZeljko TomicNo ratings yet

- Lesson Plan ECIDocument4 pagesLesson Plan ECIsureshvkumarNo ratings yet

- Nokia 9300i Repair ManualDocument27 pagesNokia 9300i Repair Manualcorie132No ratings yet

- AssignmentPM ANSWERDocument2 pagesAssignmentPM ANSWERMikey Chua0% (1)

- Iso14000 FamilyDocument2 pagesIso14000 FamilyALPER ORHANNo ratings yet

- Salesforce CRM Implementation ChecklistDocument11 pagesSalesforce CRM Implementation Checklist5gzqvjtn6qNo ratings yet

- CONSOLESDocument13 pagesCONSOLESChanabodee KittidumrungsukNo ratings yet

- Esquema Electrico 336dl Serie m4t023XXDocument24 pagesEsquema Electrico 336dl Serie m4t023XXrjan7pe100% (1)

- SOftware Construction Tools PDFDocument14 pagesSOftware Construction Tools PDFs hcNo ratings yet

- Ipaso - Exa - 03 - GGS-000546-06E - installation-OM1806 No Pass-UnlockedDocument66 pagesIpaso - Exa - 03 - GGS-000546-06E - installation-OM1806 No Pass-UnlockedMoses MussNo ratings yet

- Product SpecificationDocument35 pagesProduct SpecificationNawras HasnNo ratings yet

- Nog Mpls FRR PDFDocument232 pagesNog Mpls FRR PDFMoïse GuilavoguiNo ratings yet

- Annex No.4 VoIP VCS Tender Technical SpecificationDocument45 pagesAnnex No.4 VoIP VCS Tender Technical SpecificationasruzayNo ratings yet

- Chapter 1Document15 pagesChapter 1kelzoiNo ratings yet

- CSA Lab Report 1Document5 pagesCSA Lab Report 1Sadat AminNo ratings yet

- Sister Act Musical PlanningDocument7 pagesSister Act Musical Planningapi-720317910No ratings yet

- Ocr Media Studies Coursework Cover SheetDocument5 pagesOcr Media Studies Coursework Cover Sheetlozuzimobow3100% (2)

- Libraries: Types of Library Public Lending LibrariesDocument6 pagesLibraries: Types of Library Public Lending LibrariesRhitika SakharleNo ratings yet

- Installation, Operation & MaintenanceDocument38 pagesInstallation, Operation & MaintenanceFRANCISCO JAVIER PARAISO VUYOVICHNo ratings yet

- Oversizing of Solaredge Inverters, Technical NoteDocument1 pageOversizing of Solaredge Inverters, Technical NoteMohammad HamamdNo ratings yet

- Iso 3449 2005 en PDFDocument8 pagesIso 3449 2005 en PDFkrlos_SW2009No ratings yet

- Group-8 Group: D Date: 3 March 2021 - Experiment No.: 6Document5 pagesGroup-8 Group: D Date: 3 March 2021 - Experiment No.: 6SandeepNo ratings yet

- AE 27 Lesson 2Document37 pagesAE 27 Lesson 2MARC BENNETH BERIÑANo ratings yet

- Supply Chain Management: Fedex: Delivering The GoodsDocument29 pagesSupply Chain Management: Fedex: Delivering The Goodslucy01123No ratings yet

- Marvair Compac Avpa Avha Hvea Hvesa Pds 03-27-19 Rev-26Document37 pagesMarvair Compac Avpa Avha Hvea Hvesa Pds 03-27-19 Rev-26lasNo ratings yet

- Local Administrator Password Management Detailed Technical SpecificationDocument24 pagesLocal Administrator Password Management Detailed Technical SpecificationJitendarNo ratings yet

- Session 6 - ICT Discussion PointsDocument2 pagesSession 6 - ICT Discussion PointsMatt WilliamNo ratings yet

- PC Software and MultimediaDocument46 pagesPC Software and MultimediaPoras ChahandeNo ratings yet

- Si Partners & User List in 2020 - GiftsDocument9 pagesSi Partners & User List in 2020 - GiftsAn ThienNo ratings yet

01 Introduction Bluevison NG V1 07

01 Introduction Bluevison NG V1 07

Uploaded by

Abdul MuksithCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01 Introduction Bluevison NG V1 07

01 Introduction Bluevison NG V1 07

Uploaded by

Abdul MuksithCopyright:

Available Formats

MTU - Friedrichshafen, Training Center

Marine

BlueVision |

image

New Generation

Introduction

© MTU Friedrichshafen GmbH | Alle Rechte vorbehalten | All rights reserved

Agenda

1 Application

2 Benefits

3 Technical Features

4 Scope of Supply / Interfaces

5 Components / Technical Data

6 Navigation / Visualization

d durch Klicken auf Symbol hinzufügen

7 Options

8 Commissioning

9 Abbreviations

© MTU Friedrichshafen GmbH | Alle Rechte vorbehalten

Orientation

Today New Generation

smartline BlueVision_Basic

blueline BlueVision_Advanced

bluevision BlueVision_Premium

(Future)

