Operating Instructions: Diesel Engine 12V 4000 C64 Application Group 5B

Operating Instructions: Diesel Engine 12V 4000 C64 Application Group 5B

Uploaded by

aung minhtetOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operating Instructions: Diesel Engine 12V 4000 C64 Application Group 5B

Operating Instructions: Diesel Engine 12V 4000 C64 Application Group 5B

Uploaded by

aung minhtetCopyright:

Available Formats

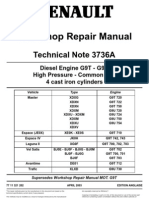

Operating Instructions

Diesel engine

12V 4000 C64

Application group 5B

MS150112/01E

Downloaded from www.Manualslib.com manuals search engine

Engine model kW/cyl. Application group

12V4000C64 155 kW/cyl. 5B; Continuous operation, variable

Table 1: Applicability

© 2014 Copyright MTU Friedrichshafen GmbH

This publication is protected by copyright and may not be used in any way, whether in whole or in part, without the prior

written consent of MTU Friedrichshafen GmbH. This particularly applies to its reproduction, distribution, editing, transla-

tion, microfilming and storage or processing in electronic systems including databases and online services.

All information in this publication was the latest information available at the time of going to print. MTU Friedrichshafen

GmbH reserves the right to change, delete or supplement the information provided as and when required.

Downloaded from www.Manualslib.com manuals search engine

Table of Contents

1 Safety 7 Task Description

1.1 Important requirements for all products 5 7.1 Engine 99

1.2 Personnel and organizational requirements 6 7.1.1 Engine – Barring manually 99

1.3 Safety requirements for startup and 7.1.2 Barring engine with starting system 100

operation 7 7.1.3 Engine – Test run 101

1.4 Safety requirements for maintenance and 7.2 Auxiliary PTO 102

repair work 8 7.2.1 Auxiliary PTO – Replacement 102

1.5 Fire prevention and environmental

7.3 Cylinder Liner 103

protection, fluids and lubricants, auxiliary 7.3.1 Cylinder liner – Endoscopic examination 103

materials 11 7.3.2 Instructions and comments on endoscopic and

1.6 Standards for safety notices in the text 13 visual examination of cylinder liners 105

1.7 Transport 14

7.4 Crankcase Breather 107

7.4.1 Crankcase breather – Oil mist fine separator

2 General Information replacement 107

2.1 Engine side and cylinder designations 15 7.5 Valve Drive 108

2.2 Engine – Overview 16 7.5.1 Valve gear – Lubrication 108

2.3 Sensors, actuators and injectors – Overview 17 7.5.2 Valve projection – Measurement 109

7.5.3 Valve clearance – Check and adjustment 112

3 Technical Data 7.5.4 Cylinder head cover ‒ Removal and

installation 115

3.1 12V 4000 C64 engine data 20

7.6 Injection Pump / HP Pump 116

3.2 Firing order 24 7.6.1 HP pump – Relief bore check 116

3.3 Engine – Main dimensions 25

7.7 Injection Valve / Injector 117

7.7.1 Injector – Replacement 117

4 Operation

7.7.2 Injector – Removal and installation 118

4.1 Putting the engine into operation after 7.8 Fuel System 122

extended out-of-service periods (>3 months) 26 7.8.1 Fuel system – Venting 122

4.2 Putting the engine into operation after

scheduled out-of-service-period 27 7.9 Fuel Filter 123

7.9.1 Fuel filter – Replacement 123

4.3 Operational checks 28

7.9.2 Additional fuel filter – Replacement 124

4.4 Engine – Starting in manual mode 29

4.5 Engine – Stopping in manual mode 30 7.10 Exhaust Turbocharger 125

4.6 After stopping the engine 31 7.10.1 Exhaust turbocharger – Turbine housing

4.7 Plant – Cleaning 32 check 125

7.10.2 Exhaust turbocharger (LP) – Turbine housing

check 126

5 Maintenance 7.10.3 Exhaust turbocharger (HP) – Turbine housing

check 134

5.1 Maintenance task reference table [QL1] 33

7.11 Charge-Air Cooling 140

DCL-ID: 0000029808 - 003

6 Troubleshooting 7.11.1 Intercooler – Leak check 140

6.1 Troubleshooting 35 7.12 Exhaust Gas Recirculation 141

7.12.1 EGR cooler – Overview 141

6.2 Fault messages on the SAM display

7.12.2 EGR cooler – Cleaning 142

(optional) 37 7.12.3 EGR cooler ‒ Check 143

6.3 Fault messages of Engine Control Unit ECU 7.12.4 Exhaust flaps – Overview 144

9 for Series 4000 38 7.12.5 Exhaust flaps – Actuator function check 145

7.12.6 Exhaust flaps – Overview 146

MS150112/01E 2014-10 | Table of Contents | 3

Downloaded from www.Manualslib.com manuals search engine

7.12.7 Exhaust flaps – Checking coupling rods 7.18.1 Drive belt – Condition check 181

operability and play 147

7.12.8 Exhaust flaps – Coupling rod replacement 149

7.19 Battery-Charging Generator 182

7.19.1 Checking battery-charging generator 182

7.13 Starting Equipment 152 7.19.2 Battery-charging generator drive – Drive belt

7.13.1 Starter – Condition check 152 tension adjustment 183

7.19.3 Battery-charging generator drive – Drive belt

7.14 Lube Oil System, Lube Oil Circuit 153 replacement 184

7.14.1 Engine oil level – Check at sight glass 153

7.14.2 Engine oil – Level check with oil dipstick 154 7.20 Fan Drive 185

7.14.3 Engine oil – Change 155 7.20.1 Fan drive – Drive belt check / adjustment 185

7.14.4 Engine oil – Sample extraction and analysis 157 7.20.2 Fan drive – Drive belt replacement 187

7.15 Oil Filtration / Cooling 158 7.21 Engine Mounting / Support 188

7.15.1 Engine oil filter – Replacement 158 7.21.1 Engine mounting – Check 188

7.15.2 Centrifugal oil filter – Cleaning and filter-

sleeve replacement 160

7.22 Wiring (General) for Engine/Gearbox/Unit 189

7.22.1 Еngine cabling ‒ Check 189

7.16 Coolant Circuit, General, High-Temperature

7.23 Accessories for (Electronic) Engine

Circuit 162

7.16.1 Engine coolant – Level check 162

Governor / Control System 190

7.23.1 Resetting CDC parameter and entering IIG

7.16.2 Engine coolant – Change 163

with DiaSys® 190

7.16.3 Engine coolant – Draining 164

7.23.2 Actuators – Visual inspection and test 191

7.16.4 Exhaust flaps – Draining coolant from

7.23.3 Engine governor and connectors – Cleaning 193

servomotors 166

7.23.4 Engine governor plug connections – Check 194

7.16.5 Engine coolant – Filling 167

7.23.5 NOx sensor – Replacement 195

7.16.6 Engine coolant pump – Relief bore check 170

7.23.6 Lambda sensor – Replacement 197

7.16.7 Engine coolant – Sample extraction and

analysis 171

7.17 Low-Temperature Circuit 172 8 Appendix A

7.17.1 Charge-air coolant – Level check 172

7.17.2 Charge-air coolant – Change 173

8.1 Abbreviations 199

7.17.3 Charge-air coolant – Draining 174 8.2 MTU contact persons/service partners 202

7.17.4 Charge-air coolant – Filling 177

7.17.5 Checking charge-air coolant pump pressure 9 Appendix B

relief port 180

9.1 Special Tools 203

7.18 Belt Drive 181 9.2 Index 212

DCL-ID: 0000029808 - 003

4 | Table of Contents | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

1 Safety

1.1 Important requirements for all products

Nameplate

The product is identified by a nameplate, model designation or serial number which must match the

information on the title page of this manual.

Nameplate, model designation or serial number can be found on the product.

General information

This product may pose a risk of injury or damage in the following cases:

• Improper use

• Operation, maintenance and repair by unqualified personnel

• Changes or modifications

• Noncompliance with the safety instructions and warning notices

Intended use

The product is intended for use in accordance with its contractually-defined purpose as described in the

relevant technical documents only.

