Piping Built in Clean Flowchart

Piping Built in Clean Flowchart

Uploaded by

AryaCopyright:

Available Formats

Piping Built in Clean Flowchart

Piping Built in Clean Flowchart

Uploaded by

AryaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Piping Built in Clean Flowchart

Piping Built in Clean Flowchart

Uploaded by

AryaCopyright:

Available Formats

Rev.

0

PIPING Clean Built Procedure Flow Chart 3-Aug-19

H.Kobayashi

Scope of Work

Piping Construction Work Flow Action by Form Sheet Construction COMM (Under Coordination of

Warehouse QC

(Subconractor) Cleanliness Coordinator)

Fabrication at SM0E Shop

Internal Cleanliness Cleanliness Check

Const. Request for Check shall be by QC Resident Inspector

Check before packing sheet

(TEP-ITR-PIP-105)

Please refer to : TEP-930-SPE-QA-BP4-0021 QCP PIPING PREFABRICATION AND ERECTION

Preservation / Packing Const.

Shipping -

Delivery at site

Receiving Inspection Warehouse

Prefabricated Spool / Loose Pipe

Warehouse shall perform random check of internal cleanliness during receiving inspection

Other piping Component

Warehouse shall perform 100% internal cleanliness during receiving inspection. Result of

Inspection, and Corrective action shall be controlled with OSD Report.

OSD Report /

Disposition Report issue For Info. For Info.

Plan

Site Storage

Storage at Laydown

Warehouse Warehouse shall control spool/component preservation during installation

yard

Preservation and Cleanliness Patrol shall be performed periodically by SUSU and Preservation

team (Commissioning)

Material Issue to Subcontractor

Issue to Subcontractor Const. Const.(Subcon) shall confirm cleanliness of internal piping before receiving materials

Const.(Subcon) shall control spool/component preservation after receiving

Preservation and Cleanliness Patrol shall be performed periodically by SUSU and Preservation team

(Commissioning)

Pipe Launching/ Installation

Please refer to : TEP-930-SPE-QA-BP4-0021 QCP PIPING PREFABRICATION AND ERECTION

Internal cleanliness Cleanliness Check

check before launching. Const. sheet Request for Check Check / Approve

(Visual Check) (TEP-ITR-PIP-107)

Orig. copy of Cleanliness Check Result shall be controlled by Const.(Subcon)

Marked Iso as record

Carbon Copy to Commissioning Cleanliness Coordinator

Installation Const. Const.(Subcon) shall control piping preservation and cleanliness during installation Preservation

and Cleanliness Patrol shall be performed periodically by SUSU and Preservation team

Flushing/Blowing

Flushing/Blowing if debris observed

Pressure Test Borescope Const.(Subcon) shall control dewatering condition of each piping system. i.e) test package wise.

Pressure Test Const. Dewatering Note: Boresoping check to have evidence of

Water quality shall be confirmed clean (including cleaning as state in the ITR-112

Cleanliness Check temporary piping/hose utilize to transfer of water)

sheet (Signed)

Flushing/Blowing (TEP-ITR-PIP-112) Cleanliness Check Sheet shall be compiled by Test Package wise by Const.(Subcon)

Review of Cleanliness

Const.

Check Sheet

Commissioning Cleanliness Coordinator shall review and evaluate the summary of Cleanliness

Draining/Drying TEP-ITR-PIP-114 Check Sheet.

Commissioning Cleanliness Coordinator shall refect the result of above mentioned evaluation to

Critical

Borescope Air Blow plan and application.

Precommissioning

Air Blow / Water COMPANY expectation to have borescoping to be include in the ITR-114 post hydrotest as part of

Const.

Non-Critical

Flushing dryness & debris free confirmation

TEP-ITR-PIP-126

Borescope Inspection Const. Please refer to : TEP-930-SPE-QA-BP4-0021 QCP PIPING PREFABRICATION AND ERECTION

Reinstatement Const. Air Blow / Water flushing can be ommitted, if result of borescope check is satisfactory.

