0 ratings0% found this document useful (0 votes)

172 viewsGen - Importance of Welding in L & T PDF

Gen - Importance of Welding in L & T PDF

Uploaded by

SivaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Gen - Importance of Welding in L & T PDF

Gen - Importance of Welding in L & T PDF

Uploaded by

Siva0 ratings0% found this document useful (0 votes)

172 views30 pagesOriginal Title

gen.importance of welding in L & T.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

172 views30 pagesGen - Importance of Welding in L & T PDF

Gen - Importance of Welding in L & T PDF

Uploaded by

SivaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 30

Importance of welding in L&T

• All fabrication consists of Forming and

Joining (welding).

• It is finally the quality of welding that

decides whether L&T gets an order,

executes it on time and books a profit.

• What is special about welding in L&T?

Welding in L&T

• Fabrication of equipment for a wide range

of industries like Food, Cement, Chemical,

Petrochemical, Fertilizer, Man-made Fibres,

Oil & Gas, Nuclear, Defence and

Aerospace. Each of these applications has

its specific requirements.

• Use of a wide range of materials like

Ferrous (CS, LAS, SS) & Non-ferrous (Ni,

Cu, Al, Ti, Zr & Alloys).

Welding in L&T

• Variety of design and fabrication codes like

ASME, BS, AD-Merkblatter.

• Emphasis on mechanized welding processes

like SAW with many variations like

Tandem, Strip cladding etc.

• Wide range of Thickness: 0.5 to 500 mm.

• Large number of highly skilled welders.

FUNCTIONS OF

WELDING ENGG.

PLANNING EXECUTION DEVELOPMENT MATERIALS TRAINING &

QUALIFICATIONS

Planning Cell

• Study drawings, specifications.

• Decide welding process/wep.

• Deciding consumable type.

• Calculating consumable and indenting.

• Availability of welding procedures.

• Deciding NDE and destructive testing.

• Documentation.

Execution Cell

• Ensure sound welding practices.

• Minimise rework.

• Suggest high productivity techniques.

• Identify need for training and qualification.

• Trouble shooting.

Development Cell

• Literature survey and analysis.

• New materials.

• New processes/techniques.

• Special applications/configurations.

• Updating know-how.

• Failure analysis.

Materials Cell

• Identifying quality vendors.

• Setting standards for consumables.

• Procuring local consumables.

• Maintaining Inventory.

Training & Qualifications

• Training welders for various processes.

• Qualification tests for welders.

• Qualification of welding procedures.

Information from Welding Engg.

• Shop Welding Plan (SWP)

• Test Plan (TP)

• Provisional Weld Plan (PWP)

• Shop Weld Repair Plan (SWRP)

• Welding Procedure Specification (WPS)

• Welder Master List

Why Preheat?

• Drive out moisture.

• Hydrogen diffuses out faster at higher temp.

• Lower cooling rate & lower hardness.

• Lower shrinkage & residual stresses.

• Prevent cold cracking in ferritic steels.

• Reduces chances of porosity.

How to Preheat? (1)

• Low intensity burners with shrouds are best.

• Avoid hot spots.

• From opposite side where feasible.

• From inside for multi-wall vessels.

• Extra care for clad vessels.

• Width of preheat- higher of 75mm on either

side or thickness.

How to Preheat? (2)

• Uniform preheat with a moderate heating

rate. Uneven heating in a restrained joint

can lead to weld cracking.

• Soot formation on vessel to be avoided.

• Temperature to be measured on the opposite

side of heat source. Otherwise remove heat

source and wait for 1minute/inch before

measuring.

Why Interpass?

• Reduces overheating and grain coarsening

thus controlling drop in impact toughness.

• Reduces the susceptibility to IGC.

Why Postheating?

• Generic term is DHT (Dehydrogenation

treatment).

• Provides more time for hydrogen to diffuse

out from the weldment.

• Diffusion of hydrogen is faster as the

temperature is higher (300-350°C)

• Prevent cold cracking.

Why portable ovens?

• Keep electrodes hot and maintain lower

moisture levels.

• All our consumables are procured with low

hydrogen coating.

• Another preventive measure for cold

cracking.

• Worldwide standard.

• Reduces chances of porosity.

Why temper bead?

• A weld layer heat treats (tempers) the

previously laid weld and improves

toughness. This beneficial action is not

available to the last layer so a temper bead.

