Result: Economizer Heating Surface and Outlet Flue Gas Temperature Calculation

Result: Economizer Heating Surface and Outlet Flue Gas Temperature Calculation

Uploaded by

jagjitCopyright:

Available Formats

Result: Economizer Heating Surface and Outlet Flue Gas Temperature Calculation

Result: Economizer Heating Surface and Outlet Flue Gas Temperature Calculation

Uploaded by

jagjitOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Result: Economizer Heating Surface and Outlet Flue Gas Temperature Calculation

Result: Economizer Heating Surface and Outlet Flue Gas Temperature Calculation

Uploaded by

jagjitCopyright:

Available Formats

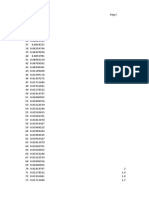

9/14/2019 EconomizerHeatingSurface

Economizer Heating Surface and Outlet Flue Gas

Temperature Calculation

Inputs = Yellow colour cells

S.NO Description Sign Values UOM

1 Steam production Qs 120000 Kg/hr

oC

2 Flue gas inlet temperature To 525

3 Water Quantity Qw 120000 Kg/hr

oC

4 Water inlet temperature to 155

oC

5 Water outlet temperature t 280

6 Steam & fuel ratio R 2.2

Heat transfer coefficient In

7 economizer K 25 kcal/m2/hr/oC

8 Solid unburned coefficient α 1.1

9 Moisture of bagasse W 50 %

10 Excess air m 11 %

Result

Weight of air required per kg of

1 bagasse Pa 3.197 Kg/hr

Weight of the gaseous products

of combustion per kg of

2 bagasse A 4.1968 Kg/kg of Fuel

3 Fuel consumption F 54545.5 Kg/hr

4 Total air requirement P 174370.9 kg/hr

5 Flue gas Quantity Pg 228916.4 Kg/hr

6 Specific heat of water CW 1 Kcal/kg

7 Specific heat of flue gas CF 0.3015 Kcal/kg

8 Ratio r 0.6327

9 Flue gas outlet temp T 327.4 oC

siva.sugarprocesstech.com/EconomizerHeatingSurface/EconomizerHeatingSurface.htm 1/2

9/14/2019 EconomizerHeatingSurface

10 Heating Surface S 2904.3 M 2

Home Page

Sugar Tech Articles

Calculators Page

siva.sugarprocesstech.com/EconomizerHeatingSurface/EconomizerHeatingSurface.htm 2/2

You might also like

- Jis G 3106 PDFDocument38 pagesJis G 3106 PDFTùng Lê Đinh50% (2)

- Regular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsDocument23 pagesRegular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsYogaAnandNo ratings yet

- Condenser DesignDocument1 pageCondenser DesignNaqqash SajidNo ratings yet

- HMBD For WhrsDocument19 pagesHMBD For WhrstejaNo ratings yet

- Astm D 3276 PDFDocument62 pagesAstm D 3276 PDFJose Luis CT100% (3)

- Chartek 8 Product Data SheetDocument4 pagesChartek 8 Product Data SheetJomer J Simpson0% (1)

- Super Critical PresentationDocument46 pagesSuper Critical PresentationSam100% (1)

- Fan Flow Calculation For FBC BoilerDocument3 pagesFan Flow Calculation For FBC BoilerOmprakaash MokideNo ratings yet

- Steam Turbine CalculationsDocument9 pagesSteam Turbine CalculationsShankarMukherjeeNo ratings yet

- 1X 66 Mwkohinoor Power Pvt. Ltd. CNT 5110122 Stack Height SizingDocument4 pages1X 66 Mwkohinoor Power Pvt. Ltd. CNT 5110122 Stack Height SizingPriyanathan ThayalanNo ratings yet

- Experiment 1 - Marcet BoilerDocument10 pagesExperiment 1 - Marcet BoilerWee Chuan YeanNo ratings yet

- Fired Boilers: 2.1 Design PrinciplesDocument6 pagesFired Boilers: 2.1 Design PrinciplesEric TingNo ratings yet

- Fuel Savings and Efficiency CalculatorDocument6 pagesFuel Savings and Efficiency CalculatorFaizan YousufNo ratings yet

- Heat BalanceDocument10 pagesHeat BalanceHoang VAN SI100% (2)

