100%(1)100% found this document useful (1 vote)

96 viewsApi 577 Questions

Api 577 Questions

Uploaded by

korichiThe document contains 10 multiple choice questions about different welding processes:

1) SMAW uses an arc between a consumable flux-coated electrode and work. GTAW uses an arc between a non-consumable tungsten electrode and work. GMAW uses an arc between a continuous consumable electrode and work.

2) STAW is not an arc welding process.

3) SAW uses a blanket of granulated flux to shield the arc. GTAW can use a shielding gas or flux to protect the arc from contaminants.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Api 577 Questions

Api 577 Questions

Uploaded by

korichi100%(1)100% found this document useful (1 vote)

96 views2 pagesThe document contains 10 multiple choice questions about different welding processes:

1) SMAW uses an arc between a consumable flux-coated electrode and work. GTAW uses an arc between a non-consumable tungsten electrode and work. GMAW uses an arc between a continuous consumable electrode and work.

2) STAW is not an arc welding process.

3) SAW uses a blanket of granulated flux to shield the arc. GTAW can use a shielding gas or flux to protect the arc from contaminants.

Original Description:

TEN QUESTION API 577 N°00 FOR API 510 AXAM PREARATION

Original Title

api 577 questions

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

The document contains 10 multiple choice questions about different welding processes:

1) SMAW uses an arc between a consumable flux-coated electrode and work. GTAW uses an arc between a non-consumable tungsten electrode and work. GMAW uses an arc between a continuous consumable electrode and work.

2) STAW is not an arc welding process.

3) SAW uses a blanket of granulated flux to shield the arc. GTAW can use a shielding gas or flux to protect the arc from contaminants.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

100%(1)100% found this document useful (1 vote)

96 views2 pagesApi 577 Questions

Api 577 Questions

Uploaded by

korichiThe document contains 10 multiple choice questions about different welding processes:

1) SMAW uses an arc between a consumable flux-coated electrode and work. GTAW uses an arc between a non-consumable tungsten electrode and work. GMAW uses an arc between a continuous consumable electrode and work.

2) STAW is not an arc welding process.

3) SAW uses a blanket of granulated flux to shield the arc. GTAW can use a shielding gas or flux to protect the arc from contaminants.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 2

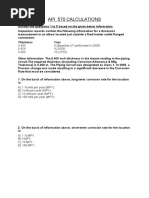

Q1. How is fusion obtained using the SMAW process?

(a) An arc is struck between a consumable flux-coated

electrode and the work &

(b) An arc is struck between a non-consumable electrode

and the work &

(c) The work is bombarded with a stream of electrons and

protons &

(d) An arc is struck between a reel-fed flux-coated electrode

and the work &

Q2. Which of the following is not an arc welding process?

(a) SMAW

(b) STAW

(c) GMAW

(d) GTAW

Q3. How is fusion obtained using the GTAW process?

(a) An arc struck between a consumable flux-coated

electrode and the work

(b) An arc between a non-consumable tungsten electrode

and the work &

(c) The work is bombarded with a stream of electrons and

protons &

(d) An arc is struck between a reel-fed flux-coated electrode

and the work &

Q4. How is the arc protected from contaminants in GTAW?

(a) By the use of a shielding gas &

(b) By the decomposition of a flux &

(c) The arc is covered beneath a fused or agglomerated

flux blanket &

(d) All of the above methods can be used &

Q5.How is fusion obtained using the GMAW process?

(a) An arc struck between a consumable flux-coated

electrode and the work &

(b) An arc between a non-consumable electrode and the

work &

(c) The work is bombarded with a stream of electrons and

protons &

(d) An arc is struck between a continuous consumable

electrode and the work &

Q6.Which of the following are modes of metal transfer in GMAW

(a) Globular transfer &

(b) Short-circuiting transfer &

(c) Spray transfer &

(d) All of the above

Q7. How is the arc shielded in the SAW process?

(a) By an inert shielding gas &

(b) By an active shielding gas &

(c) It is underneath a blanket of granulated flux &

(d) The welding is carried out underwater &

Introduction to Welding/API 577

Q8. SAW stands for:

(a) Shielded arc welding &

(b) Stud arc welding &

(c) Submerged arc welding &

(d) Standard arc welding &

Q9. Which of the following processes can weld autogenously?

