AR1206-GEN-REP-001 Rev00

AR1206-GEN-REP-001 Rev00

Uploaded by

ThirukkumaranBalasubramanianCopyright:

Available Formats

AR1206-GEN-REP-001 Rev00

AR1206-GEN-REP-001 Rev00

Uploaded by

ThirukkumaranBalasubramanianOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

AR1206-GEN-REP-001 Rev00

AR1206-GEN-REP-001 Rev00

Uploaded by

ThirukkumaranBalasubramanianCopyright:

Available Formats

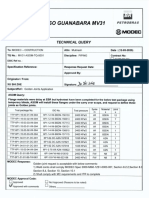

Ref: AR1206-GEN-REP-001

Rev: 00

DESIGN BASIS

Date: 18/10/2012

Page :1 / 9

Project: Installation of Cartridge Filter For

32 Gas Pipeline at Mellitah Complex

Mellitah Oil&Gas

B.V.

DESIGN BASIS

INSTALLATION OF CARTRIDGE FILTER FOR

32 GAS PIPELINE AT MELLITAH COMPLEX

ABG

BJD

ZMT

00

18/10/2012

First Issue

Prepared by

Checked by

Approved by

Rev

Date

Description

Ref: AR1206-GEN-REP-001

DESIGN BASIS

Rev: 00

Date: 18/10/2012

Page :2 / 9

Project: Installation of Cartridge Filter For

32 Gas Pipeline at Mellitah Complex

Mellitah Oil&Gas

B.V.

SOMMAIRE

1. INTRODUCTION ....................................................................................................................................... 3

2. CODES AND STANDARDS ...................................................................................................................... 3

3. SITE CONDITIONS.................................................................................................................................... 3

4. PROCESS .................................................................................................................................................... 4

4. 1. BLACK POWDER FILTER DATA.......................................................................................................... 4

4. 2. FIRE FIGHTING SYSTEM DATA .......................................................................................................... 4

4. 3. REFERENCE DOCUMENT .................................................................................................................... 4

5. PIPING ........................................................................................................................................................ 5

5. 1. PIPING DATA ......................................................................................................................................... 5

5. 2. REFERENCE DOCUMENT .................................................................................................................... 5

6. STRUCTURES & CIVIL .............................................................................................................................. 6

6. 1. STRUCTURES & CIVIL BASIS DATA .................................................................................................. 6

6. 2. REFERENCE DOCUMENT .................................................................................................................... 6

7. ELECTRICAL .............................................................................................................................................. 7

7. 1. ELECTRICAL DATA .............................................................................................................................. 7

7. 2. TIE-IN ..................................................................................................................................................... 7

7. 3. REFERENCE DOCUMENT .................................................................................................................... 7

8. INSTRUMENT DATA ............................................................................................................................... 8

8. 1. REFERENCE DOCUMENT .................................................................................................................... 8

9. HSEQ .......................................................................................................................................................... 8

9. 1. REFERENCE DOCUMENT .................................................................................................................... 8

This document is property of EMCO, unauthorized use, copying, distribution, reproduction is prohibited

Ref: AR1206-GEN-REP-001

DESIGN BASIS

Rev: 00

Date: 18/10/2012

Page :3 / 9

Project: Installation of Cartridge Filter For

32 Gas Pipeline at Mellitah Complex

Mellitah Oil&Gas

B.V.

1. INTRODUCTION

This document describes the design basis of the installation of cartridge filter for

32 gas pipeline at Mellitah Complex.

2. CODES AND STANDARDS

ASME B31.3

Process Piping

ASME B16.47

Large diameter steel flanges

ASME B16.5

API 6D

BS1873

IEC

NEC

Pipe flanges and flanged fittings

Specification for pipeline valves (Gate, ball, and check valves)

Specification for steel globe and globe stop and check valves

(flanged and butt-welding ends) for the petroleum,

petrochemical and allied industries

International electro-technical and regulation

National Electric code

EN

European standards

RP2003

Recommended practice for protection against Ignition

RP540

API

ANSI

DIN

Electrical Installation in Petroleum processing plants

Arising out of static, lightning and stray current

American Petroleum Institute

American National standard Institute

Deutsches Institut fur normung

CENELEC

European committee for electro technical standardization

ISO

International organization for standardization

ISA

NFPA

NFPA 70

International society for measurement and control

National Fire protection Association

National electrical code

3. SITE CONDITIONS

Minimum winter temperature dry bulb

:- 2.5C

Temperature to be used for cooling tower (wet bulb)

: 25C

Maximum summer temperature dry bulb

Temperature to be used for air coolers (dry bulb)

: 48.2 C

: 45C

This document is property of EMCO, unauthorized use, copying, distribution, reproduction is prohibited

Ref: AR1206-GEN-REP-001

DESIGN BASIS

Rev: 00

Date: 18/10/2012

Page :4 / 9

Project: Installation of Cartridge Filter For

32 Gas Pipeline at Mellitah Complex

Mellitah Oil&Gas

Temperature to be used for out door electrical/instrumentation

:50C

Equipment exposed to sun

:70C

equipment rating (dry bulb)

Max. Design air temperature (in instrument/electrical room)

:40C

Minimum design air temperature (for out door)

:- 2C

Maximum relative humidity value

:83 %

C/W HVAC)

B.V.

