1gr Fe Vvtisystem

1gr Fe Vvtisystem

Uploaded by

Gepenx AriesCopyright:

Available Formats

1gr Fe Vvtisystem

1gr Fe Vvtisystem

Uploaded by

Gepenx AriesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

1gr Fe Vvtisystem

1gr Fe Vvtisystem

Uploaded by

Gepenx AriesCopyright:

Available Formats

NEW FEATURES 1GR-FE ENGINE

55

8. VVT-i (Variable Valve Timing-intelligent) System

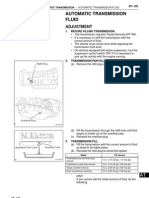

General D The VVT-i system is designed to control the intake camshaft within a range of 50_ (of Crankshaft Angle) to provide valve timing that is optimally suited to the engine condition. This improves torque in all the speed ranges as well as increasing fuel economy, and reducing exhaust emissions.

VVT Sensor (Right Bank) Camshaft Timing Oil Control Valve

Engine Coolant Temp. Sensor

Throttle Position Sensor

NF

ECM

Camshaft Timing Oil Control Valve

VVT Sensor (Left Bank) Crankshaft Position Sensor

Mass Air Flow Meter

238EG60

D Using the engine speed, intake air volume, throttle position and engine coolant temperature, the ECM can calculate optimal valve timing for each driving condition and controls the camshaft timing oil control valve. In addition, the ECM uses signals from the camshaft position sensor and the crankshaft position sensor to detect the actual valve timing, thus providing feedback control to achieve the target valve timing.

ECM Crankshaft Position Sensor Mass Air Flow Meter Throttle Position Sensor Engine Coolant Temp. Sensor VVT Sensors Vehicle Speed Signal

221EG16

Target Valve Timing Duty-cycle Control Feedback Correction Actual Valve Timing

Camshaft Timing Oil Control Valve

56

NEW FEATURES 1GR-FE ENGINE Effectiveness of the VVT-i System

Operation State

TDC

Objective

Latest Timing

Effect

During Idling

EX

IN

Eliminating overlap to reduce blow back to the intake side

D Stabilized idling rpm D Better fuel economy

BDC

188EG51

to Retard Side

At Light Load

EX

IN

Decreasing overlap to eliminate blow back to the intake side.

Ensured engine stability

188EG64

to Advance Side

At Medium Load

EX

IN

Increasing overlap to increase internal EGR to reduce pumping loss

D Better fuel economy D Improved emission control

188EG65 TDC

In Low to Medium Speed Range with Heavy Load

EX

IN

Advancing the intake valve close timing for volumetric efficiency improvement

Improved torque in low to medium speed range

to Advance Side

BDC 188EG66

In High Speed Range with Heavy Load

EX

IN

Retarding the intake valve close timing for volumetric efficiency improvement

Improved output

to Retard Side

188EG67

Latest Timing

At Low Temperatures

EX

IN

188EG53

Eliminating overlap to prevent blow back to the intake side leads to the lean burning condition, and stabilizes the idling speed at fast idle

D Stabilized fast idle rpm D Better fuel economy

Latest Timing

D Upon Starting D Stopping the Engine

EX

IN

Eliminating overlap to minimize blow back to the intake side

Improved startability

188EG53

NEW FEATURES 1GR-FE ENGINE Construction 1) VVT-i Controller

57

This controller consists of the housing driven from the timing chain and the vane coupled with the intake camshaft. The oil pressure sent from the advance or retard side path at the intake camshaft causes rotation in the VVT-i controller vane circumferential direction to vary the intake valve timing continuously. When the engine is stopped, the intake camshaft will be in the most retarded state to ensure startability. When hydraulic pressure is not applied to the VVT-i controller immediately after the engine has been started, the lock pin locks the movement of the VVT-i controller to prevent a knocking noise.