Intended use entails operation:

• Within the permissible operating parameters in accordance with the (→ Technical data)

• With fluids and lubricants approved by the manufacturer in accordance with the (→ Fluids and Lubri-

cants Specifications of the manufacturer)

• With spare parts approved by the manufacturer in accordance with the (→ Spare Parts Catalog/MTU

contact/Service partner)

• In the original as-delivered configuration or in a configuration approved by the manufacturer in writ-

ing (including engine management/parameters)

• In compliance with all safety regulations and in accordance with all warning notices in this manual

• With maintenance work performed in accordance with the (→ Maintenance Schedule) throughout the

useful life of the product

• In compliance with the maintenance and repair instructions contained in this manual, in particular

with regard to the specified tightening torques

• With the exclusive use of technical personnel trained in commissioning, operation, maintenance and

repair

• By contracting only workshops authorized by the manufacturer to carry out repair and overhaul

Any other use shall be considered non-intended. Such improper use increases the risk of injury and

damage when working with the product. The manufacturer shall not be held liable for any damage re-

sulting from improper, non-intended use.

Changes or modifications

Unauthorized changes to the product represent a contravention of its intended use and compromise

TIM-ID: 0000040530 - 005

safety.

Changes or modifications shall only be considered to comply with the intended use when expressly au-

thorized by the manufacturer. The manufacturer shall not be held liable for any damage resulting from

unauthorized changes or modifications.

MS150112/01E 2014-10 | Safety | 5

Downloaded from www.Manualslib.com manuals search engine

1.2 Personnel and organizational requirements

Organizational measures of the operator

This manual must be issued to all personnel involved in operation, maintenance, repair or transporta-

tion.

Keep this manual handy in the vicinity of the product such that it is accessible to operating, mainte-

nance, repair and transport personnel at all times.

Use this manual as a basis for instructing personnel on product operation and repair, whereby the safe-

ty-relevant instructions, in particular, must be read and understood.

This is particularly important in the case of personnel who only occasionally perform work on or around

the product. This personnel must be instructed repeatedly.

Personnel requirements

All work on the product shall be carried out by trained and qualified personnel only.

• Training at the Training Center of the manufacturer

• Qualified personnel specialized in mechanical and plant engineering

The operator must define the responsibilities of the personnel involved in operation, maintenance, re-

pair and transport.

Working clothes and personal protective equipment

Wear proper protective clothing for all work.

When working, always wear the necessary personal protective equipment (e.g. ear protectors, protec-

tive gloves, goggles, breathing protection). Observe the information on personal protective equipment

in the respective activity description.

TIM-ID: 0000040531 - 003

6 | Safety | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

1.3 Safety requirements for startup and operation

Safety requirements for startup

The product must be installed and accepted in accordance with manufacturers' specifications prior to

initial startup.

All the requisite regulatory approvals must have been granted and all startup requirements fulfilled prior

to initial startup.

Whenever the product is started, always ensure that:

• All maintenance and repair work has been completed.

• All loose parts have been removed from rotating machine components.

• Wearers of cardiac pacemakers or other active medical implants are well clear.

• The operating room is adequately ventilated.

• Exhaust pipework is leak-tight and routed to atmosphere.

• Battery terminals, generator terminals and cables are guarded to preclude accidental contact.

• All personnel is clear of the danger zone represented by moving parts.

Immediately after putting the product into operation, make sure that all control and display instruments

as well as the monitoring, signaling and alarm systems are working properly.

Safety requirements for operation

The operator must be familiar with the controls and displays.

The operator must be aware of the consequences of any operations he/she performs.

During operation, the display instruments and monitoring units must be constantly observed in regard

of present operating status, limit value violation and warning or alarm messages.

Malfunctions and emergency stop

Emergency procedures, in particular emergency stop, must be practiced on a regular basis.

Take the following steps if a system malfunction is detected or signaled by the system:

• Inform the duty supervisor(s).

• Evaluate the message.

• Respond to the emergency appropriately, e.g. execute an emergency stop.

Operation

Do not stay in the operating room when the product is running unless absolutely necessary and then as

briefly as possible.

Keep a safe distance away from the product whenever possible. Do not touch the product unless ex-

pressly instructed to do so.

Do not inhale exhaust gases emitted by the product.

Ensure that the following requirements have been fulfilled before starting the product:

• Ear protectors are worn.

• Mop up any leaked or spilled fluids and lubricants immediately or soak up with a suitable binding

TIM-ID: 0000040533 - 006

agent.

Operation of electrical equipment

Some components are live (high voltage) when electrical equipment is in operation.

Observe the safety instructions for these appliances.

MS150112/01E 2014-10 | Safety | 7

Downloaded from www.Manualslib.com manuals search engine

1.4 Safety requirements for maintenance and repair work

Safety requirements before commencing maintenance and repair work

Have maintenance or repair work carried out by qualified and authorized personnel only.

Allow the product to cool down to less than 50°C (risk of explosion for oil vapors, fluids and lubricants,

risk of burning).

Relieve pressure in fluid and lubricant systems and compressed-air lines which are to be opened. Use

suitable collection vessels with a sufficient filling volume.

Ensure that the operating room is adequately ventilated when changing the oil or working on the fuel

system.

Do not perform maintenance or repair work when the product is running unless:

• expressly instructed to do so.

• the product is running in the low load range and only for as long as necessary to complete the task.

Lock-out the product to preclude undesired starting, e.g. start interlock.

Tag-out the product with a “Do Not Start” sign in the operation room or on the control facility.

Disconnect the battery. Lock the contactor.

Close the main valve on the compressed-air system and vent the compressed-air line when pneumatic

starters are fitted.

Disconnect the control facility from the product.

For starters with pinions made of copper-beryllium alloy:

• Wear a respirator mask (filter class P3). Do not blow out the interior of the flywheel housing or the

starter with compressed air. Clean the interior of the flywheel housing with a class H dust extractor.

• Observe the safety data sheet.

Safety requirements during maintenance and repair work

Take special care when removing vent plugs or plug screws from the product. Hold a cloth over the

screw or plug to prevent discharge of highly pressurized liquids.

Take care when draining hot fluids and lubricants (risk of burning).

Use suitable and calibrated tools only. Observe the specified tightening torques during assembly or dis-

assembly.

Carry out work only on assembles and/or installations which are properly secured.

Never climb up on the lines.

Keep fuel injection lines and connections clean.

Always seal connections with caps or covers if a line is removed or opened.

Fit new seals when re-installing lines.

Avoid damaging lines, particularly the fuel lines.

TIM-ID: 0000040535 - 006

Ensure that all retainers and dampers are installed correctly.

Ensure that all fuel injection and pressurized oil lines are installed with enough clearance to prevent

contact with other components. Never route fuel or oil lines in the vicinity of hot components.

Do not touch elastomeric seals (e.g. Viton sealing rings) with your bare hands if they have a carbonized

or resinous appearance.

Observe the cooling time for components which have been heated for installation or removal (risk of

burning!).

Always use suitable ladders and work platforms when working above head-height. Ensure that compo-

nents or assemblies are placed on stable surfaces.

8 | Safety | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

Pay particular attention to cleanliness at all times.

Safety requirements after completing maintenance and repair work

Ensure that all personnel is clear of danger zones before cranking.

Check that all access ports/apertures which have been opened to facilitate working are closed again.

Check that all safety equipment has been installed and that all tools and loose parts have been re-

moved (especially the barring gear).

Ensure that no unattached parts have been left in/on the product (e.g. including rags and cable straps).

Welding work

Do not perform welding on the product or its attachments. Cover the product when performing welding

work in the vicinity.

Before commencing welding work:

• Switch off the master power supply switch.

• Disconnect the battery.

• Disconnect electronic and genset grounds.

Do not perform maintenance or repair work on the product when welding is in progress in its vicinity.

Risk of explosion or fire due to oil vapors and highly flammable process materials.

Do not use the product as a grounding terminal.

Do not route the welding cable over or near the wiring harnesses of the product. The welding current

may otherwise induce an interference voltage in the wiring harnesses which could conceivably damage

the electrical system.

Remove components (e.g. exhaust pipe) from the product before performing necessary welding work .

Hydraulic installation and removal

Check function and satisfactory condition of the jigs and fixtures to be used. Use only the specified jigs

and fixtures for hydraulic removal/installation.

Observe the max. permissible force-on pressure specified for the installation/removal jig.

Do not attempt to bend or exert force on HP lines.

Before starting work, pay attention to the following:

• Vent the installation/removal jig, the pumps and the pipework at the relevant designated points.

• For hydraulic installation, screw on the jig with the piston retracted.

• For hydraulic removal, screw on the jig with the piston extended.

For hydraulic installation/removal jigs with central expansion pressure supply, screw the spindle into

the shaft end until correct sealing has been established.

During hydraulic installation and removal, ensure that nobody is standing in the immediate vicinity of

the component to be installed/removed.

Working with batteries

TIM-ID: 0000040535 - 006

Observe the safety requirements of the battery manufacturer when working with batteries.

Gases released from the battery are explosive. Avoid sparks and naked flames.

Do not allow electrolyte (battery acid) to come into contact with skin or clothing.