Minimum relative humidity value

Highest recorded wind speed (at Gadames)

:9 %

:133 km/h

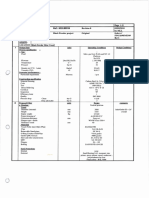

4. PROCESS

4. 1. BLACK POWDER FILTER DATA

Working Pressure

:32 barg

Design Pressure

:44 barg

Working Temperature

Design Temperature

Design Flow rate

:28C

:70C

:620000 Sm3/h

Housing Material

:carbon steel

Corrosion Allowance

:3

Construction Code

:ASME VIII div 1 (no stamp)

4. 2. FIRE FIGHTING SYSTEM DATA

Operating Pressure

:10 barg

Maximum Operating Temperature

:50.2C

Operating Temperature

:25C

4. 3. REFERENCE DOCUMENT

All data indicated in reference documents listed below, are considered as basis data

for new design:

AR16-PRO-REP-001 Rev 06 (9 sheets) : HAZOP Report-HAZOP of Pall Black

Powder Filter Installation

AR16-PRO-DRW-001 Rev 02 : P&ID Tie-in

AR16-PRO-DRW-002 Rev 06 : P&ID Full Installation

AR16-PRO-DRW-004 Rev 03 : Process Flow Diagram, Sales Gas filter

This document is property of EMCO, unauthorized use, copying, distribution, reproduction is prohibited

Ref: AR1206-GEN-REP-001

DESIGN BASIS

Rev: 00

Date: 18/10/2012

Page :5 / 9

Project: Installation of Cartridge Filter For

32 Gas Pipeline at Mellitah Complex

Mellitah Oil&Gas

B.V.

AR16-PRO-DRW-005 Rev 00 : Schematic for HAZOP

AR16-INS-DSH-006 Rev 00/PF-097-X-I-006

5. PIPING

5. 1. PIPING DATA

The second option of piping arrangement is to be considered.

Document Updating concerns only modifications caused by new piping

arrangement.

Design Pressure

:44 barg

Design Temperature

:70C

Corrosion Allowance

:3

Expected temperature for piping erection :20C

Design wind speed

:133 km/h

Horizontal acceleration (for equivalent static analysis) = 0.125 g

Vertical acceleration (for equivalent static analysis) = 0.084 g

5. 2. REFERENCE DOCUMENT

All data indicated in reference documents listed below, are considered as basis data

for new design:

J-51-S-P-0008-00 REV F1 PROJECT SPECIFICATION FOR PIPING SYSTEM

FLEXIBILITY ANALYSIS

J-60-S-C-0007-00 REV F1 DESIGN SPECIFICATION FOR FOUNDATIONS AND

EARTHWORKS (FOR WAFA COASTAL PLANT

AR16-PIP-DRW-002

AR16-PIP-DRW-004

AR16-PIP-DRW-005

GENERAL ARRANGEMENT DRAWING 3D Model

EQUIPMENT GENERAL ARRAGEMENT

PIPING GENERAL ARRANGEMENT

AR16-PIP-MTO-002

MTO Piping & fitting BPF

AR16-PIP-DRW-007

STRESS ISOMETRIC 26" LINE

AR-16-PIP-DRW-006 ISOMETRIC DRAWING B.P.F

AR16-PIP-DRW-008

STRESS ISOMETRIC 6" FLARE LINE

AR16-MEC-LST-003

LINE LIST

AR16-MEC-LST-002

VALVE LIST

AR16-MEC-DSH-003 26" BALL VALVE DATA SHEET

AR16-MEC-DSH-004 3" BALL VALVE DATA SHEET

This document is property of EMCO, unauthorized use, copying, distribution, reproduction is prohibited

Ref: AR1206-GEN-REP-001

DESIGN BASIS

Rev: 00

Date: 18/10/2012

Page :6 / 9

Project: Installation of Cartridge Filter For

32 Gas Pipeline at Mellitah Complex

Mellitah Oil&Gas

B.V.

