QAP For Ducting V1 R0

QAP For Ducting V1 R0

Uploaded by

Hema NandhCopyright:

Available Formats

QAP For Ducting V1 R0

QAP For Ducting V1 R0

Uploaded by

Hema NandhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

QAP For Ducting V1 R0

QAP For Ducting V1 R0

Uploaded by

Hema NandhCopyright:

Available Formats

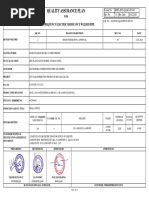

MANUFACTURER MANUFACTURING QUALITY PLAN PROJECT 1 x 800 TPD, 14.

5 MW WTE PLANT

ITEM QAP NO BOILER/QAP/007 PACKAGE BOILER PACKAGE

BOILER - DUCTING Rev 0

CUSTOMER M/s DUNDIGAL WASTE TO ENERGY PVT LTD

SUB - SYSTEM Date 03.06.2021

GREENESOL POWER SYSTEMS PVT. LTD.

FABRICATION OF FLUE GAS

M/s AVANT-GARDE SYSTEMS AND CONTROLS (P)

& AIR DUCTING & DUCT Page 1 of 1 CONSUTANT

LIMITED.

SUPPORT

INSPECTED BY

TYPE OF QUANTUM OF REFERENCE ACCEPTANCE FORMAT OF

SL.NO. OPERATION CHARACTERISTICS REMARKS

CHECK CHECK DOCUMENT NORMS RECORD M G C

1 2 3 4 5 6 7 8

1 RAW MATERIAL

Chemical,

Plates & rolled T.C Verification, Mechanical, Drawings & TC/Lab

1.1 100% Drawings & Spec P R R

sections Dimension Visual and Spec Report IS 2062 shall be used for Ducting.

Dimension

1.2 Plates Above 20 mm Thick UT 100% ASTM A 435 ASTM A 435 UT Report P R R

2 IN PROCESS

Witness/Verif

Welding WPS, PQR, Range of Qualifications WPS, PQR,

2.1 ication 100% ASME sec. IX ASME sec. IX P R R

WPQR and essential variables WPQR SYSTEMS AND CONTROLS (P) LTD

Document

Visual and Drawings &

2.2 Bought Out items Size, Workmanship Random Drawings & Spec IR P R R

Dimension Spec

3 FABRICATION 2020285 E-mail 04.06.2021 04.06.2021

Visual,

3.1 Marking, Cutting Visual and Measurement Dimension 100% Drawings Drawings IR P R R

and Profile

Visual,

Alignment

Visual, Alignment and

3.2 Fit up and Random Drawings Drawings IR P R RW G. Bhuvanesh 05.05.2021

Measurement

Measuremen

t

Visual, Identification Visual &

3.3 Welding Random Drawings Drawings IR P R RW

Mark/DPT 10% DPT

4 FINAL INSPECTION

Final Inspection for Visual and

4.1 Dimensions before Visual and Measurement Measuremen Random Drawings Drawings IR P W W

painting t

Visual &

Surface preparation, Drawing Drawing/PO/Contr

4.2 Visual & measurement measuremen Random IR P R RW

Painting & Stenciling /PO/Contract act

t

Complete

Despatch

Final inspection Review of all previous test Drawing, PO & Insp.Verification

4.3 Verification Random Clearance P R RW

Release for Despatch reports QP of all reports as

Report

per QP

LEGEND

M - MANUFACTURER

G - GREENESOL POWER SYSTEMS P - PERFORM

C - CUSTOMER / CONSULTANT R - REVIEW IR - INSPECTION REPORT Note: Ducting plates shall be dispatched in

WPS - WELDING PROCEDURE SPECIFICATION RW- RANDOM WITNESS RT - RADIOGRAPHIC TEST knocked down condition. Assembly, welding,

PQR - PROCEDURE QUALIFICATION RECORD H - HOLD PT - DIE PENETRANT TEST Smoke test & Kerosene test shall be carried out

T.C - TEST CERTIFICATE W - WITNESS UT - ULTRASONIC TEST at site, which shall be covered in FQAP.