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 3

01

Application

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 4

BlueVision Basic & BlueVision Advanced I New Generation

Application

New Generation is designed for the following applications:

Semi-Custom

Production-Yachts Tug Boat

Push Boat

Crew Boat

Custom-Yachts Inland River

Ferry

Pilot Boat PSV

Authority

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 5

02

Benefits

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 6

BlueVision Basic & BlueVision Advanced I New Generation

Engine Room

Control

e.g. BlueLine

Stand

CB MEU LOP

GCU GCU: Gearbox Control Unit

CB: Connection Box

FPP MEU: Monitoring Extension Unit

LOP: Local Operating Panel

New Generation

Control

Stand

One Box design

LOP

FPP

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 7

BlueVision I New Generation

Benefits

system extension

quick installation

flexible design

open interfaces

one box design

plug & play

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 8

BlueVision_Basic & BlueVision_Advanced I New Generation

Benefits

New Generation propulsion control and monitoring system

provides the following benefits:

• reduced number of boxes reduced cabling

• prefabricated plug and play cabling with Deutsch connectors

• simple installation

• simple interfaces to MTU Diesel Engine via EIM and gearbox

• compact hardware for simple commissioning and service

• intelligent features (e.g. MTU-Autotroll “ZF Inside”, Ethernet Bus)

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 9

03

Technical Features

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 10

BlueVision_Basic & BlueVision_Advanced I New Generation

Technical Features

• Simple commissioning & service

- Preconfigured software

- Automatic upload of the commissioning tool “Automation Suite” via MTU Business Portal

• Easy expandability

- Wheelhouse components (e.g. displays, instruments, etc.) can easily be implemented

• Systembus

- Ethernet based technology for high performance & long distances

• Flexible assignment of predefined software functions to hardware I/O

on Yard-Interface

- Example: Signals like Engine Running can be assigned to user-defined output channel

• Crash-Stop

- Reverse engagement depending on ship speed (calculated)

• ZF Autotroll Inside

- Only for ZF gearbox (replace EST-59)

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 11

04

Scope of Supply / Interfaces

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 12

BlueVision_Basic & BlueVision_Advanced I New Generation

Scope of Supply

Propulsion Control and Monitoring System

• commercial and pleasure craft applications with Series 2000 / 4000

(Advanced Diesel Engine Control ADEC and Engine Interface Module EIM)

• 1-4 shafts and 1-6 control stands

• MTU MCS and MTU RCS for FPP applications

• MTU MCS and Interface to non MTU RCS for WJ and CPP applications

• MTU interface to non MTU MCS and non MTU RCS

• Classification possible:

- non-classification with BlueVision New Generation Basic

- classification with BlueVision New Generation Advanced

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 13

BlueVision Basic I New Generation

Scope of Supply - non classified – Basic DIS (Typical)

POU

Slave Control Stand

Basic DIS PAN CL PAN Basic DIS

Instruments Instruments

Extension to 6 control stands

RIM

MCS-CAN-Bus MCS-CAN-Bus

RCS-CAN-Bus RCS-CAN-Bus

Option

Main Control Stand

Basic DIS PAN CL PAN Basic DIS

Instruments Instruments

MCS-CAN-Bus MCS-CAN-Bus

RCS-CAN-Bus RCS-CAN-Bus

LOP13 LOP13

Ethernet

Engine Room

Extension up to 4 shafts

EIM EIM

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 14

BlueVision Basic I New Generation

Scope of Supply - non classified – MFD (Typical)

POU

Slave Control Stand

MFD PAN CL PAN MFD

Instruments Instruments

RIM

only 4 control stands with MFD

MCS-CAN-Bus MCS-CAN-Bus

Extension to 6 control stands

RCS-CAN-Bus RCS-CAN-Bus

Option

MFD MFD

Main Control Stand

PAN CL PAN

Instruments Instruments

MCS-CAN-Bus MCS-CAN-Bus

RCS-CAN-Bus RCS-CAN-Bus

LOP13

LOP14* LOP13

LOP14*

Ethernet

Engine Room

Extension up to 4 shafts

EIM EIM

* optional

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 15

BlueVision Advanced I New Generation

Scope of Supply – classified (Typical)