As per TEP-900-PRC-OP-BP4-0007 General Cleaning Procedure that have been approved by CPY

Commissioning NON-CRITICAL --> Pressure Test - Borescope - Reinstatement

CRITICAL --> Pressure Test - Blowing/Flushing - Borescope - Reinstatement

L/O Flushing Comm. CRITICAL line/system need to complete ITR-126 while NON CRITICAL shall complete ITR-112

Degreasing Comm. By doing this one COMPANY expectation :

1. Decrease the activity of blowing/flushing

Steam Blow Comm. 2. Prevent internal handover which cause many problems when we have no good internal

process

Passivation Comm.

High Pressure Cleaning Comm.

You might also like

- Rx82 Sub Cont Pre Qualification-Log SheetDocument1 pageRx82 Sub Cont Pre Qualification-Log SheetQasim MalikNo ratings yet

- TWJO-ITP-EMB-0003 Reva0 ITP For Retaining WallDocument5 pagesTWJO-ITP-EMB-0003 Reva0 ITP For Retaining WallBangkit SamosirNo ratings yet

- KP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Document1 pageKP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Utku Can KılıçNo ratings yet

- Pre Commissioning Master Punch List 22 May 2018Document197 pagesPre Commissioning Master Punch List 22 May 2018Gomathyselvi100% (1)

- Chapter 7 Introduction To Regular Income TaxDocument76 pagesChapter 7 Introduction To Regular Income TaxANGELU RANE BAGARES INTOL100% (1)

- Main Inspection Test Plan SampleDocument2 pagesMain Inspection Test Plan SampleMuhd AfiqNo ratings yet

- BS en 16480 2016Document79 pagesBS en 16480 2016Ravindra PawarNo ratings yet

- Topography Survey Daily Report: Pipeline ProjectDocument1 pageTopography Survey Daily Report: Pipeline Projectarianto82No ratings yet

- Plant Location Company Doc. No. NADocument8 pagesPlant Location Company Doc. No. NAsivaNo ratings yet

- DRP001-OUF-SPE-C-000-008-B2 (Drainage Material & Workmanship)Document15 pagesDRP001-OUF-SPE-C-000-008-B2 (Drainage Material & Workmanship)Kannan MurugesanNo ratings yet

- Inspection and Test Plan Format: GeneralDocument4 pagesInspection and Test Plan Format: GeneralSABIR KHANNo ratings yet

- MM ZTK 1a ZPQ Qua TPN 8055 Rev.a1Document13 pagesMM ZTK 1a ZPQ Qua TPN 8055 Rev.a1sfd640No ratings yet

- Ke01 A1 000 NC e PR 0001 000 C01Document30 pagesKe01 A1 000 NC e PR 0001 000 C01masahinNo ratings yet

- PMI-MS-QAC-2022-03 - Method Statement For Grounding System Works - ITP 2Document3 pagesPMI-MS-QAC-2022-03 - Method Statement For Grounding System Works - ITP 2Emmanuel TamayoNo ratings yet

- NCT-SCN-000-E06-00002 - A01 - Site Query Deviation Concession RequestDocument1 pageNCT-SCN-000-E06-00002 - A01 - Site Query Deviation Concession RequestCharles KingNo ratings yet

- Method Statement-Ext Pipe FittingsDocument13 pagesMethod Statement-Ext Pipe FittingsSam JoseNo ratings yet

- ITP For Pipeline Repair Works - by Using Belzona Superwrap IIDocument4 pagesITP For Pipeline Repair Works - by Using Belzona Superwrap IIAhmedNo ratings yet

- HMSWeb - Handover Management SystemDocument21 pagesHMSWeb - Handover Management SystemGG GRNo ratings yet

- A30DEC001 - RevC Shop ITP HRSGDocument5 pagesA30DEC001 - RevC Shop ITP HRSG邢焕震No ratings yet

- 13march2020 - Construction Completion Punch List MasterfileDocument143 pages13march2020 - Construction Completion Punch List MasterfileDangolNo ratings yet

- Vendor InspectionDocument3 pagesVendor Inspectionzahid_497100% (1)

- Fabrication Inspection Progress ReportDocument4 pagesFabrication Inspection Progress ReportNorman MoralesNo ratings yet

- "Red" High (1) "Yellow" Medium (2) "Green" Low (3) : IllnessDocument2 pages"Red" High (1) "Yellow" Medium (2) "Green" Low (3) : IllnessBarb O'NeillNo ratings yet

- 1.5 Assurance ProcessDocument9 pages1.5 Assurance Processaswar100% (1)