M - MANUFACTURER

You might also like

- Domestic Cooking Appliances Burning Gas: Part 1-1: Safety - GeneralDocument152 pagesDomestic Cooking Appliances Burning Gas: Part 1-1: Safety - GeneralDDA7100% (2)

- Consumables NormsDocument24 pagesConsumables NormsHema Nandh100% (3)

- MTC-2 - Service STRCDocument1 pageMTC-2 - Service STRCHema Nandh100% (1)

- Hydro Test Loop File Index FormatDocument22 pagesHydro Test Loop File Index FormatHema Nandh100% (2)

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocument15 pagesQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarNo ratings yet

- Ductable Split MTODocument4 pagesDuctable Split MTOMuhammedShafi100% (1)

- Flash and Fire Points of Liquid Fuels and Grease Drop TestDocument27 pagesFlash and Fire Points of Liquid Fuels and Grease Drop TestJerico Llovido0% (2)

- Audi Q7 Battery Terminal Engine ManagementDocument18 pagesAudi Q7 Battery Terminal Engine ManagementAnonymous t1FCvPRSa100% (2)

- Field Joint Coating Installation ProcedureDocument2 pagesField Joint Coating Installation Procedureunix man100% (1)

- Piping Fabrication Installation QCP On SiteDocument1 pagePiping Fabrication Installation QCP On SiteTarun PatelNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- Job Procedure For Hot Insulation Work of Piping & Equipment1Document13 pagesJob Procedure For Hot Insulation Work of Piping & Equipment1ravi00098100% (1)

- PIPE SUPPORT-STR - Welding Inspection ReportDocument1 pagePIPE SUPPORT-STR - Welding Inspection ReportBWQ100% (1)

- F-035 (Valve Erection Format)Document1 pageF-035 (Valve Erection Format)Rajeev Kumar100% (1)

- Sample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Document2 pagesSample Quality Assurance Plan For Welded Ss Fittings: 25% by 1 After 100% by 2Dhvanit JoshiNo ratings yet

- Bs Tech: Electrodes Baking and Holding RegisterDocument1 pageBs Tech: Electrodes Baking and Holding RegisterRhannie GarciaNo ratings yet

- Daily Welding Report: Quality Control FormDocument1 pageDaily Welding Report: Quality Control FormashwinNo ratings yet

- Safe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallDocument1 pageSafe Distance For Radiographic Plan: Week Day Curie Unshielded Collimator T-Wall Collimator+T-WallHarun Akkaya100% (1)

- Method Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Document9 pagesMethod Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Delil Ozan100% (1)

- Welder Qualification Test - As Run Sheet: Weld Details Filler Shield Welding ParametersDocument1 pageWelder Qualification Test - As Run Sheet: Weld Details Filler Shield Welding ParametersGopalakrishnan GovindarajNo ratings yet

- Blasting & Painting ReportDocument2 pagesBlasting & Painting ReportSanjay KumarNo ratings yet

- Itp - 002 - Duct Installation - IfrDocument3 pagesItp - 002 - Duct Installation - IfrMari BelajarNo ratings yet

- Flux Baking RegisterDocument4 pagesFlux Baking RegistersurwaneNo ratings yet

- Quality Assurance Plan (Qap) For L.T.C.S. FittingsDocument2 pagesQuality Assurance Plan (Qap) For L.T.C.S. FittingsVIVEK TIWARINo ratings yet

- Tuv India Private Limited: Inspection Visit ReportDocument2 pagesTuv India Private Limited: Inspection Visit Reportdavid dagarNo ratings yet

- Welding Procedure Specification (WPS) : Page: 1/1Document5 pagesWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNo ratings yet

- ITP SampleDocument6 pagesITP SampleMat RidhanNo ratings yet

- Material Inspection Report 6426-1Document5 pagesMaterial Inspection Report 6426-1คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Al PSW FormatDocument2 pagesAl PSW Formatabhayjha1988No ratings yet