(a) SMAW

(b) GTAW

(c) GMAW

(d) SAW

Q10.Which of the following is a commonly accepted advantage of the

GTAW process?

(a) It has a high deposition rate &

(b) It has the best control of the weld pool of any of the

arc processes &

(c) It is less sensitive to wind and draughts than other

processes &

(d) It is very tolerant of contaminants on the filler or base

meta

You might also like

- API 570 Exam 2024Document20 pagesAPI 570 Exam 2024ashirm688100% (1)

- Api 510 Asme PCC2Document1 pageApi 510 Asme PCC2korichi100% (2)

- Api 510 QuizletDocument6 pagesApi 510 QuizletMahmoud Alwasif100% (1)

- Resume SampleDocument4 pagesResume SampleGokulPrasadNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingNo ratings yet

- LADWER API 510 - API RP 577 April 2017Document7 pagesLADWER API 510 - API RP 577 April 2017Luthfi ArdiansyahNo ratings yet

- API 577 EXAM QUESTION For 653 ExamsDocument27 pagesAPI 577 EXAM QUESTION For 653 ExamsEjaz Asghar100% (1)

- API 570 Mock Exam Closed Book1Document17 pagesAPI 570 Mock Exam Closed Book1mohamed.eldesouky9120No ratings yet

- Undercut (Per API 577, Table 6) Can Be Corrected by (Practical Solution Column)Document2 pagesUndercut (Per API 577, Table 6) Can Be Corrected by (Practical Solution Column)korichi100% (1)

- 17 Multiple Choice QuestionsDocument3 pages17 Multiple Choice QuestionsAnonymous Q4YUvR100% (1)

- API 577 QuestionsDocument14 pagesAPI 577 QuestionsabdoNo ratings yet

- Api 570 Calculations Final Nov 2020Document10 pagesApi 570 Calculations Final Nov 2020HARDIK PATEL100% (2)

- API 577 Sample Questions - Free Test - Welding Inspection and MetallurgyDocument12 pagesAPI 577 Sample Questions - Free Test - Welding Inspection and Metallurgysaleem alasmiNo ratings yet

- API 510 Important NotesDocument8 pagesAPI 510 Important NotesAmbreen SheikhNo ratings yet

- API 653 - 577 Flash Cards - 62 QuestionsDocument8 pagesAPI 653 - 577 Flash Cards - 62 QuestionsSERFORTEC CIA. LTDA.No ratings yet

- GT Technical & Management Institute PVT LTD Info@globaltraining - in API Inspector CV1 (Mathavaraja Ganesan)Document7 pagesGT Technical & Management Institute PVT LTD Info@globaltraining - in API Inspector CV1 (Mathavaraja Ganesan)Ganesan RamamoorthyNo ratings yet

- Api 510 Close Book - 15Document14 pagesApi 510 Close Book - 15walid walidNo ratings yet

- API 653 Day 5 BookDocument57 pagesAPI 653 Day 5 BookMadhav MathaNo ratings yet

- API-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFDocument23 pagesAPI-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFasNo ratings yet

- API 510 Question BankDocument69 pagesAPI 510 Question BankPrudvesh ChNo ratings yet

- 3.4 Arc Length: The Distance From The Tip of The WeldingDocument7 pages3.4 Arc Length: The Distance From The Tip of The WeldingMohammed IlliasuddinNo ratings yet

- API 510 Closed 4Document9 pagesAPI 510 Closed 4Mohammed ShakilNo ratings yet

- API 578 Questions - 01Document2 pagesAPI 578 Questions - 01korichiNo ratings yet

- Case Study - 7: Numerical in API 510 CodeDocument4 pagesCase Study - 7: Numerical in API 510 CodeVishal BailurNo ratings yet

- Risk Based Inspection Question BankDocument5 pagesRisk Based Inspection Question Banktraja4No ratings yet

