Wailing Check (203x203x60 UC)

Wailing Check (203x203x60 UC)

Uploaded by

hessian123Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wailing Check (203x203x60 UC)

Wailing Check (203x203x60 UC)

Uploaded by

hessian123Copyright:

Available Formats

#N/A Job No.

:

By:

WAILING DESIGN Chkd:

Date: 16-May-19

Structural Steel Design - Waling

(Structural steel design based on "Code of Practice for the Structural Use of Steel 2011"

with reference to "The Design and Construction of Sheet-Piled Cofferdams by B P Williams and D Waite")

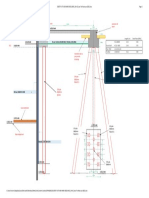

Plan P2 D

Diagonal Strut

P1 y y B

t

S S S

b a

Pc T

L2 x

L1 Ld Waling d

1. Section Properties

Try Section : Single 203 x 203 x 60 UC Grade 43 Hot Rolled

Depth of Section D = 209.6 mm Elastic Modulus (X-Axis) Zx = 581000 mm3

Zy 3

Width of Section B = 205.2 mm Elastic Modulus (Y-Axis) = 198830 mm

Web Thickness t = 9.3 mm Plastic Modulus (X-Axis) Sx = 652000 mm3

Flange Thickness T = 14.2 mm Plastic Modulus (Y-Axis) Sy = 303000 mm3

Depth between Fillets d = 160.9 mm Buckling Parameter u = 0.847

Ix 4

Second Moment of Area (X-Axis) = 60900000 mm Torsional Index x = 14.1

4

Second Moment of Area (Y-Axis) Iy = 20400000 mm Area of Section Ag = 7580 mm2

Radius of Gyration (X-Axis) rx = 89.6 mm Mass per Length w = 60.00 kg/m

Radius of Gyration (Y-Axis) ry = 51.88 mm Design Strength py = 275 N/mm2

Root Radius r = 10.2 mm

The Modulus of Elasticity for steel E = 205000.00 MPa

2. Ultimate Design Load

Resolve perpendicular to adjacent waling a Pc sinb = P1 L1 cosb + P2 L2

Compressive Force (corner) a Pc = (P1 L1 cosb + P2 L2) / sinb

Case 1 Case 2 Case 3 Case 4

Inclined prop load from Strut design, Pi1 = 36.00 kN/m 0.0 kN/m 0.0 kN/m 0.0 kN/m

Inclination of strut to wall, q1 = 90.0 ° 90.0 ° 90.0 ° 90.0 °

Horizontal pressure, P1 = Pi1 sinq1 = 36.0 kN/m 0.0 kN/m 0.0 kN/m 0.0 kN/m

Inclined prop load from Plaxis, Pi2 = 36.00 kN/m 0.0 kN/m 0.0 kN/m 0.0 kN/m

Inclination of strut to wall, q2 = 90.0 ° 90.0 ° 90.0 ° 90.0 °

Horizontal pressure, P2 = Pi2 sinq2 = 36.0 kN/m 0.0 kN/m 0.0 kN/m 0.0 kN/m

Intersection angle of end waling, b = 90.0 ° 90.0 ° 90.0 ° 90.0 °

Load bearing width of waling at corner, L1 = 0.00 m 0.00 m 0.00 m 0.00 m

Load bearing width of waling at corner, L2 = 0.00 m 0.00 m 0.00 m 0.00 m

Compressive Force (corner), Pc = 0.0 kN 0.0 kN 0.0 kN 0.0 kN

Maximum horizontal pressure, P = 36.00 kN/m

Maximum strut spacing, S = 2.00 m

Load bearing width of diagonal strut, Ld = 0.00 m

Minimum inclination of diagonal strut, a = 90.00 o

Construction Load, Qc = 1.20 kPa

2

Maximum bending moment, Mx = P x S / 10.00 = 36.00 x 2.00 x 2.00/10 = 14.40 kNm

Maximum bending moment, My = Self Weight + Construction Load = (60 x 9.81/1000 + 1.20 x 209.60/1000) x 2.00^2 / 10 = 0.34 kNm

Maximum shear force, V = PxS/2 = 36.00 x 2.00 / 2 = 36.00 kN

Compressive Force (corner) = Max. of Pc = Max. of (0, 0, 0, 0) = 0.00 kN

Compressive Force (1% Strut Force) = P x S x 1% = 36.00 x 2.00 x 1% = 0.72 kN

Compressive Force (diagonal strut) = P x S / tan a = 36.00 x 0.00 / tan 90 = 0.00 kN

