Kobelco 6E - Hyd Motors PDF

Kobelco 6E - Hyd Motors PDF

Uploaded by

Hai VanCopyright:

Available Formats

Kobelco 6E - Hyd Motors PDF

Kobelco 6E - Hyd Motors PDF

Uploaded by

Hai VanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Kobelco 6E - Hyd Motors PDF

Kobelco 6E - Hyd Motors PDF

Uploaded by

Hai VanCopyright:

Available Formats

Kobelco

Dynamic

Acera

Kobelco Construction Machinery America LLC

Hydraulic Motors

( Swing & Travel )

Kobelco Construction

Machinery America Inc.

Dynamic Acera 01/02

Page 8-1

HYDRAULIC MOTORS

7-4 Swing motor

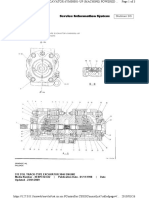

1. Appearance (In case of SK210)

• Rotation direction (SK210 · SK250) • Rotation direction (SK330)

(Viewed from shaft end) (Viewed from shaft end)

Oil inlet A ······· Clockwise Oil inlet A ······· Counterclockwise

Oil inlet B······· Counterclockwise Oil inlet B······· Clockwise

Torque

Code Name Size 2

Kgf/cm (lb/ft)

A,B Main port 2-PF 3/4 17 (122)

PF 3/4 17 (122)

M

Make-up port PF1 22 (159)

PF 3/8 7.5 (54)

DB Drain port

PF 1/2 10 (72)

PA, PB Gauge port PF 1/4 3.7 (26)

PG Brake release port PF 1/4 3.7 (26)

L Gear oil level port PF 1/2 6.6 (47)

IP Gear oil filling port PF 3/4 10 (72)

Dynamic Acera 01/02

Page 8-2

HYDRAULIC MOTORS

2. Specifications

Specifications Swing Motor

Model SK160 ED190 SK210 SK250 SK290 SK330

Type Axial piston type

Parking brake Oil type disk brake, spring applied hydraulic release

2

Working pressure Kgf/cm (psi) 350 (4980) 365 (5193) 280 (3990) 280 (3990) 280 (3990) 280 (3990)

Swing speed M-Mode/ high idle 11 RPM 11 RPM 11 RPM 11 RPM 11 RPM 9.1 RPM

Weight hydraulic motor & gear 223 (491) 223 (491) 235 (520) 235 (520) 511 (1,126) 511 (1,126)

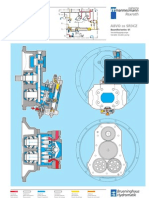

3. Hydraulic diagram

Dynamic Acera 01/02

Page 8-3

SK210 HYDRAULIC SWING MOTOR

4. Structure

Port relief

Swing shockless valve

Shoe

Cylinder block

Dynamic Acera 01/02

Page 8-4

SK210 REDUCTION HYDRAULIC SWING MOTOR

➁ Reduction unit (Swing)

Code Name Qty. Code Name Qty. Code Name Qty.

1 Pinion shaft 1 Taper roller bearing Needle bearing

12 1 24 4

2 Sleeve 1 (22218RH x 90 x 160 x 40) (28 x 43 x 43)

4 Plug (PT 1/2) 1 13 Retaining ring 1 25 Thrust washer 3

O-ring 14 Spider 1 26 Pinion 3

5 1

(JIS B2401 G100 1A) 15 Sun gear 1 27 Roller 102

6 Oil seal (160 x 190 x 13) 1 16 Ring gear 1 28 Thrust washer 3

7 Retainer 1 17 Spider assy 1 29 Retaining ring 3

8 Socket bolt (M8 x 25) 12 18 Socket bolt (M14 x 130) 10 30 Pipe 1

Taper roller bearing 19 Sun gear 1 31 Elbow 1

9 1

(22320RH 100 x 215 x 73) 20 Spring pin ( φ 8 x 25) 4 32 Plug (PT 3/4) 2

10 Housing 1 21 Shaft 4 33 Retaining ring 1

11 Spacer 1 22 Thrust washer 8 34 Set screw 2

23 Pinion 4

Dynamic Acera 01/02

Page 8-5

HYDRAULIC MOTORS

3. Parking brake

1) Cylinder block (111) is engaged with shaft (101) and spline.

2) And, the rotation in round direction of separator plate (743) is restricted by circular grooves

cut on the surface of the casing.

3) When friction plate (742) engaged with cylinder block (111) at the outside with the spline is

pressed against casing (301) by brake spring (712) through separator plate (743) and brake

piston (702), the frictional force is generated between friction plate (742) and casing (301),

and also separator plate (743) and brake piston (702).

4) This frictional force restricts the rotation of the shaft, resulting in the braking force.

5) On the other hand, after application of the release pressure to the oil chamber formed between

brake piston (702) and casing (301), if the oil pressure becomes higher than brake spring

(712) force, brake piston (702) moves and friction plate (742) separates from casing (301),

and finally the brake is released.

Dynamic Acera 01/02

Page 8-6

HYDRAULIC MOTORS SWING SK480

The SK480 swing motor uses two sets of relief

valves for hydrauic breaking and motor control.

main Relief

Overload relief

Shockless valve

Dynamic Acera 01/02

Page 8-7

HYDRAULIC MOTORS

5. Shockless valve

Structure

161. O-ring 312. Piston

162. Ring 313. Seat

163. Backup ring 315. Ball

251. Plug 321. Spring

261. O-ring 322. Spring

311. Plunger 371. Shim

• Operation of shockless valve

This graph shows the relation between

the pressure on shockless valve and the

rising process. The actuation on each

part is described below.

a. Operation on the state of P = PS

Considering the state where the brake

pressure generates on port AM side,

the pressure at port AM is conducted

to chamber n through passage , axis

hole on seat (313), and passage m on

plunger (311).