- Inspection Test Plan For Radiography: SR - No Activities by Ieccl Remarks BY Mecon/Gail Docs To Be Submitted by IecclDocument1 pageInspection Test Plan For Radiography: SR - No Activities by Ieccl Remarks BY Mecon/Gail Docs To Be Submitted by IecclRajiv KumarNo ratings yet

- Method Statement For Installation of Fire Protection SystemDocument34 pagesMethod Statement For Installation of Fire Protection SystemRM ENTERPRISESNo ratings yet

- TSR016 Ball ValvesDocument18 pagesTSR016 Ball Valvesbmanojkumar16No ratings yet

- Precision Storage Vessels PVT LTD: Pressure Test ReportDocument2 pagesPrecision Storage Vessels PVT LTD: Pressure Test ReportSenthil Kumaran100% (1)

- WPS-PQR - PipingDocument14 pagesWPS-PQR - PipingCharwin PicaoNo ratings yet

- Steel Structure Fabrication Report: Page 1/1Document8 pagesSteel Structure Fabrication Report: Page 1/1คุณพ่อน้อง บิ๊กบอสNo ratings yet

- Wps PQR Spec IndexDocument1 pageWps PQR Spec IndexTridib DeyNo ratings yet

- Radiation Safety Distance DiagramDocument3 pagesRadiation Safety Distance DiagramEswaranNo ratings yet

- QAP For Overall Mechanical ActivitiesDocument2 pagesQAP For Overall Mechanical ActivitiesMaheshwar polepallyNo ratings yet

- Itp For STR Steel WorksDocument9 pagesItp For STR Steel WorksGauravSinghNo ratings yet

- F-034 (Piping Dismantling Format)Document1 pageF-034 (Piping Dismantling Format)Rajeev KumarNo ratings yet

- QAP New Customer Nov23Document1 pageQAP New Customer Nov23RND DRAWNo ratings yet

- SATR-A-2002 Calibration Test Report-Pressure GaugeDocument1 pageSATR-A-2002 Calibration Test Report-Pressure GaugeAnonymous S9qBDVkyNo ratings yet

- Welder Test Param19!03!201211Document151 pagesWelder Test Param19!03!201211VapaVapaNo ratings yet

- Dimensional Tolerances of Fabricated PipesDocument1 pageDimensional Tolerances of Fabricated PipesMemed Permadi SatriyoNo ratings yet

- Vishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124Document2 pagesVishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124sanil50% (2)

- Quality Plan Fabrication and Installation of Silencer For BN4 & BN5Document1 pageQuality Plan Fabrication and Installation of Silencer For BN4 & BN5Aldrin HernandezNo ratings yet

- WCBDocument5 pagesWCBSuresh KrishnanNo ratings yet

- 07blasting and Painting ReportDocument2 pages07blasting and Painting ReportVenkateswaraRaoNo ratings yet

- SC09FSSDocument2 pagesSC09FSSsureshkanuboyinaNo ratings yet

- Neoprene Data SheetDocument1 pageNeoprene Data SheetsuriantoNo ratings yet

- Heavy Fab Process ChartDocument1 pageHeavy Fab Process ChartEmmanuel ofowuNo ratings yet

- Pipe Insulation: Qa / QC FormDocument1 pagePipe Insulation: Qa / QC FormShyam Sundar GayenNo ratings yet

- Yanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationDocument5 pagesYanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationHARSHAL100% (2)

- Standard QAPDocument9 pagesStandard QAPsivaNo ratings yet

- A05 004 Inspection Test Plan Shell Tube Heat Exchangers 5 210D HA 01 A B C D PDFDocument14 pagesA05 004 Inspection Test Plan Shell Tube Heat Exchangers 5 210D HA 01 A B C D PDFfdfazfzNo ratings yet

- QC Dossier 1Document1 pageQC Dossier 1VishnuGKNo ratings yet

- QAPDocument6 pagesQAPRahul ChandanNo ratings yet

- Ncpfirst - X-Form - PDF Example: (Epc - Dedicated Front Cover Sheet Here)Document11 pagesNcpfirst - X-Form - PDF Example: (Epc - Dedicated Front Cover Sheet Here)mohammed shaffi abdul rahman0% (1)

