ASTM A106 Working Pressure

ASTM A106 Working Pressure

Uploaded by

pippo2378793Copyright:

Available Formats

ASTM A106 Working Pressure

ASTM A106 Working Pressure

Uploaded by

pippo2378793Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

ASTM A106 Working Pressure

ASTM A106 Working Pressure

Uploaded by

pippo2378793Copyright:

Available Formats

Page 1 of 4

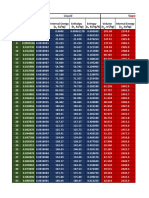

ASTM A106, API 5L and ASTM A53 Seamless Carbon Steel Pipes - Pressure and

Temperature Ratings

Pressure (kPa) and temperature (C) ratings of ASTM A106, API 5L and ASTM A53 Seamless Carbon Steel

Pipes - temperatures ranging -29 C - 450 C

Maximum allowable pressure and temperature ratings for petroleum refinery piping and chemical plant piping

systems grade B with plane ends to ANSI/ASME B31.3 Process Piping.

Nominal

Schedule

Size

no.

(mm)

15

20

25

32

40

50

65

80

STD

XS

XXS

STD

XS

XXS

STD

XS

XXS

STD

XS

XXS

STD

XS

XXS

STD

XS

XXS

STD

XS

XXS

STD

XS

XXS

STD

XS

100

XXS

125

40

80

160

40

80

160

40

80

160

40

80

160

40

80

160

40

80

160

40

80

160

40

80

160

40

80

120

160

Maximum Allowable Pressure (kPa)

Temperature (C)

Wall

-29

38

205

260

350

370

400

Thickness

Maximum Allowable Stress (kPa)

(mm)

137800 137800 130221 117130 115752 89570

2.77 34416 34416 32528 29255 28910 22372

3.73 48092 48092 45466 40878 40396 31260

4.78 62830 62830 59378 53404 52777 40837

7.47 98245 98245 92836 83507 82522 63857

2.87 28070 28070 26526 23860 23578 18245

3.91 39418 39418 37247 33506 33106 25617

5.56 58152 58152 54955 49429 48843 37799

7.82 83107 83107 78539 70643 69809 54024

3.38 26251 26251 24804 22310 22048 17060

4.55 36283 36283 34285 30862 30474 23584

6.35 52481 52481 49594 44606 44082 34112

9.09 77030 77030 72793 65476 64704 50070

3.56 21614 21614 20421 18369 18155 14049

4.85 30178 30178 28518 25651 25348 19616

6.35 40596 40596 38364 34505 34099 26389

9.70 64601 64601 61045 54906 54266 41988

3.68 19444 19444 18375 16529 16329 12636

5.08 27402 27402 25900 23295 23019 17811

7.14 39738 39738 37599 33816 33416 25858

10.16 58779 58799 55547 49966 49374 38205

3.91 16378 16378 15468 13925 13759 10645

5.54 23653 23653 22351 20105 19871 15378

8.74 38866 38866 36731 33037 32652 25266

11.07 50793 50793 48003 43173 42670 33017

5.16 17914 17914 16929 15227 15048 11644

7.01 24818 24818 23447 21097 20849 16129

9.53 34615 34615 32714 29420 29076 22503

14.02 53081 53081 50159 45116 44585 34498

5.49 15558 15558 14969 13222 13063 10108

7.62 21986 21968 20780 18693 18472 14290

11.13 33079 33079 31253 28111 27780 21497

15.24 46976 46976 44392 39928 39459 30536

6.02 13187 13187 12464 11210 11079 8571

8.56 19058 19058 18010 16198 16012 12388

11.13 25190 25190 23805 21407 21159 16371

13.49 31019 31019 29310 26368 26058 20160

17.12 40348 40348 38129 34298 33892 26230

4301)

450

74412

18589

25969

33929

53053

15158

21283

31398

44881

14173

19595

28339

41595

11672

16295

21924

34884

10550

14800

21483

31742

8847

12774

20987

27429

9674

13401

18693

28662

8399

11871

17859

25369

7124

12094

13601

16750

21786

59943

14972

20918

27333

42739

12209

17142

25293

36152

11417

15785

22827

33506

9404

13125

17659

28097

8454

11919

17308

25569

7124

10287

16908

22096

7793

10797

15055

23088

6766

9563

14386

20436

5739

8289

10995

13208

17549

Page 2 of 4

ASTM A106, API 5L and ASTM A53 Seamless Carbon Steel Pipes - Pressure and

Temperature Ratings

Pressure (kPa) and temperature (C) ratings of ASTM A106, API 5L and ASTM A53 Seamless Carbon Steel

Pipes - temperatures ranging -29 C - 450 C

Maximum allowable pressure and temperature ratings for petroleum refinery piping and chemical plant piping

systems grade B with plane ends to ANSI/ASME B31.3 Process Piping.