If pressure P is over the specified

pressure of spring (321), then the spring

is pushed, and the plunger is moved to

left. Seat (313) also moves to left

deflecting spring (322) pushed by

plunger (311).

b. Operation on the sate of P < PS

The brake pressure may be decreased

by the stop of slewing (Y point), arriving

to the state P < PS, the plunger (311) is

moved to the right by the force of spring

(321), simultaneously the seat (313) is

also moved to right by the force of

spring (322), as the chamber P contains

damping actuations caused by (g), the

return of seat (313) is late comparing it

with that of plunger (311), and the seat

part t is left away. Then the pressure

oil flows in sequence such as

→ t → r → K proportionately to the

return of plunger, finally the passage

connecting to AM and BM ports is

formed.

As a result, the pressures at both AM

and BM ports are quickly equal, and

return to the state of Z point, and then

the hydraulic motor is protected from in

version caused by the confined

pressure at AM port.

Dynamic Acera 01/02

Page 8-8

HYDRAULIC MOTORS

7-5 Travel motor

1. Appearance

Note:

1. When overhauling the travel motor or

replacing the assy., fill hydraulic oil 1.2L

through the drain port ( D ).

2. When overhauling the reduction unit, fill

the approved gear 2.5L oil through the

drain port.

In addition, when replacing the assy., as

the oil is already filled, check that the filled

oil quantity is enough for the proper

operation.

Code Name Size Torque N•m {kgf•m} Remarks

VA, VB Main port PF 1 255 ± 10 {26 ± 1} SK210 • SK330

P1, P2 Main port PF 1 255 ± 10 {26 ± 1} SK250

D Drain port PF 1/2 108 ± 10 {11 ± 1} SK210 • SK330

T Drain port PF 1/2 108 ± 10 {11 ± 1} SK250

MA, MB Gauge port PF 1/4 29.4 {3} SK210 • SK330

Pm1, Pm2 Gauge port PF 1/4 29.4 {3} SK250

P Travel 1st/2nd speed change port PF 1/4 29.4 {3} SK210 • SK330

Ps Travel 1st/2nd speed change port PF 1/4 29.4 {3} SK250

Pp Parking brake release port PF 1/4 29.4 {3} SK250

Tin Casing filling oil port PF 1/4 29.4 {3} SK250

Drain port, Filling port, Level port PF 3/4 98 {10} Wind seal tape

Dynamic Acera 01/02

Page 8-9

HYDRAULIC MOTORS

Hydraulic In-Line Piston Motor Operation

5. 3. Swash Plate

Outlet Port 4. Piston Sub assembly

Driveshaft

2.

Shoe Retainer Plate

1. Inlet Port

1. Oil is delivered under pressure at inlet port.

2. Oil exerts a force on pistons, forcing them out of the cylinder block.

3. The piston thrust is transmitted to the angled swash plate causing rotation.

4. The pistons, shoe plate, and cylinder block rotate together. The

driveshaft is splined to the cylinder block.

5. The piston passes the inlet port, and begins to return into its bore

because of the swash plate angle. Exhaust oil is pushed into the

outlet port.

Typical Piston Motor

Dynamic Acera 01/02

Page 8-10

HYDRAULIC MOTORS

Item Model SK210 SK250 SK330

M4V150/ MAG-170VP- M3V260/

Type

100-RC3.5B 3600E-2 150A-RG5.5C

Displacement 1st/2nd speed cc/rev 103.7 / 154.4 109.9 / 170.0 150.5 / 262.6

Working pressure MPa {kgf/cm²} 34.3 {350} ← ←

Max. flow L/min 210 240 250

35.8 {365} 31.1 {317} 35.8 ~ 37.2

Over load cracking press. MPa {kgf/cm²}

or more or more {365 ~ 380}

Tilting control pilot press. MPa {kgf/cm²} 4.9 {50} ← ←

Drain allowable press. Normal 0.2 {2} 0.2 {2} 0.2 {2}

MPa {kgf/cm²} Surge 1 {10} 0.5 {5} 1 {10}

441 ~ 686 22.5 kN•m 902 {92}

Parking brake torque N•m {kgf•m}

{45 ~ 70} {2292} or more

Parking brake release press. MPa {kgf/cm²} 1.57 {16} 1.1 {11} 1.54 {15.7}

Parking brake chamber

MPa {kgf/cm²} 41.2 {420} 4.9 {50} 41.2 {420}

allowable press.