AR16-MEC-DSH-005 2" RP BALL VALVE #300 DATA SHEET

AR16-MEC-DSH-006 2" FP BALL VALVE #300 DATA SHEET

AR16-MEC-DSH-007 2" RP BALL VALVE #150 DATA SHEET

AR16-MEC-DSH-008 6" BALL VALVE DATA SHEET

AR16-MEC-DSH-009 2" GLOBE VALVE#300 DATA SHEET

AR16-MEC-DSH-010 2" GLOBE VALVE#150 DATA SHEET

AR16-MEC-DSH-011 16" CHECK VALVE DATA SHEET

AR16-MEC-DSH-012 2"DOUBLE BLOCK & BLEED VALVE #300

AR16-MEC-DSH-013 26" MOTOEIZED BALL VALVE

AR16-MEC-NCA-001 PIPING STESSS ANALYSIS 26" LINE

AR16-MEC-NCA-002 PIPING STESSS ANALYSIS 6" FLARE LINE

6. STRUCTURES & CIVIL

6. 1. STRUCTURES & CIVIL BASIS DATA

Pipe rack will be checked according to new loads caused by updating of piping

arrangement.

Pipe Supports will be updated according to new piping stress analysis.

Foundations will be checked and updated according to the new arrangement.

Design thermal variation (T) for structural calculation :40C

Design wind speed :133 km/h

Seismic zone : 2A

Soil type : Sc

6. 2. REFERENCE DOCUMENT

All data indicated in reference documents listed below, are considered as basis data

for new design:

AR16-STR-NCA-001

CALCULATION NOTE PIPE RACK

AR16-STR-NCA-003

CALCULATION NOTE PIPE SUPPORT FILTERS OUTLETS

AR16-STR-NCA-002

CALCULATION NOTE PIPE SUPPORT FILTERS INLETS

AR16-STR-DRW-003 PIPE RACK DRAWING

AR16-STR-DRW-004 PLATFORM DRAWINGS

AR16-STR-DRW-005 PIPE SUPPORT SHEDULE

AR16-STR-LST-001

MTO STEEL STRUCTURE

This document is property of EMCO, unauthorized use, copying, distribution, reproduction is prohibited

Ref: AR1206-GEN-REP-001

DESIGN BASIS

Rev: 00

Date: 18/10/2012

Page :7 / 9

Project: Installation of Cartridge Filter For

32 Gas Pipeline at Mellitah Complex

AR16-CIV-DRW-001

B.V.

CIVIL GENERAL ARRANGEMENT

AR16-CIV-DRW-002

RAFT REINFORCEMENT GENERAL ARRANGEMENT

AR16-CIV-DRW-003

BASES DRAWING

DRAWING

Mellitah Oil&Gas

AR16-CIV-NCA-001

CALCULATION NOTE

REINFORCED CONCRETE SALES GAS FILTER BASE

7. ELECTRICAL

7. 1. ELECTRICAL DATA

Voltage

: 400 V

frequency

: 50Hz

voltage drop admissible for starting motor

: 15%

Certification of equipment installed in the site

: EExd IIB T3

voltage drop admissible for normal operation of the motor : 5%

Voltage drop admissible for utility equipment

Ingress protection of equipment installed in the site

: 6%

: IP 66

7. 2. TIE-IN

The electrical motor will be supplied from the distribution SS 01,power centre

Tag No 40-920-EL-011,circuit breaker tag No 16-d/S1 spare,10KW

The power source for normal lighting, emergency lighting and convent sockets

will be provided from the field lighting panel tag 40-670-EL-001-GL

7. 3. REFERENCE DOCUMENT

All data indicated in reference documents listed below, are considered as basis data

for new design:

AR16-ELE-DRW-001 (2 sheets) Rev 00 : General Earthing Layout PALL Sales Gas

Filter

AR16-ELE-DRW-002 Rev 00 : Lighting General Arrangement Plan

AR16-ELE-DRW-003 Rev 00 : Lighting Distribution Board Diagram Line

AR16-ELE-DRW-004 Rev 00 : Emergency Lighting Distribution Board Diagram

Line

AR16-ELE-DSH-001 (3 sheets) Rev 00 : Well Glass Fixture Datasheet

AR16-ELE-DSH-002 (4 sheets) Rev 00 : Fluorescent Light Datasheet

This document is property of EMCO, unauthorized use, copying, distribution, reproduction is prohibited

Ref: AR1206-GEN-REP-001

DESIGN BASIS

Rev: 00

Date: 18/10/2012

Page :8 / 9

Project: Installation of Cartridge Filter For

32 Gas Pipeline at Mellitah Complex

Mellitah Oil&Gas

B.V.