• In materials where the impact toughness is

very critical (difficult to obtain) or when

there is no PWHT.

Why buttering?

• Dissimilar materials being joined.

• Materials with different PWHT

requirements being joined.

• Reduces the risk of Lamellar tearing.

• Preferred option for critical applications.

Why depth charts?

• Improve accountability for weld quality.

• Necessary for analysis in case of repairs.

• Productivity monitoring?

Importance of good set-ups

• Excess gap can lead to solidification

cracking. It also increases the weld metal

requirement.

• Higher root face leads to less penetration

and deeper chip back.

• Improperly tacked backing strips lead to

cracking.

Temporary attachments

• More critical than the “permanent welds”.

• Preheating more important.

• Material identification.

• Removal equally critical.

Miscellaneous (1)

• Fans for welder or job?

• Earthing clamp or arcing clamp?

• Electrode holder condition.

• Does post-heat begin when burners are put

on? Or when the required temperature is

achieved?

• Clean surfaces to be welded.

Miscellaneous (2)

• Local purging is more effective.

• Set through nozzle to shell joints are highly

restrained. Weld a sufficient thickness

before cooling from preheat. Best is “Don’t

stop till joint is filled up.”

• Preheating is also required for arc air

gouging.

Miscellaneous (3)

• Run-in and run-out plates.

• Gas heaters for CO2 welding.

Cold cracking

• Occurs due to hydrogen in the presence of

stresses. Hard microstructures are more

susceptible.

• Can take place uptill 48 hours after welding

is completed and hence the name.

• Generally transverse to the weld.

• Mostly in HAZ.

Impact toughness

• Resistance to crack initiation and growth.

• Prevent brittle failures which are sudden

and hence more damaging.

• Depends upon material composition,

microstructure, geometry(notch effect).

• Microstructure depends on the heat input

(current, voltage, travel speed & weaving)

Hot cracking

• a.k.a Solidification cracking.

• Takes place during cooling.

• Concave profiles (very thin and wide bead).

• Segregation of low melting compounds at

the centre of weld bead.

• Most common form is crater crack.

• Impurities like S, Si increase tendency.

IGC

• Inter granular corrosion. a.k.a Sensitization.

• Is a problem when materials (like SS) are

used for their corrosion resistance.

• Chromium provides the resistance by

forming an adherent film on surface.

• When heated the carbon ties up chromium

and film cannot form (insufficient).

Why qualified welder?

• Quality system requirement.

• Lowering the possibility of weld defects.

Productivity

• Powai’s best SAW deposition for a circ. seam =

37kg/shift.

• We expect 7.17 hours and get about 5.9 hours in

first shift.

• At 550A & 40mm ESO actual deposition rate is

155gm/min.

• If 5.9 hours then 55kg or at least 50kg assuming

0.5hr for spool change.

• 37kg/shift indicates 4hours of arcing.

You might also like

- New Holland 200 Series L218, L220 Tier 4B (Final) Skid Steer Loader Service Repair Manual NADocument31 pagesNew Holland 200 Series L218, L220 Tier 4B (Final) Skid Steer Loader Service Repair Manual NAggjjjjotones50% (2)

- Ansi MSS SP-55-2011Document23 pagesAnsi MSS SP-55-2011Siva100% (1)

- Arc Weld ReportDocument14 pagesArc Weld ReportAsyraf Razali67% (6)

- API SPEC 16C Choke and KillDocument26 pagesAPI SPEC 16C Choke and Killu04ajf3No ratings yet

- Influence of Heat Input On The Content of Delta Ferrite in The Structure of 304L Stainless Steel Gta Welded JointsDocument7 pagesInfluence of Heat Input On The Content of Delta Ferrite in The Structure of 304L Stainless Steel Gta Welded JointsjinsthomasNo ratings yet

- A Review Paper On Effect of Input Welding Process Parameters On Structures and Properties of Weld in Submerged Arc Welding ProcessDocument5 pagesA Review Paper On Effect of Input Welding Process Parameters On Structures and Properties of Weld in Submerged Arc Welding ProcessZarif YusufNo ratings yet

- Optimization of Submerged Arc WeldingDocument4 pagesOptimization of Submerged Arc WeldingricardoNo ratings yet