- Boiler Cheat SheetDocument1 pageBoiler Cheat SheetnicolaskelseyNo ratings yet

- Chimney Height Calculation - 0-0-20102014nmpve003 - Prefeasibilityreportof - Accord - 2x180mwDocument17 pagesChimney Height Calculation - 0-0-20102014nmpve003 - Prefeasibilityreportof - Accord - 2x180mwGauri 'tika' KartikaNo ratings yet

- Power Plant and Calculations - STEAM CONDENSER, VACUUM AND CALCULATIONSDocument7 pagesPower Plant and Calculations - STEAM CONDENSER, VACUUM AND CALCULATIONSRajesh100% (1)

- Sample Computation For Boiler EfficiencyDocument6 pagesSample Computation For Boiler Efficiencyra_tagolimotNo ratings yet

- Impulse Turbine and Reaction TurbineDocument5 pagesImpulse Turbine and Reaction Turbinerahul100% (1)

- Turbine: Z=1+β-qβ ( (Z-β) / (Z+єβ) (Z+σβ) )Document144 pagesTurbine: Z=1+β-qβ ( (Z-β) / (Z+єβ) (Z+σβ) )Roahliza NalazaNo ratings yet

- Shree Mega Power FinalDocument114 pagesShree Mega Power FinalRaja RamachandranNo ratings yet

- Feed Water Heater ModellingDocument64 pagesFeed Water Heater ModellingSIVA KAVYANo ratings yet

- CSTRDocument15 pagesCSTRVismar Campos HernándezNo ratings yet

- India - Cement Tool-FinalDocument66 pagesIndia - Cement Tool-FinalAnaibar TarikNo ratings yet

- Heat Rate and Specific Fuel ConsumptionDocument1 pageHeat Rate and Specific Fuel ConsumptionDia Putranto HarmayNo ratings yet

- Sensitivity U01 U02 JUNE03Document9 pagesSensitivity U01 U02 JUNE03Adil EL FARDAOUINo ratings yet

- Waste Heat RecoveryDocument18 pagesWaste Heat RecoverywaleedyehiaNo ratings yet

- Performance Calculation Sheet Unit 5 25-02-2022Document7 pagesPerformance Calculation Sheet Unit 5 25-02-2022SHIBAM SINGHNo ratings yet

- 3 Boiler PAF and System Commissioning Procedure-TöàtéëS+Ç íTúÄ Såèsà T +T+ƑF Âf Ò Ä Û+Document34 pages3 Boiler PAF and System Commissioning Procedure-TöàtéëS+Ç íTúÄ Såèsà T +T+ƑF Âf Ò Ä Û+kvsagarNo ratings yet

- Energy Performance Assessment of Boiler at P.S.S.K. LTDDocument12 pagesEnergy Performance Assessment of Boiler at P.S.S.K. LTDPajooheshNo ratings yet

- Fan Efficiency CalculatorDocument1 pageFan Efficiency CalculatorR P Naik100% (1)

- Combustion CalculationsDocument6 pagesCombustion CalculationsMauro FerrareseNo ratings yet

- BOILER CALCULATION SYSTEM REV 3-1Document3 pagesBOILER CALCULATION SYSTEM REV 3-1Dewi FellaNo ratings yet

- Energy Audit at HETERO LABS UNIT HETERO DRUGS UNIT 6 1706212997Document74 pagesEnergy Audit at HETERO LABS UNIT HETERO DRUGS UNIT 6 1706212997varadhpharmaNo ratings yet

- Technical Data Sheet Therminol® Vp-1 Heat Transfer FluidDocument2 pagesTechnical Data Sheet Therminol® Vp-1 Heat Transfer FluidArifNo ratings yet

- Heat Balance Calculation Sheet - Part ADocument1 pageHeat Balance Calculation Sheet - Part AFer VFNo ratings yet

- DraughtDocument33 pagesDraughtNipun SabharwalNo ratings yet

- Power Plant Numerical PDFDocument3 pagesPower Plant Numerical PDFAhsan Ali0% (1)

- Boiler Efficiency at Part Load ConditionsDocument4 pagesBoiler Efficiency at Part Load ConditionsFORBESMARSHALLPVTLTD100% (1)