AR16-ELE-LST-001 (2 sheets) Rev 00 : Lighting Cable Schedule

AR16-ELE-LST-002 (2 sheets) Rev 00 : Material Take Off

8. INSTRUMENT DATA

8. 1. REFERENCE DOCUMENT

All data indicated in reference documents listed below, are considered as basis data

for new design:

PF-O97-L-I-0001-00 Rev P2 (AR16-INS-LST-001 Rev 02) (4 sheets) Rev 00 :

Instrument list

PF-O97-X-I-0001-00 Rev P2 (AR16-INS-DSH-001 Rev 02) (3 sheets) Rev 00 :

Pressure Gauge Datasheet

PF-O97-X-I-0002-00 Rev P2 (AR16-INS-DSH-002 Rev 02) Rev 00 : Differential

Pressure Transmitter Datasheet

PF-O97-X-I-0003-00 Rev P2 (AR16-INS-DSH-003 Rev 02) Rev 00 : Pressure

Safety Valve Datasheet

PF-O97-Y-I-0001-00 Rev P2 (AR16-INS-NCA-001 Rev 01) (8 sheets) Rev 00 :

Pressure Safety Valve Calculation Note

AR16-INS-LST-002 Rev 02 : Cable Schedule

PF-O97-D-I-0001-00 Rev P2 (AR16-INS-DRW-001 Rev 02) (6 sheets) Rev 02 :

Process Hook-up and Mounting Support Details

AR16-INS-DSH-004 Rev 00) : Pressure Gauge Datasheet

9. HSEQ

9. 1. REFERENCE DOCUMENT

All data indicated in reference documents listed below, are considered as basis data

for new design:

MG-HSEQ-P-220 P2 Corporate Concrete Constituent/Materials: Cement

MG-HSEQ-P-221 P2 Corporate Concrete Constituent/Materials: Aggregate

MG-HSEQ-P-222 P2 Corporate Concrete Constituent/Materials : Reinforcement

MG-HSEQ-P-249 P2 Corporate Concrete Constituent/Materials: Water

MG-HSEQ-P-250 P2 Corporate Concrete Constituent/Materials: Chemical

Admixtures

MG-HSEQ-P-251 P2 Corporate Concrete Constituent/Materials: Plasticizing

Admixtures

This document is property of EMCO, unauthorized use, copying, distribution, reproduction is prohibited

Ref: AR1206-GEN-REP-001

DESIGN BASIS

Rev: 00

Date: 18/10/2012

Page :9 / 9

Mellitah Oil&Gas

Project: Installation of Cartridge Filter For

B.V.

32 Gas Pipeline at Mellitah Complex

MG-HSEQ-Q-P-209 Rev A 1 Corporate Plant Systems Handover.

MG-HSEQ-Q-P-217 Rev A 1Corporate Post Construction Project Close Out.

MG-HSEQ-Q-P-254 Rev A 1 Corporate Project Final Handover

MOG-HSEQ-IN-M-001 and MOG-HSEQ-IN-P-002. MELLITAH OIL & GAS - Libyan

Branch Corporate HSE Manual & Plan

MOG HSEQ-P-018 MELLITAH OIL & GAS - Libyan

HSEQ-S Requirements for Suppliers and Contractors

Branch

Corporate

MOG-HESQ-SF-P-020 MELLITAH OIL & GAS Libyan Branch Corporate

Emergency Response Plan

MOG-HSEQ-SF-P-024 MELLITAH OIL & GAS- Libyan Branch Corporate Permit to

Work System

MOG-HSEQ-E-P-036 MELLITAH OIL & GAS Libyan Branch Corporate Waste

Management Plan

MOG-HSEQ-Q-M-201 & MOG HSEQ-Q-P-202 MELLITAH OIL & GAS- Libyan

Branch Corporate Quality Manual & Plan

MOG HSEQ-Q-P-208 MELLITAH OIL & GAS - Libyan Branch Corporate

Procedure for Inspection Records

MOG-HSEQ-Q-P-215 MELLITAH OIL & GAS - Libyan Branch Corporate

Procedure for Control and Calibration of Inspection Equipment

MOG-HSEQ Q-P-206 and A-00-P-Q-008 MELLITAH OIL & GAS BY - Libyan

Branch Corporate Procedure for Internal & External Auditing, and Project

Auditing

MOG-HSEQ-Q-P-218 MELLITAH OIL & GAS BY - Libyan Branch Corporate

Procedure for Control of Non-Conformance

MOG-HSEQ-Q-P-211 MELLITAH OIL & GAS BV - Libyan Branch Corporate

Procedure for Control of Records

MOG HSEQ-S-P-403 MELLITAH OIL & GAS - BV - Libyan Branch Corporate

Security Procedure for MELLITAH Complex

This document is property of EMCO, unauthorized use, copying, distribution, reproduction is prohibited

You might also like

- #214 SP 2167 HSE Specification For Fire Water Pumps Package PDODocument43 pages#214 SP 2167 HSE Specification For Fire Water Pumps Package PDOfikri adam RabbaniNo ratings yet

- Feed For West To East Pipelines Project (Wep) Cpecc Response Sheet To Adnoc Onshore Document Review CommentsDocument4 pagesFeed For West To East Pipelines Project (Wep) Cpecc Response Sheet To Adnoc Onshore Document Review CommentsAnbu KumarNo ratings yet