Wear goggles and protective gloves.

Do not place tools on the battery.

Check polarity before connecting the cable to the battery. Battery polarity reversal may lead to injury by

the sudden discharge of acid or bursting of the battery unit.

MS150112/01E 2014-10 | Safety | 9

Downloaded from www.Manualslib.com manuals search engine

Working on electrical/electronic assemblies

Always obtain the permission of the duty supervisor before commencing maintenance or repair work or

switching off any part of the electronic system required to do so.

De-energize the appropriate areas prior to working on assemblies.

Avoid damaging cabling during removal. When reconnecting, ensure that cabling cannot be damaged

during operation by:

• Contact with sharp edges

• Chafing on components

• Contact with hot surfaces.

Do not secure cabling to lines bearing fluids.

Do not use cable ties to secure cabling.

Always use connector pliers to tighten union nuts on connectors.

Subject the device and also the product to appropriate function testing whenever repair work has been

completed. In particular, check the function of the emergency stop feature.

Store spare parts properly prior to replacement, i.e. protect them against moisture in particular. Pack-

age faulty electronic components or assemblies properly before dispatching for repair:

• Moisture-proof

• Shock-proof

• Wrapped in antistatic foil if necessary.

Working with laser equipment

Always wear special laser-protection goggles when working with laser equipment (danger due to in-

tensely focused radiation).

Laser equipment must be fitted with the protective devices necessary for safe operation according to

type and application.

For conducting light-beam procedures and measurement work, only the following laser devices must be

used:

• Laser devices of classes 1, 2 or 3A.

• Laser devices of class 3B, which have maximum output in the visible wavelength range (400 nm to

700 nm), a maximum output of 5 mW, and in which the beam axis and surface are designed to pre-

vent any risk to the eyes.

Measuring component deviations

Workpieces, components and measuring instruments are within specified tolerances at a reference

temperature of 20°C. TIM-ID: 0000040535 - 006

10 | Safety | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

1.5 Fire prevention and environmental protection, fluids and

lubricants, auxiliary materials

Fire prevention

Rectify any fuel or oil leaks immediately. Oil or fuel on hot components can cause fires – therefore al-

ways keep the product in a clean condition. Do not leave rags saturated with fluids and lubricants on

the product. Do not store combustible materials near the product.

Do not carry out welding work on pipes and components carrying oil or fuel. Before welding, clean with

a nonflammable fluid.

When starting the engine with an external power source, connect the ground lead last and remove it

first. To avoid sparks in the vicinity of the battery, connect the ground lead from the external power

source to the ground lead of the engine or to the ground terminal of the starter.

Always keep suitable firefighting equipment (fire extinguishers) at hand and familiarize yourself with

their use.

Noise

Noise can lead to an increased risk of accidents if it makes it more difficult to hear audible signals,

warning calls or noises indicating danger.

Wear ear protectors in workplaces with a sound pressure level in excess of 85dB (A).

Environmental protection and disposal

Modification or removal of any mechanical/electronic components or the installation of additional com-

ponents including the execution of calibration processes that might affect the emission characteristics

of the product are prohibited by emission regulations. Emission control units/systems may only be

maintained, exchanged or repaired if the components used for this purpose are approved by the manu-

facturer. Noncompliance with these guidelines will invalidate the design type approval issued by the

emissions regulation authorities. The manufacturer does not accept any liability for violations of the

emission regulations. The maintenance schedules of the manufacturer must be observed over the entire

life cycle of the product.

Dispose of used fluids, lubricants and filters in accordance with local regulations.

Within the EU, batteries can be returned free of charge to the manufacturer where they will be properly

recycled.

Fluids and lubricants and auxiliary materials

The Fluids and Lubricants Specifications will be amended or supplemented as necessary. Prior to opera-

tion, make sure that the latest version is used. The latest version can be found on the website on the

"Technical Info" or "Spare Parts and Service" tabs at http://www.mtu-online.com.

Consumable fluids and materials may also be hazardous or toxic. When using fluids, lubricants, consum-

ables and other chemical substances, follow the safety regulations that apply to the product. Take spe-

cial care when using hot, chilled or caustic substances. When using flammable materials, prevent them

TIM-ID: 0000040536 - 006

coming into contact with ignition sources and do not smoke.

Used oil

Used oil contains combustion residues that are harmful to health.

Rub barrier cream into hands.

Wash hands after contact with used oil.

MS150112/01E 2014-10 | Safety | 11

Downloaded from www.Manualslib.com manuals search engine

Lead

• Adopt suitable measures to avoid the formation of lead dust.

• Switch on extraction system.

• When working with lead or pastes that contain lead, avoid direct contact with the skin. Do not inhale

lead vapors.

• Wash hands after contact with lead or lead-containing substances.

Compressed air

Observe special safety precautions when working with compressed air:

• Unauthorized use of compressed air, e.g. forcing flammable liquids (hazard class AI, AII and B) out of

containers, risks causing an explosion.

• Wear goggles when blowing dirt off workpieces or blowing away swarf.

• Blowing compressed air into thin-walled containers (e.g. containers made of sheet metal, plastic or

glass) for drying purposes or to check for leaks risks bursting them.

• Pay special attention to the pressure in the compressed air system or pressure vessel.

• Assemblies or products to be connected must either be designed for that pressure, or, if the permis-

sible pressure is lower than the system pressure, a pressure reducing valve and safety valve (set to

the permissible pressure) must be connected between the assemblies/products and the system.

• Hose couplings and connections must be securely attached.

• Provide the snout of the air nozzle with a protective disk (e.g. rubber disk).

• First shut off compressed air lines before compressed air device is disconnected from the supply

line, or before device or tool is to be replaced.

• Carry out leak test in accordance with the specifications.

Paints and varnishes

• Observe the relevant safety data sheet for all materials.

• When painting in areas other than spray booths equipped with extractors, ensure good ventilation.

Make sure that neighboring work areas are not adversely affected.

• There must be no naked flames in the vicinity.

• No smoking.

• Observe fire prevention regulations.

• Always wear a mask providing protection against paint and solvent vapors.

Liquid nitrogen

• Observe the relevant safety data sheet for all materials.

• Work with liquid nitrogen may be carried out only by qualified personnel.

• Store liquid nitrogen only in small quantities and always in regulation containers (without gas-tight

caps).

• Avoid body contact (eyes, hands).

• Wear protective clothing, protective gloves, closed shoes and safety goggles.

• Make sure that working area is well ventilated.

• Avoid knocking or jolting the containers, valves and fittings or workpieces in any way.

Acids/alkaline solutions/urea (AdBlue®, DEF)

TIM-ID: 0000040536 - 006

• Observe the relevant safety data sheet for all materials.

• When working with acids and alkaline solutions, wear goggles or face mask, gloves and protective

clothing.

• Do not inhale vapors.

• If urea solution is swallowed, rinse out mouth and drink plenty of water.

• If spilled onto clothing, remove the affected clothing immediately.

• After contact with skin, rinse affected parts of the body with plenty of water.

• Rinse eyes immediately with eye drops or clean tap water. Seek medical attention as soon as possi-

ble.

12 | Safety | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

1.6 Standards for safety notices in the text

DANGER

In the event of immediate danger.

Consequences: Death, serious or permanent injury!

• Remedial action.

WARNING

In the event of a situation involving potential danger.

Consequences: Death, serious or permanent injury!

• Remedial action.

CAUTION

In the event of a situation involving potential danger.

Consequences: Minor or moderate injuries!

• Remedial action.

NOTICE

In the event of a situation involving potentially adverse effects on the product.

Consequences: Material damage!

• Remedial action.

• Additional product information.

Safety notices

1. This manual with all safety instructions and safety notices must be issued to all personnel involved in

operation, maintenance, repair or transportation.

2. The higher level warning notice is used if several hazards apply at the same time. Warnings related to

personal injury shall be considered to include a warning of potential damage.

TIM-ID: 0000040578 - 004

MS150112/01E 2014-10 | Safety | 13

Downloaded from www.Manualslib.com manuals search engine

1.7 Transport

Transport

Always use the lifting eyes on the engine and generator/gearbox when transporting gensets.

Always use the lifting eyes on the engine when transporting an engine separately.

Only use transport and lifting devices approved by MTU.

The engine/genset must only be transported in installation position: maximum permissible diagonal pull

10°.

Remove any loose parts on the genset.

Raise the engine/genset slowly. The lifting ropes or chains must not make contact with the engine or

its components. Readjust lifting device as necessary.

Pay attention to the center of gravity of the engine/genset.

For special packaging with aluminium foil: Suspend the engine/genset by the lifting eyes on the bearing

pedestal or transport by means of handling equipment (forklift truck) capable of bearing the load.