Nominal

Schedule

Size

no.

(mm)

15

125

150

200

250

300

STD

XS

XXS

STD

XS

40

80

120

160

40

80

120

XXS 160

20

30

STD 40

60

XS

80

100

120

140

XXS

160

20

30

STD 40

XS

60

80

100

120

XXS 140

160

20

30

STD

40

XS

60

80

100

XXS 120

Maximum Allowable Pressure (kPa)

Temperature (C)

Wall

-29

38

205

260

350

370

400

Thickness

Maximum Allowable Stress (kPa)

(mm)

137800 137800 130221 117130 115752 89570

6.55 11561 11561 10921

9825

9708 7510

9.53 17060 17060 16122 14503 14331 11093

12.70 23130 23130 21855 19657 19430 15034

15.88 29407 29407 27787 24997 24701 19113

19.05 35897 35897 33926 30516 30158 23337

7.11 10550 10550

9928

8924

8819 6828

10.97 16474 16474 15571 14007 13842 10707

14.27 21745 21745 20553 18448 18265 14138

18.26 28325 28325 26768 24074 23784 18410

6.35

7138

7138

6745

6063

5994 4637

7.04

7924

7924

7489

6732

6656 5147

8.18

9246

9246

8737

7855

7765 6008

10.31 11741 11741 11093

9977

9860 7627

12.70 14572 14572 13766 12388 12237 9474

150.9 17452 17452 16488 14834 14655 11341

18.26 21345 21345 20174 18148 17935 13876

20.62 24308 24308 22971 20656 20415 15799

22.23 26334 26334 24877 22386 22124 17115

23.01 27340 27340 25838 23240 22964 17769

6.35

5698

5698

5388

4844

4789 3707

7.8

7028

7028

6642

5974

5905 4568

9.27

8385

8385

7923

7131

7048 5450

12.7 11596 11596 10955

9853

9736 7538

15.09 13863 13863 13098 11781 11644 9012

18.26 16922 16922 15992 14386 14214 10996

21.44 20036 20036 18934 17032 16825 13022

25.4 23998 23998 16474 20394 20153 15599

28.58 27229 27229 25734 23143 22875 17700

6.35

4795

4795

4534

4072

4024 3114

8.38

6359

6359

6008

5402

5540 4134

9.53

7241

7241

6842

6153

6084 4706

10.31

7854

7854

7421

6676

6601 5015

12.70

9722

9722

9191

8268

8165 6318

14.27 10969 10969 10363

9322

9212 7131

17.48 13525 13525 12850 11492 11362 8792

21.44 16736 16736 15819 14227 14062 10879

25.4 20015 20015 18913 17011 16811 13008

4301)

450

74412

6243

9212

12492

15881

19388

5370

8895

11747

15296

3852

4279

4995

6339

7868

9426

11527

13125

14221

14765

3080

3796

4527

6263

7483

9136

10817

12960

14703

2591

3431

3914

4244

5250

5925

7303

9040

10804

59943

5038

7421

10059

12795

15620

4568

7165

9460

12319

3100

3445

4024

5105

6338

7593

9288

10569

11458

11892

2480

3059

3652

5043

6028

7359

8716

10438

11844

2088

2763

3149

3417

4230

4768

5884

7283

8702

Page 3 of 4

ASTM A106, API 5L and ASTM A53 Seamless Carbon Steel Pipes - Pressure and

Temperature Ratings

Pressure (kPa) and temperature (C) ratings of ASTM A106, API 5L and ASTM A53 Seamless Carbon Steel

Pipes - temperatures ranging -29 C - 450 C

Maximum allowable pressure and temperature ratings for petroleum refinery piping and chemical plant piping

systems grade B with plane ends to ANSI/ASME B31.3 Process Piping.

300

Nominal

Schedule

Size

no.