- MEmaco N 907 - Al ZourDocument1 pageMEmaco N 907 - Al Zouraruncg2No ratings yet

- LampSite InstallationDocument12 pagesLampSite InstallationJoelMalangNo ratings yet

- G050PZ001000F1Document20 pagesG050PZ001000F1ThirukkumaranBalasubramanianNo ratings yet

- ITB Package Index (Vol - III) As of 31 May 2012Document11 pagesITB Package Index (Vol - III) As of 31 May 2012Venki TekkaliNo ratings yet

- SGGP Reference No: P0116-TAK-P01-0023-02Document16 pagesSGGP Reference No: P0116-TAK-P01-0023-02Jabel Oil Services Technical DPTNo ratings yet

- Geanonimiseerd 6345167 1630584461655 000-JSD-1900-0001 E 13Document50 pagesGeanonimiseerd 6345167 1630584461655 000-JSD-1900-0001 E 13reza abriNo ratings yet

- A ESIA Yemen Section 3 Revision 1Document42 pagesA ESIA Yemen Section 3 Revision 1Denstar Ricardo SilalahiNo ratings yet

- 00 Za e 85135 - 0Document25 pages00 Za e 85135 - 0Anurag SinhaNo ratings yet

- Fat - Functional Factory Acceptance Test Procedure For Flare and Burn Pit Packages 2600-PK-001 / 2600-PK-002 / 2600-PK-003Document8 pagesFat - Functional Factory Acceptance Test Procedure For Flare and Burn Pit Packages 2600-PK-001 / 2600-PK-002 / 2600-PK-003kami safaviNo ratings yet

- LFI Tool - PD-HX-REP-003 Rev.01Document26 pagesLFI Tool - PD-HX-REP-003 Rev.01Qayyum KhanNo ratings yet

- SPCC C SH PR 0024 Project Environmental Monitoring Plan F1Document18 pagesSPCC C SH PR 0024 Project Environmental Monitoring Plan F1ismayil AdishovNo ratings yet

- EBS1 FPFA00 SAPI RQMA 1032 D00 Technical Requisition For Ball Valve 16"Document27 pagesEBS1 FPFA00 SAPI RQMA 1032 D00 Technical Requisition For Ball Valve 16"AhmedNo ratings yet

- BL-22-IG-262 - 0 - Alarm Protective Equipment ManagementDocument12 pagesBL-22-IG-262 - 0 - Alarm Protective Equipment ManagementAanantharaj LourdesamyNo ratings yet

- CORP ENG PRC 009Rv1Document13 pagesCORP ENG PRC 009Rv1Mohammad SalehNo ratings yet

- SPD0055ERN: Process Design Manual Alarp Procedure (As Low As Reasonably Practicable)Document16 pagesSPD0055ERN: Process Design Manual Alarp Procedure (As Low As Reasonably Practicable)chuntao fengNo ratings yet

- CPMS-AUT-ES-001 - Instrument and Control Philosophy StandardDocument8 pagesCPMS-AUT-ES-001 - Instrument and Control Philosophy StandardChrisNo ratings yet

- F12290 A Pac SPC 0002 - D1Document11 pagesF12290 A Pac SPC 0002 - D1ThirukkumaranBalasubramanianNo ratings yet

- Foam System Hydraulic Calculation ReportDocument18 pagesFoam System Hydraulic Calculation ReportmoodydoodyNo ratings yet

- DME As Alternative Gas Turbine FuelDocument3 pagesDME As Alternative Gas Turbine FuelJacob RobinsonNo ratings yet

- 2019.09.03 - EST & SCHED - r.2 - Combined OverviewDocument1 page2019.09.03 - EST & SCHED - r.2 - Combined OverviewSriNo ratings yet

- LNG UVCE MitigtionDocument47 pagesLNG UVCE MitigtionVăn HoàngNo ratings yet

- G.A. Drawing For Pressure Vessel NSF (FM) : Epic For Dukhan Production Facilities Upgrade (Dpfu) Phase 1A - Package 1Document3 pagesG.A. Drawing For Pressure Vessel NSF (FM) : Epic For Dukhan Production Facilities Upgrade (Dpfu) Phase 1A - Package 1mujahed_muhammedNo ratings yet

- 1007 Disq 0 G Ae 30033 Rev 5 Equipment ListDocument22 pages1007 Disq 0 G Ae 30033 Rev 5 Equipment Listeng20072007100% (1)

- MKS-112-TS-AZ7-RPT-03 - A - Design Report For Internal Corrosion Monitoring SystemDocument16 pagesMKS-112-TS-AZ7-RPT-03 - A - Design Report For Internal Corrosion Monitoring SystemĐiệnBiênNhâm100% (1)