NF

Lock Pin Housing Timing Rotor Intake Camshaft

Sprocket Vane (Fixed on Intake Camshaft)

Oil Pressure

238EG61

In Operation

At a Stop

Lock Pin 2) Camshaft Timing Oil Control Valve This camshaft timing oil control valve controls the spool valve position in accordance with the duty-cycle control from the ECM. This allows hydraulic pressure to be applied to the VVT-i controller advance or retard side. When the engine is stopped, the camshaft timing oil control valve is in the most retarded state.

To VVT-i Controller (Advance Side) Sleeve Sleeve

To VVT-i Controller (Retard Side)

Drain

Drain

Coil Spool Valve

Plunger

238EG62

Oil Pressure

58 Operation 1) Advance

NEW FEATURES 1GR-FE ENGINE

When the camshaft timing oil control valve is positioned as illustrated below by the advance signals from the ECM, the resultant oil pressure is applied to the vane chamber of advance side to rotate the camshaft in the timing advance direction.

Vane

ECM

Oil Pressure Rotation Direction IN Drain

238EG63

2) Retard When the camshaft timing oil control valve is positioned as illustrated below by the retard signals from the ECM, the resultant oil pressure is applied to the vane chamber of retard side to rotate the camshaft in the timing retard direction.

Rotation Direction

ECM

Oil Pressure Vane Drain IN

238EG64

3) Hold After reaching the target timing, the valve timing is held by keeping the camshaft timing oil control valve in the neutral position unless the traveling state changes. This adjusts the valve timing at the desired target position and prevents the engine oil from running out when it is unnecessary.

You might also like

- Bobcat 630 631 632 PartsManualOCRSmallDocument242 pagesBobcat 630 631 632 PartsManualOCRSmallRicky Vil100% (11)

- Yaris TS Turbo Parts Catalogue - EUDocument35 pagesYaris TS Turbo Parts Catalogue - EUCarlos FernandoNo ratings yet

- Cat 3408 3412 Valve AdjustmentDocument10 pagesCat 3408 3412 Valve AdjustmentW Morales91% (44)

- Tenere Service ManualDocument472 pagesTenere Service Manualcerruti5100% (6)

- Troubleshooting A442Document41 pagesTroubleshooting A442Tony Ngatia100% (1)

- Lubrication (2jz-Ge)Document15 pagesLubrication (2jz-Ge)AlexendraNo ratings yet

- Daihatsu Fault Codes DTCDocument1 pageDaihatsu Fault Codes DTCمحمد عبد الفتاح محمدNo ratings yet

- Throttle Body Dan TPS Corolla 88-97Document4 pagesThrottle Body Dan TPS Corolla 88-97Fitri Wibowo100% (1)

- Corrections To Repair Manual RM990E: Prado 120Document10 pagesCorrections To Repair Manual RM990E: Prado 120Master XeotoNo ratings yet

- Preparation 2zr-Fe Engine Mechanical SST PDFDocument3 pagesPreparation 2zr-Fe Engine Mechanical SST PDFAlbert BriceñoNo ratings yet

- Ec PDFDocument419 pagesEc PDFNimsiri Abhayasinghe100% (1)

- 1MZ-FE Engine Control SystemRX300 99Document11 pages1MZ-FE Engine Control SystemRX300 99Jose Calle100% (2)

- Motor N20Document135 pagesMotor N20victor manuel100% (1)

- Corolla Altis Minor ChangeDocument156 pagesCorolla Altis Minor Changedavit eka putraNo ratings yet

- Toyota 2az FeDocument9 pagesToyota 2az FeFerran AlfonsoNo ratings yet

- The Export Version of The 2JZDocument3 pagesThe Export Version of The 2JZSaad KhanNo ratings yet

- Installation: 1Gr-Fe Exhaust - Exhaust PipeDocument3 pagesInstallation: 1Gr-Fe Exhaust - Exhaust Pipejhon greigNo ratings yet