Fit the crankshaft transportation lock on the engine and fit the engine mount locking devices prior to

transport.

TIM-ID: 0000002618 - 007

Secure the engine/genset such as to preclude tipping during transport. Secure such as to preclude slip-

ping and tipping when driving up or down inclines and ramps.

Placement after transport

Place the engine/genset on a firm, flat surface only.

Make sure that the consistency and load-bearing capacity of the ground or support surface is adequate.

Never set an engine down on the oil pan unless expressively authorized to do so by MTU on a case-to-

case basis.

14 | Safety | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

2 General Information

2.1 Engine side and cylinder designations

1 Left engine side (A-side) 3 Right engine side (B-side)

2 Engine free end in accord- 4 Engine driving end in ac-

ance with DIN ISO 1204 cordance with

(KGS = Kupplungsgegen- DIN ISO 1204 (KS = Kup-

seite) plungsseite)

Engine sides are always designated (in accordance with DIN ISO 1204) as viewed from driving end (4).

For cylinder designation (in accordance with DIN ISO 1204), the letter "Ax" refers to the cylinders on

the left-hand side of the engine (1) and letter "Bx" refers to the cylinders on the right-hand side (3). The

cylinders of each bank are numbered consecutively, starting with x=1 at driving end (4).

The numbering of other engine components also starts with 1 at driving end (4).

TIM-ID: 0000002185 - 013

MS150112/01E 2014-10 | General Information | 15

Downloaded from www.Manualslib.com manuals search engine

2.2 Engine – Overview

1 Oil heat exchanger 11 Engine mounting 21 Fuel priming pump

2 Crankcase breather 12 Cylinder head 22 Engine mounting

3 Cable harness holder 13 EGR line 23 Lube oil filter

4 Exhaust outlet 14 Flywheel 24 Vibration damper

5 Exhaust turbocharger (LP) 15 Charge-air line 25 Fan drive

6 Exhaust turbocharger (HP) 16 Starter 26 Auxiliary PTO

7 Charge-air cooler (low 17 Oil pan 27 Battery-charging generator

pressure) 18 Fuel filter head 28 Centrifugal oil filter

8 EGR cooler 19 Supplementary fuel filter

9 Engine coolant line 20 Fuel filter

10 Air intake

Engine model designation

Explanation of engine model designation 12 V 4000 C64

12 Number of cylinders

V Cylinder arrangement: V engine

4000 Series

TIM-ID: 0000045454 - 002

C Application: Construction and Industrial, mobile

6 Application segment: 6

4 Design index

16 | General Information | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

2.3 Sensors, actuators and injectors – Overview

1 B13 - Crankshaft speed 3 F57 - Charge-air coolant

2 F70 - Water level in fuel level

prefilter (external) 4 F33 - Engine coolant level

TIM-ID: 0000045455 - 001

MS150112/01E 2014-10 | General Information | 17

Downloaded from www.Manualslib.com manuals search engine

1 M52 - Bypass flap 5 B91.3 - Exhaust pressure 9 B13 - Crankshaft speed

2 B44.2 - Turbocharger B 6 B88 - NOx 10 B10.11 - Charge-air pres-

speed 7 B16 - Engine coolant pres- sure, B-side

3 B90 - Humidity (pressure, sure

temperature) of intake air 8 Y39.B1-B6 - Injectors B1-

4 B89 - Lambda B6

The injectors (8) are underneath the cylinder head covers of the cylinders. Injector replacement and

associated activities (→ Page 117).

TIM-ID: 0000045455 - 001

18 | General Information | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

1 M55 - Donor cylinder flap 6 B9 - Charge-air tempera- 11 F46 - Leak-off fuel level

2 B44.3 - Turbocharger C ture 12 B5.3 - Lube-oil pressure

speed 7 Y39.A1-A6 - Injectors A1- before filter

3 B10.1 - Charge-air pres- A6 13 B7 - Lube oil temperature

sure, A-side 8 B34.3 - Fuel pressure be- 14 B44.1 - Turbocharger A

4 M53 - EGR shutoff flap fore supplementary filter speed

5 A19 - EIL connection 9 B34.2 - Fuel pressure be- 15 B4 - Exhaust temperature

fore filter

10 B34.1 - Fuel pressure after

filter

The injectors (6) are underneath the cylinder head covers of the cylinders. Injector replacement and

associated activities (→ Page 117).

TIM-ID: 0000045455 - 001

MS150112/01E 2014-10 | General Information | 19

Downloaded from www.Manualslib.com manuals search engine

3 Technical Data

3.1 12V 4000 C64 engine data

Explanation:

DL Ref. value: Continuous power

BL Ref. value: Fuel stop power

A Design value

G Guaranteed value

R Guideline value

L Limit value, up to which the engine can be operated, without change (e.g. of power setting)

N Not yet defined value

- Not applicable

X Applicable

REFERENCE CONDITIONS

Engine model 12V

Application group 5B

Intake air temperature °C 25

Charge-air coolant temperature °C 45

Barometric pressure mbar 1000

Site altitude above sea level m 100

POWER-RELATED DATA (power ratings are net brake power as per ISO 3046)

Number of cylinders 12V

Rated engine speed A rpm 1900

Net brake power (w/o fan) (fuel stop power ISO 3046) A kW 1865

GENERAL CONDITIONS (for maximum power)

Number of cylinders 12V

Intake depression (new filter) A mbar 15

Intake depression, max. L mbar 50

Exhaust overpressure A mbar 30

Exhaust overpressure, max. L mbar 85

Fuel temperature at engine inlet connection R °C 25

Fuel temperature at engine inlet connection, max (w/o power L °C 65

TIM-ID: 0000045457 - 001

reduction)

CONSUMPTION

Number of cylinders 12V

Lube oil consumption after 100 h runtime (B = hourly fuel con- R % of B 0.2

sumption)

20 | Technical Data | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

MODEL-RELATED DATA (basic design)

Number of cylinders 12V

Number of cylinders 12

Cylinder arrangement: V angle degrees 90

Bore mm 170

Stroke mm 210

Cylinder displacement Liters 4.77

Total displacement Liters 57.2

Number of inlet valves per cylinder 2

Number of exhaust valves per cylinder 2

COMBUSTION AIR / EXHAUST GAS

Number of cylinders 12V

Charge-air pressure before cylinder R bar abs 4.9

Exhaust temperature after turbocharger R °C 370

COOLANT SYSTEM (HT circuit)

Number of cylinders 12V

Coolant temperature (at engine connection: outlet to cooling A °C 100

equipment)

Coolant temperature after engine, warning R °C 107

Coolant temperature after engine, shutdown L °C 109

Coolant antifreeze content, max. L % 50

Coolant pump: inlet pressure, max. L bar 2.5

Thermostat: Starts to open R °C 79

Thermostat: Fully open R °C 92

COOLANT SYSTEM (LT circuit)

Number of cylinders 12V

Coolant temperature difference after/before charge-air cooler, L °C 8

min.

Coolant temperature difference after/before charge-air cooler, L °C 16

max.

Coolant antifreeze content, max. L % 50

Thermostat: Starts to open R °C 38

TIM-ID: 0000045457 - 001

Thermostat: Fully open R °C 51

LUBE OIL SYSTEM

Number of cylinders 12V

Lube oil operating temperature before engine, from R °C 60

Lube oil operating temperature before engine, to R °C 95

Lube oil temperature before engine, alarm R °C 97

Lube oil temperature before engine, shutdown L °C 99

MS150112/01E 2014-10 | Technical Data | 21

Downloaded from www.Manualslib.com manuals search engine

Number of cylinders 12V

Lube oil operating pressure upstream of engine, from R bar 6.0

Lube-oil operating pressure before engine, to R bar 7.0

FUEL SYSTEM

Number of cylinders 12V

Fuel pressure at engine inlet connection, min. (when engine is L bar -0.3

starting)

Fuel pressure at return connection on engine, max. L bar 0.5

Fuel pressure at engine inlet connection, max. (when engine is L bar 1.5

starting)

GENERAL OPERATING DATA

Number of cylinders 12V

Coolant preheating: preheating temperature (min.) R °C 40

INCLINATIONS, STANDARD OIL SYSTEM (reference: waterline)

Number of cylinders 12V

Longitudinal inclination, continuous max. driving end down (op- L Degrees 15

tion: max. operating inclinations)

Longitudinal inclination, temporary max. driving end down (op- L Degrees 15

tion: max. operating inclinations)

Longitudinal inclination, continuous max. driving end up (option: L Degrees 15

max. operating inclinations)

Transverse inclination, continuous max. (option: max. operating L Degrees 15

inclinations)