- Daily Exam 2A ClosedDocument6 pagesDaily Exam 2A ClosedkhairurNo ratings yet

- Daily Exam 7 (Closed) : Professional Training and ConsultationDocument5 pagesDaily Exam 7 (Closed) : Professional Training and ConsultationCss SfaxienNo ratings yet

- Piping Inspectors Aramco QuestionnaireDocument2 pagesPiping Inspectors Aramco Questionnairemustafa abdelshafiNo ratings yet

- API 570 Questions 13Document4 pagesAPI 570 Questions 13Ravindra S. JivaniNo ratings yet

- Astm B423 PDFDocument1 pageAstm B423 PDFgaminNo ratings yet

- API 510. DAILY EXAM 9 (Closed Book)Document5 pagesAPI 510. DAILY EXAM 9 (Closed Book)Shanawas Abdul RazakNo ratings yet

- API 653 Day 6 BookDocument105 pagesAPI 653 Day 6 BookMadhav MathaNo ratings yet

- API 580 - RBI 580 Tables and Info For POF - 25 TermsDocument4 pagesAPI 580 - RBI 580 Tables and Info For POF - 25 TermsmajidNo ratings yet

- API 653 - ASME Section V - NDE Practice Questions - 68 TermsDocument7 pagesAPI 653 - ASME Section V - NDE Practice Questions - 68 TermsSERFORTEC CIA. LTDA.No ratings yet

- API 510 Course Puspatri Apr 09Document185 pagesAPI 510 Course Puspatri Apr 09ahmedelhajNo ratings yet

- Prep Material QB-576Document5 pagesPrep Material QB-576Raheem Khan100% (1)

- Api 510 Exam CB ObDocument166 pagesApi 510 Exam CB ObAhmed ShakirNo ratings yet

- (PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduDocument4 pages(PDF) PRACTICE QUESTIONS FOR API RP 577 Quizlet - Gustavo HC - Academia - EduKumar R100% (2)

- SIS Book 577Document71 pagesSIS Book 577Hamza Alam100% (1)

- Api 570 199-352Document86 pagesApi 570 199-352nancyNo ratings yet

- 0301e - Guidebook For Inspectors - 2018-3Document6 pages0301e - Guidebook For Inspectors - 2018-3FranciscoNo ratings yet

- API 510 Exam Overview - 044326Document17 pagesAPI 510 Exam Overview - 044326Yves LipoyeNo ratings yet

- 17 Multiple Choice Questions: No Answer GivenDocument5 pages17 Multiple Choice Questions: No Answer GivenAkram AlhaddadNo ratings yet

- Mockup CBDocument18 pagesMockup CBabet_singkong8930100% (1)

- API-510 QuestionsDocument21 pagesAPI-510 Questionssjois_hs100% (1)

- Api 577 Quastion01Document2 pagesApi 577 Quastion01korichiNo ratings yet

- QM 34 - TanksDocument10 pagesQM 34 - Tanksmohamed elmasryNo ratings yet

- API 570 Course Model Test 9Document5 pagesAPI 570 Course Model Test 9Ismail Jamaluddin100% (1)

- API 510 Case Study - 7Document2 pagesAPI 510 Case Study - 7Khaled FatnassiNo ratings yet

- IX Exercise Rev 02 PDFDocument11 pagesIX Exercise Rev 02 PDFweerasinghekNo ratings yet

- 270 m3 Capacity Limestone Storage Tank Calculation ReportDocument29 pages270 m3 Capacity Limestone Storage Tank Calculation ReportMert GöçerNo ratings yet

- Online API 570 Training Course With Money Back GuaranteeDocument22 pagesOnline API 570 Training Course With Money Back GuaranteeSh.nasirpurNo ratings yet

- 5 6327619470013497820Document4 pages5 6327619470013497820shaijukvNo ratings yet

- Strengthening Mechanisms: MSE3 Page 2Document17 pagesStrengthening Mechanisms: MSE3 Page 2Christian CarestiaNo ratings yet

- ASME BrochureDocument2 pagesASME BrochureumeshNo ratings yet

- Risk Based Inspection Professional: Certification Preparation ProgramDocument6 pagesRisk Based Inspection Professional: Certification Preparation ProgramMuhammad HannanNo ratings yet