- WeldingDocument24 pagesWeldingbhushan wandreNo ratings yet

- Submerged Arc WeldingDocument14 pagesSubmerged Arc WeldingRajan BhadoriyaNo ratings yet

- Types of ElectrodesDocument8 pagesTypes of ElectrodesTIBEBUNo ratings yet

- Bohler Welding 1%nickel - CatalogueDocument8 pagesBohler Welding 1%nickel - CatalogueTasmanijskaNemaNo ratings yet

- Welding Joints and PositionsDocument19 pagesWelding Joints and Positionssamadhan kambleNo ratings yet

- Welding of Cladded 625 RioPipeline1351 - 2013Document9 pagesWelding of Cladded 625 RioPipeline1351 - 2013Jacky ChinNo ratings yet

- Weld SolidificationDocument10 pagesWeld SolidificationRodrigo PrinceNo ratings yet

- Stainless SteelsDocument3 pagesStainless SteelsAbdul WahabNo ratings yet

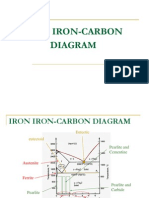

- Lec 7 Fe C DiagramDocument45 pagesLec 7 Fe C DiagramAdnan MehmoodNo ratings yet

- 4.3. Residual Stresses and Distortion in WeldmentsDocument11 pages4.3. Residual Stresses and Distortion in WeldmentsprokulisNo ratings yet

- GougingDocument6 pagesGougingP Sandana NaraNo ratings yet

- Flux-Cored Arc WeldingDocument7 pagesFlux-Cored Arc WeldingjohandreherNo ratings yet

- How To Prevent Arc BlowDocument12 pagesHow To Prevent Arc BlowFelix GomintongNo ratings yet

- Influence of Welding ParametersDocument24 pagesInfluence of Welding ParametersEhsan KhanNo ratings yet

- KEMPPI Welding Technology Course: R.BanerjeeDocument78 pagesKEMPPI Welding Technology Course: R.BanerjeeAnoop KushwahaNo ratings yet

- AME-26 RevDocument42 pagesAME-26 RevGyanr BNo ratings yet

- Submerged Arc Welding (Saw)Document5 pagesSubmerged Arc Welding (Saw)Ramesh RNo ratings yet

- Physics of WeldingDocument3 pagesPhysics of WeldingKhurram RehmanNo ratings yet

- GMAW App MechDocument39 pagesGMAW App MecharavindanNo ratings yet

- Evaluation of Fillet Weld Requirements: What We Did..Document4 pagesEvaluation of Fillet Weld Requirements: What We Did..Abhisekh GoudaNo ratings yet

- Module 3 Construction and DesignDocument5 pagesModule 3 Construction and DesignDhimas Surya Negara100% (1)

- 2-3 Diffusion WeldingDocument40 pages2-3 Diffusion WeldingDanny Vargas HuamanNo ratings yet

- Base Metal: Click On Any of The Label Images To Get More Information or in The Menu SidebarDocument3 pagesBase Metal: Click On Any of The Label Images To Get More Information or in The Menu SidebarAnonymous oUoJ4A8xNo ratings yet

- GTAW Chapter 1Document4 pagesGTAW Chapter 1Renold ElsenNo ratings yet

- Arc Welding Types MP IIDocument40 pagesArc Welding Types MP IISyedUbaidRehman100% (1)

- Miller - 2010 Welding Heavy Structural Steel SucessfulyyDocument15 pagesMiller - 2010 Welding Heavy Structural Steel SucessfulyyLleiLleiNo ratings yet

- A10 Effects of Welding Processes On The Mechanical Properties of HY 80 Steel WeldmentsDocument9 pagesA10 Effects of Welding Processes On The Mechanical Properties of HY 80 Steel WeldmentsXNo ratings yet

- B. Importance of Preheat, Interpass, DHT, Isr, PWHTDocument19 pagesB. Importance of Preheat, Interpass, DHT, Isr, PWHTJay ShahNo ratings yet

- 3 Welding Imperfections and Materials InspectionDocument31 pages3 Welding Imperfections and Materials InspectionSamerNo ratings yet

- Arc Welding and Magnetic Blow EWF Doc 41 PDFDocument1 pageArc Welding and Magnetic Blow EWF Doc 41 PDFEmad A.AhmadNo ratings yet