Load Factor = 1.4

Design Bending Moment (Major Axis) Mx = 20.2 kNm Design Shear Force V = 50.4 kN

Design Bending Moment (Minor Axis) My = 0.5 kNm Axial Force Fc = 1.0 kN

3. Section Classification (Table 7.1)

CLASS

e = [275 / py]1/2 = 1.0 b/T = 7.2 < 8.0 e (Plastic) (Table 7.1, Outstand element of compression flange)

d/t = 17.3 < 80 e (Plastic) (Table 7.1, Web with neutral axis at mid-depth)

Class of Section = Plastic Section

4. Shear Buckling Resistance (Clause 8.4.6)

d/t = 17.3 < 70e = 70.0

Therefore, Not Required to Check for Shear Buckling

5. Check Shear Capacity (Clause 8.2.1)

Shear Area Av = 1949 mm2

Shear Capacity Vc = pyAv/(3)^0.5

= 309 kN

Design Shear Force V = 50.4 kN < Pv = 309 kN Check Shear OK

Since, 0.6Vc = 186 kN > V Low Shear

203x203x60 UC, Wailing Check(203x203x60 UC)

#N/A Job No.:

By:

WAILING DESIGN Chkd:

Date: 16-May-19

Mcx = 29.42 kNm > My = 0.5 kNm Minor Moment Capacity OK

6. Check Moment Capacity (for plastic or compact sections) (Clause 8.2.2)

Major Axis Mcx = Lesser of pySx and 1.2pyZx

pySx = 179 kNm 1.2pyZx = 192 kNm

Mcx = 179 kNm > Mx = 20.2 kNm Major Moment Capacity OK

Minor Axis Mcy = Lesser of pySy and 1.2pyZy

pySy = 83 kNm 1.2pyZy = 66 kNm

Mcy = 66 kNm > My = 0.5 kNm Minor Moment Capacity OK

7. Check Lateral Torsional Buckling (Clause 8.3)

Unrestrained Span Length L = 2.00 m

Effective Length LE = 1.0 L = 2.0 m (Clause 8.3.4)

Minor Axis Slenderness l = LE / ry = 38.6

Buckling parameter u = 0.85 (Clause 8.3.5.3)

l/x = 2.73

Slenderness factor n = 1/(1+0.05(l/x)2)0.25 (Clause 8.3.5.3 Eqn 8.27)

= 0.924

bw = 1.000 (Clause 8.3.5.3 Eqn 8.28, 8.29)

lLT

0.5

Equivalent Slenderness = uvl(bw) = 30.2 (Clause 8.3.5.3 Eqn 8.25)

Design strength py = 275.00 N/mm2

Buckling strength pb = 273.0 N/mm2 (Table 8.3a for rolled section)

Buckling resistance moment Mb = 178.0 kNm (Clause 8.3.5.2 Eqn 8.20, 8.21, 8.22, 8.23, 8.24)

Equivalent uniform moment factor mLT = 0.93 (Table 8.4a for no intermediate lateral restraint)

mLTMx = 18.75 < Mb= 178.0 kNm (Clause 8.3.5.2 Eqn 8.18)

and Mx = 20.16 < Mcx= 179.3 kNm (Clause 8.3.5.2 Eqn 8.19)

Lateral Torsional Buckling Resistance OK

8. Cross-section Capacity Check (Clause 8.9.1)

Fc Mx My 1.0 20.2 0.5

+ + = + +

Agpy Mcx Mcy 2084.5 179.3 65.6

= 0.00 + 0.11 + 0.01

= 0.12

< 1 Cross-section Capacity OK

9. Member Buckling Resistance Check (Clause 8.9.2)

Axis of buckling = x-x

Unrestrain length (X-Axis) Lx = 2.00 m

Effective Length (X-Axis) LEx = 1.0 Lx = 2.00 m (Clause 8.3.4)

Major Axis Slenderness lx = LEx / rx = 22.3 ≈ 25

Maximum Thickness T = 14.2 mm ≤ 40 mm

Type of Section = Rolled H-section ≤ 40mm

Designation of buckling curves for different section types: Buckling Curve b) (Table 8.7)