- At - Automatic TransaxelDocument400 pagesAt - Automatic TransaxelIlarion CiobanuNo ratings yet

- Installation: 1Gr-Fe Engine Mechanical - Drive BeltDocument1 pageInstallation: 1Gr-Fe Engine Mechanical - Drive BeltPedro Javier Castro SanchezNo ratings yet

- 2UZTRDDocument33 pages2UZTRDJd BuzzNo ratings yet

- Adjustment: 1. Inspect Park/Neutral Position Switch AssyDocument50 pagesAdjustment: 1. Inspect Park/Neutral Position Switch AssyRobert VargasNo ratings yet

- 1gr-Fe Engine Control System - Sfi SystemDocument5 pages1gr-Fe Engine Control System - Sfi Systemtef4u100% (3)

- Torque Converter: Chassis - A340E, A340F, A343E and A343F Automatic Transmissions CH-13Document1 pageTorque Converter: Chassis - A340E, A340F, A343E and A343F Automatic Transmissions CH-13Maxi SardiNo ratings yet

- 1gr-Fe SfiDocument68 pages1gr-Fe SfiByron GómezNo ratings yet

- DTC P1349/73 VVT System Malfunction: Wiring DiagramDocument5 pagesDTC P1349/73 VVT System Malfunction: Wiring DiagramAnonymous tWYsgPmNo ratings yet

- Honda Diagnostic CodesDocument10 pagesHonda Diagnostic CodesAngela Easter100% (1)

- Расшифровка CHEVROLET PDFDocument61 pagesРасшифровка CHEVROLET PDFАлександрNo ratings yet

- E Manage Ultimate Wiring Steps For JDM Supra With 2JZ GEDocument7 pagesE Manage Ultimate Wiring Steps For JDM Supra With 2JZ GECosta TsimiklisNo ratings yet

- Fuse Box Diagram Toyota Alphard 1G and Relay With Assignment and LocationDocument1 pageFuse Box Diagram Toyota Alphard 1G and Relay With Assignment and LocationSiu Kit YauNo ratings yet

- Ta1248 PDFDocument38 pagesTa1248 PDFbad_boyz1989No ratings yet

- Pre Check: 1. Diagnosis SystemDocument10 pagesPre Check: 1. Diagnosis Systemcelestino tuliaoNo ratings yet

- Transmission Servicing AT PDFDocument7 pagesTransmission Servicing AT PDFMiike Md ZamriNo ratings yet

- V4A51 Disassembly SectionDocument45 pagesV4A51 Disassembly SectionTravis ObrienNo ratings yet

- Diagnostic Trouble Code Chart: 2Az-Fe Engine Control System - Sfi SystemDocument11 pagesDiagnostic Trouble Code Chart: 2Az-Fe Engine Control System - Sfi SystemDark SideNo ratings yet

- 3.3L 6-Cyl VinDocument28 pages3.3L 6-Cyl VingypsyshortNo ratings yet

- Blitz FATT DC InstallationDocument4 pagesBlitz FATT DC InstallationDave_BNo ratings yet

- A750E Automatic Transmission Fluid AdjusmentDocument3 pagesA750E Automatic Transmission Fluid AdjusmentMarivic Diaz100% (2)

- Elantra 2004 2.0LDocument277 pagesElantra 2004 2.0LJohan7880No ratings yet

- 4 Throttles' Vacuum From Toyota Corolla Levin AE101 4A-GE 20vDocument6 pages4 Throttles' Vacuum From Toyota Corolla Levin AE101 4A-GE 20vTobyNo ratings yet

- DTC P0500 Vehicle Speed Sensor "A": Circuit DescriptionDocument4 pagesDTC P0500 Vehicle Speed Sensor "A": Circuit Descriptionjeremih alhegnNo ratings yet

- Captiva Control Valve Body Removal PDFDocument2 pagesCaptiva Control Valve Body Removal PDFBurhan udinNo ratings yet