- Block 5 Al Shaheen Field Development: Velocity Energy - P01 - Manual Valve General Arrangement Drawings - StarlineDocument39 pagesBlock 5 Al Shaheen Field Development: Velocity Energy - P01 - Manual Valve General Arrangement Drawings - StarlineNews GetNo ratings yet

- Fakhr-9 (A3)Document11 pagesFakhr-9 (A3)Qayyum KhanNo ratings yet

- Spec 2022-02 A00Document24 pagesSpec 2022-02 A00Anoop GokhaleNo ratings yet

- Methanol Bunkering Barge Supplier Conssolidated Checklist PackDocument20 pagesMethanol Bunkering Barge Supplier Conssolidated Checklist PackMehtab Alam ShaikhNo ratings yet

- EOL-Engg-M-001 - R1 - Tank Product Pipeline Hydro Testing Doping and InstallationDocument11 pagesEOL-Engg-M-001 - R1 - Tank Product Pipeline Hydro Testing Doping and InstallationRanjit MandalNo ratings yet

- SP1246 Part-5 PDFDocument23 pagesSP1246 Part-5 PDFMohammad Aamir Perwaiz100% (1)

- Document DetailsDocument28 pagesDocument DetailsSubash ChandraboseNo ratings yet

- Paint Specification Package CDocument32 pagesPaint Specification Package CMohammedNo ratings yet

- Belzona 1831 Instruction For UseDocument2 pagesBelzona 1831 Instruction For UseshambhoiNo ratings yet

- RZK NSS CMG Cec Ins 21001 00 C1 DDocument30 pagesRZK NSS CMG Cec Ins 21001 00 C1 DNitin JadhavNo ratings yet

- N.SDS - 3 ENI Tech Doc Identif and Classif.Document36 pagesN.SDS - 3 ENI Tech Doc Identif and Classif.Chokri HmeidiNo ratings yet

- SP 2094Document48 pagesSP 2094ArshadNo ratings yet

- Indra: For ReviewDocument40 pagesIndra: For ReviewSkan DerNo ratings yet

- 3225.03.DIST.24028 - R3 - Technical Specification For Oil Metering PackageDocument31 pages3225.03.DIST.24028 - R3 - Technical Specification For Oil Metering PackageChijioke Obi100% (2)

- I Et 6000.67 5423 260 Wap 005 02Document22 pagesI Et 6000.67 5423 260 Wap 005 02jlellisNo ratings yet

- Process Duty Spec (IA)Document13 pagesProcess Duty Spec (IA)Pasquale CutriNo ratings yet

- ABB-GEN-CNS-MOS-GPS-16015-00002-U-00 - Earth Work For Off Loading FaciliDocument10 pagesABB-GEN-CNS-MOS-GPS-16015-00002-U-00 - Earth Work For Off Loading Facilisaravana.bNo ratings yet

- Ralf Bruyninckx Case 1 Fire Water NetworkDocument16 pagesRalf Bruyninckx Case 1 Fire Water NetworkBaba JohnehNo ratings yet

- Shg-Sf-Ep-800-0006 - Rev0 - Afd - Passive Fire Protection Philosophy (Phase 3 Feed)Document27 pagesShg-Sf-Ep-800-0006 - Rev0 - Afd - Passive Fire Protection Philosophy (Phase 3 Feed)T-ru Loga RajanNo ratings yet

- PDO Guide To Engineering Standards and ProceduresDocument1 pagePDO Guide To Engineering Standards and Proceduresegy pureNo ratings yet

- 1411-SP-0004 Rev EDocument20 pages1411-SP-0004 Rev ERubénNo ratings yet

- CMIT-801-BECO-15.81-18005 Project Execution PlanDocument142 pagesCMIT-801-BECO-15.81-18005 Project Execution PlanRAZANo ratings yet

- 0468 Asom20 00TQ 0001 001 BDocument14 pages0468 Asom20 00TQ 0001 001 BDenny AgusNo ratings yet

- GLF-WHP03-EPC05 EXHIBIT J Rev CDocument189 pagesGLF-WHP03-EPC05 EXHIBIT J Rev CTuan DauNo ratings yet

- IONE-VP-02-H-001-075 - Rv11 - C - INSTRUMENT ALARM AND TRIP LIST - R11Document3 pagesIONE-VP-02-H-001-075 - Rv11 - C - INSTRUMENT ALARM AND TRIP LIST - R11dhiaa mohammedNo ratings yet

- 8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9503-00001 - 00 - ItpDocument5 pages8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9503-00001 - 00 - ItpRami KsidaNo ratings yet

- SSM Su 5297 ADocument62 pagesSSM Su 5297 Aresp-ect100% (2)