Approx. 27.4 {280} Approx. 27.4 {280}

Set press. of auto 0.4 {4} or less

MPa {kgf/cm²} Pilot press. Pilot press.

speed select 1.5 {15} or more

4.9 {50} 4.9 {50}

Brake valve spool 0.59 ~ 0.95 0.48 ~ 0.88 0.59 ~ 0.98

MPa {kgf/cm²}

switch press. {6 ~ 9.7} {4.9 ~ 9} {6 ~ 10}

Check valve cracking press. MPa {kgf/cm²} 0.018 {0.18} 0.03 {0.3} 0.01 {0.1}

Oil qty. in casing L 0.7 0.5 1.5

Reduction ratio 41.46 43.246 39.875

Output torque of 1st speed kN•m {kgf•m} 35.0 {3570} 40.2 {4100} 57.2 {5830}

Output torque of 2nd speed kN•m {kgf•m} 23.5 {2400} 25.0 {2550} 32.8 {3350}

32.81 32.6 24.83

Revolution at 1st speed min-1 {rpm}

at 210 L/min at 240 L/min at 260 L/min

48.84 50.5 43.32

Revolution at 2nd speed min-1 {rpm}

at 210L/min at 240 L/min at 260 L/min

Oil qty. in reduction L 5.5 3.5 10.5

Rotating direction VA Port inlet: RH P1 Port inlet: RH VA Port inlet: RH

(Viewed from valve side) VB port inlet: LH P2 Port inlet: LH VB Port inlet: LH

Weight Approx. kg 238 290 360

3. Hydraulic diagram

Dynamic Acera 01/02

Page 8-11

HYDRAULIC MOTORS

4. Structure

➀ Travel motor

Dynamic Acera 01/02

Page 8-12

HYDRAULIC MOTORS

Code Name Qty. Code Name Qty.

1 Case 1 49 Spring 1

2 Cover 1 50 Connector 1

3 Cylinder block 1 51 Spool assy 1

4 Shoe retainer 1 52 Cover 2

5 Friction plate 3 53 Spring 2

6 Brake piston 1 54 Spring seat 2

7 Separator plate 4 55 Valve 2

8 Valve plate 1 56 Spring 2

9 Shaft 1 57 Plug 2

10 Coupling 1 58 O-ring 2

11 Shoe plate 1 59 O-ring 2

12 Ball joint 1 60 Socket bolt 8

13 Spring seat 1

14 Piston assy 9

15 Ring 1

16 Ring 1

17 Check valve 3

18 Retaining ring 1

19 Retaining ring 1

20 Piston 1

21 Ball 1

22 Pivot 2

23 Piston seal 1

24 Orifice 2

25 Oil seal 1

26 Spring 3

27 Spring 9

28 Spring 12

29 Bearing 1

30 Bearing 1

31 Socket bolt 8

32 Shim 2

33 Pin 1

35 Plug 1

36 Plug 10

37 Plug 1

38 Plug 3

39 Plug 2

40 O-ring 5

41 O-ring 4

42 O-ring 2

43 O-ring 1

44 Overload relief valve assy 2

45 Spool 1

46 Plug 1

47 Spring seat 1

48 Pin 1

Dynamic Acera 01/02

Page 8-13

HYDRAULIC MOTORS

➁ Reduction assy

Item Model SK210 SK250 SK330

M2X210CHB-

M2X120B-CHB- M2X146B-CHB-

Type 10A-39M/280-

10A-37/285 10A-15/300

197

Displacement cc/rev 121.6 145.9 197

27.9 {285} 29.4 {300} 27.4 {280}

Working pressure MPa {kgf/cm²}

at 179 L/min at 207 L/min at 235 L/min

Max. flow rate L/min 179 207 235

Rated speed min-1 {rpm} 1,400 {1,400} 1,600 {1,600} 1,284 {1,284}

665 {67.8} 767 {81.3} 859 {87.8}

Output torque N•m {kgf•m}

at 350 kgf/cm² at 350 kgf/cm² at 280 kgf/cm²

Brake torque N•m {kgf•m} 540+110

0

+11

{55 0 } 776 {79.2} +245

875 0 {89 0 }

+25

+0.4 +4 +0.5 +5

Brake release Cracking 2.5 0 {25 0} 2.3 {23.7} 2.3 0 {23 0}

pressure MPa {kgf/cm²} Stroke end 2.8 {29} 2.5 {25.8} 2.8+0.5

0 {29+50}

Inner press. of casing MPa {kgf/cm²} 0.29 {3} or low ← 0.2 {2} or low

Oil quantity in casing L 0.8 0.9 1.5

Weight kg 54 66.5 74.5

2KAR6P72 2KAR6P72 2KAR6P72

Type of swing shockless valve

/ 240-712 / 250-712 / 240-712

Weight of swing shockless valve 2.5 ← ←

Weight (Total) kg 56.5 69 77

Dynamic Acera 01/02

Page 8-14

HYDRAULIC MOTORS

5. Over load relief valve (Code 70)

Code Name Qty. Code Name Qty.

1 Socket 1 8 Shim 1

2 Valve 1 9 Spring 1

3 Valve seat 1 10 O-ring 1

4 Piston 1 11 Back up ring 2

5 Cap 1 12 O-ring 2

6 Plunger 1 13 Back up ring 1

7 Piston 1

Item Unit Specifications

Type ORV-240L3

Max. working press. MPa {kgf/cm²} 41.2 {420}

Setting pressure MPa {kgf/cm²} 40.7 {415} or low at 50 L/min

Cracking rpessure MPa {kgf/cm²} 35.8 ~ 37.3 {365 ~ 380} at 1 L/min

Boosting initial pressure MPa {kgf/cm²} 9.8 ~ 24.5 {100 ~ 250}

Max. flow rate L/min 240

Boosting time sec Max. 0.28

Note: Standard thickness of the shim is 2mm in condition of cracking

pressure.

This illustration shows the case of SK210. Refer to the Parts Manual

for other machine models.