Compressive Strength pcx = 267.00 N/mm2 (Table 8.8(b))

Axis of buckling = y-y

Unrestrain length (Y-Axis) Ly = 2.00 m

Effective Length (Y-Axis) LEy = 1.0 Ly = 2.00 m (Clause 8.3.4)

Minor Axis Slenderness ly = LEy / ry = 38.6 ≈ 40

Maximum Thickness T = 14.2 mm ≤ 40 mm

Type of Section = Rolled H-section ≤ 40mm

Designation of buckling curves for different section types: Buckling Curve c) (Table 8.7)

2

Compressive Strength pcy = 238.00 N/mm (Table 8.8(c))

Design Compressive Strength pc = min. of pcx & pcy = 238.0 N/mm2

Moment equivalent factor m for flexural buckling

mx = 0.95 (Table 8.9)

my = 0.95 (Table 8.9)

Fc mxMx myMy 1.0 19.2 0.4

+ + = + +

Agpc Mcx Mcy 1804.0 179.3 65.6

= 0.00 + 0.11 + 0.01

= 0.11

< 1 Overall Capacity OK

203x203x60 UC, Wailing Check(203x203x60 UC)

You might also like

- Jack Well - Well FoundationDocument3 pagesJack Well - Well FoundationRamakanth PuttyNo ratings yet

- Fe Sheet Pile WallDocument22 pagesFe Sheet Pile WallBogie Prastowo MahardhikaNo ratings yet

- CIRC - Uni-Axial Column Capacity ACI 318-08 R2Document2 pagesCIRC - Uni-Axial Column Capacity ACI 318-08 R2Glenn Enrico AmoloNo ratings yet

- W169 WIS Remove - Install Oil Pressure SwitchDocument1 pageW169 WIS Remove - Install Oil Pressure Switchhessian123100% (1)

- CBC Animal Health Care & Management NC IIIDocument66 pagesCBC Animal Health Care & Management NC IIIMaria Angellie S. Bellido - EramisNo ratings yet

- E-Gov Maharashtra Training ModuleDocument53 pagesE-Gov Maharashtra Training ModuleconnectprajaktaNo ratings yet

- Quay Wall DesignDocument1 pageQuay Wall DesignJohn SalvadorNo ratings yet

- Geotechnical Engineering E4.3Document43 pagesGeotechnical Engineering E4.3Gilberto Yoshida100% (1)

- LECTURE2 Shear ConnectionDocument36 pagesLECTURE2 Shear ConnectionMahmoud A SalamaNo ratings yet

- CombiwallDocument20 pagesCombiwallPeyman MznNo ratings yet

- Design of Circular BeamDocument2 pagesDesign of Circular BeamShane BondNo ratings yet

- Differential Settlement Bh7Document9 pagesDifferential Settlement Bh7Zhi Ming CheahNo ratings yet

- ELS DrawingDocument2 pagesELS Drawinghessian123No ratings yet

- CE3155 Introduction To ETABS (Multi-Storey)Document42 pagesCE3155 Introduction To ETABS (Multi-Storey)Imran SaikatNo ratings yet

- 1.0 Early Thermal CheckDocument7 pages1.0 Early Thermal CheckklynchelleNo ratings yet

- Eccentric Footing Design PDFDocument9 pagesEccentric Footing Design PDFmsiddiq1100% (1)

- Stability Analysis of Retaining StructuresDocument15 pagesStability Analysis of Retaining StructuresSanko Kosan100% (1)

- Beam On Elastic Foundation AnalysisDocument5 pagesBeam On Elastic Foundation AnalysisMagdy BakryNo ratings yet

- Grlweap 2005Document3 pagesGrlweap 2005José RuizNo ratings yet

- Check Kick-Out Failure Check For Trench For M Deep Trench ExcavationDocument3 pagesCheck Kick-Out Failure Check For Trench For M Deep Trench Excavationhessian123No ratings yet

- IS 2911 Part 3 - 2015Document47 pagesIS 2911 Part 3 - 2015NishantRathiNo ratings yet

- Ass 4 Cofferdam Solution 12 13 PTDocument1 pageAss 4 Cofferdam Solution 12 13 PTsyakirohNo ratings yet

- Seismic Response of Elevated Water Tanks An OverviewDocument5 pagesSeismic Response of Elevated Water Tanks An OverviewRaeghoNo ratings yet