- Waad Al-Shamal ISCCPP: CONTRACT NO.4500869246Document1 pageWaad Al-Shamal ISCCPP: CONTRACT NO.4500869246ananth rajanNo ratings yet

- FInal QAP HDPE WeldingDocument2 pagesFInal QAP HDPE Weldingkannagi198No ratings yet

- Sample Quality Assurance Plan For Welded Cs Butt Weld Fittings (Sa 234)Document2 pagesSample Quality Assurance Plan For Welded Cs Butt Weld Fittings (Sa 234)Dhrumil ChauhanNo ratings yet

- Certificate of Origin Form F For China-Chile FTADocument2 pagesCertificate of Origin Form F For China-Chile FTAinspectormetNo ratings yet

- Protocol Column AlignmentDocument9 pagesProtocol Column AlignmentManikandan elumalaiNo ratings yet

- Form UT, MT, PT, RTDocument5 pagesForm UT, MT, PT, RTLuong Ho Vu100% (1)

- Piping Daily Fit Up Quality Control and Inspection Report FormDocument1 pagePiping Daily Fit Up Quality Control and Inspection Report FormOnM deptNo ratings yet

- Acc Fqap Rev 1 - DundigalDocument2 pagesAcc Fqap Rev 1 - DundigalHema NandhNo ratings yet

- Acc Fqap Rev 1 - DundigalDocument2 pagesAcc Fqap Rev 1 - DundigalHema NandhNo ratings yet

- Epilux 4 Zinc Rich PrimerDocument2 pagesEpilux 4 Zinc Rich PrimerHema NandhNo ratings yet

- Piping EstimationDocument19 pagesPiping EstimationHema NandhNo ratings yet

- Acc - Fqap - P3011 - R2 - RewaDocument2 pagesAcc - Fqap - P3011 - R2 - RewaHema NandhNo ratings yet

- MR Page (1033)Document1 pageMR Page (1033)Hema NandhNo ratings yet

- VRMP REFINERY Milestone Summary For Project..Document2 pagesVRMP REFINERY Milestone Summary For Project..Hema NandhNo ratings yet

- Ahp 2X660 (WPS) )Document17 pagesAhp 2X660 (WPS) )Hema NandhNo ratings yet

- Signature Not Verified: Digitally Signed by Rakesh Sharma Date: 2012.08.10 18:01:23 IST Reason: CAT I Location: NtpceocDocument2 pagesSignature Not Verified: Digitally Signed by Rakesh Sharma Date: 2012.08.10 18:01:23 IST Reason: CAT I Location: NtpceocHema NandhNo ratings yet

- Jagriti Steel Pvt. LTD.: Test Cerctificate For Hot Rolled Medium & High Tensile Structural SteelDocument1 pageJagriti Steel Pvt. LTD.: Test Cerctificate For Hot Rolled Medium & High Tensile Structural SteelHema NandhNo ratings yet

- HRSG PDFDocument248 pagesHRSG PDFHema Nandh100% (1)

- WLDNG ElectrodeDocument1 pageWLDNG ElectrodeHema NandhNo ratings yet

- Pipe Support StandardDocument32 pagesPipe Support StandardHema Nandh100% (1)

- Shop Inspections of Alloy PipesDocument45 pagesShop Inspections of Alloy PipesHema NandhNo ratings yet

- Session I - II - Power Cycle Piping PDFDocument122 pagesSession I - II - Power Cycle Piping PDFHema NandhNo ratings yet

- RRL of Effectiveness of Baking Soda and Vinegar As An Alternative Fire ExtinguisherDocument2 pagesRRL of Effectiveness of Baking Soda and Vinegar As An Alternative Fire ExtinguisherEarl Crystal67% (3)

- Telecom Data QueryDocument21 pagesTelecom Data QueryHassan Mody TotaNo ratings yet

