Risk Assessment No. 02 ANCHOR HANDLING, RETREVING CRUCIFIX B

Risk Assessment No. 02 ANCHOR HANDLING, RETREVING CRUCIFIX B

Uploaded by

Devi Ratna PratiwiCopyright:

Available Formats

Risk Assessment No. 02 ANCHOR HANDLING, RETREVING CRUCIFIX B

Risk Assessment No. 02 ANCHOR HANDLING, RETREVING CRUCIFIX B

Uploaded by

Devi Ratna PratiwiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Risk Assessment No. 02 ANCHOR HANDLING, RETREVING CRUCIFIX B

Risk Assessment No. 02 ANCHOR HANDLING, RETREVING CRUCIFIX B

Uploaded by

Devi Ratna PratiwiCopyright:

Available Formats

.

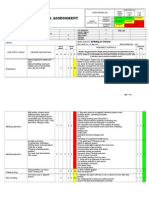

RISK ASSESSMENT

PT. SWIBER BERJAYA

CHECK PPE & CONTROLS REQUIRED

Hard Hats

Safety Shoes

Safety Glasses

Hearing Protection

Cotton Gloves

Leather Gloves

Respirator

Work Vest

Safety Harness

Face Shield

Goggles

Ventilation

Fire Extinguisher

Lockout / Tag-out

Permit to Work

Stokes Basket

Life Rings

Barricades

WORK ACTIVITY:

VESSEL:

AHT run over buoy, propeller

fouled; damage to property.

Man overboard due to

slippery deck or lost balance

when throwing the buoy

catcher.

Slip, trip and fall on deck due

to slippery deck or rolling

vessel; injury to crew.

Metabolic (body) heat

aggravated by full body PPE;

externally imposed heat.

Exposure to sun.

*S

*E

REGISTERED NO :- 002

INITIAL

RISK

REQUIRED CONTROLS

Describe fully all equipment, facility, and/or procedure controls applicable for each

hazard (i.e. if PPE is used as control, it must be specifically describe.) If a control can

only be verified by documentation then it must be available. All controls must be valid

in that they reduce severity, probability of both.

S: Conduct Toolbox talk prior to work.

Test engines, bow thruster and other work related equipment.

Main deck to be made clean and tidy before operations.

Exercise good seamanship to manoeuvre vessel clear of buoy.

Maintain communication between bridge and deck crew.

Station look out at stern to report distance if required.

Crew in full PPE + work vest until completion of anchor handling.

Steel deck must be painted with non-skip paint.

Crew to have good footing & well balanced prior to throwing out the buoy

catcher, use safety line if weather not favourable.

Crew throwing the catcher must synchronize their movement.

Crew stay clear of stern once the buoy hooked by the catcher.

H: Increased fluid intake (Awareness)

Provision of shade where possible

Scheduling of tasks

Ship captains medical guide

COSWP.

Sun block

Sun shade brims on hats

Tinted glasses

Long sleeve coveralls.

HAZARD DESCRIPTION

*H

Catching anchor buoy

from the sea.

Anchor Handling. Recovering anchor, crucifix buoy.

REV. DATE: 02 / 20 Mar 2009

Risk to

WHAT?

JOB STEPS / TASKS

Other - List

RESIDUAL

RISK

Page 1 of 5

Heaving buoy onto deck.

Disconnect buoy on deck

Shifting buoy to the crash

rail to clear deck for

working.

If tugger instead of work wire

is used, tugger wire or buoy

catcher on tension may

parted; injury to crew.

Injury to crew due to sudden

movement of buoy.

Marine growth on buoy can

cause cuts or abrasions on

crew body/limbs.

Back pain when lifting heavy

shackles.

Trap fingers, hand or feet

when making up or undoing

shackles pin.

Shark Jaw or wire socket

failure; injury to crew.

Metabolic (body) heat

aggravated by full body PPE;

externally imposed heat.

Exposure to sun.

Parting of tugger wire being

used to shift buoy.

Injury to crew due to rolling

buoy on deck caused by

sudden movement of AHT.

Metabolic (body) heat

aggravated by full body PPE;

externally imposed heat.