Dynamic Acera 01/02

Page 8-15

BRAKE VALVE

VA VB

Tightening Torque

8 ± 0.8 Kgf-m (58 ± 6 ft.lbs)

MA MB

Port Port Tightening Torque Function

Name Diameter Kgf-m (Ft. Lbs)

VA PF1 25 ± 2 (180 +14 -0) Drive pressure circuit port

VB PF1 25 ± 2 (180 +14 -0) Drive pressure circuit port

MA PF 1/4 3.7 ± 2 (27 ± 1) Pressure measuring port

MB PF 1/4 3.7 ± 2 (27 ± 1) Pressure measuring port

Major Specifications

Item Model RBV - 24D

Rated Pressure Kgf/cm (psi) 355 (5050)

Rated Flow L/min (gal/min) 240 (63)

Spool Switching Pressure Kgf/cm (psi) 6 - 10 (85~140)

Check Valve Cracking Pressure Kgf/cm (psi) 0.3 (4.0)

Weight Kg (Lbs) 11Kg (24 Lbs)

Typical of SK210

Dynamic Acera 01/02

Page 8-16

BRAKE VALVE

Brake Valve Construction

1 Body

2 Spool

3 Spring Seat

4 Spring

7 Cover T

8 Restrictor

9 Spring

10 Plug

12 Socket Bolt

14 Socket Bolt

MB Pressure Measuring Port

MA Pressure Measuring Port

VA Drive Pressure Circuit Port

VB Drive Pressure Circuit Port

T Open to Hydraulic Tank

P Parking Brake

Typical of SK210

Dynamic Acera 01/02

Page 8-17

BRAKE VALVE

Brake Valve Function

The Brake Valve controls the flow of oil into and out of the hydraulic travel motor in

the following conditions:

Brake Holding: in neutral position the brake valve function is to keep the hydraulic

motor from turning.

Motor Acceleration: when the brake valve is not in the neutral position the motor is

able to turn.

Stopping the motor: when brake valve is brought to neutral the flow of oil to the

motor is shut off and the motor is no longer able to turn.

Counter balancing: to slowly de-celerate the hydraulic motor that is rotating by

external forces applied to the motor, causing the motor to become a pump.

Three major components to safeguard the hydraulic motor:

Break Spool

Shifting of brake spool to allows the brake valve to:

a. Supply oil to the hydraulic motor

b. Shut off the flow of oil to the hydraulic motor

c. Restrict the flow of oil discharged to the hydraulic motor

This allows the hydraulic motor to:

a. Accelerate

b. Stop, hold

c. Counterbalance

Check Valve (built in the brake spool)

The check valve serves as an oil feeding path to the hydraulic motor, stops the oil

discharged from the hydraulic motor, acts as a suction (anti-cavitation) valve for

the hydraulic motor, and a holding valve.

Relief Valve (located in the hydraulic motor)

Each motor assembly has two relief valves which work with the brake valve to

protect the motor. When oil under pressure at the discharge path of the hydraulic

motor reaches a set point, the relief valve bypasses high pressure oil to either of

the low pressure paths to safeguard the circuit.

Typical of SK210

Dynamic Acera 01/02

Page 8-18

BRAKE VALVE

Brake Valve Assembly

Plug

2 Brake Valve Spool

2a Check Valve

4a VA Drive Pressure Circuit Port

4b VB Drive Pressure Circuit Port

3a MA Pressure Measuring Port

3b MB Pressure Measuring Port

8 Restrictor & Check Valve

8

Typical of SK210

Dynamic Acera 01/02

Page 8-19

BRAKE VALVE

Brake Valve (Stop Operation)

When the flow of oil to the brake valve is shut off, oil pressure in the pilot chambers on

both sides of the brake valve spool are equalized, causing brake spool (2) to return to its

neutral position by the action of return springs (4). The hydraulic tank will supply oil to both

ports VA and VB with the brake valve spool in neutral.

With brake valve spool in neutral, oil path MA→VA is shut off, and oil flow to port P (travel

motor parking brake) is shut off. The spring applied hydraulic release travel motor parking

brake mechanically stops the travel motor from turning. Movement of the excavator (inertia)

will attempt to rotate the hydraulic motor. The hydraulic motor turned by inertia continues to

discharge oil from the hydraulic motor to port MB. The trapped oil at port MB will restrict the

movement of the hydraulic motor until the oil at port MB actuates the MB port relief valve.

Check Valve in Spool 2

VB VA

2

MB MA

VA Drive Pressure Circuit Port from Hyd.

Pump

VB Drive Pressure Circuit Port to Hyd. Tank

MA Pressure Measuring Port

MB Pressure Measuring Port

2 Brake Valve Spool

Dynamic Acera 01/02

Page 8-20

BRAKE VALVE

Brake Valve (Counterbalancing)

Counterbalancing action is required to keep a positive pressure at the inlet of

the hydraulic motor by restricting the oil discharged from the hydraulic motor.

Counterbalancing prevents over-speeding of the hydraulic motor, example;

The excavator is traveling downhill, the weight of the machine on an incline

removes the positive pressure at the inlet of the motor. The hydraulic motor is

in an over-speed or run-a-way condition.

Note: The hydraulic motor will loose the positive pressure at the inlet in

a slow turn.

To stop the hydraulic motor from cavitating, the brake valve spool will shift,

restricting the flow of oil from the hydraulic motor. Pressure in the pilot cham-

ber on the path MA→VA (inlet) drops, and brake valve spool (2) is pushed to

the right (restricted position) by the action of spring (4). As a result, pressure

at MB (outlet) increases, thus the hydraulic motor is subjected to a braking

action.