- Product Chemical CompositionDocument1 pageProduct Chemical CompositionMohammed HamedNo ratings yet

- DRP001 Puc Pro N 000 004 - 6Document58 pagesDRP001 Puc Pro N 000 004 - 6aasss100% (1)

- RFI & ITR Workflow - 20200116Document1 pageRFI & ITR Workflow - 20200116nickoNo ratings yet

- Iwp Hydrotesting Checklist: Appendix - 14Document4 pagesIwp Hydrotesting Checklist: Appendix - 14Soumitra GuptaNo ratings yet

- Rumaila Operating Organisation Specification For Carbon Steel Pipeline Welding and InspectionDocument89 pagesRumaila Operating Organisation Specification For Carbon Steel Pipeline Welding and InspectionNooraldeen AlarajyNo ratings yet

- AWI 412 Commissioning GuidelinesDocument7 pagesAWI 412 Commissioning GuidelinesJoel AlcantaraNo ratings yet

- Ras Markaz Crude Oil Park Project (Phase1)Document17 pagesRas Markaz Crude Oil Park Project (Phase1)anil pkNo ratings yet

- Extra Work ModelDocument2 pagesExtra Work ModelkathalyogiNo ratings yet

- 06.daily Quality Report BSML-JUNE-2021Document11 pages06.daily Quality Report BSML-JUNE-2021Md. Mamunur RashidNo ratings yet

- Record For Hydro TestDocument42 pagesRecord For Hydro Testfaisal jasimNo ratings yet

- Itr-Pug (Ug Piping)Document12 pagesItr-Pug (Ug Piping)mahmoud100% (1)

- Sample RACI DocumentDocument4 pagesSample RACI DocumentAhamedSharifNo ratings yet

- Performa For Project Completion Report (P.C.R.)Document4 pagesPerforma For Project Completion Report (P.C.R.)Dwijendra ChanumoluNo ratings yet

- Gulf Consult Job Application Form PDFDocument3 pagesGulf Consult Job Application Form PDFSudhi NNo ratings yet

- Monthly Quality Report: Akt Oil ServicesDocument4 pagesMonthly Quality Report: Akt Oil ServicesLaith SalmanNo ratings yet

- Project: Samsun CCPP: Title: ITP of SwitchgearsDocument4 pagesProject: Samsun CCPP: Title: ITP of SwitchgearsUtku Can Kılıç100% (1)

- 250600DBQRD0008 - Exde00 - 22 - Procedure For Handling, Transport and Storage of Pipes From The Stock Pile To TrenchDocument22 pages250600DBQRD0008 - Exde00 - 22 - Procedure For Handling, Transport and Storage of Pipes From The Stock Pile To TrenchAbdullah AbdullahNo ratings yet

- Annex 2 Scope of WorkDocument37 pagesAnnex 2 Scope of WorkWilliam PENGNo ratings yet

- Daily Report Construction FormDocument2 pagesDaily Report Construction FormGirma AssefaNo ratings yet

- Commissioning Procedure of CB 150 KV - ENDIRADocument10 pagesCommissioning Procedure of CB 150 KV - ENDIRAYoga SamNo ratings yet

- ITP For CW and ACW Piping WorkDocument8 pagesITP For CW and ACW Piping WorkPhong DoNo ratings yet

- 2h Hvac-102 Roof Floor Hvac Layout-Rf HvacDocument1 page2h Hvac-102 Roof Floor Hvac Layout-Rf HvacWaqar KhanNo ratings yet

- High Pressure Water Cleaning ProcedureDocument19 pagesHigh Pressure Water Cleaning ProcedureGuruh SuprayitnoNo ratings yet

- Weld Cleaning MethodsDocument7 pagesWeld Cleaning MethodsTrần Thùy LinhNo ratings yet

- Soil Investigation and Topographical Works Rev ADocument5 pagesSoil Investigation and Topographical Works Rev ARiko Bin ZulkifliNo ratings yet

- Pipeline Consultation PlanDocument37 pagesPipeline Consultation PlanhutuguoNo ratings yet

- Red Bag Checklist For Mechanical CompletionDocument9 pagesRed Bag Checklist For Mechanical Completionhitm357No ratings yet

