Utp A 3444

Utp A 3444

Uploaded by

Sun SunCopyright:

Available Formats

Utp A 3444

Utp A 3444

Uploaded by

Sun SunOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Utp A 3444

Utp A 3444

Uploaded by

Sun SunCopyright:

Available Formats

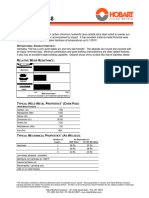

UTP A 3444

TIG rod

Classifications

EN ISO 24373 AWS A5.7 Material-No.

S Cu 6328 (CuAl9Ni5Fe3Mn2) ER CuNiAl 2.0923

Characteristics and field of use

UTP A 3444 is a copper aluminium multi bronzes with a high Ni and Fe addition. Weld cladding on

cast iron materials and steel. Mixed joints with aluminium bronze steel. It is resistant to seawater

and cavitation resistant.

The weld metal of UTP A 3444 is resistant to seawater and cavitation. Good suitability for

simultaneous stress strain caused by seawater, cavitation and erosion.

Typical analysis in %

Mn Ni Cu Al Fe

1,0 4,5 balance 9,0 3,5

Mechanical properties of the weld metal

Yield Tensile Elongation Hardness El. Melting range

strength strength conductivity

RP0,2 Rm A5 S · m / mm2

MPa MPa % HB °C

400 700 15 200 4 1015-1045

Welding instruction

The weld seam area has to be machined to a metallic bright by grinding, sand blasting or pickling in

order to avoid crack formation or the development of pores. To avoid oxyd formation, UTP Flux 34

Sp needs to be deposited onto the base rods prior to the welding process.

Approvals

TÜV (No. 01896), GL

Rod diameter x length [mm] Current type Shielding gas (EN ISO 14175)

2,0 x 1000 DC (-) I1

2,4 x 1000 DC (-) I1

3,2 x 1000 DC (-) I1

All information provided is based upon careful investigation and intensive research. 03/2014 Rev. 0

However, we do not assume any liability for correctness and information is subject to change without notice. www.voestalpine.com/welding

You might also like

- Rocker SwitchDocument24 pagesRocker Switchyamaha640No ratings yet

- SSPC Standards ListDocument8 pagesSSPC Standards Listsina_840% (1)

- Utp A 3444 - 2Document1 pageUtp A 3444 - 2Sun SunNo ratings yet

- Utp 34 NDocument1 pageUtp 34 NbrayanNo ratings yet

- Sdfs Dfsfs v4t Eg Gyt4fdg e Erert34 GG Efr DFGDGDFG DFG G Sfsfs Gsdfgsdfsdfsdgds FSF STGVDocument1 pageSdfs Dfsfs v4t Eg Gyt4fdg e Erert34 GG Efr DFGDGDFG DFG G Sfsfs Gsdfgsdfsdfsdgds FSF STGVsadiqNo ratings yet

- A389 CuNiDocument1 pageA389 CuNiPrathamesh OmtechNo ratings yet

- UTP A 6222 MoDocument1 pageUTP A 6222 MoKara WhiteNo ratings yet

- UTP A 8051 Ti: ClassificationsDocument1 pageUTP A 8051 Ti: ClassificationsGustavo OrozcoNo ratings yet

- Utp A 80 M: ClassificationsDocument1 pageUtp A 80 M: ClassificationsInaamNo ratings yet

- UTP A 3545 NBDocument1 pageUTP A 3545 NBNapol HengbumrungNo ratings yet

- UTP A 3545 NB PDFDocument1 pageUTP A 3545 NB PDFNNo ratings yet

- UTP A 3545 NB PDFDocument1 pageUTP A 3545 NB PDFNNo ratings yet

- Utp 630Document1 pageUtp 630brayanNo ratings yet

- 11042016000000T - Thermanit 22 - 09 - Tig RodDocument1 page11042016000000T - Thermanit 22 - 09 - Tig RodKonrad MatuszkiewiczNo ratings yet

- T - Thermanit 25 - 09 CuT - de - en - 5Document1 pageT - Thermanit 25 - 09 CuT - de - en - 5NAVANEETH NAVANINo ratings yet

- L1 34428 en B Boehler-AWS-ER309L Ss en 1Document1 pageL1 34428 en B Boehler-AWS-ER309L Ss en 1Edgar HornusNo ratings yet