- What Is Arc Blow and How Do You Prevent It?Document2 pagesWhat Is Arc Blow and How Do You Prevent It?amalhaj2013No ratings yet

- Weld Over WeldDocument1 pageWeld Over Weldmoha23No ratings yet

- Arc Wandering Arc Blow Back Step WeldingDocument4 pagesArc Wandering Arc Blow Back Step WeldingJoseph PeterNo ratings yet

- BohlerThyssen PDFDocument386 pagesBohlerThyssen PDFElMacheteDelHuesoNo ratings yet

- ISF Aachen Welding Technology Part II PDFDocument140 pagesISF Aachen Welding Technology Part II PDFscott2355No ratings yet

- Elimination of Crack Formation in Stainless Steel After Tig Welding - 2-427-151816990575-79Document5 pagesElimination of Crack Formation in Stainless Steel After Tig Welding - 2-427-151816990575-79arjun prajapatiNo ratings yet

- ME WT 2016 - Curriculum and Syllabi PDFDocument37 pagesME WT 2016 - Curriculum and Syllabi PDFKarthi KeyanNo ratings yet

- CTS - Controlled Thermal Severity TEST: Steels - Cast IronsDocument8 pagesCTS - Controlled Thermal Severity TEST: Steels - Cast IronsPetrr RavvNo ratings yet

- Non-Arc Welding ProcessesDocument30 pagesNon-Arc Welding ProcessesKhalid El MasryNo ratings yet

- Composition of Steels PDFDocument5 pagesComposition of Steels PDFNitin SharmaNo ratings yet

- 02 Welding Repair On Steel and Cast Iron PDFDocument21 pages02 Welding Repair On Steel and Cast Iron PDFsyarif irwantoNo ratings yet

- Catalogue Revolloy Welding ConsumablesDocument30 pagesCatalogue Revolloy Welding ConsumablesAdi SutardiNo ratings yet

- 6 Material InspectionDocument8 pages6 Material Inspectionazizieh5701No ratings yet

- Lec24 PDFDocument69 pagesLec24 PDFsskiitbNo ratings yet

- WPS & PQR & WPQDocument26 pagesWPS & PQR & WPQrakanalammari505No ratings yet

- Soudokay Strip Cladding - PrincipesDocument31 pagesSoudokay Strip Cladding - PrincipesRenny DevassyNo ratings yet

- Tabla de Referencia de Materiales: Material Reference ChartDocument2 pagesTabla de Referencia de Materiales: Material Reference Chartsateesh chandNo ratings yet

- Ceramic Weld Backing EvaluationDocument106 pagesCeramic Weld Backing EvaluationcanakyuzNo ratings yet

- Heat Treatment ProcessDocument4 pagesHeat Treatment ProcessSuhaib AshrafNo ratings yet

- WeldingDocument19 pagesWeldingAlexander Muñoz SánchezNo ratings yet

- Defects Reheat CrackingDocument5 pagesDefects Reheat Crackingguru_terexNo ratings yet

- Challenges in Corrosion: Costs, Causes, Consequences, and ControlFrom EverandChallenges in Corrosion: Costs, Causes, Consequences, and ControlNo ratings yet

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelNo ratings yet

- Overview On PreheatingDocument24 pagesOverview On PreheatingVenkateshNo ratings yet

- Chemical Engineering Plant DesignDocument16 pagesChemical Engineering Plant DesignUsamaNo ratings yet

- Semiwelded PlateDocument23 pagesSemiwelded Plateinspectormag8793No ratings yet

- Pro - Super H Maintenance ManualDocument20 pagesPro - Super H Maintenance ManualSivaNo ratings yet

- Gen IMTS-2004 PDFDocument179 pagesGen IMTS-2004 PDFSivaNo ratings yet

- Taylor's PrincipleDocument16 pagesTaylor's PrincipleSivaNo ratings yet

- Gen - QIT SVG PDFDocument17 pagesGen - QIT SVG PDFSivaNo ratings yet

- 1.heat Treatment - Avsp 01Document10 pages1.heat Treatment - Avsp 01Siva100% (1)

- 1 API Q1 and API 6D Welding RequirementsDocument25 pages1 API Q1 and API 6D Welding RequirementsSiva100% (2)

