Welding Procedure Specifications (Wps - 6G) : 2mm (Max)

Welding Procedure Specifications (Wps - 6G) : 2mm (Max)

Uploaded by

Gbenga MoboladeCopyright:

Available Formats

Welding Procedure Specifications (Wps - 6G) : 2mm (Max)

Welding Procedure Specifications (Wps - 6G) : 2mm (Max)

Uploaded by

Gbenga MoboladeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Welding Procedure Specifications (Wps - 6G) : 2mm (Max)

Welding Procedure Specifications (Wps - 6G) : 2mm (Max)

Uploaded by

Gbenga MoboladeCopyright:

Available Formats

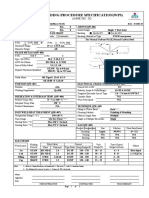

WELDING PROCEDURE SPECIFICATIONS (WPS -6G)

COMPANY NAME: SUNATECH INTERNATIONAL LIMITED/AYKERS LIMITED

WPS No- SIL-WPS-002 REV A

Welding Process: SMAW

Welding Type: Manual

Standard Single Vee butt joint (Coupon At Angle 45º)

JOINT DESIGN

Joint Type: Butt Joint 60±2

Joint Groove: Single Bevel

Backing: Not Required

Qualification in Accordance With: AWS D1.1-2010 EDTN 8-24mm

Backing material : No Required

1.6mm

Edge Preparation: Gas/Flame Cutting & Grinding 2mm±1.0mm

Fit-Up Method- Bullet Tack or Root Tack Sequence of bead

4

3 2mm (max)

2

1

BASE METALS :

Material specification: ASTM A 106 / API 5L

Pipe Thickness Tested : 12mm

Pipe Diameter Tested : 6’’

Pipe Diameter Qualified : 9mm - Unlimited

Base Material Group- I & II

Thickness Range -5mm-30mm

FILLER METALS ROOT HOT/FILL/CAP

AWS Specification 5.1 5.1

AWS Classification E6010 E7018

F- No. 3 4

A-No 1 1

Size of Filler Metals 2.5mm 3.2/4mm

Welding Progression Uphill Uphill

Groove Position All All

Electrode Flux (class) N/A N/A

Consumable Manufacturer/ Trade Name Lincoln Fleet Low Hydrogen

POSITIONS POST WELD HEAT TREATMENT

Welding Position: 6G Temperature Range: N/A

Welding Progression: Vertical Uphill Time Range: N/A

Slope Down Cooling- NA

Soak Temperature- NA

Soak Duration –NA

Slope Heating Rate- NA

Withdrawal Temperature-NA

PREHEAT: GAS:

Preheat Temperature: 25ºC < 55ºC Percent composition

Interpass Temperature: > 55ºC < 300ºC Gas(es) Mixture Flow Rate

Preheat Method : Propane Heating Touch Shielding N/A N/A N/A

Control Method : Tempilstick / Thermometer Trailing N/A N/A N/A

Backing N/A N/A N/A

ELECTRICAL CHARACTERISTICS: Tungsten Electrode size and type; N/A

Current AC or DC: DC Electrode Wire feed Speed Range: N/A

Polarity: DCEP

Amps (Range): 60-130

Volts (Range) 20-35

TECHNIQUE

String or Weave Bead: STRING AND WEAVE

Single/Multiple Pass: Multiple Pass Type of line up clamp: External (where applicable)

Single/Multiple Arc: Single Arc Electrode: (single or multiple) Single

Joint Cleaning : Chipping, Grinding & Brushing Peening : Not Allowed

Travel speed

Filler Metal Current Travel

Pass or

Speed Heat Input

Weld Dia Type of Amp. Volt Range Others

Run Process Class Range (Kj/mm)

layers (mm) polarity Range (mm/min)

1 Rooting SMAW E6010 2.5 DCEN 46-57 27-31 67-91 1.10-1.20 Weave

2 Hot/P SMAW E7018 3.2 DCEP 108-132 22-26 103-140 1.30-1.50 Weave

3 Filling1 SMAW E7018 4.0 DCEP 116-142 23-27 120-168 1.30-1.40 Weave

4 Filling2 SMAW E7018 4.0 DCEP 119-146 23-27 136-185 1.20-1.30 Weave

4 Capping SMAW E7018 3.2 DCEP 106-130 22-26 113-154 1.23-1.32 Stringer

Bevel surface shall be free from rust, oil, paint and other contaminants prior to welding

Number of welders per joint: 1

Welding to be a continuous operation. Weld to completion (one heat cycle)