CAPACITIES

Number of cylinders 12V

Engine coolant, engine side (without cooling equipment) R Liters 220

Charge-air coolant, engine side R Liters 69

Engine oil on initial filling (standard oil system) (option: max. op- R Liters 245

erating inclinations)

Oil pan capacity at dipstick mark “min.” (standard oil system) L Liters 150

(option: max. operating inclinations)

Oil pan capacity at dipstick mark “max.” (standard oil system) L Liters 190

(option: max. operating inclinations)

TIM-ID: 0000045457 - 001

WEIGHTS (basic design, dry engine)

Number of cylinders 12V

Engine dry weight (with attached standard accessories, without R kg 8200

coupling)

22 | Technical Data | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

ACOUSTICS

Number of cylinders 12V

Exhaust noise, unsilenced - BL (free-field sound-pressure level R dB(A) 112

Lp, 1m distance, ISO 6798)

Exhaust noise, unsilenced - BL (sound power level LW, ISO R dB(A) 124

6798)

Engine surface noise with attenuated intake noise (filter) - BL R dB(A) 109

(free-field sound-pressure level Lp, 1m distance, ISO 6798)

Engine surface noise with attenuated intake noise (filter) - BL R dB(A) 128

(sound power level LW, ISO 6798)

TIM-ID: 0000045457 - 001

MS150112/01E 2014-10 | Technical Data | 23

Downloaded from www.Manualslib.com manuals search engine

3.2 Firing order

Firing order

Number of cylinders Firing order

12V A1-B5-A5-B3-A3-B6-A6-B2-A2-B4-A4-B1

TIM-ID: 0000026627 - 002

24 | Technical Data | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

3.3 Engine – Main dimensions

Engine – Main dimensions

Item Dimensions

Length (A) approx. 2878 mm

Width (B) approx. 1631 mm

Height (C) approx. 2393 mm

TIM-ID: 0000045458 - 001

MS150112/01E 2014-10 | Technical Data | 25

Downloaded from www.Manualslib.com manuals search engine

4 Operation

4.1 Putting the engine into operation after extended out-of-service

periods (>3 months)

Preconditions

☑Engine is stopped and starting disabled.

☑MTU Preservation and Represervation Specifications (A001070/..) are available.

Putting the engine into operation after extended out-of-service periods

(>3 months)

Item Action

Engine Depreserve (→ Preservation and Represervation Specifications A001070/..).

Cylinder liner Perform endoscopic examination of cylinder liner (→ Page 103).

Valve drive Lubricate valve gear every ≥ 6 months (→ Page 108).

Lube oil system Check engine oil level (→ Page 154).

Bar engine using starting system (→ Page 100).

Fuel prefilter Fill with fuel (if fitted).

Coolant circuit If engine has been out of service for more than 1 year, change engine cool-

ant (→ Page 163).

Change charge-air coolant (→ Page 173).

Coolant circuit Check engine coolant level (→ Page 162);

Check charge-air coolant level (→ Page 172).

Coolant circuit Preheat coolant with coolant preheating unit (if available).

Engine governor Check electrical connections (→ Page 194).

Engine management Read out fault memory using DiaSys, see (→ manufacturer's documentation).

Check all active fault messages, eliminate faults as necessary (→ Page 38).

TIM-ID: 0000045459 - 002

26 | Operation | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

4.2 Putting the engine into operation after scheduled out-of-

service-period

Preconditions

☑Engine is stopped and starting disabled.

Startup

Item Action

Lube oil system Check engine oil level (→ Page 154).

Coolant circuit Check engine coolant level (→ Page 162);

Check charge-air coolant level (→ Page 172).

Coolant circuit Heat coolant with coolant preheater (if available; see manufacturer's docu-

mentation).

Engine control system Put into operation (see manufacturer's documentation).

TIM-ID: 0000002683 - 006

MS150112/01E 2014-10 | Operation | 27

Downloaded from www.Manualslib.com manuals search engine

4.3 Operational checks

DANGER

Rotating, moving engine parts.

Risk of crushing! Risk of body parts being caught or drawn in!

• Take special care when the engine is running.

• Stay well clear of danger zones at the engine.

WARNING

Loud engine noises with the engine running:

Risk of hearing damage!

• Wear ear protection.

Operational checks

Item Action

Control and display panels Check readings of operational data (speed, temperature, pressures).

Engine oil Check engine oil level (→ Page 154).

Engine operation Visually inspect engine for leaks and general condition.

Check engine for abnormal running noises, exhaust color and vibrations.

Air filter Check signal ring position of service indicator on air filter (if fitted).

Battery-charging generator Check battery-charging generator for contamination, clean as necessary

(→ Page 182).

Exhaust system Check exhaust color (→ Page 35).

Fuel prefilter Drain water and contaminants via drain cock on fuel prefilter (if fitted, see

manufacturer's documentation).

Check service indicator at fuel prefilter (if fitted, see manufacturer's docu-

mentation).

Engine coolant pump Check relief bore (→ Page 170).

Charge-air coolant pump Check relief bore (→ Page 180).

TIM-ID: 0000030232 - 003

28 | Operation | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

4.4 Engine – Starting in manual mode

Preconditions

☑Engine is not under load.

☑External start interlock is not activated.

DANGER

Rotating and moving engine parts.

Risk of crushing, danger of parts of the body being caught or pulled in!

• Before cranking the engine with starter system, make sure that there are no persons in the en-

gine's danger zone.

WARNING

High level of engine noise when the engine is running.

Risk of damage to hearing!

• Wear ear protectors.

Preparation

Item Measure

Operating mode switch (if Switch to manual mode.

applicable).

Coolant preheating unit (if Switch ON

applicable).

Start engine

Item Measure

Switchgear cabinet, opera- 1. If no coolant preheater is fitted, make sure that the coolant tempera-

tor station etc. (depending ture is > 40 °C.

on manufacturer). 2. Press start button.

• Automatic starting procedure is performed.

• Engine speed instrument indicates increasing speed.

• After the starting sequence is completed, engine is running at idle

speed.

TIM-ID: 0000002233 - 006

MS150112/01E 2014-10 | Operation | 29

Downloaded from www.Manualslib.com manuals search engine

4.5 Engine – Stopping in manual mode

Preconditions

☑Engine is not under load.

☑Engine is running in manual mode.

NOTICE

Stopping the engine when it is running at full load subjects it to extreme thermal and mechanical

stresses.

Overheating of and, therefore, damage to components is possible!

• Before shutting down the engine, allow it to idle until the engine temperatures decrease and

constant levels are indicated.

Preparation

Item Measure

Engine Operate engine at idling speed for approx. 5 minutes.

Stop engine

Item Measure

Switch cabinet, operator Press stop button.

station etc. (depending on • Automatic stopping sequence is executed.

manufacturer)

TIM-ID: 0000002291 - 005

30 | Operation | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

4.6 After stopping the engine

Preconditions

☑MTU Preservation and Represervation Specifications (A001070/..) are available.

NOTICE

Coolant sensors may freeze if there is a risk of frost.

Risk of sensor damage!

• Protect sensors from frost.

After stopping the engine

Item Action

Coolant circuit Drain engine coolant (→ Page 164) and

Drain charge-air coolant (→ Page 174) if

• freezing temperatures are expected, the engine is to remain out of

service for an extended period, but engine coolant has no antifreeze

additive.

• the engine room is not heated.

• the coolant is not kept at a suitable temperature.

• the antifreeze concentration is insufficient for the engine-room tem-

perature.

• the antifreeze concentration is 50 % and the engine-room temperature

is below -40°C.

Engine control system Switch off (see manufacturer's documentation).

Air intake and exhaust sys- If the engine is to remain out of service for more than one week, seal the en-

tem gine's air and exhaust sides. Otherwise, the components that carry air or ex-

haust gas are at risk of corrosion.

If the engine is to remain out of service for more than one month, carry out

preservation (→ MTU Preservation and Represervation Specifications

(A001070/..) ).

TIM-ID: 0000002709 - 007

MS150112/01E 2014-10 | Operation | 31

Downloaded from www.Manualslib.com manuals search engine

4.7 Plant – Cleaning

Preconditions

☑Engine is stopped and starting disabled.

☑Operating voltage is not applied.

Special tools, Material, Spare parts

Designation / Use Part No. Qty.

Steam jet cleaner - 1

Cleaner (Hakupur 312) 30390 1

WARNING

Compressed air gun ejects a jet of pressurized air.

Risk of injury to eyes and damage to hearing, risk of rupturing internal organs!

• Never direct air jet at people.

• Always wear safety goggles/face mask and ear defenders.

WARNING

Steam jet cleaner ejects jet of pressurized water.