Exposure to sun.

S: Tugger wire and buoy catcher must have certificate and tugger

operated by experienced crew. All crew stay clear of aft deck.

Master manoeuvre vessel to ease tension on the tugger or buoy catcher

wires.

S: Exercise good seamanship to manoeuvre AHT to reduce roll, pitch and

strain on pennant wire.

Buoy to be secured off with wedges/chocks.

Stay clear of buoy rolling direction.

Crew to avoid too close to buoy or picking marine growth.

Use correct manual lifting technique.

Use pulling hooks to dislodge shackles pin.

Crew to assist each other each other to handle heavy loads.

Crow bar used to turn shackle and person using it must steady himself on

good footing to ensure he and the crow bar will not slip.

Raise cable/wire lifter to lift socket to suitable height so that crew can

disconnect shackles from wire socket.

Do not stay in the wires line of fire.

H: Increased fluid intake (Awareness)

Provision of shade where possible

Scheduling of tasks

Ship captains medical guide

COSWP.

Sun block

Sun shade brims on hats

Tinted glasses

Long sleeve coveralls.

S: All crew to stay clear from aft deck when pulling the buoy.

Condition of tugger wire must be inspected prior to using it.

Use wedge/chock to stop buoy from rolling.

Lashing of buoy as soon as buoy reached crash rail.

Master to manoeuvre AHT to reduce rolling and pitching.

H: Increased fluid intake (Awareness)

Provision of shade where possible

Scheduling of tasks

Ship captains medical guide

COSWP.

Sun block

Sun shade brims on hats

Tinted glasses

Long sleeve coveralls.

Page 2 of 5

Connecting work wire to

anchor pennant.

Breaking loose the anchor

off bottom and heaving up

to stern roller or onto

deck.

Sudden jerk on pennant wire

due to vessel movement;

injury to crew.

Back pain when lifting heavy

shackles.

Trapped fingers between

shackle and pin or wire.

Shark Jaw or wire sockets

failure; injury to crew.

Metabolic (body) heat

aggravated by full body PPE;

externally imposed heat.

Exposure to sun.

Parting of tensioned pennant

wire and lateral/sweeping

movement of pennant wire.

Injury to deck crew.

Anchor sliding side to side on

deck, damage to vessel.

Decking anchor.

Disconnecting anchor (if

required.)

Sudden jerk on anchor wire

due to vessel movement.

Shark Jaw or wire socket

failure; Injury to crew.

Back pain.

Trapped finger/hand/feet

causing injury to crew.

S: Master manoeuvre vessel to ensure pennant wire resting on Shark

Jaw with no strain.

Maintain communication bridge-deck to ensure safe operations.

Use correct manual lifting technique.

Use pulling hook to pull heavy shackle, etc.

Crew to assist each other to handle heavy objects.

Crow bar used to turn shackle and person using it must steady himself on

good footing to ensure he and the crow bar will not slip.

Raise cable/wire lifter to lift socket to suitable height so that crew can

disconnect shackles from wire socket.

Do not stay in the wires line of fire.

H: Increased fluid intake (Awareness)

Provision of shade where possible

Scheduling of tasks

Ship captains medical guide

COSWP.

Sun block

Sun shade brims on hats

Tinted glasses

Long sleeve coveralls.

S: Crew to stay clear of aft deck.

Manoeuvre vessel to keep pennant wire in the middle of stern roller and

avoid jerking of pennant wire.

Guide/Tow Pins used to advantage to stop wire sweeping movement and

to align pennant wire to work winch.

Adhere to Anchor Handling Procedure.

S: Maintain tension on wire and manoeuvre vessel to keep stern inline

with the anchor wire direction.

Raise tow pin and shark jaw as soon as anchor past the equipment.

Crew to keep clear of aft deck until instructed by Master/CO

Anchor to be choked or lashed if necessary.

S: Master manoeuvre vessel to ensure anchor wire is kept slack.

Anchor wire socket resting on Shark Jaw with no strain.

Maintain communication between bridge, deck and barge/rig to ensure

safe operations.

Stay clear of wires line of fire.

Use correct manual lifting technique.

Use pulling hooks.