(mm)

15

STD

140

160

10

20

30

40

XS

350

STD

XS

400

STD

XS

30

STD

40

60

80

100

120

140

160

10

20

450

500

60

80

100

120

140

160

10

20

30

40

60

80

100

120

140

160

10

20

Maximum Allowable Pressure (kPa)

Temperature (C)

Wall

-29

38

205

260

350

370

400

Thickness

Maximum Allowable Stress (kPa)

(mm)

137800 137800 130221 117130 115752 89570

28.58 22682 22682 21435 19278 19051 14744

33.32 26740 26740 25273 22730 22461 17383

6.35

4361

4361

4120

3707

3665 2831

7.92

5457

5457

5161

4644

4589 3548

9.53

6580

6580

6222

5595

5533 4279

11.13

7717

7717

7310

6559

6477 5016

12.70

8833

8833

8351

7510

7421 5739

15.09 10541 10541

9963

8964

8861 6855

19.05 13421 13421 12684 11410 11272 9723

23.83 16949 16949 16019 14407 14242 11017

27.79 19933 19933 18837 16943 16743 12960

31.75 22964 22964 21703 19519 19292 14931

35.71 26051 26051 24618 22144 21883 16936

6.35

3810

3810

3603

3238

3197 2474

7.92

4768

4768

4507

4051

4004 3100

9.53

5746

5746

5429

4885

4830 3734

12.70

7703

7703

7283

6545

6470 5009

16.66 10176 10176

9618

8654

8550 6614

21.44 13208 13208 12478 11224 11093 8585

26.19 16274 16274 15378 13835 13670 10576

30.96 19409 19409 18341 16481 16302 12616

36.53 23130 23130 21855 19657 19430 15034

40.49 25824 25824 24404 21952 21697 16784

6.35

3383

3383

3197

2873

2839 2198

7.92

4230

4230

3996

3597

3555 2749

9.53

5099

5099

4816

4334

4286 3314

11.13

5967

5967

5643

5071

5016 3879

12.70

6835

6835

6456

5808

5739 4437

14.27

7696

7696

7276

6545

6463 5002

19.05 10349 10349

9784

8799

8695 6725

23.83 13043 13043 12326 11086 10955 8475

29.36 16219 16219 15323 13787 13622 10542

34.93 19464 19464 18389 16543 16350 12650

39.67 22282 22282 21056 18941 18713 11483

45.24 25638 25638 24225 21793 21531 16660

6.35

3038

3038

2873

2574

2556 1977

9.53

4582

4582

4327

3893

3852 2976

4301)

450

74412

12244

14441

2356

2949

3555

4168

4768

5691

7248

9157

10762

12402

14069

2060

2577

3100

4126

5498

7131

8785

10480

12492

13945

1826

2287

2756

3225

3686

4155

5588

7042

8757

10507

12030

13842

1640

2474

59943

9866

11630

1895

2377

2866

3355

3845

4589

5836

7372

8675

9990

11334

1660

2074

2501

3349

4430

5746

7076

8440

10059

11238

1474

1839

2219

2598

2969

3349

4499

5670

7055

8468

9694

11155

1323

1991

Page 4 of 4

ASTM A106, API 5L and ASTM A53 Seamless Carbon Steel Pipes - Pressure and

Temperature Ratings

Pressure (kPa) and temperature (C) ratings of ASTM A106, API 5L and ASTM A53 Seamless Carbon Steel

Pipes - temperatures ranging -29 C - 450 C

Maximum allowable pressure and temperature ratings for petroleum refinery piping and chemical plant piping

systems grade B with plane ends to ANSI/ASME B31.3 Process Piping.

Nominal

Schedule

Size

no.

(mm)

XS

15

500

STD

XS

600

30

40

60

80

100

120

140

160

10

20

30

40

60

80

100

120

140

160

Maximum Allowable Pressure (kPa)

Temperature (C)

Wall

-29

38

205

260

350

370

400

Thickness

Maximum Allowable Stress (kPa)

(mm)