SMAW Basic electrode to be baked in Oven at 350ºC for Two hours or as per Manufacturer’s Instruction, but not required if the

electrode are provided in a vacuum pack ,Holding Oven Temperature shall be 150ºC and Quiver Temperature shall be 75ºC

CONTRACTOR THIRD PARTY OWNER/CLIENT

NAME: NAME: NAME:

DESIGNATION: DESIGNATION: DESIGNATION:

SIGN: SIGN: SIGN:

DATE : DATE : DATE:

You might also like

- Machine Design ElementsDocument12 pagesMachine Design ElementsMarco Paolo Avenir Magay80% (5)

- Weld Visual Inspection ReportDocument1 pageWeld Visual Inspection Reportfarjadulhaq100% (1)

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki HasyaNo ratings yet

- Atf Wpqr-Blank v1Document1 pageAtf Wpqr-Blank v1lth770310No ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- Welding Procedure Specification: Page 1 of 1Document2 pagesWelding Procedure Specification: Page 1 of 1Anderson Perez Martinez100% (1)

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- Carbon Steel: Wps No. Rev. P.No Material PQR Thickness Process PWHT Preheat SR # Filler MaterialDocument6 pagesCarbon Steel: Wps No. Rev. P.No Material PQR Thickness Process PWHT Preheat SR # Filler Materialvipin100% (1)

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 pagesWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (3)

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Document1 pageWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- Guidance To Prepare Wps PQR For WeldingDocument1 pageGuidance To Prepare Wps PQR For WeldingHamid MansouriNo ratings yet

- Weld Repair Rev. 1Document3 pagesWeld Repair Rev. 1vinas kusdinarNo ratings yet

- 3g Tar WPQTR Form Aws d1.1Document2 pages3g Tar WPQTR Form Aws d1.1Scott AdkinsNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Pt. Saferad Servis Indonesia: Ultrasonic Inspection ReportDocument3 pagesPt. Saferad Servis Indonesia: Ultrasonic Inspection Reportkucing_batam0% (1)

- Format WPQDocument2 pagesFormat WPQAkash Singh TomarNo ratings yet

- WPQ FormatDocument8 pagesWPQ FormatsanjaykumarmauryaNo ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFBernathTurnipNo ratings yet

- Prequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Document2 pagesPrequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Nuril VS theWorldNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- PEIPL-WI-01Electrode BakingDocument2 pagesPEIPL-WI-01Electrode BakingBalkishan Dyavanapelly100% (1)

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Approved Structural Steel-Welding Procedures - Double V-Groove With Back Gouge PDFDocument3 pagesApproved Structural Steel-Welding Procedures - Double V-Groove With Back Gouge PDFBhavani PrasadNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Welding Procedure Specification (WPS) : Page: 1/1Document5 pagesWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNo ratings yet

- WPS & SmawDocument12 pagesWPS & Smawnuke apriyaniNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191100% (1)

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- WPS ISO 15614-1 WeldNote MetricDocument1 pageWPS ISO 15614-1 WeldNote MetricVirgil Sorcaru0% (1)

- Weld Test Checklist: Welder (S) DetailsDocument2 pagesWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- Blank Sample WPS Form (SAW) Welding Procedure Specification (WPS)Document1 pageBlank Sample WPS Form (SAW) Welding Procedure Specification (WPS)GMNo ratings yet

- Procedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Document2 pagesProcedure Qualification Records (PQR) : KAL.f.009 REV:01 01.07.2002Walid BdeirNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- Welding VI ProcedureDocument5 pagesWelding VI Proceduretri_bobNo ratings yet

- Pipe Fit Up ReportDocument2 pagesPipe Fit Up ReportnguyenquanghiepNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Mild Steel Welding ElectrodeDocument12 pagesMild Steel Welding ElectrodeVĩnh NguyễnNo ratings yet

- 26.WPS Log CoilDocument1 page26.WPS Log CoilAvishek GuptaNo ratings yet

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 pagesWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad Daniel100% (1)

- Blasting & Painting Inspection Report Format For Bottom Plate 01Document7 pagesBlasting & Painting Inspection Report Format For Bottom Plate 01ABEC Trombay siteNo ratings yet

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavNo ratings yet

- Premier Engineering Industries: List of WPS/PQRDocument1 pagePremier Engineering Industries: List of WPS/PQRBalkishan DyavanapellyNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNo ratings yet

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- WPS BhelDocument2 pagesWPS BhelpradhankruhsnaNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya Barani100% (1)

- WPS - Merd-01Document3 pagesWPS - Merd-01Phuong NguyenNo ratings yet

- Wps 7018 SmawDocument1 pageWps 7018 SmawErick VazquezNo ratings yet

- Welding Procedure Specification (WPS) : Asme Ix & Asme B31.3Document1 pageWelding Procedure Specification (WPS) : Asme Ix & Asme B31.3Elias JarjouraNo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Document3 pagesWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNo ratings yet

