Design Alum Cladding - AC1

Uploaded by

Con CanCopyright:

Available Formats

Design Alum Cladding - AC1

Uploaded by

Con CanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Design Alum Cladding - AC1

Uploaded by

Con CanCopyright:

Available Formats

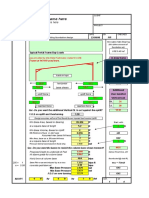

1.

0 Design Loading

1.1 Wind on R/F:

Max Level: Lvmax:= 16.710 m

Level of Ground: LvG := 8.070 m

Height above ground: h := 8.64 m 1 of 3

Basic Wind Pressure: qz := 1.958 kpa

Pressure Coefficient: Cp := 2.00 or -2.00

Design Wind Load WL := 1.4qz* Cp

= 5.48 or -5.48 kPa

2.0 Material Properties

2.1 Stainless Steel screws/ bolts / Self drilling screw:

All screws /bolts to be A2-70, comply to BS EN ISO 3506 :1998

Specified Min. Tensile strength, Ub, for stainless steel screws/bolts = 700 N/mm2

0.2% Proof Stress 450 MPa

Design Tensile stress 374 MPa

Design Shear stress 311 MPa

2.2 Aluminum Extrusions

Extrusions are to be grade 6063-T5, with p0 = 110 N/mm 2 to BS 8118

Young's Modulus 70000 MPa

Design Shear stress, pv 65 MPa

Design Bearing stress, pa 130 MPa

2.3 Aluminum Panel

To be grade 3003-H14, with p0 = 125 N/mm 2 to BS EN 485-2:2007

Young's Modulus 70000 MPa

Design Shear stress, pv 75 MPa

Design Bearing stress, pa 125 MPa

A. Loading Design

Design Wind Load: WL: = 5.48 kPa

Design Dead Load: DL: = 27.2 kN/m³* 3.0 mm

= 0.16 kPa

Design Imposed Load: (Refer to Table 3.8, note 2, Code of Practice for Dead and Imposed Loads 2011)

LL: = 0.75 kPa (lightweight material: metal sheet)

Load Combination of Cladding:

LC1: = 1.2DL + 1.33LL LC1: = 1.19 kPa

LC2: = 1.2DL + 1.4WL LC2: = 7.87 kPa

LC3: = 1.2DL + 1.2LL + 1.4WL LC3: = 8.77 kPa

B. Check Cladding

i) Panel:

Factored UDL w: = 8.77 kPa

Cladding Span a: = 400 mm

Cladding width b: = 1000 mm 2 of 3

Wind Force Fw: = wab Fw: = 3.509 kN

Moment Mw: = wb a^2/8 Mw: = 0.175 kNm

Shear Fv: = 0.5Fw Fv: = 1.754 kN

Section properties: (3003-H14)

Thickness: t: = t: = 3 mm

Section Area: Av: = bt Av: = 3000 mm2

Section Modulus: Zx: = 1.2bt^2/6 Zx: = 1800.0 mm3

Moment Interia: Ix: = bt^3/12 Ix: = 2250.0 mm4 Cladding Span

0.2% proof stress: po: = po: = 125 MPa 400mm c/c max

Shear Stress: pv: = 0.6po pv: = 75 MPa

Partial Factor: γf : = γf : = 1.2

Moment Capacity: Mc: = poZx /γf Mc: = 0.188 kNm

> 0.175 kNm , ∴ OK !

Shear Capacity: Vc: = pvAv /γf Vc: = 187.50 kN

> 1.75 kN , ∴ OK !

Deflection: δ: = wba^4/384EI δ: = 2.65 mm

< L/120 = 3.33 mm , ∴ OK !

ii) Aluminium Stiffener:

Factored UDL w: = 8.77 kPa

Stiffener Span a: = 1000 mm

Cladding width: b: = 400 mm

Wind Force Fw: = wab Fw: = 3.509 kN

Moment Mw: = wb a^2/8 Mw: = 0.437 kNm

Shear Fv: = 0.5Fw Fv: = 1.754 kN

Section properties: (3003-H14) 34

Thickness t: = 3 mm 3

Section Area: A: = 672 mm2

Moment Interia: Ix: = 144928 mm4

Section Modulus: Zx: = 6301.2 mm3 35

0.2% proof stress: po: = 125 MPa 3

Shear Stress: pv: = 75 MPa

Partial Factor: γf : = 1.2 23 23

Moment Capacity: Mc: = poZx /γf Mc: = 0.656 kNm

> 0.437 kNm , ∴ OK !

Shear Capacity: Vc: = pvAv /γf Vc: = 42.00 kN

> 3.51 kN , ∴ OK !