Crew to assist each other to handle heavy objects.

Crow bar used to turn shackle and person using it must steady himself on

good footing to ensure he and the crow bar will not slip.

Raise cable/wire lifter to lift socket to suitable height so that crew can

disconnect shackles from wire socket.

Page 3 of 5

Recovering of anchor wire

by barge/rig.

Shifting anchor to stern

roller

of AHT.

Passing anchor from stern

roller to anchor rack of

barge/rig.

Disconnect pennant wire

from work wire.

Passing pennant wire

socket end to barge/rig.

Parting of tensioned anchor

wire; human injury.

Lateral/sweeping movement

of anchor wire across the

stern; damage to property.

Anchor wire crossing pipeline

causes chafing on the

pipeline; damage to property.

Parting of tension pennant wire causing injury to crew.

Parting of tensioned pennant

causing anchor to drop onto

pipeline or power cable;

gas/oil leak, fire/explosion,

pollution.

Human injury/fatality.

Anchor sliding side to side

causing damage to ships

stern structure.

Lateral/sweeping movement

of pennant wire across stern.

Parting of tension pennant

wire while transferring anchor

Accidental dropping of anchor

and hit pipeline; gas/oil leak,

fire/explosion, pollution.

Human injury/fatality.

AHT collision with barge/rig;

damage to property.

Sudden tension on work wire

due to movement of vessel

may cause: injury to crew,

damage to anchor rack,

parting of pennant wire.

Heavy wire and shackle may

cause back pain to crew.

Trapped fingers, hand or feet.

Shark Jaw or wire socket

failure.

Swinging crane

block/headache ball &

overhead load may strike

crew or ship structure.

Crane rigging failure.

S: Maintain communication with barge foreman to coordinate backing up

or applying some tension on the wire while being winched in by barge/rig.

Crew to stay clear of aft deck.

Guide/Tow Pin kept raised to hold wire in position.

Master to manoeuvre vessel to keep stern in line with the anchor wire fair

lead & Maintain a slight tension on the wire to avoid wire touching bottom.

Latest TOPO chart with current anchor pattern available for reference.

Colour marking of pipe line on the survey equipment screen if possible.

S: Maintain good communication with barge/rig and deck.

Coordinate winch slacking with vessel manoeuvre.

Never shift anchor at position less than 100 meters from pipeline/cable.

Never leave anchor over stern roller when crossing pipeline/cable.

Master manoeuvre vessel to ensure AHT stern is in line with barge/rig

wire fair lead while lowering.

S: Crew to stay clear of open aft deck.

Towing pin kept raised to control wire movement.

Master to manoeuvre AHT to line up stern towards anchor rack for

passing the anchor.

Maintain communication with barge/rig foreman to coordinate anchor

transfer.

Good seamanship to maintain vessel in good distance from anchor rack.

Winch slacking of wire pennant in coordination with heaving of anchor

winch.

AHT to stand off at safe distance taking into consideration wind, swell and

currents.

S: Crew stay clear until pennant wire socket resting on Shark Jaw.

Master to manoeuvre vessel to keep station and pennant wire has no

tension.

Post look out at stern behind crash bar to report distance from barge/rig.

Use correct manual lifting technique. Use pulling hook.

Crew to assist each other to handle heavy objects.

Crow bar used to turn shackle and person using it must steady himself on

good footing to ensure he and the crow bar will not slip.

Raise cable/wire lifter to lift socket to suitable height so that crew can

disconnect shackles from wire socket.

S: Crane cargo block/Headache ball must have hooks sling extension.

Tag line available to steady/control load and crew to stay away from

hooks swing direction.

Crew to stay clear of overhead/suspended load.

Banksman to give good/correct signal to crane operator.

Page 4 of 5

(If anchor was

disconnected)

Passing anchor from AHT

deck to barge/rig by crane.

Passing of buoy to

barge/rig.

Unspooling pennant wire

from work drum,

disconnecting from work

wire.

Shifting buoy, anchor and

pennant wire to stow

position & lashing.

Swinging crane

block/headache ball &

overhead load may strike

crew or ship structure.

Crane rigging failure.