If the volume of oil supplied to hydraulic motor is reduced below the amount of

oil the hydraulic motor can displace, the pressure in the pilot chamber on the

VA (inlet) port drops, causing spool (2) to move right due to spring action on

the left hand side of the spool.

The result is that the braking action of the counterbalance valve is increased,

and the revolution of the hydraulic motor is regulated to a level equal to the oil

supply at path MA→VA (inlet).

To dampen the movement of brake spool (2), two restrictor’s (8) are built in

the pilot chamber of the brake valve assembly . This restrictor is located in

each of the brake valve caps to provide steady counterbalancing action.

Dynamic Acera 01/02

Page 8-21

BRAKE VALVE

Brake Valve (Counterbalance)

2 VB VA

MB MA

VA Drive Pressure Circuit Port from Hyd. Pump

VB Drive Pressure Circuit Port to Hyd. Tank

MA Pressure Measuring Port

MB Pressure Measuring Port

2 Brake Valve Spool

Typical of SK210

Dynamic Acera 01/02

Page 8-22

HYDRAULIC MOTORS

6. Operation of travel motor

(1) Parking brake

1) When traveling (when brake is

released)

1. After pressure oil has been feed into

from brake valve, spool (123) of brake

valve in hydraulic motor section starts

operating, the passage to parking

brake opens, and the oil flows into

cylinder chamber (a) made up of

spindle (2) and piston (112).

2. When the oil pressure is increased

8 kgf/cm² or higher, the pressure rises

higher than the force of spring, and

moves piston (112) to rear flange (101)

side.

3. With movement of piston (112), the

pushing force to separator plate (116)

and friction plate (115) dies out, the

friction plate (115) which is placed in

cylinder block of hydraulic motor

section can be freely moved, and

braking force to cylinder block is

released.

2) When Stopping (when brake is

operated)

1. Pressure oil from brake valve is cut

off, and when the pressure in cylinder

chamber (a) is 8 kgf/cm² or lower,

piston (112) tends to return due to the

force of spring (113).

2. The piston (112) is pushed by the force

of spring (113), and pushes the

separator plate (116) and friction plate

(115) in free condition to spindle (2) on

reduction unit.

3. The frictional force caused by the

pushing force stops rotating force of

cylinder block (104), and transmits

braking torque (18.2 kgf·m) to

hydraulic motor shaft.

4. This braking torque stops rotation of

hydraulic motor.

5. In addition, the flow rate of oil is

regulated with appropriate oil passage,

enabling the smooth operation.

Dynamic Acera 01/02

Page 8-23

HYDRAULIC MOTORS

(2) Auto two (High/Low) speed change mechanism

1) At low speed

1. When the pilot pressure is not supplied through port (D), spool (163) is pushed up by

spring (166) force or the oil pressure through port (A) or (B), the pressure oil through port

(C) is cut, and the oil in P chamber flows into the drain (motor case) through spool (163).

2. Consequently, the tilting angle of swash plate (103) increases to the maximum, and the

motor speed slows down.

2) At high speed

1. When the pilot pressure (50 kgf/cm²) is supplied through port (D), spool (163) is pushed

down by spring (166) force or the oil pressure through port (A) or (B), the pressure oil

through port (C) is led into (P) chamber, and the piston (161) is pushed up to the position

where swash plate (103) is brought in contact with the face X and maintained.

2. Then the tilting angle of swash plate (103) is of the minimum, and the stroke capacity of

Dynamic Acera 01/02

Page 8-24

HYDRAULIC MOTORS

3) Auto speed change from high speed to low speed

1. As the load rises while traveling at high speed, the quantity of oil pressure at (A) and (B) ports

is also raised, and if the pressure reaches 290 kgf/cm², the pressure rises higher than the

pilot pressure (50 kfg/cm²) at (D) port ;and spool (163) is pushed up, and the oil in P chamber

flows into the drain (motor case) through spool (163).

2. Then, swash plate (103) comes into contact with the face Y of spindle (2), the max. tilting

angle is maintained, and consequently the motor speed reduces.

21 1-1 41

1-1 Stopper

11 Swash Plate

21 Piston

23 Pivot Balls

41 Pilot Selector Valve

23

11

Dynamic Acera 01/02

Page 8-25

You might also like

- Komatsu Basic ElectricDocument163 pagesKomatsu Basic ElectricHai Van96% (25)

- SANY SY215C Testing and AdjustingDocument37 pagesSANY SY215C Testing and AdjustingHai Van100% (11)

- SANY SY215C Hydraulic System DiagramDocument1 pageSANY SY215C Hydraulic System DiagramHai Van100% (2)

- Atlas Copco Boomer L2D Operators InstructionsDocument120 pagesAtlas Copco Boomer L2D Operators InstructionsHai Van100% (14)

- PC78US-8 General Information On TroubleshootingDocument50 pagesPC78US-8 General Information On TroubleshootingHai Van60% (5)

- Hyundai R140W-9 Electrical SystemDocument56 pagesHyundai R140W-9 Electrical SystemHai Van100% (4)

- Komatsu PC100-3 Hydraulic SchematicDocument16 pagesKomatsu PC100-3 Hydraulic SchematicHai Van100% (2)