- Gross Turbine Cycle Heat Rate Ch-8.2Document12 pagesGross Turbine Cycle Heat Rate Ch-8.2levelhead28No ratings yet

- Design Theory of Circulating Fluidized Bed Boilers: KeywordsDocument15 pagesDesign Theory of Circulating Fluidized Bed Boilers: KeywordsAnonymous PkeI8e84RsNo ratings yet

- ACW Flow Calculation BasisDocument4 pagesACW Flow Calculation Basisdebu1985No ratings yet

- NTPC Gas Power PlantDocument32 pagesNTPC Gas Power PlantBlack PantherNo ratings yet

- XSteam ExcelDocument10 pagesXSteam ExcelSIVANo ratings yet

- Ignitor & Scanner Air ControlDocument5 pagesIgnitor & Scanner Air ControlJKKNo ratings yet

- 2X500 MW Neyveli New Thermal Power Project (NNTPP) Neyveli, Tamilnadu, IndiaDocument6 pages2X500 MW Neyveli New Thermal Power Project (NNTPP) Neyveli, Tamilnadu, IndiaDenkaNo ratings yet

- Design ConsiderationsDocument6 pagesDesign ConsiderationssatyacvaNo ratings yet

- Aux Power Consumption For Power PlantsDocument2 pagesAux Power Consumption For Power Plantsabhiknit0% (1)

- Latest Design of ChimneysDocument2 pagesLatest Design of ChimneysHussam Udein50% (2)

- Home Heat Loss Calculator: How To UseDocument3 pagesHome Heat Loss Calculator: How To Usefadlul akbar herfiantoNo ratings yet

- Procedure For: Unit Low Load Operation: Sasan Ultra Mega Power ProjectDocument5 pagesProcedure For: Unit Low Load Operation: Sasan Ultra Mega Power ProjectSatyanarayan SinghaNo ratings yet

- Turbine Efficiency - Ch-8.1 PDFDocument8 pagesTurbine Efficiency - Ch-8.1 PDFGopal Chandra SahuNo ratings yet

- Boiler Chemical Cleaning Procedure DT 19 12 2020 - For OfferDocument21 pagesBoiler Chemical Cleaning Procedure DT 19 12 2020 - For OfferNeeraj HegdeNo ratings yet

- Organic - New - 2019 Product ProfileDocument15 pagesOrganic - New - 2019 Product Profilevaibhav khodakeNo ratings yet

- CRHsteamforsootblowing PDFDocument9 pagesCRHsteamforsootblowing PDFUdhayakumar VenkataramanNo ratings yet

- Steam TablesDocument16 pagesSteam TablesDanu MamlukatNo ratings yet

- Tatyasaheb Kore Institute of Engineering and Technology, WarananagarDocument17 pagesTatyasaheb Kore Institute of Engineering and Technology, WarananagarajayNo ratings yet

- New Concept For Utilization COG & BFGDocument2 pagesNew Concept For Utilization COG & BFGAhmad FaisalNo ratings yet

- Byproduct Operations and ProcessDocument8 pagesByproduct Operations and ProcessAbhaySnghNo ratings yet

- Impact of SC On Specific EnergyDocument33 pagesImpact of SC On Specific EnergyManish GautamNo ratings yet

- Calculation Form CombustionDocument2 pagesCalculation Form CombustionKrishna KameshNo ratings yet

- Plant InvesticationDocument3 pagesPlant InvesticationirfanNo ratings yet

- 1.8 Example For Coal Fired Boiler Energy Performance Assesment of BoilersDocument3 pages1.8 Example For Coal Fired Boiler Energy Performance Assesment of BoilersAyiRahmawatiNo ratings yet

- Condenser: HeaderDocument1 pageCondenser: HeaderjagjitNo ratings yet

- 6.2.3 Cane Calorific ValueDocument4 pages6.2.3 Cane Calorific ValuejagjitNo ratings yet

- Parameters For Feed Water: Parameters Standard Actual: Chloride Iron (Fe)Document2 pagesParameters For Feed Water: Parameters Standard Actual: Chloride Iron (Fe)jagjitNo ratings yet

- Pump Input Power Calculation: S.No Particulars Values UOMDocument2 pagesPump Input Power Calculation: S.No Particulars Values UOMjagjitNo ratings yet