- Inspection Test Plan (Itp) : Mobile Fire ExtinguisherDocument4 pagesInspection Test Plan (Itp) : Mobile Fire Extinguisher87482127No ratings yet

- 001-Pro Document and Data ControlDocument25 pages001-Pro Document and Data ControlKöksal PatanNo ratings yet

- Drp001-Ouf-Inc-Gmd-Z-000-038-S1. Code 4Document26 pagesDrp001-Ouf-Inc-Gmd-Z-000-038-S1. Code 4rodman823No ratings yet

- Elm 02 JGC PM SPC 0008Document25 pagesElm 02 JGC PM SPC 0008Amine GuedjibaNo ratings yet

- Non-Destructive Testing Methods & Applications TableDocument2 pagesNon-Destructive Testing Methods & Applications TableAlzaki Abdullah100% (1)

- Oil Penetrant Test ProcedureDocument4 pagesOil Penetrant Test Procedurehasan_676489616No ratings yet

- ITR-B (Piping) Witness Joint1Document1 pageITR-B (Piping) Witness Joint1Momo ItachiNo ratings yet

- TWJO-ITP-PRC-0005 Reva2 ITP For PC BoxCul in LBDPTDocument6 pagesTWJO-ITP-PRC-0005 Reva2 ITP For PC BoxCul in LBDPTBangkit SamosirNo ratings yet

- Change SummaryDocument21 pagesChange SummaryNguyễn LucyNo ratings yet

- WANGEN Reference List KL30SDocument1 pageWANGEN Reference List KL30SAryaNo ratings yet

- Fluke 805FC Data-Sheet ENDocument5 pagesFluke 805FC Data-Sheet ENAryaNo ratings yet

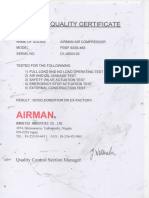

- Test Quality & Manufacture Cert Compressor 920 CFM 5733Document1 pageTest Quality & Manufacture Cert Compressor 920 CFM 5733AryaNo ratings yet

- Pentek Ecp Series Spec SheetDocument2 pagesPentek Ecp Series Spec SheetAryaNo ratings yet

- Fluke 805-FC Brochure Fluke-Connect ENDocument2 pagesFluke 805-FC Brochure Fluke-Connect ENAryaNo ratings yet

- Flange Bolt Torque Calculation and Pipe Flange Bolt Torque ChartDocument6 pagesFlange Bolt Torque Calculation and Pipe Flange Bolt Torque ChartArya0% (1)

- Flange Bolt Tightening ProcedureDocument5 pagesFlange Bolt Tightening ProcedureArya100% (1)

- SV COMM TEP 023 Preservation - Fernando Arya NDocument1 pageSV COMM TEP 023 Preservation - Fernando Arya NAryaNo ratings yet

- RAPP Soil Study Proposal - 0Document55 pagesRAPP Soil Study Proposal - 0AryaNo ratings yet

- SUSU Surveillance Plan Week 46-47Document1 pageSUSU Surveillance Plan Week 46-47AryaNo ratings yet

- Guidelines For Engineering Project Proposals: What Makes A Good Proposal?Document7 pagesGuidelines For Engineering Project Proposals: What Makes A Good Proposal?AryaNo ratings yet

- Enquiry Slope Protection For BM1 Project R02Document12 pagesEnquiry Slope Protection For BM1 Project R02AryaNo ratings yet

- Pump Performance Test ProcedureDocument11 pagesPump Performance Test ProcedureAryaNo ratings yet

- Cost Proposal PlajuDocument2 pagesCost Proposal PlajuAryaNo ratings yet

- Testo 184H1 Data SheetDocument2 pagesTesto 184H1 Data SheetAryaNo ratings yet

- TEP-MS-AJU 004-REV 01 MS Preservation of New Amine Tank Using VpCI 609 - Comments PDFDocument3 pagesTEP-MS-AJU 004-REV 01 MS Preservation of New Amine Tank Using VpCI 609 - Comments PDFAryaNo ratings yet

- Perpedicular With Safety BannerDocument1 pagePerpedicular With Safety BannerAryaNo ratings yet

- SUSU Site Surveillance Check List (Area Wise) - New PDFDocument2 pagesSUSU Site Surveillance Check List (Area Wise) - New PDFAryaNo ratings yet