137800 137800 130221 117130 115752 89570

12.70

6139

6139

5801

5216

5154 3989

15.09

7317

7317

6911

6215

6146 4754

20.62 10080 10080

9522

8564

8468 6552

26.19 12898 12898 12188 10962 10831 8385

32.54 16171 16171 15287 13746 13580 10514

38.10 19085 19085 18037 16226 16033 12409

44.45 22475 22475 21242 19106 18879 14614

50.01 25450 25450 24094 21675 21421 16577

6.35

2529

2529

2391

2150

2129 1647

9.53

3810

3810

3603

3238

3197 2474

12.70

5097

5097

4816

4334

4286 3314

14.27

5739

5739

5423

4878

4823 3734

17.48

7055

7055

6670

5994

5925 4589

24.61 10018 10018

9467

8516

8420 6511

30.96 12691 12691 12002 10783 10659 8254

38.89 16102 16102 15220 13690 10528 10466

46.02 19223 19223 18168 16336 16150 12491

52.37 22048 22048 20835 18741 18520 14331

59.54 25279 25279 23888 21489 21235 16433

4301)

450

74412 59943

3314 2666

3948 3183

5443 4382

6966 5608

8730 7035

10307 8302

12140 9777

13766 11093

1364 1102

2060 1660

2756 2219

3100 2494

3810 3066

5409 4361

6856 5519

8695 7007

10383 8364

11906 9591

13649 10996

1)

Due to possible conversion of carbon to graphite (graphitization) - carbon steel pipes should be avoided for

temperatures above 425oC. Instead Alloy steel should be used.

1 Pa = 10-6 N/mm2 = 10-5 bar = 0.1020 kp/m2 = 1.02x10-4 m H2O = 9.869x10-6 atm = 1.45x10-4 psi (lbf/in2)

T(oF) = [T(oC)](9/5) + 32

You might also like

- Solvent Cement For Joining PVC Pipe FormulationDocument2 pagesSolvent Cement For Joining PVC Pipe Formulationnano100% (1)

- PTP5 Assembly GuideDocument8 pagesPTP5 Assembly Guidepippo2378793100% (1)

- Metric Dimensions and Weights of Seamless and Welded Steel Pipe PDFDocument1 pageMetric Dimensions and Weights of Seamless and Welded Steel Pipe PDFAnonymous xcFcOgMiNo ratings yet

- Conmaco 385 Winch ManualDocument44 pagesConmaco 385 Winch ManualdarioNo ratings yet

- Calculation According To Euler: Piston Rod SelectionDocument2 pagesCalculation According To Euler: Piston Rod SelectionbalajimetturNo ratings yet

- FRP Duct ThicknessDocument33 pagesFRP Duct ThicknessAdrian RogersNo ratings yet

- ManualDocument71 pagesManualMichael Adu-boahenNo ratings yet

- Table A.23 Physical Properties of Selected Fluids (Engineering Thermodynamics by Burghardt & Harbach)Document1 pageTable A.23 Physical Properties of Selected Fluids (Engineering Thermodynamics by Burghardt & Harbach)lemuel andrezaNo ratings yet

- MaterialData - Nylon 101Document3 pagesMaterialData - Nylon 101maxthesuperiorNo ratings yet

- Saturation TablesDocument44 pagesSaturation TablesPrathik KaundinyaNo ratings yet

- Design of Joints and SupportDocument7 pagesDesign of Joints and SupportMuhammad Muzamil Mazri0% (1)

- A5 15-90 (R2006) PV PDFDocument5 pagesA5 15-90 (R2006) PV PDFAnghelo AlcaldeNo ratings yet

- Pipe Schedule and Thickness PDFDocument2 pagesPipe Schedule and Thickness PDFskychurch100% (1)

- Nace HT ServiceDocument34 pagesNace HT ServiceKARTHIKPRITHEEPNo ratings yet

- Pipe Coupling DimensionsDocument7 pagesPipe Coupling DimensionssuryohandokoNo ratings yet

- STAHL Poster Safety RealityDocument1 pageSTAHL Poster Safety Realityedwardesjr100% (1)

- KSB Sicca HP Cast Gate Valve PDFDocument4 pagesKSB Sicca HP Cast Gate Valve PDFJamalNo ratings yet

- Steam Traps SIPDocument71 pagesSteam Traps SIPAqeel Bisma100% (1)

- Velcon FiltersDocument2 pagesVelcon FiltersLungisani100% (1)

- Dimensions of End Caps According To Asme b16Document2 pagesDimensions of End Caps According To Asme b16jfl2096No ratings yet