Parting slings causing anchor

to drop on AHT.

Damage to property.

Fire, Pollution & Injury to

crew.

Slip, trip and fall.

Hit by swinging anchor.

Finger trapped between

crane hook and sling.

Marine growth cuts.

Back pain injury.

Hand or finger injury due to

broken wires/splinters.

Hit by springing action of

coiled wire.

Buoy rolling.

Tugger wire parting.

Injury to crew.

S: Crane cargo block/Headache ball must have hooks sling extension.

Tag line available to steady/control load and crew to stay away from

hooks swing direction.

Crew to stay clear of overhead/suspended load.

Banksman to give good/correct signal to crane operator.

As soon as anchor lifted from deck, crane operator must swing anchor

away from ship.

Crew to stay away from direction of hanging anchor swing.

Crew to watch for their own position when trying to steady the lifted

anchor.

When hooking slings, two crew need to do it.

Master to bring vessel away from barge/rig if anchor already lifted clear

of crash rail level.

S: Crew in full PPE including good leather gloves.

Use correct manual lifting technique.

Use pulling hooks.

Crew to assist each other to handle heavy objects.

H Crow bar used to turn shackle and person using it must steady himself on

good footing to ensure he and the crow bar will not slip.

Raise cable/wire lifter to lift socket to suitable height so that crew can

disconnect shackles from wire socket.

Coordinate movement to coil up the pennant wire.

S: Stop buoy from rolling by putting wedges/chock to hold it in position

and lash as soon as it reached the crash rails.

M Stay away from back lash/snap back zone.

Tugger to be operated by competent crew.

Anchor to be lashed if necessary.

Page 5 of 5

You might also like

- Risk Assessment No 01 ANCHOR HANDLING IN GENERAL Rev 03Document5 pagesRisk Assessment No 01 ANCHOR HANDLING IN GENERAL Rev 03Devi Ratna Pratiwi70% (10)

- The Milk Train Doesn't Stop Here Anymore - Tennessee WilliamsDocument94 pagesThe Milk Train Doesn't Stop Here Anymore - Tennessee WilliamsLauraNadeszhdaFernándezRojas100% (3)

- Risk Assessment No. 24 MOORING TO WHARF - VESSELS Rev. 02 28.1Document3 pagesRisk Assessment No. 24 MOORING TO WHARF - VESSELS Rev. 02 28.1Devi Ratna Pratiwi100% (6)

- Risk Assessment No. 08 BUNKERING IN GENERAL Rev. 02 20.03.09Document2 pagesRisk Assessment No. 08 BUNKERING IN GENERAL Rev. 02 20.03.09Devi Ratna Pratiwi91% (11)

- Risk Assessment No. 08 BUNKERING IN GENERAL Rev. 02 20.03.09Document2 pagesRisk Assessment No. 08 BUNKERING IN GENERAL Rev. 02 20.03.09Devi Ratna Pratiwi91% (11)

- Risk Assessment No. 06 ASCENDING & DESCENDING STAIRWAY RevDocument1 pageRisk Assessment No. 06 ASCENDING & DESCENDING STAIRWAY RevDevi Ratna Pratiwi100% (1)

- Risk Assessment No. 25 PAINTING in GENERAL Rev. 02 20.03.09Document2 pagesRisk Assessment No. 25 PAINTING in GENERAL Rev. 02 20.03.09Devi Ratna Pratiwi89% (9)

- Risk Assessment No. 41 WORKING IN MACHINERY SPACE Rev. 02 20Document3 pagesRisk Assessment No. 41 WORKING IN MACHINERY SPACE Rev. 02 20Devi Ratna Pratiwi100% (5)

- Contoh Soal Marlin TestDocument7 pagesContoh Soal Marlin TestDevi Ratna Pratiwi80% (15)

- Risk Assessment No. 06 ASCENDING & DESCENDING STAIRWAY RevDocument1 pageRisk Assessment No. 06 ASCENDING & DESCENDING STAIRWAY RevDevi Ratna Pratiwi100% (1)