- Oring Sizes BS1806 PDFDocument6 pagesOring Sizes BS1806 PDFSivaNo ratings yet

- Gas Tungsten Arc Welding: by L D PoyyaraDocument37 pagesGas Tungsten Arc Welding: by L D PoyyaraRajeeb MohammedNo ratings yet

- Steel Structure Buildings: "Loss Coefficient" CF Analysis and EstimationDocument2 pagesSteel Structure Buildings: "Loss Coefficient" CF Analysis and Estimationrinkesh patelNo ratings yet

- AIAA Design CompetitionDocument25 pagesAIAA Design CompetitionBhoomikaNo ratings yet

- HRC-AMS-CIV-F001 Refractory Works Quality ControlDocument6 pagesHRC-AMS-CIV-F001 Refractory Works Quality ControlFadzil AmalludinNo ratings yet

- Radiographic Testing ProcedureDocument12 pagesRadiographic Testing ProcedureAdham AhmedNo ratings yet

- Hot Welding CuttingDocument19 pagesHot Welding Cuttingtheblues2708No ratings yet

- Piping QC Guide (For Saudi Aramco Project)Document11 pagesPiping QC Guide (For Saudi Aramco Project)Heng100% (1)

- Method Statement For Ug Piping 6423dp420 00 00200 00 Rev03 PDFDocument20 pagesMethod Statement For Ug Piping 6423dp420 00 00200 00 Rev03 PDFadventmanurungNo ratings yet

- Radiograph Interpretation - CastingsDocument5 pagesRadiograph Interpretation - CastingshoscriNo ratings yet

- STICK WELDING 101 - Getting Started With SMAWDocument5 pagesSTICK WELDING 101 - Getting Started With SMAWisaias.prestesNo ratings yet

- Acceptance Criteria of Weld Defects As Per Different CodesDocument17 pagesAcceptance Criteria of Weld Defects As Per Different CodesDudy Pindayana FirdausNo ratings yet

- Supplier Template - Rev A - NAVSEA Tech Pub 248 WPS Essential Variable ChecklistDocument5 pagesSupplier Template - Rev A - NAVSEA Tech Pub 248 WPS Essential Variable ChecklistHenry CedeñoNo ratings yet

- 504 Hot Work Permit Rev 8Document18 pages504 Hot Work Permit Rev 8Nikorn SornpromNo ratings yet

- Macro Inspection Part IIDocument16 pagesMacro Inspection Part IImohammed dallyNo ratings yet

- Planning 21 Januari 2023Document1 pagePlanning 21 Januari 2023Ferdie OSNo ratings yet

- PD 6705-3 - 2009Document28 pagesPD 6705-3 - 2009Pedro BaltazarNo ratings yet

- EIGA Doc 04 09 EDocument34 pagesEIGA Doc 04 09 EFrancisco Campos ParadaNo ratings yet

- Scope of WorkDocument24 pagesScope of WorkGijo GeorgeNo ratings yet

- Bronze c54400 SpecificationsDocument3 pagesBronze c54400 SpecificationsRam Parimalam100% (1)

- NCC33-RINA Rules For Carrying Out Non-Destructive Examinations of WeldingDocument43 pagesNCC33-RINA Rules For Carrying Out Non-Destructive Examinations of WeldingDeDe DanielaNo ratings yet

- S-A-3-230-003-H en CHECKING INSTRUCTIONS FOR ROLLSDocument7 pagesS-A-3-230-003-H en CHECKING INSTRUCTIONS FOR ROLLShakan tatlisuNo ratings yet

- DM-BSB60-SA Manual SB-60-SADocument16 pagesDM-BSB60-SA Manual SB-60-SAPedro MartinezNo ratings yet

- CPF - GANDHAR, ONGC, Ankleshwar Daily Progress Report Site ProgressDocument6 pagesCPF - GANDHAR, ONGC, Ankleshwar Daily Progress Report Site ProgressSunil KumarNo ratings yet

- VERDANA SPECIFICATIONS UpdatedDocument32 pagesVERDANA SPECIFICATIONS UpdatedPrinces Jecyvhel De LeonNo ratings yet

- Power Tools Study Guide PDFDocument23 pagesPower Tools Study Guide PDFChezer KiethNo ratings yet

- Datasheet Kynar 2500Document20 pagesDatasheet Kynar 2500mlombardiTONo ratings yet

- FMDS0100Document20 pagesFMDS0100kskadryNo ratings yet