- Analysis of Tank 1Document20 pagesAnalysis of Tank 1BALRAJNo ratings yet

- Hydraulic Injection Piles-KL - 2Document6 pagesHydraulic Injection Piles-KL - 2Ferdi AparatNo ratings yet

- Ground Beam PlanDocument1 pageGround Beam PlanAung Thit LwîñNo ratings yet

- CV DM 001 100dpiDocument58 pagesCV DM 001 100dpighazi andonoNo ratings yet

- Pile Wall DesignDocument43 pagesPile Wall DesignefackopaNo ratings yet

- Piled Raft Case Study in MalaysiaDocument6 pagesPiled Raft Case Study in Malaysiasuman33No ratings yet

- 13 PDFDocument220 pages13 PDFPrsNo ratings yet

- APPENDIX C Worked ExampleDocument20 pagesAPPENDIX C Worked Examplenorsam1511No ratings yet

- Calculation of Voided Slabs RigiditiesDocument4 pagesCalculation of Voided Slabs RigiditiesNgô Khánh TiểnNo ratings yet

- ACI Moment Coefficient Design AID PDFDocument13 pagesACI Moment Coefficient Design AID PDFSufian Ahmad50% (4)

- Soil+Surcharge From Adjacent Building On 12m RCC Pile Ø500mm@1m CCDocument11 pagesSoil+Surcharge From Adjacent Building On 12m RCC Pile Ø500mm@1m CCPrakash Singh Rawal100% (1)

- Spring Value CalculationDocument16 pagesSpring Value CalculationSrishti Project ConsultantsNo ratings yet

- CE5107 - Laterally Loaded Piles IDocument62 pagesCE5107 - Laterally Loaded Piles IMartin ČudejkoNo ratings yet

- Bay 1 Soil SpringDocument1 pageBay 1 Soil SpringVegetable BunNo ratings yet

- Pile DesignDocument16 pagesPile DesignDivyesh100% (1)

- Axial Load Capacity For Deep Foundations Piles: Sand Input ResultsDocument8 pagesAxial Load Capacity For Deep Foundations Piles: Sand Input Resultsacidrisamuel2656No ratings yet

- Retaining Wall Analysis & Design (BS8002)Document10 pagesRetaining Wall Analysis & Design (BS8002)Thoong Yew ChanNo ratings yet

- Temperature Difference ECDocument1 pageTemperature Difference ECIrfan AliNo ratings yet

- Load Takedown (Example 1)Document137 pagesLoad Takedown (Example 1)Ang Swee ChenNo ratings yet

- Design of Composite ColumnsDocument7 pagesDesign of Composite Columnsabozaid19No ratings yet

- 6.1 Repeat Load and Load Combination Difference - PDF - (Freecourseweb - Com)Document2 pages6.1 Repeat Load and Load Combination Difference - PDF - (Freecourseweb - Com)prince francisNo ratings yet

- Pile Structural CapacityDocument6 pagesPile Structural CapacitybuddhikaNo ratings yet

- Bridge Concrete CalculationsDocument19 pagesBridge Concrete CalculationsKibe KTNo ratings yet

- Diff CreepDocument1 pageDiff CreepSharyn PolleyNo ratings yet

- Reinforced Concrete Column Capacity: MaterialsDocument8 pagesReinforced Concrete Column Capacity: Materialsqazalbash1109588No ratings yet

- Schmertmann Method 2008Document20 pagesSchmertmann Method 2008pnNo ratings yet

- Sea WallsDocument13 pagesSea WallsKezala JereNo ratings yet

- Analysis of Laterally Loaded Drilled Shafts and Piles Using LpileDocument51 pagesAnalysis of Laterally Loaded Drilled Shafts and Piles Using LpileFernando ChiribogaNo ratings yet

- Up PileDocument273 pagesUp PileJorge PalominoNo ratings yet

- Steel Sheet Piles Ing.D.Kohnen-DK PDFDocument33 pagesSteel Sheet Piles Ing.D.Kohnen-DK PDFSaravanan MuthuramanNo ratings yet

- Closure of Tidal BasinsDocument30 pagesClosure of Tidal BasinsAyman Al HasaarNo ratings yet

- Load TypesDocument5 pagesLoad TypesKutty MansoorNo ratings yet

- Design of Cellular Rafts Foundations 1Document17 pagesDesign of Cellular Rafts Foundations 1Victor OmotoriogunNo ratings yet