- Drill PlanDocument1 pageDrill Planss_tayadeNo ratings yet

- Risk Assessment No. 42 WORKING OVER-SIDE Rev. 02 28.12.09Document2 pagesRisk Assessment No. 42 WORKING OVER-SIDE Rev. 02 28.12.09Devi Ratna Pratiwi80% (5)

- Risk Assesment Towing 14sep10Document3 pagesRisk Assesment Towing 14sep10Haldar BishwajitNo ratings yet

- Passage Planning Risk Assessment SampleDocument1 pagePassage Planning Risk Assessment SampleRobert M. Maluya100% (1)

- Risk Assessment For Working in Confined SpaceDocument1 pageRisk Assessment For Working in Confined SpaceRicardo Dalisay100% (1)

- Anchor Handling and Towing OperationsDocument37 pagesAnchor Handling and Towing OperationsRomi Oktavianus75% (4)

- Risk Assessment No. 46 PERSONNEL TRANSFER Rev. 02 20.03.09Document1 pageRisk Assessment No. 46 PERSONNEL TRANSFER Rev. 02 20.03.09Devi Ratna PratiwiNo ratings yet

- Enjoying English 8 - Testovi Za 8. RazredDocument16 pagesEnjoying English 8 - Testovi Za 8. RazredMaja Hadzic50% (2)

- Time Traveling With A Hamster Sneak PeekDocument35 pagesTime Traveling With A Hamster Sneak PeekRandom House Kids0% (1)

- JSA 001 Tug Boat Positioning and Crew TransferDocument1 pageJSA 001 Tug Boat Positioning and Crew TransferRyanNo ratings yet

- Risk Assessment No. 04 ANCHOR HANDLING, RUNNING, SUIT CASE BUDocument3 pagesRisk Assessment No. 04 ANCHOR HANDLING, RUNNING, SUIT CASE BUDevi Ratna PratiwiNo ratings yet

- Risk Assessment No. 07 BUNKER SHIP TO SHIP Rev. 02 20.03.09Document3 pagesRisk Assessment No. 07 BUNKER SHIP TO SHIP Rev. 02 20.03.09Devi Ratna Pratiwi86% (7)

- Risk Assessment No 01 Anchor Handling in General Rev 03Document5 pagesRisk Assessment No 01 Anchor Handling in General Rev 03Bhaskar AgnihotriNo ratings yet

- Enclosed Space Drill ScenarioDocument1 pageEnclosed Space Drill ScenarioWisnu Kertaningnagoro100% (1)

- Risk Assessment: Bunkering in GeneralDocument2 pagesRisk Assessment: Bunkering in Generaloto saviour0% (1)

- Tech Tips CanyoningDocument3 pagesTech Tips CanyoningRonald RamirezNo ratings yet

- OFF HIRE CERTIFICATE (Panduan)Document1 pageOFF HIRE CERTIFICATE (Panduan)Devi Ratna PratiwiNo ratings yet

- #304 Cargo Operation - DischargingDocument3 pages#304 Cargo Operation - DischargingTolias Egw100% (1)

- #406 Maintenance On Main EngineDocument3 pages#406 Maintenance On Main EngineTolias Egw100% (2)

- Abandon Ship Drills: To Be Used During Toolbox Meeting As A Guide For DiscussionDocument2 pagesAbandon Ship Drills: To Be Used During Toolbox Meeting As A Guide For Discussioncoc verificationNo ratings yet

- 105 Embarking Disembarking PilotDocument1 page105 Embarking Disembarking PilotMr-SmithNo ratings yet

- Risk Assessment No. 26 PASSENGER TRANSFER Rev. 02 20.03.09Document2 pagesRisk Assessment No. 26 PASSENGER TRANSFER Rev. 02 20.03.09Devi Ratna Pratiwi100% (2)

- JSA 06 - Towing-Rig MoveDocument6 pagesJSA 06 - Towing-Rig MoveHaldar Bishwajit100% (2)

- Risk Assessment No. 39 WELDING IN GENERAL Rev. 02 20.03.09Document2 pagesRisk Assessment No. 39 WELDING IN GENERAL Rev. 02 20.03.09Devi Ratna Pratiwi100% (2)

- Join DrillDocument2 pagesJoin Drillbinsar800% (1)