- Support 1.1Document87 pagesSupport 1.1Shreyas AlagundiNo ratings yet

- TESDocument4 pagesTESkgaria79No ratings yet

- Basic Propeller and Helicopter DesignDocument6 pagesBasic Propeller and Helicopter DesignJoe Francis LapeñaNo ratings yet

- RJS Pattern Making NewDocument23 pagesRJS Pattern Making NewRam Janm SinghNo ratings yet

- PUT Paper of Manufacturing Science II (2019-20)Document3 pagesPUT Paper of Manufacturing Science II (2019-20)Tulsi ChouhanNo ratings yet

- CBR and Bearing CapacityDocument8 pagesCBR and Bearing Capacityzagros100% (1)

- CATALOGO Gea T Smart Butterfly Valves Catalog Tcm38 13853Document94 pagesCATALOGO Gea T Smart Butterfly Valves Catalog Tcm38 13853Matheus Vinicius SilvaNo ratings yet

- Spray-Drying: Basic Theory and ApplicationsDocument15 pagesSpray-Drying: Basic Theory and ApplicationsDarkwraith007100% (1)

- Composite Compression Unsupported Gage SectionDocument4 pagesComposite Compression Unsupported Gage SectionKarishma PrabhuNo ratings yet

- Gol 2010Document16 pagesGol 2010Fabian SandezNo ratings yet

- Sany Crane-Brochure SCC600A-5 024249Document30 pagesSany Crane-Brochure SCC600A-5 024249ganjar.bmi100% (1)

- Ground Anchors and Anchored Structures SeminarDocument105 pagesGround Anchors and Anchored Structures SeminarJonathan Bennett PE DGE100% (2)

- DST Tools CatalogDocument103 pagesDST Tools CatalogSikander Mushtaq100% (1)

- FLOWTITE Jacking Pipe ID Series Type SE Joint Non Pressure ChartDocument2 pagesFLOWTITE Jacking Pipe ID Series Type SE Joint Non Pressure ChartNADEEM AHMEDNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: 110, 130, 100: Structural Steel, Carbon Steel, KilledDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: 110, 130, 100: Structural Steel, Carbon Steel, Killedamit kumar sarkarNo ratings yet

- Jignesh Steel Maharashtra IndiaDocument10 pagesJignesh Steel Maharashtra IndiaJignesh Steel IndiaNo ratings yet

- Motion With Constant AccelerationDocument33 pagesMotion With Constant AccelerationJohn Kristoffer VillarNo ratings yet

- Unit Manhour Mep WorksDocument662 pagesUnit Manhour Mep Worksedla3710No ratings yet

- 24 Tornillos 2022Document22 pages24 Tornillos 2022Miguel Angel Gaytán PérezNo ratings yet

- Bidge Deck AnalysisDocument37 pagesBidge Deck AnalysisGaurab100% (1)

- 7.example ProblemsDocument396 pages7.example ProblemsPhuoc100% (1)

- Industrial Products Motors: FeaturesDocument70 pagesIndustrial Products Motors: FeaturesVicente BenitezNo ratings yet

- FRLO 14410C T2 Fuller 10 Speed Parts Breakdown ManualDocument27 pagesFRLO 14410C T2 Fuller 10 Speed Parts Breakdown ManualFlorencio MaximilianoNo ratings yet

- Parts Book Vol 2Document412 pagesParts Book Vol 2jacques SUIRENo ratings yet

- MCQ Unit 2 Fluid Statics, BuoyancyDocument6 pagesMCQ Unit 2 Fluid Statics, BuoyancySiddhant100% (1)

- Igcse Physics 3ed TR End of Chapter Test 8Document4 pagesIgcse Physics 3ed TR End of Chapter Test 8Abdullah MuhammadNo ratings yet

- Service Manual: Washer Extractor W565H, W575H, W5105H, W5130H, W5180H, W5240H, W5300HDocument120 pagesService Manual: Washer Extractor W565H, W575H, W5105H, W5130H, W5180H, W5240H, W5300HBruno Martins100% (1)

- Truss & Frame: Ahsanullah University of Science and Tecnology Dhaka, BangladeshDocument12 pagesTruss & Frame: Ahsanullah University of Science and Tecnology Dhaka, BangladeshMir Mustafa AliNo ratings yet

- Fluid Mechanics: Lecture Notes Module-IDocument21 pagesFluid Mechanics: Lecture Notes Module-Iamlan sahuNo ratings yet