Risk of injury to eyes and scalding!

• Never direct water jet at people.

• Wear protective clothing, protective gloves and safety goggles/face mask.

NOTICE

Cleaning agents should not be left to take effect for too long.

Damage to components is possible!

• Observe manufacturer's instructions.

NOTICE

Blowing down product with compressed air.

Entry of dirt and damage to components is possible!

• Do not aim compressed air gun directly at seals or electronic components such as connectors

or ECUs.

Plant – Cleaning

1. Carry out plant cleaning only in areas where an appropriate oil separator is provided (environmental

protection).

2. Prior to putting the cleaning unit into operation, read the operating instructions of the water/steam jet

unit carefully and observe the safety precautions.

3. For external cleaning of the plant with water or steam-jet cleaners:

• The pressure of the high-pressure jet (cleaning jet) must not exceed 50 bar.

• A minimum distance between spray nozzle and plant of 1 m must be observed.

TIM-ID: 0000010171 - 029

• The temperature of the cleaning medium must not exceed 80°C.

4. For external cleaning with high-pressure jet, use a flat-mouth nozzle only.

Note: Never aim compressed air directly at electronic components.

5. Carry out external cleaning as follows:

a) Seal all openings in a suitable way.

b) Remove coarse dirt.

c) Spray on cleaner sparingly and leave it for 1 to 5 minutes.

d) Use the high-pressure jet to remove the loosened dirt.

e) Dry engine with compressed air.

32 | Operation | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

5 Maintenance

5.1 Maintenance task reference table [QL1]

The required maintenance tasks and intervals for this product are defined in the Maintenance Schedule.

The Maintenance Schedule is a stand-alone publication.

The task numbers in this table provide reference to the maintenance tasks specified in the Maintenance

Schedule.

Task Option Maintenance tasks

W0500 Check engine oil level. (→ Page 154)

W0501 Visually inspect engine for leaks and general condition.

W0502 X Check charge-air cooler drain. (→ Page 140)

W0505 Check relief bores of coolant pump(s). (→ Page 170)

(→ Page 180)

W0506 Check engine for abnormal running noises, exhaust color (→ Page 28)

and vibrations.

W0507 X Drain water and contaminants from fuel prefilter.

W0508 X Check reading on differential pressure gauge of fuel prefil-

ter.

W1001 Replace fuel filter or fuel filter element. (→ Page 123)

W1006 Replace fuel injectors. (→ Page 117)

W1008 X Replace engine oil filter when changing engine oil, or (→ Page 158)

when the interval (years) is reached, at the latest.

W1009 Check layer thickness of the oil residue, clean out and re- (→ Page 160)

place filter sleeve after every oil change at the latest.

W1011 Perform endoscopic examination of cylinder chambers. (→ Page 103)

W1207 Check valve clearance and adjust if necessary. IMPOR- (→ Page 112)

TANT! First adjustment after 1,000 operating hours.

W1241 Check condition of belt drive and replace if necessary; ad- (→ Page 181)

just belt tension.

W1481 Replace fuel intermediate filter or filter element. (→ Page 124)

W1525 Replace sensor. (→ Page 195)

W1526 Replace sensor. (→ Page 197)

W1581 Replace impactors. (→ Page 107)

W1610 Check securing screws of trunnion bearings for secure (→ Page 188)

seating.

TIM-ID: 0000045502 - 003

W1636 Enter parameters for drift correction (CDC) and coding for (→ Page 190)

the injectors (IIG).

W1735 Replace auxiliary PTO. (→ Page 102)

W1817 Check clearance of coupling rod of EGR flaps and replace (→ Page 147)

if necessary. (→ Page 149)

MS150112/01E 2014-10 | Maintenance | 33

Downloaded from www.Manualslib.com manuals search engine

Task Option Maintenance tasks

W1906 In case of valve clearance deviations, check valve depth. (→ Page 109)

W1907 Check and clean EGR cooler. (→ Page 142)

(→ Page 143)

Table 2: Maintenance task reference table [QL1]

TIM-ID: 0000045502 - 003

34 | Maintenance | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

6 Troubleshooting

6.1 Troubleshooting

Engine does not turn when starter is actuated

Component Cause Action

Battery/UltraCaps Low or faulty. Charge or replace (see manufacturer's

documentation).

Cable connections defective. Check if cable connections are properly

secured (see manufacturer's documen-

tation).

Starter Engine wiring, POM or starter defective. Check if cable connections are properly

secured, contact Service.

Engine wiring Faulty Check (→ Page 189).

Engine/generator Secure seating of assemblies or connec- Perform visual inspection (see manufac-

control system tors not provided. turer's documentation).

Engine governor Plug-in connections are loose. Check plug connections(→ Page 194).

Engine Running gear blocked (engine cannot be Contact Service.

barred manually).

Engine turns but does not fire

Component Cause Action

Engine Too cold. Preheat (25 °C)

Starter Poor rotation by starter: Battery/Ultra- Charge or replace battery/UltraCaps

Caps low or defective. (see manufacturer's documentation).

Engine wiring Faulty Check (→ Page 189).

Fuel system Air in fuel system. Vent fuel system (→ Page 122).

Engine governor Faulty Contact Service.

Engine fires unevenly

Component Cause Measure

Fuel injection equip- Injector defective. Replace (→ Page 117).

ment

Engine wiring Faulty Check (→ Page 189).

Fuel system Air in fuel system. Vent fuel system (→ Page 122).

TIM-ID: 0000018860 - 005

Engine governor Faulty Contact Service.

Engine does not reach rated speed

Component Cause Measure

Fuel supply Fuel prefilter clogged. Replace

Easy-change fuel filter clogged. Replace (→ Page 123).

Air supply Air filter clogged. Clean.

Fuel injection equip- Injector faulty. Replace (→ Page 117).

ment

MS150112/01E 2014-10 | Troubleshooting | 35

Downloaded from www.Manualslib.com manuals search engine

Component Cause Measure

Engine wiring Faulty Check (→ Page 189).

Engine Overloaded Contact Service.

Engine speed not steady

Component Cause Measure

Fuel injection equip- Injector faulty. Replace (→ Page 117).

ment

Speed sensor Faulty Contact Service.

Fuel system Air in fuel system. Vent fuel system (→ Page 122).

Engine governor Faulty Contact Service.

Charge-air temperature too high

Component Cause Measure

Coolant Coolant treatment incorrect. Check (MTU test kit).

Intercooler Contaminated Contact Service.

Engine room Inlet air temperature too high. Check fans and air supply / ventilation

ducts.

Charge-air pressure too low

Component Cause Measure

Air supply Air filter clogged. Check

Intercooler Contaminated Contact Service.

Exhaust turbocharger Faulty Contact Service.

Coolant discharge at intercooler

Component Cause Measure

Intercooler Leaking, major coolant discharge. Contact Service.

Blue exhaust gas

Component Cause Measure

Engine oil Too much oil in engine. Drain engine oil (→ Page 155).

Oil separator of crankcase breather con- Replace filter.

taminated.

Exhaust turbocharger, Faulty Contact Service.

cylinder head, piston

TIM-ID: 0000018860 - 005

rings, cylinder liner

White exhaust gas

Component Cause Measure

Engine Not at operating temperature. Run up to operating temperature.

Fuel system Water in fuel. Check fuel system on fuel prefilter.

Drain fuel prefilter.

Intercooler Leaking Contact Service.

36 | Troubleshooting | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

6.2 Fault messages on the SAM display (optional)

The fault code numbers are generated by the engine governor and transmitted to the following display:

The fault code (1) comprises three digits.

Fault messages can also be caused by faulty sensors/actuators. If the fault cannot be corrected with

the troubleshooting information provided in the following table, contact Service. Our Service will check

sensors/actuators and replace them if necessary.

The following fault codes may appear on the display: (→ Page 38).

TIM-ID: 0000029308 - 003

MS150112/01E 2014-10 | Troubleshooting | 37

Downloaded from www.Manualslib.com manuals search engine

6.3 Fault messages of Engine Control Unit ECU 9 for Series 4000

3 – HI T-Fuel

ZKP-Number: 2.0122.931

Fuel temperature too high (limit value 1)

Yellow alarm – warning

Cause Corrective action

Fuel tank may be exposed to 1. Reduce power.

heat. 2. Contact Service.

4 – SS T-Fuel

ZKP-Number: 2.0122.932

Fuel temperature too high (limit value 2)

Red alarm – engine shutdown

Cause Corrective action

Fuel tank may be exposed to u Contact Service.

heat.

5 – HI T-Charge Air

ZKP-Number: 2.0121.931

Charge-air temperature too high (limit value 1)

Yellow alarm – warning

Cause Corrective action

Intercooler not operating 1. Reduce power.

correctly. 2. Check intercooler.