- Settlement Computations: Ratio, and Base Embedment Depth D Elastic Soil ParametersDocument5 pagesSettlement Computations: Ratio, and Base Embedment Depth D Elastic Soil ParametersmscivilengNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Numerical Methods and Implementation in Geotechnical Engineering – Part 1From EverandNumerical Methods and Implementation in Geotechnical Engineering – Part 1No ratings yet

- SteelChk - Strut (Rev. D) 20190508Document5 pagesSteelChk - Strut (Rev. D) 20190508hessian123No ratings yet

- Tabla PerfilesDocument39 pagesTabla PerfilesAna Carolina Félix CamachoNo ratings yet

- Engr. Mark Christian D. EsguerraDocument1 pageEngr. Mark Christian D. EsguerraMARKCHRISTMASNo ratings yet

- Work Safety Alert Pressed To Death by An Elevating Work PlatformDocument3 pagesWork Safety Alert Pressed To Death by An Elevating Work Platformhessian123No ratings yet

- Site Arrangement Plan KFRDocument10 pagesSite Arrangement Plan KFRhessian123No ratings yet

- Check Kick-Out Failure Check For Trench For M Deep Trench ExcavationDocument3 pagesCheck Kick-Out Failure Check For Trench For M Deep Trench Excavationhessian123No ratings yet

- Ground Settlement Analysis For Pipe JackingDocument5 pagesGround Settlement Analysis For Pipe Jackinghessian123No ratings yet

- Formwork Design CalculationDocument6 pagesFormwork Design Calculationhessian123100% (1)

- Work Safety Alert Fallen With A Collapsed Suspended Working PlatformDocument4 pagesWork Safety Alert Fallen With A Collapsed Suspended Working Platformhessian123No ratings yet

- SteelChk - Strut (Rev. D) 20190508Document5 pagesSteelChk - Strut (Rev. D) 20190508hessian123No ratings yet

- Trappedcollapsedbambooscaffolds 202110 enDocument5 pagesTrappedcollapsedbambooscaffolds 202110 enhessian123No ratings yet

- Foundation Works For Mini PileDocument3 pagesFoundation Works For Mini Pilehessian123No ratings yet

- Soil ParameterDocument3 pagesSoil Parameterhessian123No ratings yet

- Kick-Out Checking (20190508)Document2 pagesKick-Out Checking (20190508)hessian123No ratings yet

- Ice HKDocument84 pagesIce HKhessian123No ratings yet

- MS - Road Works For Stage 2 of KFR Road Diversion (Combine)Document111 pagesMS - Road Works For Stage 2 of KFR Road Diversion (Combine)hessian123No ratings yet

- Sheet Pile Design: Fspiii S275 Hot RolledDocument1 pageSheet Pile Design: Fspiii S275 Hot Rolledhessian123No ratings yet

- Strut StiffnessDocument1 pageStrut Stiffnesshessian123No ratings yet

- ELS DrawingDocument2 pagesELS Drawinghessian123No ratings yet

- Fence Construction DrawingDocument1 pageFence Construction Drawinghessian123No ratings yet

- Ground Settlement Check Due To Wall DeflectionDocument1 pageGround Settlement Check Due To Wall Deflectionhessian123No ratings yet

- RC Staircase DetailDocument1 pageRC Staircase Detailhessian123No ratings yet

- RC Staircase at GradeDocument1 pageRC Staircase at Gradehessian123No ratings yet

- Certificate CIC PDFDocument1 pageCertificate CIC PDFhessian123No ratings yet

- Road Note 06Document32 pagesRoad Note 06hessian123No ratings yet

- B1 XPMS Waiver Processing Training Notes 30-July-09Document34 pagesB1 XPMS Waiver Processing Training Notes 30-July-09hessian123No ratings yet

- ICE HKA G&S Webinar PDFDocument1 pageICE HKA G&S Webinar PDFhessian123No ratings yet

- Manhole TypeDocument1 pageManhole Typehessian123No ratings yet

- BS 4662Document41 pagesBS 4662hessian123100% (1)

- Shown On Model 245.2: DivertDocument1 pageShown On Model 245.2: Diverthessian123No ratings yet

- Dynamic Set For Shear Resistance UpgradeDocument2 pagesDynamic Set For Shear Resistance Upgradehessian123No ratings yet