- API653 - Guidelines - 653 Certification - ExamDocument11 pagesAPI653 - Guidelines - 653 Certification - ExamirfanlarikhotmailcomNo ratings yet

- Rbi Q&a 2Document7 pagesRbi Q&a 2eslam_el_dinNo ratings yet

- ASME 31.3 - 2016 VT, UtDocument2 pagesASME 31.3 - 2016 VT, Utsanket100% (1)

- Challenges in Corrosion: Costs, Causes, Consequences, and ControlFrom EverandChallenges in Corrosion: Costs, Causes, Consequences, and ControlNo ratings yet

- Critere Accptance NDEDocument2 pagesCritere Accptance NDEkorichiNo ratings yet

- Api Publication IntegrityDocument4 pagesApi Publication IntegritykorichiNo ratings yet

- NDT-TEC-U115C Issue 1 Rev 0 UT Thickness Repeat Echo ModeDocument2 pagesNDT-TEC-U115C Issue 1 Rev 0 UT Thickness Repeat Echo ModekorichiNo ratings yet

- Non-Planar Settlement CalculationsDocument7 pagesNon-Planar Settlement CalculationskorichiNo ratings yet

- Api 578 Questions-03Document3 pagesApi 578 Questions-03korichiNo ratings yet

- IIMOPR040-21 The Inspection of Pressure SystemsDocument12 pagesIIMOPR040-21 The Inspection of Pressure SystemskorichiNo ratings yet

- 1 API 571 Exam QuestionsDocument10 pages1 API 571 Exam Questionskorichi100% (1)

- 2-REPONSE API 650 Question N°02 2022 DETAILSDocument5 pages2-REPONSE API 650 Question N°02 2022 DETAILSkorichiNo ratings yet

- Api 653 QuestionsDocument28 pagesApi 653 Questionskorichi100% (3)

- 1-Ansewrs API 650 Question N°01 2022 Q11 and Q12Document2 pages1-Ansewrs API 650 Question N°01 2022 Q11 and Q12korichiNo ratings yet

- Tank SettlementDocument6 pagesTank SettlementkorichiNo ratings yet

- 2-Questions API 650 Question N°02 2022Document3 pages2-Questions API 650 Question N°02 2022korichi100% (1)

- Api 510 Exam: Api576 Questions - 02Document3 pagesApi 510 Exam: Api576 Questions - 02korichiNo ratings yet

- API 578 Reponses - 01Document2 pagesAPI 578 Reponses - 01korichiNo ratings yet

- Preparation Exam ICP API 510 API 650 Chapitre 1-3Document4 pagesPreparation Exam ICP API 510 API 650 Chapitre 1-3korichiNo ratings yet

- Api 510 Exam: Api576 Questions - 01Document3 pagesApi 510 Exam: Api576 Questions - 01korichiNo ratings yet

- Preparation Exam ICP API 510 API 650 Chapitre 1-3 Answers N°01Document7 pagesPreparation Exam ICP API 510 API 650 Chapitre 1-3 Answers N°01korichiNo ratings yet

- Api 577 Reponse01Document3 pagesApi 577 Reponse01korichiNo ratings yet

- Api 578 Question - 02Document2 pagesApi 578 Question - 02korichiNo ratings yet

- Preparation Exam API 510:N°02 QuestionsDocument2 pagesPreparation Exam API 510:N°02 QuestionskorichiNo ratings yet

- API 653 PREPARATION/ Question N°09 Close Book RESPONSESDocument2 pagesAPI 653 PREPARATION/ Question N°09 Close Book RESPONSESkorichiNo ratings yet

- 5Hvhdufkri&Xuyh) Lwwlqj0Hwkrgrqwkh0Hdvxuhg6Hwwohphqwri 7Dqnv: SciencedirectDocument8 pages5Hvhdufkri&Xuyh) Lwwlqj0Hwkrgrqwkh0Hdvxuhg6Hwwohphqwri 7Dqnv: SciencedirectkorichiNo ratings yet

- Preparation Exam API 510:N°01 QuestionsDocument3 pagesPreparation Exam API 510:N°01 QuestionskorichiNo ratings yet