3. Contact Service.

6 – SS T-Charge Air

ZKP-Number: 2.0121.932

Charge-air temperature too high (limit value 2)

Red alarm – engine shutdown

Cause Corrective action

Intercooler not operating 1. Check intercooler.

TIM-ID: 0000029153 - 005

correctly. 2. Contact Service.

38 | Troubleshooting | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

9 – HI T-Coolant Intercooler

ZKP-Number: 2.0124.931

Coolant pressure in intercooler too high (limit value 1)

Yellow alarm – warning

Cause Corrective action

Coolant circuit for charge air 1. Reduce power.

faulty. 2. Check intercooler and coolant cooler.

3. Contact Service.

10 – SS T-Coolant Intercooler

ZKP-Number: 2.0124.932

Coolant pressure in intercooler too high (limit value 2).

Red alarm – engine shutdown

Cause Corrective action

Coolant circuit for charge air 1. Check intercooler and coolant cooler.

faulty. 2. Contact Service.

15 – LO P-Lube Oil

ZKP-Number: 2.0100.921

Lube oil pressure too low (limit value 1)

Yellow alarm – warning

Cause Corrective action

Insufficient oil. 1. Check oil level, top up as necessary (→ Page 154).

2. Contact Service.

16 – SS P-Lube Oil

ZKP-Number: 2.0100.922

Lube oil pressure too low (limit value 2)

Red alarm – engine shutdown

Cause Corrective action

Insufficient oil. 1. Check oil level, top up as necessary (→ Page 154).

2. Acknowledge alarm.

3. Restart engine (→ Page 29).

4. Contact Service.

TIM-ID: 0000029153 - 005

MS150112/01E 2014-10 | Troubleshooting | 39

Downloaded from www.Manualslib.com manuals search engine

19 – HI T-Exhaust A

ZKP-Number: 2.0126.931

Exhaust temperature (A-side) too high (limit value 1)

Yellow alarm – warning

Cause Corrective action

Cable damage. 1. Check air filter and wiring (→ Page 189).

2. Contact Service.

20 – SS T-Exhaust A

ZKP-Number: 2.0126.932

Exhaust temperature (A-side) too high (limit value 2)

Red alarm – engine shutdown

Cause Corrective action

Cable damage. 1. Check air filter and wiring (→ Page 189).

2. Contact Service.

21 – HI T-Exhaust B

ZKP-Number: 2.0127.931

Exhaust temperature (B-side) too high (limit value 1)

Yellow alarm – warning

Cause Corrective action

Cable damage. 1. Check air filter and wiring (→ Page 189).

2. Contact Service.

22 – SS T-Exhaust B

ZKP-Number: 2.0127.932

Exhaust temperature (B-side) too high (limit value 2)

Red alarm – engine shutdown

Cause Corrective action

Cable damage. 1. Check air filter and wiring (→ Page 189).

2. Contact Service.

23 – LO Coolant Level

TIM-ID: 0000029153 - 005

ZKP-Number: 2.0152.921

Coolant level too low (limit value 1)

Yellow alarm – warning

Cause Corrective action

Leak in coolant circuit. u Check coolant level in expansion tank (→ Page 162).

40 | Troubleshooting | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

25 – HI P-Diff. Lube Oil

ZKP-Number: 2.0154.931

Differential oil pressure at oil filter too high (limit value 1)

Yellow alarm – warning

Cause Corrective action

Oil filter not operating correctly. u Replace oil filter (→ Page 158).

26 – SS P-Diff. Lube Oil

ZKP-Number: 2.0154.932

Differential oil pressure at oil filter too high (limit value 2)

Red alarm – engine shutdown

Cause Corrective action

Oil filter not operating correctly. 1. Replace oil filter (→ Page 158).

2. Contact Service.

27 – HI Leak Fuel Level

ZKP-Number: 2.0151.931

Leak-off fuel level too high (limit value 1)

Yellow alarm – warning

Cause Corrective action

Leak in fuel lines. 1. Check fuel system.

2. Contact Service.

30 – SS Engine Overspeed

ZKP-Number: 2.2510.932

Engine overspeed (limit value 2)

Red alarm – engine shutdown

Cause Corrective action

No fuel injection. 1. Restart engine. Fault can possibly be eliminated through restart

(→ Page 29).

2. Contact Service.

31 – HI ETC1 Overspeed

TIM-ID: 0000029153 - 005

ZKP-Number: 2.3011.931

Speed of primary turbocharger too high (limit value 1)

Yellow alarm – warning

Cause Corrective action

Obstructed charge-air circuit or 1. Reduce power.

fault in turbocharger. 2. Check air filter.

3. Contact Service.

MS150112/01E 2014-10 | Troubleshooting | 41

Downloaded from www.Manualslib.com manuals search engine

32 – SS ETC1 Overspeed

ZKP-Number: 2.3012.932

Speed of primary turbocharger too high (limit value 2)

Red alarm – engine shutdown

Cause Corrective action

Obstructed charge-air circuit or 1. Check air filter.

fault in turbocharger. 2. Contact Service.

33 – HI P-Diff. Fuel

ZKP-Number: 2.0114.931

Fuel filter differential pressure too high (limit value 1)

Yellow alarm – warning

Cause Corrective action

Fuel filter not operating 1. Replace fuel filter (→ Page 123).

correctly. 2. Contact Service.

34 – SS P-Diff. Fuel

ZKP-Number: 2.0114.932

Fuel filter differential pressure too high (limit value 2)

Red alarm – engine shutdown

Cause Corrective action

Fuel filter not operating 1. Replace fuel filter (→ Page 123).

correctly. 2. Contact Service.

36 – HI ETC2 Overspeed

ZKP-Number: 2.3013.931

Speed of 1st secondary turbocharger too high (limit value 1)

Yellow alarm – warning

Cause Corrective action

Obstructed charge-air circuit or 1. Reduce power.

fault in turbocharger. 2. Contact Service.

37 – SS ETC2 Overspeed

TIM-ID: 0000029153 - 005

ZKP-Number: 2.3013.912

Speed of 1st secondary turbocharger too high (limit value 2)

Red alarm – engine shutdown

Cause Corrective action

Obstructed charge-air circuit or u Contact Service.

fault in turbocharger.

42 | Troubleshooting | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

44 – LO Coolant Level Intercooler

ZKP-Number: 2.0153.921

Coolant level of intercooler too low (limit value 1)

Yellow alarm – warning

Cause Corrective action

Insufficient charge-air coolant, 1. Check coolant level (→ Page 172).

e.g. due to leaks in charge-air 2. Contact Service.

coolant circuit.

51 – HI T-Lube Oil

ZKP-Number: 2.0125.931

Lube oil temperature too high (limit value 1)

Yellow alarm – warning

Cause Corrective action

Insufficient oil. 1. Reduce power.

2. Check engine oil level (→ Page 154).

3. Contact Service.

52 – SS T-Lube Oil

ZKP-Number: 2.0125.932

Lube oil temperature too high (limit value 2)

Red alarm – engine shutdown

Cause Corrective action

Insufficient oil. 1. Check engine oil level (→ Page 154).

2. Contact Service.

57 – LO P-Coolant

ZKP-Number: 2.0101.921

Coolant pressure too low (limit value 1)

Yellow alarm – warning

Cause Corrective action

Leak in coolant circuit. u Check coolant level (→ Page 162).

58 – SS P-Coolant

TIM-ID: 0000029153 - 005

ZKP-Number: 2.0101.922

Coolant pressure too low (limit value 2)

Red alarm – engine shutdown or reduced injection quantity

Cause Corrective action

Leak in coolant circuit. u Check coolant level (→ Page 162).

MS150112/01E 2014-10 | Troubleshooting | 43

Downloaded from www.Manualslib.com manuals search engine

59 – SS T-Coolant L3

ZKP-Number: 2.0120.933

Coolant temperature too high / low (limit value 3)

Red alarm – forced idle

Cause Corrective action

Coolant circuit not operating 1. Activate fan emergency operating mode if required.

correctly (e.g. damage, leaks, 2. Allow engine to cool down.

low coolant level). 3. Check engine coolant cooler, clean if dirty.

4. Acknowledge alarm.

5. Restart engine (→ Page 29).

6. Contact Service.

60 – SS T-Coolant L4

ZKP-Number: 2.0120.934

Coolant temperature too high / low (limit value 4)

Red alarm – engine shutdown

Cause Corrective action

Coolant circuit not operating 1. Activate fan emergency operating mode if required.

correctly (e.g. damage, leaks, 2. Allow engine to cool down.

low coolant level). 3. Check engine coolant cooler, clean if dirty.