- Influence of Post-Heat Treatment On Microstructure, Mechanical, and Wear Properties of Maraging Steel Fabricated Using Direct Metal Laser Sintering TechniqueDocument17 pagesInfluence of Post-Heat Treatment On Microstructure, Mechanical, and Wear Properties of Maraging Steel Fabricated Using Direct Metal Laser Sintering TechniqueANIGANI SUDARSHAN REDDYNo ratings yet

- Brick MaterialsDocument29 pagesBrick MaterialsSyazwanatiyahNo ratings yet

- CfmotoDocument155 pagesCfmotoUmar ShamsudinNo ratings yet

- Extron Price ListDocument96 pagesExtron Price ListYoav Carribana100% (1)

- Prevention of Evaporation Losses From Gasoline Storage Tanks'Document6 pagesPrevention of Evaporation Losses From Gasoline Storage Tanks'LAURA LUC�A ATENCIA CASTILLONo ratings yet

- C&D KCR Manual PDFDocument6 pagesC&D KCR Manual PDFSteven MarksNo ratings yet

- Analiza OpterecenjaDocument44 pagesAnaliza OpterecenjaMilosNo ratings yet

- WWTP Package Load List (Revd) 3-2-11Document2 pagesWWTP Package Load List (Revd) 3-2-11Alaa RamadanNo ratings yet

- Building Materials: 1. Particle Board 2. Block BoardDocument31 pagesBuilding Materials: 1. Particle Board 2. Block BoardArnav DasaurNo ratings yet

- Geometrical Tolerancing On Technical Drawings: IS: 8000 (Part IV) - 1976Document7 pagesGeometrical Tolerancing On Technical Drawings: IS: 8000 (Part IV) - 1976jijinjohnNo ratings yet

- Flowhead 10K: Welltest Process DiagramDocument2 pagesFlowhead 10K: Welltest Process Diagramanugrah_dimas5441100% (1)

- Artilce - Potential Detrimental Consequences of Excessive PWHT On Steel PropertiesDocument8 pagesArtilce - Potential Detrimental Consequences of Excessive PWHT On Steel PropertieswholenumberNo ratings yet

- Parts List FerraraDocument8 pagesParts List Ferraramark_59No ratings yet

- Stainless Steel Centrifugal Pumps CP-ST4 CP-ST6Document8 pagesStainless Steel Centrifugal Pumps CP-ST4 CP-ST6Enrico MazzettoNo ratings yet

- BC2-Double 2m X 2mDocument1 pageBC2-Double 2m X 2moseni momoduNo ratings yet

- A Report On The Exceptional Superhydrophobicity of Slippery Liquid Infused Porous Surface and The Recent Advancements in Boosting Its DurabilityDocument38 pagesA Report On The Exceptional Superhydrophobicity of Slippery Liquid Infused Porous Surface and The Recent Advancements in Boosting Its DurabilityBangla BoyNo ratings yet

- I Et 301000 1200 540 p4x 001 - A - Prelim PDFDocument44 pagesI Et 301000 1200 540 p4x 001 - A - Prelim PDFzsx zsxNo ratings yet

- 8.5 Reactions of Metals With Dilute AcidsDocument18 pages8.5 Reactions of Metals With Dilute Acidsdua ahmad100% (2)

- Safety ChecklistDocument1 pageSafety ChecklistSvetoslav Stoimenov100% (1)

- Sihi 105Document8 pagesSihi 105Sandi AslanNo ratings yet

- Scope of Work-Fabrication of Pressure VesselsDocument3 pagesScope of Work-Fabrication of Pressure VesselsAsad Khan100% (2)

- Valves CatalogueDocument33 pagesValves CatalogueDheeraj ThakurNo ratings yet

- Material and Design Optimization For An Aluminum Bike FrameDocument101 pagesMaterial and Design Optimization For An Aluminum Bike Frame69x4No ratings yet

- Evaluation of Leaching Parameters For A Refractory GoldDocument10 pagesEvaluation of Leaching Parameters For A Refractory Goldboanerges wino pattyNo ratings yet