MFD PAN PAN CL PAN PAN MFD

Slave Control Stand

Instruments Instruments

Extension to 6 control stands

MCS-CAN-Bus MCS-CAN-Bus

SCU SCU

RCS-CAN-Bus

MFD PAN PAN CL PAN PAN MFD

Main Control Stand

Instruments Instruments

MCS-CAN-Bus MCS-CAN-Bus

Switch

SCU SCU

RCS-CAN-Bus

LOP14 LOP14

Ethernet

Engine Room

Ethernet-Ring

Extension up to 4 shafts

EIM EIM

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 16

BlueVision Basic & BlueVision Advanced I New Generation

Interfaces

Systembus Processing Unit SPU Connection Mini Display with

Interfaces: CAN, Ethernet, SD-Card, I/O LOS 3 or LOS 4 Push buttons

• X1 Gearbox Interface (classified scope)

• X2 Gearbox Interface

• X3 Trolling

• X4 Engine Interface Modul (EIM)

• X5 Connection for Main Control Stand (CAN)

• X6 Connection for Slave Control Stand (CAN)

• X7 Emergency Panel

• X8 Fuel Filter

• X9 MCS I/O Extension for future use

• X10 RCS I/O Extension (not supported yet)

X7 X8 - -

• X11.1 Network on

• X11.2 Network on

• X20.1 Ethernet 1 (Systembus)

• X20.2 Ethernet 2 (Systembus)

• X40.1 / X40.2 24V Power Supply (Main)

• X41.1 / X41.2 24V Power Supply (Back-Up)

Ship Yard Interfaces

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 17

BlueVision Advanced I New Generation

Interfaces

Systembus Coupling Unit SCU (CoE Gateway)

Interfaces: CAN, Ethernet Ethernet Power supply

• X11 Connection CAN (MCS)

• X12 Connection CAN (MCS)

• X21 Connection CAN (RCS)

• X22 Connection CAN (RCS)

• X13 Emergency Stop

• X23 Emergency Stop (not used)

• X20.1 Ethernet 1 (Systembus)

• X20.2 Ethernet 2 (Systembus)

• X40.1 / X40.2 24V Power Supply (Main) Connection MCS / RCS Emergency Stop

• X41.1 / X41.2 24V Power Supply (Backup) Node ID

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 18

BlueVision Advanced I New Generation

Interfaces

Switch

Interfaces: Systembus (Ethernet)

- SCU

- SPU

- Service Port

Power Supply

MEM Module

(Media Redundancy Protocol)

8 x Ethernet Port

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 19

05

Components / Technical Data

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 20

BlueVision Basic & BlueVision Advanced I New Generation

LOP configuration

Systembus Processing Unit (SPU1) Local Operating Station (LOS3) Local Operating Panel (LOP-13)

+ =

Systembus Processing Unit (SPU1) Local Operating Station (LOS4) Local Operating Panel (LOP-14)

+ =

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 21

BlueVision Basic I New Generation

Engine Room

Local Operating Panel LOP-13 READY FOR

Dimension 419 x 315 x 231 mm OPERATION

Weight app. 15,4 kg

Protection IP 44

Ambient temperature -25°C to +55°C START

Relative humidity max. 0% to 95%; non condensation

STOP

COMBINED ALARM

HORN OFF

TEST

OVERSPEED

EMERGENCY

STOP

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 22

BlueVision Advanced I New Generation

Engine Room

Local Operating Panel LOP-14

Dimension 419 x 315 x 227 mm

Weight app. 17,4 kg

Protection IP 44

Ambient temperature -25°C to +55°C

Relative humidity max. 0% to 95%; non condensation

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 23

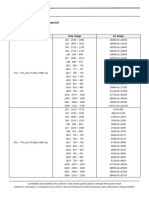

BlueVision Basic & BlueVision Advanced I New Generation

Monitoring Control System MCS

Color Graphic Display Basic DIS (HV780)

Dimension 254 x 150 x 65,5 mm

Weight app.1 kg

Protection front panel IP 66, rear panel IP 67

Ambient temperature -40°C to +85°C

Relative humidity 5% to 100%; condensation

Color Graphic Display MFD

Dimension 246 x 150 x 120 mm

Weight app. 4,2 kg

Protection front panel IP 66, rear panel IP 65

Ambient temp. -25°C to +70°C

Relative humidity 5% to 98%; condensation

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 24

BlueVision Basic & BlueVision Advanced I New Generation

Monitoring Control System MCS

Function Panel PAN-MCS

Dimension 167 x 69 x 65 mm

Weight app. 0,54 kg

Protection front panel IP 66, rear panel IP 65

Ambient temp. -25%°C to +70°C

Relative humidity max. 95% / 55°C, condensation

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 25

BlueVision Advanced I New Generation

Monitoring Control System MCS

Systembus Coupling Unit SCU

Dimension 320 x 150,5 x 87,8 mm

Weight app. 2,3 kg

Protection IP 56

Ambient temp. -25°C to +70°C

Relative humidity max. 95% (at 55°C), condensation

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 26

BlueVision Advanced I New Generation

Monitoring Control System MCS

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 27

BlueVision Basic & BlueVision Advanced I New Generation

Monitoring Control System MCS

Analogue Instruments (Basic)