- NCG MeasuringDocument20 pagesNCG MeasuringAhmed AlfatihNo ratings yet

- Gauge Accessories - Syphons TypeDocument2 pagesGauge Accessories - Syphons Typecasio662No ratings yet

- Compilation OF Air Pollutant Emission Factors: Third EditionDocument548 pagesCompilation OF Air Pollutant Emission Factors: Third EditionMelvinDapitanonNo ratings yet

- Maximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDocument5 pagesMaximum Pressure Rating Schedule 160, Schedule 40 and Schedule 80 - Engineers EdgeDevanshu KrNo ratings yet

- BN-DS-C58 90 Degree Three Weld Long Radius Miter ElbowDocument7 pagesBN-DS-C58 90 Degree Three Weld Long Radius Miter ElbowGunanithi RathnavelNo ratings yet

- Petroleum Asphalt Plant: Q - Iso Technology Co., Ltd. Seoul, KoreaDocument8 pagesPetroleum Asphalt Plant: Q - Iso Technology Co., Ltd. Seoul, KoreaCalNo ratings yet

- Lifting Eye Blind: NotesDocument1 pageLifting Eye Blind: Notesnarutothunderjet216No ratings yet

- Design-Calculation Acid Wash TankDocument5 pagesDesign-Calculation Acid Wash TankWiz DomNo ratings yet

- Bell Method Example 7 5Document9 pagesBell Method Example 7 5Amin FarukiNo ratings yet

- CPA 50E Type A RF Dimensional Specifications - May 2013Document1 pageCPA 50E Type A RF Dimensional Specifications - May 2013Karthick RamasubramanianNo ratings yet

- Manholes Asme VIII 1 2010Document1 pageManholes Asme VIII 1 2010zopitaNo ratings yet

- Babcock & Wilcox Steam TablesDocument5 pagesBabcock & Wilcox Steam Tablesnum0067No ratings yet

- Acessórios Cloro Gás - VaccupermDocument28 pagesAcessórios Cloro Gás - Vaccupermbalzac1910% (1)

- AV-C Butterfly ValveDocument20 pagesAV-C Butterfly ValveSopon SrirattanapiboonNo ratings yet

- Pressure. Pressure and Temperature Ratings For Steel Pipe Flanges and Flanged Fittings. ANSI B16.5Document45 pagesPressure. Pressure and Temperature Ratings For Steel Pipe Flanges and Flanged Fittings. ANSI B16.5vyrgoNo ratings yet

- KB Coupling CatalogueDocument2 pagesKB Coupling CatalogueGaurav BedseNo ratings yet

- D3567Document4 pagesD3567Chengkc2014No ratings yet

- Wartsila 34df LeafletDocument5 pagesWartsila 34df LeafletJaya BharathiNo ratings yet

- ScrollDocument8 pagesScrolltrung2iNo ratings yet

- Diaphragm Pump Viscosity Correction GraphDocument2 pagesDiaphragm Pump Viscosity Correction GraphSebastian BaezNo ratings yet

- Flygt 3153 PDFDocument38 pagesFlygt 3153 PDFMarcelo DelgadoNo ratings yet

- Tank Sizes and Corresponding Nominal CapacitiesDocument1 pageTank Sizes and Corresponding Nominal Capacitieskaito kidNo ratings yet

- Calculation of Pentock SizeDocument1 pageCalculation of Pentock SizePhyu Mar Thein KyawNo ratings yet

- Guidelines For Certification of Lifting Appliances (7-1) - 2013Document116 pagesGuidelines For Certification of Lifting Appliances (7-1) - 2013irmaNo ratings yet

- Carbon Steel Flanges Dimensions and WeightsDocument3 pagesCarbon Steel Flanges Dimensions and WeightsChandan AulakhNo ratings yet

- Bandlock2 LiteratureDocument2 pagesBandlock2 LiteraturelaiminhtheNo ratings yet

- Catalogo Valvulas Forged Velan PDFDocument36 pagesCatalogo Valvulas Forged Velan PDFCarlosEduardoMorenoManceraNo ratings yet

- Tubesheet As Per ASME Sec. VIII-Div.1 UHXDocument1 pageTubesheet As Per ASME Sec. VIII-Div.1 UHXruponline1No ratings yet

- Product Catlogue Piping MaterialDocument25 pagesProduct Catlogue Piping Materialnedumaran.sNo ratings yet