- PC78US-8 Troubleshooting of Hydraulic System (H-Mode) PDFDocument30 pagesPC78US-8 Troubleshooting of Hydraulic System (H-Mode) PDFHai Van88% (8)

- PC200-8 Hydraulic SystemDocument148 pagesPC200-8 Hydraulic SystemHai Van86% (7)

- PC228USLC-10 Electric Circuit DiagramDocument7 pagesPC228USLC-10 Electric Circuit DiagramHai Van100% (1)

- Kobelco 200 LC ManualDocument4 pagesKobelco 200 LC ManualRett Ser33% (3)

- Hyundai R140W-9 Hydraulic SystemDocument33 pagesHyundai R140W-9 Hydraulic SystemHai VanNo ratings yet

- PC78US-8 Testing and AdjustingDocument124 pagesPC78US-8 Testing and AdjustingHai Van100% (3)

- PC78US-8 Troubleshooting by Failure Code PDFDocument144 pagesPC78US-8 Troubleshooting by Failure Code PDFHai Van100% (1)

- Dx55w Main Pump Ap2d28Document14 pagesDx55w Main Pump Ap2d28Zawminhtun100% (1)

- Valve Ls LindeDocument24 pagesValve Ls Lindele100% (4)

- Schematic: 311B, 312B, and 312B L Excavators Two Pump Flow (Attachment) Hydraulic SystemDocument2 pagesSchematic: 311B, 312B, and 312B L Excavators Two Pump Flow (Attachment) Hydraulic Systemlevinton jose tobias genesNo ratings yet

- Virabrequim C32Document3 pagesVirabrequim C32PauloNo ratings yet

- Información de Transmisión CVT ToyotaDocument151 pagesInformación de Transmisión CVT ToyotaMauricio Exequiel Chavez93% (15)

- Hyundai R130W-3 Electrical SystemDocument49 pagesHyundai R130W-3 Electrical SystemHai VanNo ratings yet

- Hyundai R140W-7 Electrical SystemDocument52 pagesHyundai R140W-7 Electrical SystemHai Van75% (4)

- PC78US-8 Electrical SystemDocument56 pagesPC78US-8 Electrical SystemHai Van100% (4)

- PC78US-8 Troubleshooting of Electrical System (E-Mode)Document76 pagesPC78US-8 Troubleshooting of Electrical System (E-Mode)Hai VanNo ratings yet

- PC78US-8 Troubleshooting of Electrical System (E-Mode)Document76 pagesPC78US-8 Troubleshooting of Electrical System (E-Mode)Hai VanNo ratings yet

- Dual Clutch TransmissionDocument22 pagesDual Clutch Transmissionsaifz201283% (12)

- CPR Crown Energy-July 7 2016 PDFDocument42 pagesCPR Crown Energy-July 7 2016 PDFSky walkingNo ratings yet

- Axial Piston Pumps For Open Circuits in Mobile, Industrial and Marine ApplicationsDocument36 pagesAxial Piston Pumps For Open Circuits in Mobile, Industrial and Marine ApplicationsKamal Solanki100% (1)

- 311B, 312B, and 312B L Excavators Double Action 1 Pump Hydraulic System - AttachmentDocument2 pages311B, 312B, and 312B L Excavators Double Action 1 Pump Hydraulic System - AttachmentGavin LiNo ratings yet

- 320A Hydraulic System OperationDocument135 pages320A Hydraulic System OperationZawminhtunNo ratings yet

- 325C Excavators Hydraulic System: Crb1-Up Jlc1-Up Jld1-Up Csj1-UpDocument2 pages325C Excavators Hydraulic System: Crb1-Up Jlc1-Up Jld1-Up Csj1-UpAndrei Bleoju50% (2)

- CONTROL VALVE DX Valve DisassemblyDocument23 pagesCONTROL VALVE DX Valve DisassemblyArbey Gonzalez100% (1)

- D8R II Plano Electrico PDFDocument2 pagesD8R II Plano Electrico PDFDarío Ache EmeNo ratings yet

- CONTROL VALVE KVMG270 DisassemblyDocument22 pagesCONTROL VALVE KVMG270 DisassemblyArbey Gonzalez100% (2)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document11 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768falahNo ratings yet

- Plano Hidraulico EXCAVADORA 345DDocument2 pagesPlano Hidraulico EXCAVADORA 345DJaime Basquez Pacco100% (2)

- K3V63Document3 pagesK3V63Star SealNo ratings yet

- Denison HydraulicsDocument48 pagesDenison HydraulicsPartagon Pow100% (2)

- VPL Valve OverviewDocument12 pagesVPL Valve OverviewKhaled Rashed100% (2)

- 320F Diagrama Hidraulico PDFDocument2 pages320F Diagrama Hidraulico PDFRICHARD100% (1)

- Control Valve AnimationDocument30 pagesControl Valve Animationvitor santos100% (1)

- Eaton Catalogo GeneralDocument60 pagesEaton Catalogo GeneralFrancisco Renteria100% (1)

- R300LC 9S (H)Document2 pagesR300LC 9S (H)AimHighNo ratings yet

- Proportional Amplifier PV: For The Control of A Proportional SolenoidDocument8 pagesProportional Amplifier PV: For The Control of A Proportional SolenoidIvan BeljinNo ratings yet

- Sk330-8 Motor SwingDocument3 pagesSk330-8 Motor SwinglionkinghdNo ratings yet

- CONTROL VALVE KVMG270 DisassemblyDocument22 pagesCONTROL VALVE KVMG270 DisassemblyArbey Gonzalez100% (4)