Dimension ø 105 x 70 mm

ø 62,5 x 69 mm

Weight app. 0,3 kg / 0,2 kg

Protection front side IP 65

Ambient temp. -20°C to +70°C

Relative humidity 5% to 98% (non-condensing)

Analogue Instruments (Advanced)

Dimension 96 x 96 x 74 mm

72 x 72 x 54 mm

Weight app. 0,5 kg / 0,3 kg

Protection IP 69k

Ambient temp. -20°C to +70°C

Relative humidity max. 97% (at 55°C), non-condensing

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 28

BlueVision Basic & BlueVision Advanced I New Generation

Monitoring Control System MCS

Buzzer

Dimension ø 55,8 x 69 mm

Weight app. 0,17 kg

Protection class front side IP 55

Ambient temp. -20°C to +70°C

Buzzer

Dimension ø 28 x 54 mm

Weight app. 0,17 kg

Protection class front side IP 65

Ambient temp. -20°C to +70°C

Key switch (optional)

Dimension ø 28 x 76 mm

Weight app. 0,06 kg

Protection class front without cap IP 65, with cap IP 66

Ambient temp. -25°C to +65°C

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 29

BlueVision Basic & BlueVision Advanced I New Generation

Remote Control System RCS

Control Lever DUO

also available for UNO, DUO short and TRIO

Dimension 125 x 157 x 62 mm

Weight app. 1,32 kg

Protection IP 66

Ambient temp. -25°C to +70°C

Relative humidity 5% to 98%, condensing

Details DUO:

6 Pushbuttons for direct access of the different drive modes:

- CMD = Command

- SYNC = Synchro (SCL or Smart Sync)

- AUX = Auxilliary modes (High Idle, Smart Speed etc.)

- CRS = Cruising

- SCRS = SmartCruise (combination of TRL and CRS)

- TRL = Trolling

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 30

BlueVision Advanced I New Generation

Remote Control System RCS

Transfer Indication position

Function Panel PAN-RCS

PAN PAN control lever

Dimension 167 x 69 x 65 mm

Weight app. 0,54 kg

Protection front panel IP 66, rear panel IP 65

Ambient temp. -25%°C to +70°C

AFT STATION AHEAD

FLYING BRIDGE NEUTRAL

WHEELHOUSE ASTERN feedback

gear

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 31

06

Navigation / Visualization

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 32

BlueVision Basic I New Generation

Navigation Color Graphic Display Basic DIS

Color Graphic Display Basic DIS

Soft keys correspond to the key

command

and allow you to make selections

Menu key at any time Enter key

displays the list of menu

options

The display is operated by means of ten keys of the display. Their respective functions

vary depending on the screen pages.

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 33

BlueVision Basic I New Generation

Navigation Color Graphic Display Basic DIS

Color Graphic Display Basic DIS

Single-Engine Dashboard (Examples)

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 34

BlueVision Basic & BlueVision Advanced I New Generation

Navigation Color Graphic Display MFD

Color Graphic Display MFD

Set values in active input field = Increase values

Set values in active input field = Decrease values

Navigate between individual input field = Navigate forwards

Navigate between individual input field = Navigate backwards

Adopt settings

Exit device configuration page

Indicates current key assignment of screen page on display

The display is operated by means of five keys on the right of the display.

Their respective functions vary depending on the screen pages.

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 35

BlueVision Basic & BlueVision Advanced I New Generation

Navigation Color Graphic Display MFD

Color Graphic Display MFD

Day View

Night View

(Examples) High Contrast View

Single-Engine Dashboard

only!!!

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 36

BlueVision Advanced I New Generation

Navigation Color Graphic Display LOP-14

Local Operating Panel LOP-14

(Examples)

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 37

BlueVision Advanced I New Generation

Navigation Push Button LOP-14

Local Operating Panel (LOP-14)

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 38

BlueVision Advanced I New Generation

Navigation Push Button LOP-14

Local Operating Panel (LOP-14)

Overview Page

All pages not listed here

Alarm Page

Brightness Page

Service Page in display mode

Service Page in edit mode

System Page

Error Annular Memory

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 39

07

Options

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 40

BlueVision I New Generation

J1939 Interfaces (3rd Party MCS)

SCU

• One SCU interface can operate up to 2 shafts

and displays.

• Ring topologies require a network switch

(see following slides)

• Systems with more than 2 shafts have always a

Switch

ring topology.

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 41

BlueVision I New Generation

J1939 Interfaces (3rd Party MCS)

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 42

BlueVision I New Generation

J1939 Interfaces (3rd Party MCS)

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 43

BlueVision I New Generation

J1939 Interfaces (3rd Party MCS)

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 44

BlueVision Basic I New Generation

RCS – Palm Beach

Control Lever Palm Beach

Handle available w/o thruster control push button

Dimension 163 x 65 x 80 mm

Weight app. 6kg

Protection IP 66

Ambient temp. -25°C to +70°C

Relative humidity 5% to 98%, condensing

Details DUO:

6 Pushbuttons for direct access of the different drive modes:

- CMD = Command

- SYNC = Synchro (SCL or Smart Sync)

- AUX = Auxilliary modes (High Idle, Smart Speed etc.)