- Molino 490pmb Vers 3.0 InglDocument14 pagesMolino 490pmb Vers 3.0 InglMahmoud Abd-Elhamid Abu EyadNo ratings yet

- IanDickie Euroflo EU Series 2 2013 PDFDocument11 pagesIanDickie Euroflo EU Series 2 2013 PDFduongpnNo ratings yet

- Fluid Mechanics ÇENGELDocument5 pagesFluid Mechanics ÇENGELNameis GhoffarNo ratings yet

- Electric Hoists PDFDocument18 pagesElectric Hoists PDFedark2009No ratings yet

- Digital Online TDS MeterDocument6 pagesDigital Online TDS MeterArun GuptaNo ratings yet

- Style Size Part # I.D. O.D. B.C. Hole Dia.: Ttma Flange & Sump GasketsDocument1 pageStyle Size Part # I.D. O.D. B.C. Hole Dia.: Ttma Flange & Sump GasketsDaniel Farfan100% (1)

- Mechanical Engineering ProblemsDocument2 pagesMechanical Engineering ProblemsEnriv YasiladNo ratings yet

- Zeng 1987Document12 pagesZeng 1987obaidullah.dsuNo ratings yet

- Pressure Relief Valve Sizing and Selection CheckDocument2 pagesPressure Relief Valve Sizing and Selection CheckGiftObionochie100% (2)

- Dimensions Spiral Wound Gaskets (ASME B16-20) For Flanges According To ASME EN 1759-1 Part2Document6 pagesDimensions Spiral Wound Gaskets (ASME B16-20) For Flanges According To ASME EN 1759-1 Part2Emil Florin TutaNo ratings yet

- Utilities - 2019 - : PreambleDocument110 pagesUtilities - 2019 - : PreambleHARINo ratings yet

- Flange GradesDocument8 pagesFlange Gradesaateka02No ratings yet

- Maximum Allowable Pressure and Temperature Ratings For Petroleum Refinery Piping and Chemical Plant Piping Systems Grade B With Plane Ends ToDocument9 pagesMaximum Allowable Pressure and Temperature Ratings For Petroleum Refinery Piping and Chemical Plant Piping Systems Grade B With Plane Ends Toaran1000No ratings yet

- Protractor IEC PDFDocument1 pageProtractor IEC PDFpippo2378793No ratings yet

- Outermost Groove: 146.05 MM (IEC) Tracking Error: Mounting D Istance OverhangDocument1 pageOutermost Groove: 146.05 MM (IEC) Tracking Error: Mounting D Istance Overhangpippo2378793No ratings yet

- Composites Part B: Rafal Oliwa, Maciej Heneczkowski, Mariusz Oleksy, Henryk GalinaDocument8 pagesComposites Part B: Rafal Oliwa, Maciej Heneczkowski, Mariusz Oleksy, Henryk Galinapippo2378793No ratings yet

- Ve Denon Da-307 Template en JPDocument2 pagesVe Denon Da-307 Template en JPpippo2378793No ratings yet

- P103 Vibration Damping of Fiber-Reinforced Polyurethane Using High and Negative Poisson'S Ratio LaminatesDocument15 pagesP103 Vibration Damping of Fiber-Reinforced Polyurethane Using High and Negative Poisson'S Ratio Laminatespippo2378793No ratings yet

- StereoLife - Devialet Expert 140 ProDocument15 pagesStereoLife - Devialet Expert 140 Propippo2378793No ratings yet

- Mist Elimination Liquid Liquid CoalescingDocument20 pagesMist Elimination Liquid Liquid Coalescingpippo2378793No ratings yet

- Gas Liquid Separators Bothamley JM CampbellDocument9 pagesGas Liquid Separators Bothamley JM CampbellLTORRESM100% (1)

- Self On Audio Book ReviewDocument4 pagesSelf On Audio Book Reviewpippo2378793No ratings yet

- Hfe Vincent Hear The Sound 2012-13 enDocument43 pagesHfe Vincent Hear The Sound 2012-13 enpippo2378793No ratings yet

- Design of Partition PlateDocument5 pagesDesign of Partition Platepippo2378793No ratings yet

- Ammonium Chloride: Safety Data SheetDocument8 pagesAmmonium Chloride: Safety Data Sheetpippo2378793No ratings yet