- Section 6 Hydraulic System: Group 1 Structure and FunctionDocument21 pagesSection 6 Hydraulic System: Group 1 Structure and FunctionAndré Targino100% (1)

- Boom Hydraulic System CAT 330Document17 pagesBoom Hydraulic System CAT 330hectorNo ratings yet

- Lifting MachinesDocument8 pagesLifting MachinesJoseph JoseNo ratings yet

- K3VL Presentation 2010 MDDocument15 pagesK3VL Presentation 2010 MDHamza Lashin100% (2)

- K3V Hyd PumpDocument4 pagesK3V Hyd Pumpbrunosamaeian100% (1)

- Motor GraderDocument11 pagesMotor GraderDEEPAKNo ratings yet

- Manual Caterpillar d5m d6m d6r Track Type Tractors Power Train Control System Components Diagramspdf CompressDocument12 pagesManual Caterpillar d5m d6m d6r Track Type Tractors Power Train Control System Components Diagramspdf CompressEdwin garciaNo ratings yet

- Plano Hidraulico-7Document1 pagePlano Hidraulico-7RodolfoNo ratings yet

- 7 ElectricDocument30 pages7 ElectricJorge Rojas100% (2)

- Roto KSCDocument4 pagesRoto KSCdaniel ortegaNo ratings yet

- A10v Pump Catalog PDFDocument32 pagesA10v Pump Catalog PDFerickcaparochavez100% (1)

- Ta TM 0902148 Chapter3Document36 pagesTa TM 0902148 Chapter3Wahyu Maryadi100% (2)

- Section 3 Hydraulic SystemDocument3 pagesSection 3 Hydraulic SystemAyman EsaNo ratings yet

- Elektric PC220 - 7Document110 pagesElektric PC220 - 7rahman asadiNo ratings yet

- PC200-6 Colour Hydraulic CircuitDocument1 pagePC200-6 Colour Hydraulic CircuitAKHILNo ratings yet

- Group 2 Main Control Valve: A. ALP165 1. StructureDocument46 pagesGroup 2 Main Control Valve: A. ALP165 1. StructureJuan GarciaNo ratings yet

- A8vo 28 SR3CZDocument1 pageA8vo 28 SR3CZEng-Mohammed Salem100% (3)

- Convertidor y Transmision Hiunday HL760-7Document66 pagesConvertidor y Transmision Hiunday HL760-7MarioDelgado100% (3)

- Exc 315L - 6ym DiagHydDocument2 pagesExc 315L - 6ym DiagHydLuis Eduardo Corzo EnriquezNo ratings yet

- Sistemas Hidrostáticos para Rodillos VibratoriosDocument12 pagesSistemas Hidrostáticos para Rodillos VibratoriosJheins Gupe100% (1)

- Hydraulic - Parts - Catalog PanatDocument32 pagesHydraulic - Parts - Catalog PanatЕкатерина КалашниковаNo ratings yet

- Inspection and Adjustment of Pump Ls ControlDocument10 pagesInspection and Adjustment of Pump Ls ControlHai Van100% (2)

- SM Eng Isuz 4 & 6 HK1 - FD135-3 (ME-AI-4HK1XAE)Document344 pagesSM Eng Isuz 4 & 6 HK1 - FD135-3 (ME-AI-4HK1XAE)vaneedenerikNo ratings yet

- TTLA0561Document111 pagesTTLA0561Valourdos Lukas100% (1)

- K3V PartsDocument2 pagesK3V Partstheflaco20100% (10)

- Calibration Relief Valve ExcavatorDocument36 pagesCalibration Relief Valve Excavatorcriman4550% (2)

- Rcoa1806 03 03Document36 pagesRcoa1806 03 03Fernando Sabino100% (1)

- Excavadora 336D - Plano HidraulicoDocument13 pagesExcavadora 336D - Plano Hidraulicojunior100% (1)

- E307C Hydraulic Circuit Diagram SimpleDocument2 pagesE307C Hydraulic Circuit Diagram Simplekhun shwe htoo100% (1)

- Hyundai R210LC-9 Excavator - S Hydraulic System SchematicsDocument70 pagesHyundai R210LC-9 Excavator - S Hydraulic System Schematicsmohammed barghothi100% (2)

- 11 Main Hydraulic PumpDocument4 pages11 Main Hydraulic PumpZawminhtun100% (1)

- 330bl NFC AdjustDocument10 pages330bl NFC AdjustDaniel Rhasty-ghee AhmanorNo ratings yet

- Crane Main Directional Control ValveDocument4 pagesCrane Main Directional Control ValveMiguel100% (1)

- Adobeair Arctic Circle ED830 A-D Parts Breakdown ListDocument4 pagesAdobeair Arctic Circle ED830 A-D Parts Breakdown ListMirjana PrekovicNo ratings yet

- Welgro Holmes RBTM6insMaint DRI-114-0502 SmallDocument16 pagesWelgro Holmes RBTM6insMaint DRI-114-0502 SmalldumsergiyNo ratings yet

- BW216D-3 Single Drum Roller SpecsDocument3 pagesBW216D-3 Single Drum Roller SpecsHai VanNo ratings yet

- Hyundai R130W-3 Hydraulic SystemDocument31 pagesHyundai R130W-3 Hydraulic SystemHai Van100% (1)

- Hyundai R140W-7 Hydraulic SystemDocument33 pagesHyundai R140W-7 Hydraulic SystemHai Van100% (2)