- Ignition System 1. General: Engine - 2Tr-Fe Engine EG-24Document2 pagesIgnition System 1. General: Engine - 2Tr-Fe Engine EG-24Maxi SardiNo ratings yet

- EngineDocument321 pagesEngineKammoeNo ratings yet

- Prelude Usdm Pk2 (B20a5) Ecu PinoutDocument1 pagePrelude Usdm Pk2 (B20a5) Ecu PinoutluckypicturesNo ratings yet

- Technical Service Bulletin: M.I.L. On" 1Mz-Fe Engine Misfire DTC P0300, P0301, P0302, P0303, P0304, P0305 OR P0306Document3 pagesTechnical Service Bulletin: M.I.L. On" 1Mz-Fe Engine Misfire DTC P0300, P0301, P0302, P0303, P0304, P0305 OR P0306Sesan Fesobi100% (1)

- Tormoza HD-120 PDFDocument91 pagesTormoza HD-120 PDFанджелаNo ratings yet

- DTC 61 No. 2 Speed Sensor Circuit MalfunctionDocument3 pagesDTC 61 No. 2 Speed Sensor Circuit Malfunctioncelestino tuliao100% (1)

- P0405-96 P0406-96 Taken From 2KD Manual - To Be CheckedDocument4 pagesP0405-96 P0406-96 Taken From 2KD Manual - To Be CheckedBiniyam BekeleNo ratings yet

- A340E and A343E Automatic Transmissions: DescriptionDocument8 pagesA340E and A343E Automatic Transmissions: DescriptionArda Billy24No ratings yet

- Engine Control For 2TR-FE: 90 Toyota Tacoma (Em01D0U)Document12 pagesEngine Control For 2TR-FE: 90 Toyota Tacoma (Em01D0U)hamayunNo ratings yet

- Enginecontrol VVTi EnglishDocument13 pagesEnginecontrol VVTi EnglishSatrio Ongis NadeNo ratings yet

- Checkballbook: Import Volume IIIDocument10 pagesCheckballbook: Import Volume IIIFS TRANSMISSÕESNo ratings yet

- Toyota TSB - Hard Start or Poor Idle After 12V Power InterruptionDocument2 pagesToyota TSB - Hard Start or Poor Idle After 12V Power InterruptionMaster XeotoNo ratings yet

- Diagramas El - Ctricos TOYOTA LANDCRUISER V8-4.7L (2UZ-FE) 2003Document72 pagesDiagramas El - Ctricos TOYOTA LANDCRUISER V8-4.7L (2UZ-FE) 2003RustiSnorkelNo ratings yet

- Windows PDFDocument43 pagesWindows PDFCatalin BuleandraNo ratings yet

- Auto Trans DiagnosisDocument31 pagesAuto Trans Diagnosissonny1234No ratings yet

- Pressure Reducing Valve Kit: Hyundai/Kia A4CF1, A4CF2Document2 pagesPressure Reducing Valve Kit: Hyundai/Kia A4CF1, A4CF2ossoskiNo ratings yet

- ECM TerminalsDocument2 pagesECM TerminalsDaniel Mamani ParedezNo ratings yet

- RE4F04Document81 pagesRE4F04Derek Cisneros LeonNo ratings yet

- VVT Sensor PDFDocument4 pagesVVT Sensor PDFDoDuyBac100% (1)

- VVT-i (Variable Valve Timing-Intelligent) System: GeneralDocument5 pagesVVT-i (Variable Valve Timing-Intelligent) System: GeneralsadiksnmNo ratings yet

- VVT-i (Variable Valve Timing-Intelligent) SystemDocument4 pagesVVT-i (Variable Valve Timing-Intelligent) SystemJorge Armando VelázquezNo ratings yet

- VVT (Variable Valve Timing)Document26 pagesVVT (Variable Valve Timing)PramodPradhan100% (1)