- BOMMI-PRD-07.0013-Rev.00 - Anchor Handling and Towing OperationsDocument10 pagesBOMMI-PRD-07.0013-Rev.00 - Anchor Handling and Towing Operationsfundatia_gaudeamus100% (4)

- Emergency Towing Booklet-EngDocument24 pagesEmergency Towing Booklet-Engaktugship100% (1)

- Master Standing OrderDocument2 pagesMaster Standing OrderDevi Ratna Pratiwi100% (3)

- Towing Arrangement DDocument2 pagesTowing Arrangement DDevi Ratna Pratiwi67% (3)

- Orland Bus Crash CHP Collision (Part 2)Document305 pagesOrland Bus Crash CHP Collision (Part 2)Stephanie BaerNo ratings yet

- Risk Assessment No. 45 LIFTING OPERATIONS Rev. 02 20.03.09Document2 pagesRisk Assessment No. 45 LIFTING OPERATIONS Rev. 02 20.03.09Devi Ratna PratiwiNo ratings yet

- Risk Assessment No. 03 ANCHOR HANDLING, RETRIEVING, SUIT CASDocument2 pagesRisk Assessment No. 03 ANCHOR HANDLING, RETRIEVING, SUIT CASDevi Ratna Pratiwi80% (5)

- Risk Assessment No. 48 USE OF ELECTRICITY Rev. 02 28.12.09Document1 pageRisk Assessment No. 48 USE OF ELECTRICITY Rev. 02 28.12.09Devi Ratna Pratiwi0% (1)

- Mock Drill - EMERGENCY TOWINGDocument4 pagesMock Drill - EMERGENCY TOWINGsaurav naskar100% (1)

- #101 Anchoring & Weighing AnchorDocument6 pages#101 Anchoring & Weighing AnchorTolias Egw50% (2)

- Risk Assessment No. 05 APPROACHING INSTALLATION Rev. 02 20.0Document2 pagesRisk Assessment No. 05 APPROACHING INSTALLATION Rev. 02 20.0Devi Ratna PratiwiNo ratings yet

- RA 002 - D.O. Tank Inspection and CleaningDocument6 pagesRA 002 - D.O. Tank Inspection and Cleaningdassi99100% (1)

- RA 002 - Engine Casing Exhaust Funnel - Hot WorkDocument6 pagesRA 002 - Engine Casing Exhaust Funnel - Hot Workdassi99No ratings yet

- Risk Assessment For Offshore Refuelling Rev 0Document9 pagesRisk Assessment For Offshore Refuelling Rev 0ringbolt100% (1)

- 14.1.1 Risk Assessment: PurposeDocument3 pages14.1.1 Risk Assessment: PurposeSaurabh Yadav100% (2)

- Risk Assessment No. 22 LOSS OF STEERAGE Rev. 02 28.12.09Document4 pagesRisk Assessment No. 22 LOSS OF STEERAGE Rev. 02 28.12.09Devi Ratna PratiwiNo ratings yet

- Anchor Handling ManualDocument15 pagesAnchor Handling ManualBrian Smith100% (3)

- #408 Steering Gear Overhaul or MaintenanceDocument3 pages#408 Steering Gear Overhaul or MaintenanceTolias EgwNo ratings yet

- Tug-Barge-Towing-Operations-Risk-Assessment SheetDocument12 pagesTug-Barge-Towing-Operations-Risk-Assessment SheetVM QHSE100% (1)

- #402 Valve Overhauling in A Cargo TankDocument4 pages#402 Valve Overhauling in A Cargo TankTolias EgwNo ratings yet

- #014 Working AloftDocument4 pages#014 Working AloftTolias EgwNo ratings yet

- Passage Plan Flow ChartDocument1 pagePassage Plan Flow ChartКирилл Ананченко100% (2)

- HSE Bridging PlanDocument22 pagesHSE Bridging PlansergioNo ratings yet

- JSA Boat OperationsDocument3 pagesJSA Boat OperationsCristina Rican100% (1)

- Anchor Handling Manual Template MSF Rev01a Oct15Document47 pagesAnchor Handling Manual Template MSF Rev01a Oct15QHSSE ArakkonamNo ratings yet