- PC228USLC-10 Troubleshooting by Failure Code (Display of Code)Document443 pagesPC228USLC-10 Troubleshooting by Failure Code (Display of Code)Hai Van100% (1)

- BMR Orbit Hydraulic Motor With Spool ValveDocument10 pagesBMR Orbit Hydraulic Motor With Spool ValveHai VanNo ratings yet

- Solar 130lc-V Hydraulic SystemDocument289 pagesSolar 130lc-V Hydraulic SystemHai Van83% (6)

- Boomer L2D Maintenance Instructions - Electrical SystemDocument12 pagesBoomer L2D Maintenance Instructions - Electrical SystemHai Van0% (1)

- Komatsu PC400LC-7L A86001 TESTDocument408 pagesKomatsu PC400LC-7L A86001 TESTHai Van100% (2)

- S130LC-V Hydraulic Schematic PDFDocument5 pagesS130LC-V Hydraulic Schematic PDFHai VanNo ratings yet

- Atlas Copco Boomer L2D Component and Signallists RCS4Document34 pagesAtlas Copco Boomer L2D Component and Signallists RCS4Hai Van100% (4)

- Atlas Copco Boomer L2D Component and Signallists RCS4Document34 pagesAtlas Copco Boomer L2D Component and Signallists RCS4Hai Van100% (4)

- PC200-8 Troubleshooting by Failure Code Part 2 PDFDocument59 pagesPC200-8 Troubleshooting by Failure Code Part 2 PDFHai VanNo ratings yet

- Course of Multiphase FlowDocument185 pagesCourse of Multiphase FlowArindam DeyNo ratings yet

- IB Chemistry Online SAQ - Ans - 001 021 PDFDocument22 pagesIB Chemistry Online SAQ - Ans - 001 021 PDFVia PetitNo ratings yet

- Guidelines For Ethylene Quench Tower Rev IntroDocument13 pagesGuidelines For Ethylene Quench Tower Rev IntroMubarik AliNo ratings yet

- Legrand Energypac Price List 02-04-2023Document13 pagesLegrand Energypac Price List 02-04-2023M A SalamNo ratings yet

- Net Metering Aggrement 2019-2020 PDFDocument8 pagesNet Metering Aggrement 2019-2020 PDFBhavik PrajapatiNo ratings yet

- WI 2414 5CT Oblique Angle RequirementDocument2 pagesWI 2414 5CT Oblique Angle RequirementzhiqianxuNo ratings yet

- 3 Point BendingDocument1 page3 Point BendingLohashenpahan ShanmugananthaNo ratings yet

- Hea 120Document2 pagesHea 120mostafa ibrahimNo ratings yet

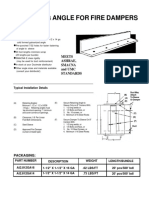

- Fire Damper Installations-1Document1 pageFire Damper Installations-1Pradeep SukumaranNo ratings yet

- Thermodynamics (H. B. Sta. Maria)Document184 pagesThermodynamics (H. B. Sta. Maria)lasner.rinzalNo ratings yet

- Kreatryx Signals & SystemsDocument31 pagesKreatryx Signals & SystemsBharghav RoyNo ratings yet

- Transmission Media Are Usually Categorized AsDocument9 pagesTransmission Media Are Usually Categorized AsSuneel Kumar100% (1)

- Minnpar Replacement Parts For Iveco Engines: June 2013Document36 pagesMinnpar Replacement Parts For Iveco Engines: June 2013Luis JesusNo ratings yet

- Hydrology Tour III-IIDocument9 pagesHydrology Tour III-IIAyanilNo ratings yet

- OSS PresentationDocument20 pagesOSS PresentationMona Abouzied IbrahimNo ratings yet

- Sra2203 PDFDocument4 pagesSra2203 PDFFireElectrickNo ratings yet

- T 1 SolDocument5 pagesT 1 SolMichael Alex MabaoNo ratings yet

- Flash PointDocument2 pagesFlash PointShailendra ThakurNo ratings yet

- Time Variance Report 17.12.2020Document6 pagesTime Variance Report 17.12.2020Cliff Jude ZehnderNo ratings yet

- Ford Diesel 3-Cylinder Liquid-Cooled 201 Ci: (3.3 L) (112 X 112 MM)Document5 pagesFord Diesel 3-Cylinder Liquid-Cooled 201 Ci: (3.3 L) (112 X 112 MM)Alex CastilloNo ratings yet

- Service Manual: TV-A20S2Document12 pagesService Manual: TV-A20S2ISMAIL ELECTRNo ratings yet

- Schedule of Doors and WindowsDocument1 pageSchedule of Doors and Windowsgalano.cybeleNo ratings yet

- Accident Reconstruction Journal May/June 2011Document3 pagesAccident Reconstruction Journal May/June 2011andrewb2005No ratings yet

- Model AC/ TC-30: ApplicationsDocument2 pagesModel AC/ TC-30: ApplicationsTotok Nurrochman100% (1)

- Chapter 12 - Kinematics of Particles Sample ProblemsDocument82 pagesChapter 12 - Kinematics of Particles Sample ProblemsZizhen JiNo ratings yet

- BukuDocument6 pagesBukuAsep SaefullohNo ratings yet

- About Helios TelecomDocument29 pagesAbout Helios Telecomehab1976No ratings yet

- TwilightDocument2 pagesTwilightamrik51072No ratings yet