- UTP 655 32 SpecSheetDocument1 pageUTP 655 32 SpecSheetFadi HasnNo ratings yet

- Utp 63Document1 pageUtp 63brayanNo ratings yet

- ER316L Ss en 1Document1 pageER316L Ss en 1brayanNo ratings yet

- 11042016000000T - Thermanit 25 - 09 CuT - Tig RodDocument1 page11042016000000T - Thermanit 25 - 09 CuT - Tig Rodrodrigongr7No ratings yet

- Utp 2949 WDocument1 pageUtp 2949 Wrajbujji478sdNo ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- UTP Cladding en 2017Document12 pagesUTP Cladding en 2017Gourav SharmaNo ratings yet

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Document3 pagesAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Jessicalba LouNo ratings yet

- BOEHLER Q T 309L TIG RodDocument1 pageBOEHLER Q T 309L TIG RodbrayanNo ratings yet

- UTP 3545 NB PDFDocument1 pageUTP 3545 NB PDFhqnscNo ratings yet

- UTP_Cladding filler materials Brochure_WEBDocument12 pagesUTP_Cladding filler materials Brochure_WEBRohitNo ratings yet

- Utp 7015Document1 pageUtp 7015cesarlopezpolysiusNo ratings yet

- Thermanit GE-316L PDFDocument1 pageThermanit GE-316L PDFsmpoe017No ratings yet

- Stainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsDocument3 pagesStainless Steel 1.4462 (2205) Sheet and Plate: Specifications Alloy DesignationsPaulNo ratings yet

- T - Thermanit ATS 4 - Ss - en - 5Document1 pageT - Thermanit ATS 4 - Ss - en - 5rusf123No ratings yet

- Utp 068 HHDocument1 pageUtp 068 HHRoberto_PrrNo ratings yet

- 05042016000000A - Avesta 904L - CeDocument1 page05042016000000A - Avesta 904L - CeJorge Uribe RochaNo ratings yet

- 01112015000000B - Boehler FA-IG - Tig Rod1.4820Document1 page01112015000000B - Boehler FA-IG - Tig Rod1.4820ArielNo ratings yet

- Bohler Aws Er308lDocument1 pageBohler Aws Er308lJuan ShunaNo ratings yet

- Bohler Fox S 308L-16Document1 pageBohler Fox S 308L-16HAKANNo ratings yet

- UTP For OffshoreDocument16 pagesUTP For Offshorekamals55No ratings yet

- item22-LNT 502Document1 pageitem22-LNT 502VVan TanNo ratings yet

- Utp A 068 HH: ClassificationsDocument1 pageUtp A 068 HH: ClassificationsErickNo ratings yet

- Thermanit Nicro 82: TIG Rods, Nickel-AlloyDocument2 pagesThermanit Nicro 82: TIG Rods, Nickel-AlloyMaximiliano Ezequiel LopezNo ratings yet

- Afrox Subarc 347: Back To Section 12Document2 pagesAfrox Subarc 347: Back To Section 12Branko FerenčakNo ratings yet

- Böhler Cat 409 Cb-Ig: Classifi CationsDocument1 pageBöhler Cat 409 Cb-Ig: Classifi CationsBranko FerenčakNo ratings yet

- Thermanit Nimo C 24 (ERNiCrMo3) GTAWDocument1 pageThermanit Nimo C 24 (ERNiCrMo3) GTAWNiranjan Fakirchand YadavNo ratings yet

- Fluxofil 41 (T 55 6 1nimo B M, C 3 h5)Document1 pageFluxofil 41 (T 55 6 1nimo B M, C 3 h5)brunizzaNo ratings yet

- EJ Handbook.A5Document261 pagesEJ Handbook.A5ElMacheteDelHuesoNo ratings yet

- Thermanit 308 Mo 1SE3A00G 3407112 ENDocument1 pageThermanit 308 Mo 1SE3A00G 3407112 ENbrayanNo ratings yet

- T - Thermanit 22 - 09 - de - en - 5Document1 pageT - Thermanit 22 - 09 - de - en - 5brayanNo ratings yet

- Barrettetig Catalogo Oerlikon 35035Document44 pagesBarrettetig Catalogo Oerlikon 35035mp303No ratings yet

- L1 11991 en Thermanit 13 04 Si de en 21Document1 pageL1 11991 en Thermanit 13 04 Si de en 21k.sourenaNo ratings yet