- CRS = Cruising

- SCRS = SmartCruise (combination of TRL and CRS)

- TRL = Trolling

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 45

BlueVision Basic I New Generation

RCS – Portable Control (Basic only!)

Portable Operator Unit POU

Dimension 190 x 110 x 100 mm

Weight app. 1,4 kg

Protection IP 66

Ambient temp. -25°C to +70°C

Relative humidity 0% to 98% (non-condensing)

Remote Interface Module RIM

Dimension 300 x 150 x 80 mm

Weight app. 2,6 kg

Protection IP 23

Ambient temp. 0°C to +55°C

Relative humidity 5% to 95%; non-condensing

Max. distance (CAN bus) between LOP

and RIM box: 100m!!!

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 46

BlueVision Basic I New Generation

Joystick System (Xenta)

RCS Joystick

Dimension 100 x 133 mm

Weight app. 0,8 kg

Protection IP 67 (with cables connected)

Ambient temp. -25°C to +70°C

Relative humidity 97%, condensing

Details JSK:

3 Push buttons for different modes:

- C = Command

- T = Thruster mode

- E = Maneuvering mode / engine availability

- The RCS joystick is an extension to the RCS-6.

- It can be used to control the propulsion plant and the bow/stern thrusters.

- Available w/o GPS Hold Function

- Only available in combination with BASIC Display!!!!

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 47

BlueVision I New Generation

Emergency Panel

Function Panel Emergency

Dimension 167 x 69 x 65 mm

Weight app. 0,54 kg

Protection front panel IP 56

Ambient temp. -25%°C to +70°C INTERLOCK

F FORWARD push button

GEAR

Relative humidity max. 96% / 55°C, condensation

INTERLOCK feedback

N NEUTRAL push button

LOCAL

R REVERSE push button

LOCAL feedback RPM + push button

RPM

WARNING!

Read documentation

before use. Improper

use may lead to severe

personal injury and/or

damage to equipment.

RPM - push button

EMERGENCY

PANEL

ON/OFF push button

Diagnostic lamp

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 48

BlueVision Basic I New Generation

Pininfarina design – Integrated in bridge

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 49

BlueVision Basic I New Generation

Pininfarina design – Display / Gauges

Touch Screen Display

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 50

BlueVision Basic I New Generation

Pininfarina design – PAN

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 51

BlueVision Basic I New Generation

Pininfarina design – Control Lever

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 52

08

Commissioning

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 53

BlueVision I New Generation

Commissioning via Automation Suite software

• Configurator

- Guided user dialog for configuring the series system via Standard Service Laptop

• Dialog (online and offline parameterization)

- Access controlled by authorisation concept (licence file), no hardware dongle required

• Displaying of system and device status

- System level: List of devices connected to the System Bus included device operating status

- Detailed device level: CPU load, software version, actives alarms, alarm log, etc.

• Monitoring

- Monitoring, recording and analysis of measured values

• Stimulation

- Manual forcing of measured values

• Data-Retrieval

- Data return of active parameter settings and log files to MTU

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 54

BlueVision I New Generation

Commissioning Tool - Automation Suite

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 55

BlueVision I New Generation

Commissioning Tool - Automation Suite

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 56

BlueVision I New Generation

Commissioning Tool - Automation Suite

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 57

09

Abbreviations

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 58

Abbreviations

CL: Control Lever

CPP: Controllable Pitch Propeller

CoE: CAN over Ethernet

DIS: Display

EIM: Engine Interface Module

FPP: Fixed Pitch Propeller

LOP: Local Operating Panel

LOS: Local Operating Station

MCS: Monitoring Control System

PAN: Panel

POU: Portable Operator Unit

RCS: Remote Control System

RIM: Remote Interface Module

SCU: Systembus Coupling Unit

SPU: Systembus Processing Unit

Global Training Introduction_Bluevision_NG | Version 1_07 | J.Liebminger 03.02.2022 | Sheet 59

Vielen Dank für Ihre Aufmerksamkeit.