- Risk Assessment Form Entry Into Enclosed Spaces 0119Document9 pagesRisk Assessment Form Entry Into Enclosed Spaces 0119Thurdsuk NoinijNo ratings yet

- Emergency Response Manual PDFDocument113 pagesEmergency Response Manual PDFSafix Yazid100% (1)

- Harc OffshoreDocument5 pagesHarc OffshoreMajdiSahnounNo ratings yet

- Conversion Table For PressureDocument4 pagesConversion Table For Pressuredassi99No ratings yet

- GMP - UniverseDocument27 pagesGMP - UniverseShahid Ali Syed100% (1)

- H - SMS - Manual PDFDocument7 pagesH - SMS - Manual PDFRabahNo ratings yet

- #102 Mooring-Unmooring OperationsDocument5 pages#102 Mooring-Unmooring OperationsTolias EgwNo ratings yet

- MOPO 2019 Updated Rev. 10 PDFDocument1 pageMOPO 2019 Updated Rev. 10 PDFdede SinbadNo ratings yet

- Mooring AnchooringDocument10 pagesMooring AnchooringLuffy KingNo ratings yet

- Anchor Handling EquipmentDocument33 pagesAnchor Handling EquipmentJayvee Bongon Galos80% (10)

- Chief Mates OralsDocument44 pagesChief Mates OralsrigelNo ratings yet

- Lsa & Ffa Inventories 2013Document1 pageLsa & Ffa Inventories 2013Devi Ratna Pratiwi100% (1)

- Towing Arrangement ADocument2 pagesTowing Arrangement ADevi Ratna Pratiwi71% (7)

- Towing Arrangement CDocument2 pagesTowing Arrangement CDevi Ratna PratiwiNo ratings yet

- Towing Arrangement BDocument2 pagesTowing Arrangement BDevi Ratna PratiwiNo ratings yet

- BEAUFORT SCALE - PhotoDocument2 pagesBEAUFORT SCALE - PhotoDevi Ratna PratiwiNo ratings yet

- Towing ArragementDocument1 pageTowing ArragementDevi Ratna PratiwiNo ratings yet

- Risk Assessment No. 05 APPROACHING INSTALLATION Rev. 02 20.0Document2 pagesRisk Assessment No. 05 APPROACHING INSTALLATION Rev. 02 20.0Devi Ratna PratiwiNo ratings yet

- MASTER CABLE (Panduan)Document1 pageMASTER CABLE (Panduan)Devi Ratna PratiwiNo ratings yet

- LOG ABSTRACT (Panduan)Document1 pageLOG ABSTRACT (Panduan)Devi Ratna Pratiwi50% (2)

- ULLAGE REPORT (Panduan)Document1 pageULLAGE REPORT (Panduan)Devi Ratna PratiwiNo ratings yet

- NOTICE OF SEALING (Panduan)Document1 pageNOTICE OF SEALING (Panduan)Devi Ratna PratiwiNo ratings yet

- STOP TEMPORARY (Panduan)Document1 pageSTOP TEMPORARY (Panduan)Devi Ratna PratiwiNo ratings yet

- Job Safety Analysis02-01-2014Document2 pagesJob Safety Analysis02-01-2014Devi Ratna PratiwiNo ratings yet

- QSA-319 Fire DrillDocument1 pageQSA-319 Fire DrillDevi Ratna PratiwiNo ratings yet

- QSA-319 Oil Spill DrillDocument1 pageQSA-319 Oil Spill DrillDevi Ratna PratiwiNo ratings yet

- 2014 Aht. Swiber Anna /JSA-14 1 2: Job Safety Analysis (JSA)Document2 pages2014 Aht. Swiber Anna /JSA-14 1 2: Job Safety Analysis (JSA)Devi Ratna PratiwiNo ratings yet

- Job Safety AnalysisDocument2 pagesJob Safety AnalysisDevi Ratna PratiwiNo ratings yet

- QSA-319 Abandon ShipDocument1 pageQSA-319 Abandon ShipDevi Ratna PratiwiNo ratings yet