- Create Innovative Customer Experiences Using AIDocument18 pagesCreate Innovative Customer Experiences Using AIDeproder MoralesNo ratings yet

- Dujeds 001 - Ibrahim Umar BambaleDocument8 pagesDujeds 001 - Ibrahim Umar Bambale0703055No ratings yet

- Part III Project Planning - Topic 3 Project Appraisal and Project Risk ManagementDocument19 pagesPart III Project Planning - Topic 3 Project Appraisal and Project Risk ManagementchusnuhNo ratings yet

- U.S. Individual Income Tax Return: Staples 219-19-7094 Jaimar HDocument4 pagesU.S. Individual Income Tax Return: Staples 219-19-7094 Jaimar HJayam Jai Maharaj100% (1)

- BPI Vs CA 216 SCRA 51 1992Document2 pagesBPI Vs CA 216 SCRA 51 1992Vincent Rey BernardoNo ratings yet

- Employment State Insurance Act, 1948 Advisory Committee and PowersDocument11 pagesEmployment State Insurance Act, 1948 Advisory Committee and PowersatipriyaNo ratings yet

- Bitly TransactionDocument3 pagesBitly TransactionSimanchala SahuNo ratings yet

- Assignment 1 M.Rabi Ijaz 10678Document23 pagesAssignment 1 M.Rabi Ijaz 10678Rabi IjazNo ratings yet

- Severina May20 To May26 - Collection ReportDocument2 pagesSeverina May20 To May26 - Collection ReportJohn GuillermoNo ratings yet

- Finance Project Rubric 2023Document7 pagesFinance Project Rubric 2023Xansos0% (1)

- Online 18 OrgDocument2 pagesOnline 18 OrgNovi Dianti KarsyaniNo ratings yet

- 3.SMC Realty Digital Media Plan by GTF Technologies (Google Partner)Document6 pages3.SMC Realty Digital Media Plan by GTF Technologies (Google Partner)deepak.pahariyaNo ratings yet

- Actg MCQDocument8 pagesActg MCQhello hahaNo ratings yet

- VUL SEC 17Q Mar312019 (SEC RCVD May202019)Document47 pagesVUL SEC 17Q Mar312019 (SEC RCVD May202019)atescandorNo ratings yet

- Sanjog Jolly: PGDM, IIM Kozhikode Summer Internship CVDocument2 pagesSanjog Jolly: PGDM, IIM Kozhikode Summer Internship CVJohn AcidNo ratings yet

- Tesfaye Beyene GCDocument126 pagesTesfaye Beyene GCMegersa TadeleNo ratings yet

- (RO) MS7SL82O - 21598794 - Ethical AuditDocument21 pages(RO) MS7SL82O - 21598794 - Ethical AuditKrishan hunukumburaNo ratings yet

- MCQ Unit 1 - 1 Mark Answer KeyDocument12 pagesMCQ Unit 1 - 1 Mark Answer KeyShashi Kumar C GNo ratings yet

- IndexDocument107 pagesIndexAina RazafimandimbyNo ratings yet

- MM ScriptDocument3 pagesMM ScriptPratik R PanchalNo ratings yet

- Chap 9 - Proof of Cash Fin Acct 1 - Barter Summary Team PDFDocument7 pagesChap 9 - Proof of Cash Fin Acct 1 - Barter Summary Team PDFCarl James Austria100% (1)

- Cloud Kitchen Business PlanDocument42 pagesCloud Kitchen Business PlanSai Krishna SkNo ratings yet

- Ii - CorporationsDocument4 pagesIi - Corporationsby ScribdNo ratings yet

- Apple ReportDocument20 pagesApple ReportLuke RatnasingamNo ratings yet

- RXUK TOP500 2020 v2Document48 pagesRXUK TOP500 2020 v2Íñigo PérezNo ratings yet

- Feasibility Study On Dairy Products Industry - QalyubiaDocument24 pagesFeasibility Study On Dairy Products Industry - Qalyubiaamaal100% (1)

- SENSEXDocument10 pagesSENSEXMohamed ImranNo ratings yet

- 65 PGDM Mip ReportDocument43 pages65 PGDM Mip ReportVIKAS DIGHENo ratings yet

- Macroeconomics Key GraphsDocument5 pagesMacroeconomics Key Graphsapi-243723152100% (1)