- Field Instrumentation: SpecificationDocument25 pagesField Instrumentation: SpecificationnknfiveNo ratings yet

- Welding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement ConsumablesDocument10 pagesWelding Consumable Calculation (WCC) : Doc. No P.O No Rev. No Project Details Technical Requirement Consumableskeymal9195No ratings yet

- Witness Joint & Sampling MatrixDocument13 pagesWitness Joint & Sampling MatrixPazhamalai RajanNo ratings yet

- Spec - 2017-02 - A01-NOISE CONTROL InfoDocument21 pagesSpec - 2017-02 - A01-NOISE CONTROL InfoshaileshgadbailNo ratings yet

- 9686-6120-Pr-Po0031-0004 - 01 CommentedDocument14 pages9686-6120-Pr-Po0031-0004 - 01 CommentedSachin PatilNo ratings yet

- Spd0016ern-Usa-Process ControlDocument40 pagesSpd0016ern-Usa-Process Controlchuntao fengNo ratings yet

- SPCC C SH PR 0004 Environmental Management Procedures F1Document26 pagesSPCC C SH PR 0004 Environmental Management Procedures F1ismayil AdishovNo ratings yet

- PCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Document6 pagesPCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Moises Alvarez LeandroNo ratings yet

- 27617E01 Design Criteria For Liquid Hydrocarbons FISCAL METERING SYSTEMDocument65 pages27617E01 Design Criteria For Liquid Hydrocarbons FISCAL METERING SYSTEMThirukkumaranBalasubramanianNo ratings yet

- MCX Site Survey Report (Sensia & SGS)Document79 pagesMCX Site Survey Report (Sensia & SGS)ThirukkumaranBalasubramanianNo ratings yet

- CEIL Engineering FinHR Advt 202324 02Document6 pagesCEIL Engineering FinHR Advt 202324 02ThirukkumaranBalasubramanianNo ratings yet

- AGT - Jobs 29.12.2023Document23 pagesAGT - Jobs 29.12.2023ThirukkumaranBalasubramanianNo ratings yet

- Lube Oil Cooler Data SheetDocument1 pageLube Oil Cooler Data SheetThirukkumaranBalasubramanianNo ratings yet

- TDW Pipeline Pigs & AccessoriesDocument66 pagesTDW Pipeline Pigs & AccessoriesThirukkumaranBalasubramanianNo ratings yet

- AIFDocument2 pagesAIFThirukkumaranBalasubramanianNo ratings yet

- Esd Logic Diagrams 7-124-3Document42 pagesEsd Logic Diagrams 7-124-3ThirukkumaranBalasubramanianNo ratings yet

- Job Description-Process EngineerDocument1 pageJob Description-Process EngineerThirukkumaranBalasubramanianNo ratings yet

- Ab CoverDocument1 pageAb CoverThirukkumaranBalasubramanianNo ratings yet

- Job Description-Piping EngineerDocument1 pageJob Description-Piping EngineerThirukkumaranBalasubramanianNo ratings yet

- D2-001-AM Part 1Document118 pagesD2-001-AM Part 1ThirukkumaranBalasubramanianNo ratings yet

- DS 7502Document4 pagesDS 7502ThirukkumaranBalasubramanianNo ratings yet

- Job Description-Mechanical EngineerDocument1 pageJob Description-Mechanical EngineerThirukkumaranBalasubramanianNo ratings yet

- A Guide To Failure Analysis For The Oil and Gas IndustryDocument6 pagesA Guide To Failure Analysis For The Oil and Gas IndustryThirukkumaranBalasubramanian100% (2)

- Mellitah Oil & Gas BV: Field Bending OF LinepipeDocument4 pagesMellitah Oil & Gas BV: Field Bending OF LinepipeThirukkumaranBalasubramanianNo ratings yet

- Cold CuttingDocument2 pagesCold CuttingThirukkumaranBalasubramanianNo ratings yet

- PALL FILTER - Process Data SheetDocument2 pagesPALL FILTER - Process Data SheetThirukkumaranBalasubramanianNo ratings yet

- Execution of Tie-Ins Without A Plant ShutdownDocument3 pagesExecution of Tie-Ins Without A Plant ShutdownThirukkumaranBalasubramanianNo ratings yet

- Mellitah Oil & Gas BVDocument12 pagesMellitah Oil & Gas BVThirukkumaranBalasubramanianNo ratings yet

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureDocument19 pagesMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanianNo ratings yet

- JERES-D-001 Design Criteria For Pressure VesselsDocument37 pagesJERES-D-001 Design Criteria For Pressure VesselsThirukkumaranBalasubramanianNo ratings yet

- Aspee Hi-Tech: Knapsack SprayerDocument2 pagesAspee Hi-Tech: Knapsack SprayerThirukkumaranBalasubramanianNo ratings yet