- Esab 56Document1 pageEsab 56Greynaldi GasraNo ratings yet

- Hard Alloy 148Document2 pagesHard Alloy 148ander1246mNo ratings yet

- Special Alloy: Covered Arc Welding Electrodes Submerged Arc Welding Materials Gas Tungsten Arc Welding WiresDocument10 pagesSpecial Alloy: Covered Arc Welding Electrodes Submerged Arc Welding Materials Gas Tungsten Arc Welding WiresCarlos PadillaNo ratings yet

- Fluxofil M42: Cored Wires High-Strength SteelsDocument1 pageFluxofil M42: Cored Wires High-Strength SteelsCristian BoselliNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- Section 2 - Nikko Welding ConsumablesDocument9 pagesSection 2 - Nikko Welding Consumablesangga franugrahaNo ratings yet

- Doclib 4677 Autocraft 316lsi DatasheetDocument1 pageDoclib 4677 Autocraft 316lsi Datasheetamir moniriNo ratings yet

- Nedal Alloy DataDocument1 pageNedal Alloy DataMurali KrishnaNo ratings yet

- Copper Electrodeposition for Nanofabrication of Electronics DevicesFrom EverandCopper Electrodeposition for Nanofabrication of Electronics DevicesNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Utp 83 FNDocument1 pageUtp 83 FNSun SunNo ratings yet

- B Boehler FOX EV 50-A Se en 5Document1 pageB Boehler FOX EV 50-A Se en 5Sun SunNo ratings yet

- Recommended KISWEL Products As Per ASTMDocument21 pagesRecommended KISWEL Products As Per ASTMSun SunNo ratings yet

- Welding Consumables GuidenceDocument3 pagesWelding Consumables GuidenceSun SunNo ratings yet

- Lorch X 350 Leaflet EngDocument3 pagesLorch X 350 Leaflet EngSun SunNo ratings yet

- MRRDocument2 pagesMRRSun SunNo ratings yet

- WM 0977 01Document276 pagesWM 0977 01Sun SunNo ratings yet

- Edogawa 3Document11 pagesEdogawa 3Sun SunNo ratings yet

- DocLib 4660 170 InverterDocument1 pageDocLib 4660 170 InverterSun SunNo ratings yet

- Good WeldDocument2 pagesGood WeldSun SunNo ratings yet

- Pipe - Line Bevel MachineDocument24 pagesPipe - Line Bevel MachineSun SunNo ratings yet

- Surfox: Weld Cleaning System For Stainless SteelDocument16 pagesSurfox: Weld Cleaning System For Stainless SteelSun SunNo ratings yet

- E6010 - WPS PQR Agency Letter - 19042017Document10 pagesE6010 - WPS PQR Agency Letter - 19042017Sun SunNo ratings yet

- Surfox: Weld Cleaning System For Stainless SteelDocument16 pagesSurfox: Weld Cleaning System For Stainless SteelSun SunNo ratings yet

- SMAW InstructionDocument20 pagesSMAW InstructionSun Sun100% (1)

- E7016 - Wps PQR Agency Letter Kiswel - 19042017Document8 pagesE7016 - Wps PQR Agency Letter Kiswel - 19042017Sun SunNo ratings yet

- E7010 - Wps PQR Agency Letter Kiswel - 19042017Document10 pagesE7010 - Wps PQR Agency Letter Kiswel - 19042017Sun SunNo ratings yet

- Antech Gtaw Tig315p Acdc PDFDocument1 pageAntech Gtaw Tig315p Acdc PDFSun Sun0% (1)

- Time Mma Zx7-400 PDFDocument1 pageTime Mma Zx7-400 PDFSun SunNo ratings yet

- E71t-1 - Agency Letter Kiswel Wps Fcaw - 19042017Document8 pagesE71t-1 - Agency Letter Kiswel Wps Fcaw - 19042017Sun SunNo ratings yet

- Antech Gtaw Tig315p Acdc PDFDocument1 pageAntech Gtaw Tig315p Acdc PDFSun Sun0% (1)

- E7018 - Wps PQR Agency Letter Kiswel - 19042017Document8 pagesE7018 - Wps PQR Agency Letter Kiswel - 19042017Sun SunNo ratings yet

- Antech Saw MZ-1000R & 1250RDocument1 pageAntech Saw MZ-1000R & 1250RSun Sun0% (1)

- Antech Saw MZ-1000R & 1250RDocument1 pageAntech Saw MZ-1000R & 1250RSun Sun0% (1)

- Antech Gmaw 350 & 500Document1 pageAntech Gmaw 350 & 500Sun Sun0% (1)