Thank you for your attention

© MTU Friedrichshafen GmbH | Alle Rechte vorbehalten | All rights reserved

You might also like

- MTU 4000 Maintenance ScheduleDocument35 pagesMTU 4000 Maintenance Schedulenereomad100% (8)

- Mtu Sam & Adec E532304 - 00eDocument216 pagesMtu Sam & Adec E532304 - 00ecampioed85% (13)

- MTU 4000 With MIP v1.8Document23 pagesMTU 4000 With MIP v1.8Aurelio Serrano100% (2)

- MtuDocument464 pagesMtuDarin Hood100% (13)

- Manual MTUDocument134 pagesManual MTUjuan pablo zuniga100% (2)

- System Documentation: Electronics Electronic Engine Control Unit Ecu 9 Application: Genset Series 2000 Gx6Document198 pagesSystem Documentation: Electronics Electronic Engine Control Unit Ecu 9 Application: Genset Series 2000 Gx6Minh Le100% (1)

- MDEC Stationary DieselDocument5 pagesMDEC Stationary DieselAhmad Shahrul Mohamed100% (2)

- E532284 - Funcional Descrition MtuDocument42 pagesE532284 - Funcional Descrition MtuNippur de Lagash100% (1)

- Field Automation Level Assembly CatalogDocument254 pagesField Automation Level Assembly CatalogAbdul Khaliq100% (1)

- Mtu 4000 Water Pump DismantleDocument93 pagesMtu 4000 Water Pump Dismantlesxturbo100% (1)

- Mtu 1600 1600G 00 Parts Catalog 154pagesDocument154 pagesMtu 1600 1600G 00 Parts Catalog 154pagesertl100% (1)

- Maintenance Schedule: Diesel Engine EPA V 4000 Mx3 V 4000 Mx3 X Application Group 1ADocument79 pagesMaintenance Schedule: Diesel Engine EPA V 4000 Mx3 V 4000 Mx3 X Application Group 1AshashirajNo ratings yet

- 4000 G OverhoolDocument745 pages4000 G Overhoolaup100% (2)

- MTU Technical DocumentationDocument157 pagesMTU Technical DocumentationAhmadTaufikMurad100% (3)

- E531827 00E CAN FieldbusDocument46 pagesE531827 00E CAN Fieldbusarcangel_pic100% (1)

- MTU Engine 4000-Series Functional DescriptionDocument42 pagesMTU Engine 4000-Series Functional DescriptionAlex100% (1)

- Mtu 1600 Operating InstructionsDocument134 pagesMtu 1600 Operating InstructionsGerman O.No ratings yet

- ADEC Advancet Diesel Engine Controller For BR 4000 and BR 2000 Generator Application MTU PDFDocument49 pagesADEC Advancet Diesel Engine Controller For BR 4000 and BR 2000 Generator Application MTU PDFaup100% (4)

- 12v2000 CR OperatingDocument170 pages12v2000 CR OperatingANDREA100% (4)

- Error Code ECU8Document16 pagesError Code ECU8Giang DoNo ratings yet

- Engine Control Unit Type ECU 4/G: MTU/DDC Series 4000 Genset ApplicationsDocument62 pagesEngine Control Unit Type ECU 4/G: MTU/DDC Series 4000 Genset ApplicationsGeorge Barsoum100% (3)

- PrachFreqAdjSwitch - Trial ReportDocument16 pagesPrachFreqAdjSwitch - Trial ReportMunir AlamNo ratings yet

- Day 1 - Chris Sivertz - S2C2 SatcomDocument55 pagesDay 1 - Chris Sivertz - S2C2 SatcomEkrem ErginNo ratings yet

- Farmers First FormatDocument9 pagesFarmers First FormatAkhil ANo ratings yet

- Adec Advanced Diesel Engine Controller For Genset Application 2007Document11 pagesAdec Advanced Diesel Engine Controller For Genset Application 2007Mauro Miranda Couto100% (2)

- Dvigatel Mtu 12v2000g65eDocument155 pagesDvigatel Mtu 12v2000g65eAziz Arrahal100% (2)

- MTU 12V4000M53 Spare Parts Catalog PDFDocument745 pagesMTU 12V4000M53 Spare Parts Catalog PDFkhaireddin100% (2)

- Installation and Commissioning InstructionsDocument170 pagesInstallation and Commissioning InstructionsvanduongNo ratings yet

- SensorsDocument9 pagesSensorsGiang DoNo ratings yet

- Mtu - Technical Documentation: ServiceDocument154 pagesMtu - Technical Documentation: Serviceabduh qaidNo ratings yet

- 1600 Series Parts and OverviewDocument94 pages1600 Series Parts and OverviewJorge Eraldo Albarran PoleoNo ratings yet

- Edoc - Pub E53173000eDocument64 pagesEdoc - Pub E53173000eBayanaka TehnikNo ratings yet

- Мануал L33 - new - MS50199 - 01EDocument16 pagesМануал L33 - new - MS50199 - 01EAleksey100% (1)

- Part Catalog 12V 4000 M93 LDocument847 pagesPart Catalog 12V 4000 M93 LDimas Destriyan100% (1)

- Plan de Manteniemiento m53 MtuDocument9 pagesPlan de Manteniemiento m53 MtuNippur de LagashNo ratings yet