- Installation PlanDocument28 pagesInstallation PlanThirukkumaranBalasubramanianNo ratings yet

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureDocument583 pagesMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanian0% (1)

- Reference ListDocument28 pagesReference ListThirukkumaranBalasubramanianNo ratings yet

- Heating of Pipelines DEH SmallDocument2 pagesHeating of Pipelines DEH SmallThirukkumaranBalasubramanianNo ratings yet

- DataSheet 105723Document2 pagesDataSheet 105723ThirukkumaranBalasubramanianNo ratings yet

- A4 Piping Vibration Risks and Integrity Assessment ARTICLEDocument5 pagesA4 Piping Vibration Risks and Integrity Assessment ARTICLEDavid SmithNo ratings yet

- Sesa GoaDocument8 pagesSesa Goamek00sNo ratings yet

- Crack Width CheckDocument7 pagesCrack Width CheckAnand SoniNo ratings yet

- Air Cooled Heat ExchangersDocument5 pagesAir Cooled Heat ExchangersRamuAlagappan0% (1)

- Sanitary Works 2009Document57 pagesSanitary Works 2009Akhlaq HussainNo ratings yet

- Ab 747Document3 pagesAb 747Ιάκωβος ΣαϊντNo ratings yet

- FrictionDocument7 pagesFrictionAviralNo ratings yet

- How To Make Your Own Six Yard Bell Target Mechanism: Glossary of TermsDocument24 pagesHow To Make Your Own Six Yard Bell Target Mechanism: Glossary of TermsJose German Ojeda CruzNo ratings yet

- Exciter Gearbox Service ExchangeDocument2 pagesExciter Gearbox Service ExchangeRafael JaraNo ratings yet

- Rapid PrototypingDocument17 pagesRapid PrototypingAnkitNo ratings yet

- Section 2: Insulation Materials and PropertiesDocument10 pagesSection 2: Insulation Materials and PropertiesJersey PerlasNo ratings yet

- FINs & NCRsDocument5 pagesFINs & NCRsRaj KiranNo ratings yet

- Service Manual: Room Air ConditionerDocument49 pagesService Manual: Room Air ConditionerОрикс ОриксNo ratings yet

- Design of Repair Clamp For Online Elimination of Leakage From Bolted Flanged JointsDocument7 pagesDesign of Repair Clamp For Online Elimination of Leakage From Bolted Flanged JointsAlberto Fernando Leon Arismendy100% (1)

- Pipe AbstractDocument2 pagesPipe AbstractBipin PatilNo ratings yet

- MDSP Set 6Document78 pagesMDSP Set 6Dhin TolentinoNo ratings yet

- Polyester ResinDocument5 pagesPolyester Resinrajesh kothariNo ratings yet

- An Introduction Into The Production and Specification of Steel PipeDocument5 pagesAn Introduction Into The Production and Specification of Steel PipeIkhsani IzaNo ratings yet

- How To Clean The Dräger Babyleo TN500 Cleaning in 5 Steps: PrerequisitesDocument2 pagesHow To Clean The Dräger Babyleo TN500 Cleaning in 5 Steps: PrerequisitesHesham AlqassabNo ratings yet

- Analysis of Glass - Glass EvidenceDocument40 pagesAnalysis of Glass - Glass EvidenceCebotarenco TamaraNo ratings yet

- 1 Exercise - FANUCDocument175 pages1 Exercise - FANUCdickyohhimNo ratings yet

- Possible Viva QuestionsDocument11 pagesPossible Viva QuestionsambiliNo ratings yet

- Print Head Replacement HM1Document6 pagesPrint Head Replacement HM1joecentroneNo ratings yet

- Impacts of Cement Industry On Environment - An Overview: February 2018Document7 pagesImpacts of Cement Industry On Environment - An Overview: February 2018Glen Carlo VillanuevaNo ratings yet

- General PumpsDocument178 pagesGeneral PumpsSudhanshu ShekharNo ratings yet

- Paul Olivier - Making Waste Our Greatest ResourceDocument38 pagesPaul Olivier - Making Waste Our Greatest ResourceWSSP_QuyNhonNo ratings yet

- Item 1018Document5 pagesItem 1018Ester MarianNo ratings yet

- Inflatable Packers enDocument51 pagesInflatable Packers enDavid LuhetoNo ratings yet

- Latest Advances in The Micro-Milling of Titanium Alloys: A Review Latest Advances in The Micro-Milling of Titanium Alloys: A ReviewDocument8 pagesLatest Advances in The Micro-Milling of Titanium Alloys: A Review Latest Advances in The Micro-Milling of Titanium Alloys: A ReviewMZSHBNo ratings yet

- Factors Influencing The Selection Of: MaterialsDocument22 pagesFactors Influencing The Selection Of: MaterialsMaulik KotadiyaNo ratings yet