- Need of Boiler Feed Water Treatment - Boiler Water Treatment ProcessDocument14 pagesNeed of Boiler Feed Water Treatment - Boiler Water Treatment ProcessjagjitNo ratings yet

- Characteristics of Boiler Feedwater - LenntechDocument1 pageCharacteristics of Boiler Feedwater - LenntechjagjitNo ratings yet

- Case Study 10Document36 pagesCase Study 10amareshscribdNo ratings yet

- Project Modified GuarDocument27 pagesProject Modified GuarAhsum HaleemNo ratings yet

- LATICRETE 325 High Flex TDSDocument4 pagesLATICRETE 325 High Flex TDSrvbadal23498No ratings yet

- B 429 - 00 Qjqyos1sruqDocument10 pagesB 429 - 00 Qjqyos1sruqGalih PutraNo ratings yet

- Measuring Field PipeDocument5 pagesMeasuring Field PipeVitor OlivettiNo ratings yet

- Insulation Joint PDFDocument7 pagesInsulation Joint PDFBabatunde OlalekanNo ratings yet

- Belge No1 Sartopore 2 0 45 DatDocument7 pagesBelge No1 Sartopore 2 0 45 DatFarhan FachrizaNo ratings yet

- Graziano Shifting Solutions BrochureDocument7 pagesGraziano Shifting Solutions Brochurebinhui wanNo ratings yet

- LRS 645 Brochure en - 8588-0Document8 pagesLRS 645 Brochure en - 8588-0Ivan ErmolaevNo ratings yet

- Scythe TutorialDocument3 pagesScythe TutorialAditiya MuaffanNo ratings yet

- Thermashield PDFDocument8 pagesThermashield PDFromeo pedranoNo ratings yet

- Evnkc enDocument24 pagesEvnkc ensalvoNo ratings yet

- N.V. Nayak - A.K. Jain - Handbook On Advanced Concrete Technology (2012, Alpha Science International) - Libgen - LiDocument637 pagesN.V. Nayak - A.K. Jain - Handbook On Advanced Concrete Technology (2012, Alpha Science International) - Libgen - LiSanjay BhadelNo ratings yet

- United States Patent (19) : Pre-Mixed Catalyzed WinylacetateDocument6 pagesUnited States Patent (19) : Pre-Mixed Catalyzed WinylacetateSHRINIL DESAINo ratings yet

- Technology: Answers Drawing BDocument5 pagesTechnology: Answers Drawing BWellington S. França100% (1)

- Dell 3100 3000 Service ManualDocument641 pagesDell 3100 3000 Service Manualoralbnetwork50% (2)

- ActiveCell Brochure WEB LTR PDFDocument4 pagesActiveCell Brochure WEB LTR PDFab5918590No ratings yet

- Rewind Motor BrushlessDocument11 pagesRewind Motor Brushlesssharingiscaring69No ratings yet

- Ammonia ScrubbersDocument7 pagesAmmonia Scrubbersangelo pascuaNo ratings yet

- Avk Fabricated Flange Adaptor, Pn16 260: Features: OptionsDocument2 pagesAvk Fabricated Flange Adaptor, Pn16 260: Features: Optionskhai ruleNo ratings yet

- Codigo de Falha GMDocument8 pagesCodigo de Falha GMDedeh SilvaNo ratings yet

- A Study On Performance of Bricks Producing From Solid WasteDocument8 pagesA Study On Performance of Bricks Producing From Solid WasteDharma banothuNo ratings yet

- 4690 MH2 Metal HoseDocument28 pages4690 MH2 Metal HosePedro Alberto BenitesNo ratings yet

- Bench Grinder: DO NOT Use This Machine Unless A Teacher Has InstructedDocument2 pagesBench Grinder: DO NOT Use This Machine Unless A Teacher Has InstructedNabil Qayyum Roslee100% (1)

- 1 s2.0 S0043164822003702 MainDocument13 pages1 s2.0 S0043164822003702 Main039 Asma SanjumNo ratings yet

- SFC Technical CatalogDocument5 pagesSFC Technical CatalogGomathi SankarNo ratings yet

- Lorry AirBrakesDocument3 pagesLorry AirBrakesEnache CristinaNo ratings yet