- Miscellaneous Information On AutomotiveDocument6 pagesMiscellaneous Information On AutomotiveShashank ChheniyaNo ratings yet

- DTU New Syllabus For MEDocument83 pagesDTU New Syllabus For MEHari SreyasNo ratings yet

- Lubricants Fundamentals IociDocument84 pagesLubricants Fundamentals IociSrikanth AnchulaNo ratings yet

- MSG425 Parts Manual Rev5Document34 pagesMSG425 Parts Manual Rev5aramosmadisaNo ratings yet

- N60 Ent M37 DS P3d04n002eDocument4 pagesN60 Ent M37 DS P3d04n002eEko Prayitno100% (1)

- Bulker LoadingDocument8 pagesBulker LoadingStathis MoumousisNo ratings yet

- Buildjournal B-Spec Tune OptionsDocument2 pagesBuildjournal B-Spec Tune OptionsTony MergouzyNo ratings yet

- 89p303 Touareg Electronic Diesel Control EDC 16 Design and FunctionDocument55 pages89p303 Touareg Electronic Diesel Control EDC 16 Design and Functioneduardorojas007100% (1)

- ED1811Document3 pagesED1811Serví Diesel San juan SACNo ratings yet

- Electronic Parts Catalog - Option DetailDocument2 pagesElectronic Parts Catalog - Option DetailhastaNo ratings yet

- Hydraulic Roller CamshaftsDocument12 pagesHydraulic Roller Camshaftscrower_scribdNo ratings yet

- Electrical and Electronic SystemsDocument49 pagesElectrical and Electronic SystemsHartono Exca100% (1)

- Catalog FFS PDFDocument24 pagesCatalog FFS PDFDANE80No ratings yet

- Kta19 P525Document4 pagesKta19 P525Benjamin FigueroaNo ratings yet

- DTS-i EngineDocument20 pagesDTS-i EngineRajesh PandaNo ratings yet

- Fuels and LubricantsDocument2 pagesFuels and Lubricantsraumil1237590No ratings yet

- Yamaha Y80 PartsCatalogue PDFDocument55 pagesYamaha Y80 PartsCatalogue PDFJowo LineNo ratings yet

- Ty Tg8000cxev PL M Rev01Document11 pagesTy Tg8000cxev PL M Rev01xmlchulipaNo ratings yet

- Graph Between 1 Stage, 2 Stage and Overall Pressure Ratio With Air Flow Volume With IntercoolingDocument3 pagesGraph Between 1 Stage, 2 Stage and Overall Pressure Ratio With Air Flow Volume With IntercoolingTalha RaeesNo ratings yet

- Caterpillar C280 Series Engine Product GuideDocument221 pagesCaterpillar C280 Series Engine Product GuideIvan Aditya100% (1)

- Mazda 626 B 1998 EU SupplementDocument270 pagesMazda 626 B 1998 EU SupplementCarlitos RamosNo ratings yet

- H2S Tower DesignDocument20 pagesH2S Tower DesignAnonymous hThGjdZbNo ratings yet

- Jarvi 2010-Methane Slip Reduction in Wartsila Lean Burn Gas EnginesDocument11 pagesJarvi 2010-Methane Slip Reduction in Wartsila Lean Burn Gas EnginessestoubosNo ratings yet

- TM 9-1827aDocument223 pagesTM 9-1827aNestor AmayaNo ratings yet

- Micro CHP PDFDocument4 pagesMicro CHP PDFtrungnguyenphuoc100% (1)

- PDF Solution Manual For Gas Turbine Theory 6th Edition Saravanamuttoo Rogers CompressDocument7 pagesPDF Solution Manual For Gas Turbine Theory 6th Edition Saravanamuttoo Rogers CompressErickson Brayner MarBerNo ratings yet

- Aircraft EnginesDocument20 pagesAircraft EnginesMuhammad AbidNo ratings yet