4. Acknowledge alarm.

5. Restart engine (→ Page 29).

6. Contact Service.

63 – HI P-Crankcase

ZKP-Number: 2.0106.931

Crankcase pressure too high (limit value 1)

Yellow alarm – warning

Cause Corrective action

Crankcase extraction system 1. Reduce power.

obstructed or leaking. 2. Replace oil mist fine separator insert .

3. Contact Service.

64 – SS P-Crankcase

ZKP-Number: 2.0106.932

Crankcase pressure too high (limit value 2)

TIM-ID: 0000029153 - 005

Red alarm – engine shutdown

Cause Corrective action

Crankcase extraction system 1. Reduce power.

obstructed or leaking. 2. Replace oil mist fine separator insert .

3. Contact Service.

44 | Troubleshooting | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

65 – LO P-Fuel

ZKP-Number: 2.0102.921

Fuel supply pressure too low (limit value 1)

Yellow alarm – warning

Cause Corrective action

Leaky or obstructed fuel lines or 1. Check fuel lines for leakage.

fuel filter. 2. Check fuel filter, low-pressure side.

3. Replace fuel filter (→ Page 123).

66 – SS P-Fuel

ZKP-Number: 2.0102.922

Fuel supply pressure too low (limit value 2)

Red alarm – engine shutdown

Cause Corrective action

Leaky or obstructed fuel lines or 1. Check fuel lines for leakage.

fuel filter. 2. Check fuel filter, low-pressure side.

3. Replace fuel filter (→ Page 123).

4. Contact Service.

67 – HI T-Coolant

ZKP-Number: 2.0120.931

Coolant temperature too high (limit value 1)

Yellow alarm – warning

Cause Corrective action

Coolant circuit not operating 1. Reduce power.

correctly (e.g. damage, leaks, 2. Check coolant circuit.

low coolant level).

68 – SS T-Coolant

ZKP-Number: 2.0120.932

Coolant temperature too high (limit value 2)

Red alarm – engine shutdown

Cause Corrective action

Coolant circuit not operating u Check coolant circuit.

TIM-ID: 0000029153 - 005

correctly (e.g. damage, leaks,

low coolant level).

MS150112/01E 2014-10 | Troubleshooting | 45

Downloaded from www.Manualslib.com manuals search engine

81 – AL Rail Leakage

ZKP-Number: 1.8004.046

Leakage

Yellow alarm – warning

Cause Corrective action

During start: Pressure gradient 1. Check engine for leaks.

in rail too low (HP system 2. Contact Service.

leaking, air in system).

During stop: Pressure gradient 1. Seal engine system.

in rail too high. 2. Contact Service.

82 – HI P-Fuel (Common Rail)

ZKP-Number: 2.0104.931

Rail pressure > set value

Red alarm – DBR fuel limitation, start of injection readjusted towards late

Cause Corrective action

HP fuel block jamming or HP 1. Check wiring (→ Page 189).

fuel control block wiring faulty. 2. Contact Service.

83 – LO P-Fuel (Common Rail)

ZKP-Number: 2.0104.921

Rail pressure < set value

Red alarm – DBR limitation

Cause Corrective action

HP fuel control block faulty or u Contact Service.

leakage in HP fuel system.

89 – SS Engine Speed too Low

ZKP-Number: 2.2500.030

Engine speed too low

Red alarm – engine shutdown

Cause Corrective action

Various causes possible. 1. Acknowledge alarm.

2. Observe additional messages.

TIM-ID: 0000029153 - 005

3. Contact Service.

46 | Troubleshooting | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

90 – SS Idle Speed Not Reached

ZKP-Number: 2.1090.925

Idling speed not attained

Red alarm – warning

Cause Corrective action

Various causes possible. 1. Observe additional messages.

2. Contact Service.

91 – SS Release Speed Not Reached

ZKP-Number: 2.1090.924

Runup speed was not attained

Red alarm – warning

Cause Corrective action

Various causes possible. 1. Observe additional messages.

2. Contact Service.

92 – SS Starter Speed Not Reached

ZKP-Number: 2.1090.923

Starter speed not reached

Red alarm – warning

Cause Corrective action

Starter rotates too slowly or 1. Observe additional messages.

does not rotate at all. 2. Contact Service.

93 – SS T-Preheat

ZKP-Number: 2.1090.922

Preheating temperature too low (limit value 2)

Red alarm – engine start interlock

Cause Corrective action

Coolant temperature for engine 1. Check preheating unit.

start too low because preheater 2. Contact Service.

is not working.

94 – LO T-Preheat

TIM-ID: 0000029153 - 005

ZKP-Number: 2.1090.921

Preheating temperature too low (limit value 1)

Yellow alarm – warning

Cause Corrective action

Coolant temperature for engine 1. Check preheating unit.

start too low because preheater 2. Contact Service.

is not working.

MS150112/01E 2014-10 | Troubleshooting | 47

Downloaded from www.Manualslib.com manuals search engine

95 – AL Priming Fault

ZKP-Number: 2.1090.920

Oil priming fault.

Yellow alarm – warning

Cause Corrective action

Priming oil pressure not 1. Check priming system.

reached. 2. Contact Service.

102 – AL Fuel Cons. Counter Defect

ZKP-Number: 1.8004.624

Fault in fuel checksum

Yellow alarm – warning

Cause Corrective action

Consumption meter faulty. u Contact Service.

104 – AL Eng Hours Counter Defect

ZKP-Number: 1.8004.623

Fault in operating hours monitoring system

Yellow alarm – warning

Cause Corrective action

Hour meter faulty. u Contact Service.

118 – LO ECU Supply Voltage

ZKP-Number: 2.0140.921

Supply voltage too low (limit value 1)

Yellow alarm – warning

Cause Corrective action

Supply voltage at engine 1. Check engine governor supply voltage.

governor too low. 2. Contact Service.

119 – LOLO ECU Supply Voltage

ZKP-Number: 2.0140.922

TIM-ID: 0000029153 - 005

Supply voltage too low (limit value 2)

Red alarm – start terminated

Cause Corrective action

Supply voltage at engine 1. Check engine governor supply voltage.

governor too low. 2. Contact Service.

48 | Troubleshooting | MS150112/01E 2014-10

Downloaded from www.Manualslib.com manuals search engine

120 – HI ECU Supply Voltage

ZKP-Number: 2.0140.931

Supply voltage too high (limit value 1)

Yellow alarm – warning

Cause Corrective action

Supply voltage at engine 1. Check engine governor supply voltage.

governor too high. 2. Contact Service.

121 – HIHI ECU Supply Voltage

ZKP-Number: 2.0140.932

Supply voltage too high (limit value 2)

Red alarm – start terminated or engine shutdown

Cause Corrective action

Supply voltage at engine 1. Check engine governor supply voltage.

governor too high. 2. Contact Service.

122 – HI T-ECU

ZKP-Number: 2.0132.921

Electronics temperature too high (limit value 1)

Yellow alarm – warning

Cause Corrective action

Electronics overheated. 1. Reduce power.

2. Improve engine room ventilation.

180 – AL CAN1 Node Lost

ZKP-Number: 2.0500.680

Connection to a node on CAN bus 1 failed

Yellow alarm – warning

Cause Corrective action

Connection to or communication 1. Check devices connected to CAN.

with a node at CAN bus 1 has 2. Check wiring (→ Page 189).

failed. 3. Contact Service.

181 – AL CAN2 Node Lost

TIM-ID: 0000029153 - 005

ZKP-Number: 2.0500.681

Connection to a node on CAN bus 2 failed

Yellow alarm – warning

Cause Corrective action

Connection to or communication 1. Check devices connected to CAN.

with a node at CAN bus 2 has 2. Check wiring (→ Page 189).

failed. 3. Contact Service.

MS150112/01E 2014-10 | Troubleshooting | 49

Downloaded from www.Manualslib.com manuals search engine

182 – AL CAN Wrong Parameters

ZKP-Number: 2.0500.682

Incorrect parameters at CAN

Yellow alarm – warning

Cause Corrective action

Incorrect parameter values u Contact Service.

entered in data record.

183 – AL CAN No PU Data

ZKP-Number: 2.0500.683

CAN PU data not present or available

Yellow alarm – warning

Cause Corrective action

The selected CAN mode 1. Check devices connected to CAN.

initializes communication by 2. Contact Service.

means of the PU data module. A

fault occurred during an attempt

to copy a received data module

to the engine governor.

184 – AL CAN PU Data Flash Error

ZKP-Number: 2.0500.684

CAN PU data flash fault

Cause Corrective action

A programming error occurred u Contact electronic Service.