- TrenchlessDocument46 pagesTrenchlesshessian123No ratings yet

- Novena of Confidence 2Document2 pagesNovena of Confidence 2AvieNorañaNo ratings yet

- Food Safety OfficerDocument3 pagesFood Safety OfficerGyana SahooNo ratings yet

- NCCCCCPDocument10 pagesNCCCCCPjonel lorenzoNo ratings yet

- DLL MTB-2 Weeks78 Q4Document18 pagesDLL MTB-2 Weeks78 Q4Magie Lyn MendozaNo ratings yet

- Safety Data Sheet: 1 IdentificationDocument10 pagesSafety Data Sheet: 1 IdentificationLokesh HNo ratings yet

- Solid-State Off-Delay Timer Relay: Vehicle Control ModulesDocument2 pagesSolid-State Off-Delay Timer Relay: Vehicle Control ModulesJoseph VincentNo ratings yet

- 02.11 Bibliografia - Referencias - Links UteisDocument2 pages02.11 Bibliografia - Referencias - Links UteisVictor LauneNo ratings yet

- Expressionism in FILM - Donald RichieDocument6 pagesExpressionism in FILM - Donald RichieBo-Won KeumNo ratings yet

- Five Functions of ManagementDocument5 pagesFive Functions of ManagementMi ChelleNo ratings yet

- Ecdl v4 Module 4 Office 2007 OutlineDocument2 pagesEcdl v4 Module 4 Office 2007 Outlinea.blytheNo ratings yet

- Video 21Document41 pagesVideo 21AssyakurNo ratings yet

- An 915Document6 pagesAn 915Glenn100% (1)

- Unit 17 Risk Decision MakingDocument6 pagesUnit 17 Risk Decision MakingmidoriNo ratings yet

- HBH FPDocument9 pagesHBH FPNone None NoneNo ratings yet

- 22-1 OM Activity 4.1Document2 pages22-1 OM Activity 4.1TaniyaNo ratings yet

- Interesting Plumbing Facts and TipsDocument2 pagesInteresting Plumbing Facts and TipsLara Jessica LittauaNo ratings yet

- HP Auto Port Aggregation (APA) Release HP UX 11.33Document8 pagesHP Auto Port Aggregation (APA) Release HP UX 11.33icanariNo ratings yet

- Chapter 3 UpdatedDocument45 pagesChapter 3 Updatedfilibertpatrick_tad-awanNo ratings yet

- An Industrial Training Report On Data ScienceDocument36 pagesAn Industrial Training Report On Data ScienceAtharv PatharkarNo ratings yet

- ASTM F606 - 05 Fastener Test MethodsDocument15 pagesASTM F606 - 05 Fastener Test MethodsFernado RinconNo ratings yet

- Meth4Unit3Teaching GrammarfinalDocument21 pagesMeth4Unit3Teaching GrammarfinalGjurgjicaNo ratings yet

- Final Exam AnswersDocument8 pagesFinal Exam AnswersLance Eleazar BersalesNo ratings yet

- 8 - Stephen O. Presley - The Intertextual Reception of Genesis 1-3 in Irenaeus of LyonsDocument318 pages8 - Stephen O. Presley - The Intertextual Reception of Genesis 1-3 in Irenaeus of LyonsH0ldUrFireNo ratings yet

- Cellular Movement and Muscles: Powerpoint Lecture Slides Prepared by Stephen Gehnrich, Salisbury UniversityDocument89 pagesCellular Movement and Muscles: Powerpoint Lecture Slides Prepared by Stephen Gehnrich, Salisbury UniversityJennie LaoNo ratings yet

- 2520 7434 1 PBDocument11 pages2520 7434 1 PBDeny KrisnandaNo ratings yet

- Alief Muhammad, Dani Hari Tunggal Prasetiyo, Akbar Anugrah Ikhsani, Dan Setyo PambudiDocument5 pagesAlief Muhammad, Dani Hari Tunggal Prasetiyo, Akbar Anugrah Ikhsani, Dan Setyo PambudikontlNo ratings yet

- FOR ENS IC MED Icin E: ALM Edic Ine)Document231 pagesFOR ENS IC MED Icin E: ALM Edic Ine)Gina Cambongga0% (1)

- Business IntelligenceDocument18 pagesBusiness IntelligenceNikita Agarwal100% (1)