- Hfe Marantz Pm6010 Ose enDocument10 pagesHfe Marantz Pm6010 Ose enpippo2378793No ratings yet

- Tubesheet: Design of Collar BoltDocument1 pageTubesheet: Design of Collar Boltpippo2378793No ratings yet

- Ch3pro220 1 PDFDocument25 pagesCh3pro220 1 PDFpippo2378793No ratings yet

- !!! 1 Cold-Formed Steel Framing Standards Design Aids Roger LaBoubeDocument108 pages!!! 1 Cold-Formed Steel Framing Standards Design Aids Roger LaBoubeAnonymous hprsT3WlP100% (3)

- Term Project-I Mechanics of CompositesDocument2 pagesTerm Project-I Mechanics of CompositesParveen Sahni ErNo ratings yet

- Certifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itDocument1 pageCertifcato Di Collaudo/Test Certificate: Info@lame-Srl.191.itMohamed RaafatNo ratings yet

- Kecacatan KimpalanDocument26 pagesKecacatan KimpalanMaruan MuhammadNo ratings yet

- Conbextra GPIDocument4 pagesConbextra GPIVenkata Raju KalidindiNo ratings yet

- Acristar #200Document1 pageAcristar #200ChristinaNo ratings yet

- Equal Leg Angles To en 10056-1 1998 Dim - PropDocument2 pagesEqual Leg Angles To en 10056-1 1998 Dim - PropJagdish Chhugani100% (2)

- Bolts Connection Technique of Bamboo inDocument7 pagesBolts Connection Technique of Bamboo inBRYLLE KYLLE OIDEMNo ratings yet

- LibanCables PDFDocument62 pagesLibanCables PDFRony NasrNo ratings yet

- 2017-11-06 Guideline 36 Draft 3Document182 pages2017-11-06 Guideline 36 Draft 3Jack Ng100% (2)

- Example of A Landslide StabilizationDocument45 pagesExample of A Landslide StabilizationAnonymous D5s00DdUNo ratings yet

- PCI Product Tolerances Manual MNL-135-00Document191 pagesPCI Product Tolerances Manual MNL-135-00karledwards713No ratings yet

- Effizienzhausplus Elektromobil en Aufl1Document17 pagesEffizienzhausplus Elektromobil en Aufl1Wessel SimonsNo ratings yet

- Bill of Quantity For Silo FoundationDocument6 pagesBill of Quantity For Silo Foundationlaxmi sunder libiNo ratings yet

- Soil Release FinishesDocument25 pagesSoil Release Finisheschahat anejaNo ratings yet

- ASTM C143 ProcedureDocument2 pagesASTM C143 ProcedurefarooqNo ratings yet

- Design For Reinforcement in Pier: Slenderness RatioDocument2 pagesDesign For Reinforcement in Pier: Slenderness RatioPreetam SundarayNo ratings yet

- Question Bank 1 CastingDocument14 pagesQuestion Bank 1 Castingbadr31102005No ratings yet

- Element of Structure: Construction of HCB: Submitted By: For ContractorDocument1 pageElement of Structure: Construction of HCB: Submitted By: For Contractorbedr kemeredinNo ratings yet

- 02 - Technical Specifications - Cast-In-Place ConcreteDocument15 pages02 - Technical Specifications - Cast-In-Place ConcreteMarcons Jon Maturan CasabaNo ratings yet

- CE - McGraw HillDocument6 pagesCE - McGraw HilldeathesNo ratings yet

- Trojan UVMax G H J ManualDocument24 pagesTrojan UVMax G H J ManualGreg ReynekeNo ratings yet

- Type-61 ElastomerSeatedButterflyValves 10 28 2022Document10 pagesType-61 ElastomerSeatedButterflyValves 10 28 2022viksursNo ratings yet

- Project InformationDocument203 pagesProject InformationPaul RaduNo ratings yet

- Dairy PlanDocument1 pageDairy PlanAmol GhodkeNo ratings yet

- Cement Mill 1 Inspection 12th Feb. 2019 and CALCULATIONSDocument7 pagesCement Mill 1 Inspection 12th Feb. 2019 and CALCULATIONSBenNo ratings yet

- A PistonDocument3 pagesA PistonSamuel NapitupuluNo ratings yet

- Consumer Chemistry (CH 419)Document9 pagesConsumer Chemistry (CH 419)Mihir Kumar MechNo ratings yet