- Antech Smaw Zx7 Series-1Document1 pageAntech Smaw Zx7 Series-1Sun Sun100% (1)

- Antech FluxcoreDocument1 pageAntech FluxcoreSun SunNo ratings yet

- 5.K-7018 (AP) Brochure R3Document2 pages5.K-7018 (AP) Brochure R3Sun SunNo ratings yet

- COFMOW CompendiumDocument27 pagesCOFMOW CompendiumSrinivas GuduruNo ratings yet

- Term Work Machine GuardingDocument41 pagesTerm Work Machine GuardingSonika SinghNo ratings yet

- Gravure-Coating in PrintingDocument29 pagesGravure-Coating in PrintingKeerthanaNo ratings yet

- Unit 4 Drilling MachinesDocument91 pagesUnit 4 Drilling MachinesMALINo ratings yet

- Mech MICROMACHINING PPT MechDocument23 pagesMech MICROMACHINING PPT MechUrvashiNo ratings yet

- AP Cretex SandStoneSmallBookletC 5Document36 pagesAP Cretex SandStoneSmallBookletC 5Rohit WanderlustNo ratings yet

- Repair Guard - F (M55)Document3 pagesRepair Guard - F (M55)Santosh Kumar PatnaikNo ratings yet

- How Is Paper MadeDocument10 pagesHow Is Paper MadeJhuliane RalphNo ratings yet

- 1.11KV H.g.fuse Unit (Solid Core Type)Document1 page1.11KV H.g.fuse Unit (Solid Core Type)SSK IndustriesNo ratings yet

- IOZ PaintingDocument3 pagesIOZ PaintingDhinesh ThanappanNo ratings yet

- 1.2 Raw Materials and Its Preparation For Iron MakingDocument107 pages1.2 Raw Materials and Its Preparation For Iron MakingDrTrinath Talapaneni100% (1)

- Uniform Standardfor Wood Pallets 2007Document49 pagesUniform Standardfor Wood Pallets 2007McArthur2010No ratings yet

- Brochure - VN - OL - Cracking Mill - OLCB - SCREENDocument4 pagesBrochure - VN - OL - Cracking Mill - OLCB - SCREENCaio CostaNo ratings yet

- MK - Adhesive Used in - Corugate IndustryDocument2 pagesMK - Adhesive Used in - Corugate Industryamila209No ratings yet

- Deposition & Planarization: EE 311 Notes Prof SaraswatDocument28 pagesDeposition & Planarization: EE 311 Notes Prof SaraswatRIZA MELİH KÖKSALLINo ratings yet

- Lecture 08 - Corrosion and Degradation of Materials - 2020Document61 pagesLecture 08 - Corrosion and Degradation of Materials - 2020Tuhafeni HailekaNo ratings yet

- Notes On The Application of SYNERGEN 718Document2 pagesNotes On The Application of SYNERGEN 718Bachrul UlumNo ratings yet

- Dissimilar WeldDocument24 pagesDissimilar WeldBenjapon bt7No ratings yet

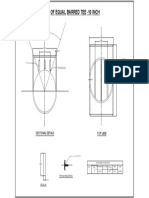

- Fabrication GAD of Equal Barred Tee - 10 Inch PDFDocument1 pageFabrication GAD of Equal Barred Tee - 10 Inch PDFThamaraikani Mani100% (1)

- Test Methods For Hydraulic CementDocument2 pagesTest Methods For Hydraulic CementanbertjonathanNo ratings yet

- Toolzone WhitworthDocument5 pagesToolzone WhitworthJanice WilliamsNo ratings yet

- Ichem LabDocument4 pagesIchem LabDiana BunaganNo ratings yet

- Common Metal Casting DefectsDocument12 pagesCommon Metal Casting DefectsMACKAY9999No ratings yet

- SPS807 270701495 699Document18 pagesSPS807 270701495 699Mostfa RiahiNo ratings yet

- Abrasive WaterjetDocument15 pagesAbrasive WaterjetAniket HardeNo ratings yet

- Manufacturing Technology: Unit - IDocument12 pagesManufacturing Technology: Unit - Iapi-271354682No ratings yet

- DIIPA Lecture-1C Columns 07042020Document16 pagesDIIPA Lecture-1C Columns 07042020amul ghimireNo ratings yet

- Managing An On-Premises LaundryDocument4 pagesManaging An On-Premises LaundryGil TeodosipNo ratings yet

- 555 MMN332Document16 pages555 MMN332khaireddinNo ratings yet