Deflection: δ: = 5wba^4/384EI δ: = 4.32 mm

< L/180 = 5.56 mm , ∴ OK !

iii) Aluminium Stud:

Bolt Spacing: Sp: = 300 mm c/c

Panel Width: a: = 400 mm

Tensile Force on stud: Ft: = waSp Ft: = 1052.7 N

3 of 3

Bolt Properties (Select M6)

Bolt Dia: d: = 6 mm

Net Area: Anet: = 20.1 mm2

Capacity Tensile Stress: pt: = 0.87 x125 pt: = 108.75 MPa

Allow Tensile Strength: T: = pt Anet /γf T: = 1821.6 N

> 1052.7 N , ∴ OK !

iv) Ending Detail of stiffeners

Panel Width: a: = 400 mm

Span Ls: = 1000 mm

Shear Force per Rivet: F: = waLs /2 F: = 1754.5 N

Stainless Steel Bolt (Select M5 - A2-70)

Bolt Dia: d: = 5 mm

Net Area: Anet: = 14.2 mm2

Capacity Shear Stress: pv: = 311 MPa

Allow Shear Strength: V: = pvAnet/ 1.4 V: = 3154.4 N

> 1754.5 N , ∴ OK !

Bearing Strength on Cladding Panel:

Bearing Area: Abr: = 5 x3 x2 Abr: = 30 mm2

Bearing Capacity: Pbr: = Abr (po) /γf Pbr: = 3125 N

> 1052.7 N , ∴ OK !

v) Aluminium Bracket & Bolt for fix cladding Edge

a) Alu. Bracket:

Tensile Force form stiffener: Ft: = 1052.7 N

Capacity of tensile force: T: = po (3 x35) /γf T: = 10938 N

> 1052.7 N , ∴ OK !

b) Stainless Steel Screw (Select M5 - A2-70)

Bolt Dia: d: = 5 mm

Net Area: Anet: = 19.635 mm2

Capacity Tensile Stress: pt: = 374 MPa

Allow Tensile Strength: T: = pt Anet / 1.4 T: = 5245.3 N

> 1052.7 N , ∴ OK !

c) Rivet Bolt (Select M6)

Bolt Dia: d: = 6 mm

Net Area: Anet: = 28.2743 mm2

Capacity Shear Stress: pv: = 0.6 x125 pv: = 75 MPa

Allow Shear Strength: V: = pv Anet /γf V: = 1767.1 N

> 1052.7 N , ∴ OK !

You might also like

- ALUMINUM BOUNDARY FENCE STRUCTURE CALCULATIONNo ratings yetALUMINUM BOUNDARY FENCE STRUCTURE CALCULATION51 pages

- Membrane Lined Insulated Gutter - BrochureNo ratings yetMembrane Lined Insulated Gutter - Brochure8 pages

- Balcony Glass Partition Calculation - JBRS100% (1)Balcony Glass Partition Calculation - JBRS63 pages

- Wind Loading Calculator Sheet (Per ASCE 7-02 Building Code)No ratings yetWind Loading Calculator Sheet (Per ASCE 7-02 Building Code)5 pages

- 1-Calculation Package - NC-House Pergola-Sep 2019No ratings yet1-Calculation Package - NC-House Pergola-Sep 201935 pages

- Design of Fillet Welds:-: Al Mawaleh South Al SeebNo ratings yetDesign of Fillet Welds:-: Al Mawaleh South Al Seeb1 page

- Clean Copy Metal Building Foundation Rev 2.1No ratings yetClean Copy Metal Building Foundation Rev 2.114 pages

- Retrofitting of Exiting Building by Using ETABS: G J, C B RNo ratings yetRetrofitting of Exiting Building by Using ETABS: G J, C B R6 pages

- Higher College of Technology Department of Engineering: Mechanical and Industrial Engineering SectionNo ratings yetHigher College of Technology Department of Engineering: Mechanical and Industrial Engineering Section13 pages

- Kirby Building Systems: Preventive Maintenance ManualNo ratings yetKirby Building Systems: Preventive Maintenance Manual12 pages

- REF Calculations Output Code of PracticeNo ratings yetREF Calculations Output Code of Practice4 pages

- Ahmed Ragab - Senior Structural Engineer - UAENo ratings yetAhmed Ragab - Senior Structural Engineer - UAE3 pages

- Glass Panel (2-Side Supported) : Calculation SheetNo ratings yetGlass Panel (2-Side Supported) : Calculation Sheet1 page

- L0099 - PE Design and Calculation of Pilecap FormworkNo ratings yetL0099 - PE Design and Calculation of Pilecap Formwork12 pages