- Series 8000 Diesel Engines For Marine ApplicationsDocument3 pagesSeries 8000 Diesel Engines For Marine ApplicationsMaurizioNo ratings yet

- MTU 12 V 4000M Main Engine Workshop ManualDocument1,922 pagesMTU 12 V 4000M Main Engine Workshop ManualSavindu Nanayakkara100% (2)

- MTUDocument7 pagesMTUGerman O.No ratings yet

- ADEC Genset Functions and ParameterDocument52 pagesADEC Genset Functions and ParameterRizki Heru Hermawan83% (23)

- MTU 16V 2000 M93 Brochure SpecificationDocument2 pagesMTU 16V 2000 M93 Brochure SpecificationPedro Mas0% (1)

- Series 2000 For Power GenerationDocument6 pagesSeries 2000 For Power GenerationBarham Gen Barham100% (2)

- MTU Gendrive SalesProgramDocument55 pagesMTU Gendrive SalesProgramEdutamNo ratings yet

- Diesel Engines 8V/10V 2000 M72: For Vessels With High Load Factors (1B)Document2 pagesDiesel Engines 8V/10V 2000 M72: For Vessels With High Load Factors (1B)zaki100% (1)

- MTUDocument7 pagesMTUABOUDH60% (5)

- 16 V 4000Document4 pages16 V 4000aup0% (1)

- Part Catalog MTU 12V 4000 M73, M73L PDFDocument813 pagesPart Catalog MTU 12V 4000 M73, M73L PDFDimas Saputro100% (2)

- MS15018 01eDocument162 pagesMS15018 01eاشرينكيل مسونكيلNo ratings yet

- Adec 1600Document84 pagesAdec 1600Sudiono Ajb50% (2)

- MTU Marine SalesProgramDocument49 pagesMTU Marine SalesProgramselleriverket100% (1)

- MTU BLUE VISION AdVANCED PDFDocument8 pagesMTU BLUE VISION AdVANCED PDFomar alayash100% (1)

- Operating Instructions: Diesel Engine 12V2000G65, G65-TB 16V2000G65, G65-TB 18V2000G65, G65-TB Application Group 3ADocument155 pagesOperating Instructions: Diesel Engine 12V2000G65, G65-TB 16V2000G65, G65-TB 18V2000G65, G65-TB Application Group 3APetrus GunturNo ratings yet

- Operating Instructions: Diesel Engine 16 V 1163 Mx4 20 V 1163 Mx4Document280 pagesOperating Instructions: Diesel Engine 16 V 1163 Mx4 20 V 1163 Mx4AGugerNo ratings yet

- 12V Mtu 4000Document248 pages12V Mtu 4000Mig Vazq100% (5)

- Mtu PDFDocument170 pagesMtu PDFjeferson de castro souza100% (1)

- DD TurbosDocument245 pagesDD TurbosAHMED MAHMOUDNo ratings yet

- MTU 2000 M94 OperationDocument153 pagesMTU 2000 M94 OperationDimas Saputro100% (1)

- Modelo 1Document74 pagesModelo 1lfrn2004No ratings yet

- DAVE Quick Start PresentationTutorial v2-1 PDFDocument39 pagesDAVE Quick Start PresentationTutorial v2-1 PDFAndrei LavricNo ratings yet

- Storage Configuration: HK902S E.00Document27 pagesStorage Configuration: HK902S E.00itnetmanNo ratings yet

- SOG QuickStartGuide v4.00Document172 pagesSOG QuickStartGuide v4.00Himansu Sekhar PradhanNo ratings yet

- Floor Plan Manager Learning & ExercisesDocument44 pagesFloor Plan Manager Learning & ExercisestopankajNo ratings yet

- CES Wrong Answer SummaryDocument3 pagesCES Wrong Answer SummaryAbdul Muksith100% (1)

- Klein KCHIRP 3310 SBP 1217Document2 pagesKlein KCHIRP 3310 SBP 1217Abdul MuksithNo ratings yet

- Mag Log ManualDocument345 pagesMag Log ManualAbdul MuksithNo ratings yet

- Data Sheet US - K3G310PV6905 KM218409 44d9e0c5-3ed1-4493-8787-1e907d8f04...Document7 pagesData Sheet US - K3G310PV6905 KM218409 44d9e0c5-3ed1-4493-8787-1e907d8f04...Abdul MuksithNo ratings yet

- 2021 Guidelines For Remuneration of Group Executive Board and Board Members in YaraDocument6 pages2021 Guidelines For Remuneration of Group Executive Board and Board Members in YaraAbdul MuksithNo ratings yet

- Data Analysis To Evaluate Reliability of A Main EngineDocument5 pagesData Analysis To Evaluate Reliability of A Main EngineAbdul MuksithNo ratings yet