- Job Safety AnalysisDocument2 pagesJob Safety AnalysisDevi Ratna PratiwiNo ratings yet

- Attendance ListDocument1 pageAttendance ListDevi Ratna PratiwiNo ratings yet

- School of Airport Emergency Services ARFFDocument14 pagesSchool of Airport Emergency Services ARFFcarlosbomNo ratings yet

- Eurotech B1200 Lathes SeriesDocument8 pagesEurotech B1200 Lathes SeriesCNC SYSTEMSNo ratings yet

- Marpol 73 78 Anex IIDocument32 pagesMarpol 73 78 Anex IIstabinmathewNo ratings yet

- Japan Discovers Massive Treasure Trove Worth Over $26B, Enough To SupportDocument4 pagesJapan Discovers Massive Treasure Trove Worth Over $26B, Enough To SupportBhadresh PrajapatiNo ratings yet

- Elliot Wagner v. Delta Steamship Lines, Inc., Defendant-Third Party T. Smith & Son, Inc., Third Party, 465 F.2d 387, 3rd Cir. (1972)Document2 pagesElliot Wagner v. Delta Steamship Lines, Inc., Defendant-Third Party T. Smith & Son, Inc., Third Party, 465 F.2d 387, 3rd Cir. (1972)Scribd Government DocsNo ratings yet

- Discussion TextDocument4 pagesDiscussion TextMaftuhaaNo ratings yet

- Intelligent Transport SystemDocument26 pagesIntelligent Transport SystemchinchuNo ratings yet

- Basic English Grammar TestDocument7 pagesBasic English Grammar TestThe-Junk Assasaqi QB0% (1)

- Physics ALMCDocument185 pagesPhysics ALMClavina rachelNo ratings yet

- The Shadows: Part One: The NoteDocument14 pagesThe Shadows: Part One: The NoteJeremy Kapp100% (1)

- Mobile Phone ReportDocument40 pagesMobile Phone ReportA. AkbariNo ratings yet

- Explosion and Fire at Himeji PlantDocument3 pagesExplosion and Fire at Himeji PlantRyuzaki HayabusaNo ratings yet

- Oil Spill Report Form: Attachment ADocument4 pagesOil Spill Report Form: Attachment ADaniel EvansNo ratings yet

- Msds Colonial Lanco 75Document2 pagesMsds Colonial Lanco 75mndmattNo ratings yet

- Kito ER2 Owners ManualDocument157 pagesKito ER2 Owners ManualBuAlison35100% (1)

- DRA, LEILA A DELA LLANO vs. REBECCA BIONG - Case DigestDocument2 pagesDRA, LEILA A DELA LLANO vs. REBECCA BIONG - Case DigestRaiza SarteNo ratings yet

- Manila Steamship Co Vs AbdulhamanDocument1 pageManila Steamship Co Vs AbdulhamanQue EnNo ratings yet

- Introduction To Personal Fall ProtectionDocument20 pagesIntroduction To Personal Fall ProtectionSatria 'igin' Girindra NugrahaNo ratings yet

- Clarence Tiu Supplement PDFDocument21 pagesClarence Tiu Supplement PDFApril GuiangNo ratings yet

- 1984 Physics B Multiple Choice PDFDocument51 pages1984 Physics B Multiple Choice PDFengrroyNo ratings yet

- ATC-PILOT Relationship: A Social Perspective of Improving Safety PerformanceDocument12 pagesATC-PILOT Relationship: A Social Perspective of Improving Safety PerformancebilelNo ratings yet

- Yobido Vs CA 281 SCRA 1 (1997)Document2 pagesYobido Vs CA 281 SCRA 1 (1997)Benitez GheroldNo ratings yet

- Flight Review EvaluationDocument1 pageFlight Review EvaluationtailwindflightcenterNo ratings yet

- AMP Adventures (7379055)Document104 pagesAMP Adventures (7379055)VernonWilliamReichNo ratings yet

- NHAI Safety Manual PDFDocument239 pagesNHAI Safety Manual PDFSonia MazumderNo ratings yet

- Decision Tree For Incident ClassificationDocument1 pageDecision Tree For Incident ClassificationAdrian BagayanNo ratings yet