- Scaffold Safe Working Load Normal Value and CalculationNo ratings yetScaffold Safe Working Load Normal Value and Calculation6 pages

- Toaz - Info Design Calculation Skylight Structure PRNo ratings yetToaz - Info Design Calculation Skylight Structure PR7 pages

- Arch Girder - Repair Calculation SheetNo ratings yetArch Girder - Repair Calculation Sheet74 pages

- API 650 Storage Tank Load Computations With Ring Wall Foundation Design 8 7 M Diameter X 9 0 M HeightNo ratings yetAPI 650 Storage Tank Load Computations With Ring Wall Foundation Design 8 7 M Diameter X 9 0 M Height15 pages

- Etabs Automation Building Models With PythonNo ratings yetEtabs Automation Building Models With Python6 pages

- Shis Park - Mosque and Retail, KHORFAKKAN SHARJAH: Structrual Calcualtion Report For Sign WallNo ratings yetShis Park - Mosque and Retail, KHORFAKKAN SHARJAH: Structrual Calcualtion Report For Sign Wall23 pages

- Pages From Aluminium Cladding (Type 8) (BD Submission)No ratings yetPages From Aluminium Cladding (Type 8) (BD Submission)6 pages

- Pages From Curtain Wall (BD Submission) - 9No ratings yetPages From Curtain Wall (BD Submission) - 96 pages

- Pages From Curtain Wall (BD Submission) - 3No ratings yetPages From Curtain Wall (BD Submission) - 36 pages

- Pages From Curtain Wall (BD Submission) 1No ratings yetPages From Curtain Wall (BD Submission) 16 pages

- Pages From Curtain Wall (BD Submission) - 2No ratings yetPages From Curtain Wall (BD Submission) - 26 pages

- Loading Analysis For: Unfactored Load (KN/M)No ratings yetLoading Analysis For: Unfactored Load (KN/M)7 pages

- Design Base Plate For I Beam - FD01 BracketNo ratings yetDesign Base Plate For I Beam - FD01 Bracket1 page

- Pellegrini, L. Scacchetti, F. Observations On Italian Bronze Age Swords ProductionNo ratings yetPellegrini, L. Scacchetti, F. Observations On Italian Bronze Age Swords Production1 page

- In Lanthanoids, Elements With 4f and 4f Configuration Are Not KnownNo ratings yetIn Lanthanoids, Elements With 4f and 4f Configuration Are Not Known3 pages

- Non Ferrous Extraction Metallurgy (19Y502 NFEM)100% (1)Non Ferrous Extraction Metallurgy (19Y502 NFEM)17 pages

- Connection Design Standard Document PDFNo ratings yetConnection Design Standard Document PDF47 pages

- 4-Q1-SCOPUS-Modeling of The Carburizing and Nitriding Processes PDFNo ratings yet4-Q1-SCOPUS-Modeling of The Carburizing and Nitriding Processes PDF10 pages

- Industrial Steels Properties & MachiningNo ratings yetIndustrial Steels Properties & Machining68 pages

- API 570 Exam Publications Effectivity Sheet: June 2021 and October 2021No ratings yetAPI 570 Exam Publications Effectivity Sheet: June 2021 and October 20211 page

- ( (Manufacturing) ) : Permanent Mold Casting ProcessesNo ratings yet( (Manufacturing) ) : Permanent Mold Casting Processes15 pages

- Casting Process: Dr.L.Saravanan Assistant Professor Department of Mechanical EngineeringNo ratings yetCasting Process: Dr.L.Saravanan Assistant Professor Department of Mechanical Engineering35 pages

- Effect of Pre Oxidation On The Steam Oxidation of Heat ResistantNo ratings yetEffect of Pre Oxidation On The Steam Oxidation of Heat Resistant7 pages

- Product Quality Plan: Customer Manufacturer Conductor Type SizesNo ratings yetProduct Quality Plan: Customer Manufacturer Conductor Type Sizes7 pages

- Welder Qualification Test Log: Engineering Standards Manual OST220-03-01-ESM Chapter 13, Welding100% (1)Welder Qualification Test Log: Engineering Standards Manual OST220-03-01-ESM Chapter 13, Welding1 page

- Latas Eletrosoldadas Aspectos Tecnológicos e Avaliação Da Qualidade100% (1)Latas Eletrosoldadas Aspectos Tecnológicos e Avaliação Da Qualidade85 pages

- Galvotec Alloys, Inc.: Z036112BOT-HALF Z036112BOT-HALFNo ratings yetGalvotec Alloys, Inc.: Z036112BOT-HALF Z036112BOT-HALF1 page

- Product Brochure Aurubis Heat ExchangerNo ratings yetProduct Brochure Aurubis Heat Exchanger12 pages