- Spares ManagemtDocument13 pagesSpares ManagemtAbdul MuksithNo ratings yet

- Using Reliability Block Diagrams and Fault Tree Circuits, To Develop A Condition Based Maintenance Model For A Vessel's Main Propulsion System and Related SubsystemsDocument5 pagesUsing Reliability Block Diagrams and Fault Tree Circuits, To Develop A Condition Based Maintenance Model For A Vessel's Main Propulsion System and Related SubsystemsAbdul MuksithNo ratings yet

- Alarm and Monitoring System Wärtsilä SAM Electronics MCS Platinum Training Vigo 26.09.2018Document2 pagesAlarm and Monitoring System Wärtsilä SAM Electronics MCS Platinum Training Vigo 26.09.2018Abdul MuksithNo ratings yet

- Lambda VegaDocument6 pagesLambda VegaZeljko TomicNo ratings yet

- Lesson Plan ECIDocument4 pagesLesson Plan ECIsureshvkumarNo ratings yet

- Nokia 9300i Repair ManualDocument27 pagesNokia 9300i Repair Manualcorie132No ratings yet

- AssignmentPM ANSWERDocument2 pagesAssignmentPM ANSWERMikey Chua0% (1)

- Iso14000 FamilyDocument2 pagesIso14000 FamilyALPER ORHANNo ratings yet

- Salesforce CRM Implementation ChecklistDocument11 pagesSalesforce CRM Implementation Checklist5gzqvjtn6qNo ratings yet

- CONSOLESDocument13 pagesCONSOLESChanabodee KittidumrungsukNo ratings yet

- Esquema Electrico 336dl Serie m4t023XXDocument24 pagesEsquema Electrico 336dl Serie m4t023XXrjan7pe100% (1)

- SOftware Construction Tools PDFDocument14 pagesSOftware Construction Tools PDFs hcNo ratings yet

- Ipaso - Exa - 03 - GGS-000546-06E - installation-OM1806 No Pass-UnlockedDocument66 pagesIpaso - Exa - 03 - GGS-000546-06E - installation-OM1806 No Pass-UnlockedMoses MussNo ratings yet

- Product SpecificationDocument35 pagesProduct SpecificationNawras HasnNo ratings yet

- Nog Mpls FRR PDFDocument232 pagesNog Mpls FRR PDFMoïse GuilavoguiNo ratings yet

- Annex No.4 VoIP VCS Tender Technical SpecificationDocument45 pagesAnnex No.4 VoIP VCS Tender Technical SpecificationasruzayNo ratings yet

- Chapter 1Document15 pagesChapter 1kelzoiNo ratings yet

- CSA Lab Report 1Document5 pagesCSA Lab Report 1Sadat AminNo ratings yet

- Sister Act Musical PlanningDocument7 pagesSister Act Musical Planningapi-720317910No ratings yet

- Ocr Media Studies Coursework Cover SheetDocument5 pagesOcr Media Studies Coursework Cover Sheetlozuzimobow3100% (2)

- Libraries: Types of Library Public Lending LibrariesDocument6 pagesLibraries: Types of Library Public Lending LibrariesRhitika SakharleNo ratings yet

- Installation, Operation & MaintenanceDocument38 pagesInstallation, Operation & MaintenanceFRANCISCO JAVIER PARAISO VUYOVICHNo ratings yet

- Oversizing of Solaredge Inverters, Technical NoteDocument1 pageOversizing of Solaredge Inverters, Technical NoteMohammad HamamdNo ratings yet

- Iso 3449 2005 en PDFDocument8 pagesIso 3449 2005 en PDFkrlos_SW2009No ratings yet

- Group-8 Group: D Date: 3 March 2021 - Experiment No.: 6Document5 pagesGroup-8 Group: D Date: 3 March 2021 - Experiment No.: 6SandeepNo ratings yet

- AE 27 Lesson 2Document37 pagesAE 27 Lesson 2MARC BENNETH BERIÑANo ratings yet

- Supply Chain Management: Fedex: Delivering The GoodsDocument29 pagesSupply Chain Management: Fedex: Delivering The Goodslucy01123No ratings yet

- Marvair Compac Avpa Avha Hvea Hvesa Pds 03-27-19 Rev-26Document37 pagesMarvair Compac Avpa Avha Hvea Hvesa Pds 03-27-19 Rev-26lasNo ratings yet

- Local Administrator Password Management Detailed Technical SpecificationDocument24 pagesLocal Administrator Password Management Detailed Technical SpecificationJitendarNo ratings yet

- Session 6 - ICT Discussion PointsDocument2 pagesSession 6 - ICT Discussion PointsMatt WilliamNo ratings yet

- PC Software and MultimediaDocument46 pagesPC Software and MultimediaPoras ChahandeNo ratings yet

- Si Partners & User List in 2020 - GiftsDocument9 pagesSi Partners & User List in 2020 - GiftsAn ThienNo ratings yet