586 Code - Engine Speed Control Test

586 Code - Engine Speed Control Test

Uploaded by

Dibas BaniyaCopyright:

Available Formats

586 Code - Engine Speed Control Test

586 Code - Engine Speed Control Test

Uploaded by

Dibas BaniyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

586 Code - Engine Speed Control Test

586 Code - Engine Speed Control Test

Uploaded by

Dibas BaniyaCopyright:

Available Formats

Page 1 of 4

Previous Screen

Welcome: j250sgm

Product: EXCAVATOR

Model: 323D3 EXCAVATOR FEY

Configuration: 323D3 Excavator FEY00001-UP (MACHINE) POWERED BY C7.1 Engine

Troubleshooting

320D3 and 323D3 Excavators Machine Electronic Control System

Media Number -M0094857-00 Publication Date -01/08/2015 Date Updated -25/07/2018

i07450729

Engine Speed Control - Test

SMCS - 7332-038-VF

Machine ECM

The following code is associated with the engine speed dial related to the Machine ECM.

Table 1

Machine ECM (MID 299)

DTC Code Description System Response

586-12 Engine Speed Dial Switch : Bad device or component Cannot control engine speed.

Possible causes for an FMI 12 Diagnostic code are:

• The dial switch has failed.

• The engine governor control has failed.

• The CAN Data Link between the Switch Panel and the Machine ECM is working intermittently or has

failed.

• The machine harness to the dial switch or the governor control has failed.

• The ECM has failed. This situation is unlikely.

Page 2 of 4

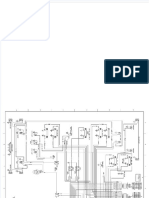

Illustration 1 g03860086

Engine Speed (Governor control) schematic

Note: The diagram above is a simplified schematic of the Machine ECM connections. The schematic is

electrically correct. However, not all of the possible harness connectors are shown. Refer to the latest revision

of Electrical Schematic, M0094859 for 320D3 and M0094901 for 323D3 excavator electrical systems.

Diagnostic Trouble Code Procedure

Note: Prior to beginning this procedure, inspect the harness connectors that are involved in this circuit. Poor

connections can often be the cause of a problem in an electrical circuit. Verify that all connections in the

circuit are clean, secure, and in good condition. If a problem with a connection is found, correct the problem

and verify that the diagnostic code is active before performing a troubleshooting procedure.

Table 2

Troubleshooting Test Steps Values Results

OK - DTC 586-12 is active without either DTC

246-9 or DTC 246-19 being active.

1. Check For An Active Diagnostic

Code

Proceed to Test Step 2.

A. Turn the key start switch to the

NOT OK - Diagnostic code DTC 586-12 AND

ON position.

DTC 246-9 or DTC 246-19 are active.

Diagnostic

B. Use Cat ET to check for all active code CID 586

Repair: Follow the procedure for

diagnostic codes. FMI 12 is

troubleshooting the code for the data link circuit.

active.

B. Check for DTC 586-12.

Result: If DTC code 586-12 is no longer active,

return the machine to service.

C. Check for DTC 246-9 or DTC

246-19.

If, after troubleshooting the data link, DTC 586-

12 is active, proceed to Test Step 2.

2. Inspect The Switch Panel OK - The machine harness connectors are tight

Harness Connection The machine and free of corrosion.

harness

A. Turn the disconnect switch to the connectors are Proceed to Test Step 3.

OFF position. tight and free of

corrosion. NOT OK - The machine harness connectors are

B. Inspect the harness connector in need of repair.

making sure that the connector is

clean and tight. Repair: Repair or replace the machine harness.

C. Check the connector for proper Proceed to Test Step 5.

Page 3 of 4

mating.

D. Check the connector. Ensure that

the wires are secured tightly into the

connector. Take care not to pull the

wire out of the connector.

E. Check any exposed wires at the

connector for nicks or signs of

abrasion.

F. Check for moisture inside the

connector.

G. Check the connector for dirty

contacts or corroded contacts.

H. Check each pin and each socket

of the switch panel harness

connectors. Ensure that the contacts

are properly installed. The contacts

should mate correctly when the two

pieces of the connector are placed

together.

3. Check The Governor Signal

Circuit

OK - The resistance is less than 5 Ω. The

NOTE: Reference the Illustration in resistance of the circuit is correct.

this section of the manual for Step 3.

A. The disconnect switch and the Proceed to Test Step 4.

key start switch remain in the OFF

position. NOT OK - The resistance is greater than 5K Ω .

The resistance of the circuit is not correct.

B. Disconnect the ECM and the

"governor" control from the machine Repair: Replace the machine harness or repair

harness. the machine harness.

The reading is

less than 5 Ω.

C. Use a 151-6320 Removal Tool to Note: A resistance that is greater than 5 Ω but

remove the wire M736-BU(Blue) less than 5K Ω would indicate a loose connection

from the connector at the governor. or a corroded connection in the circuit. A check

of all connector locations within the circuit is

D. Connect wire M736-BU(Blue)to recommended. A resistance measurement that is

a ground location, using a jumper greater than 5K Ω would indicate an open in the

wire. circuit.

E. At the Machine ECM harness Proceed to Test Step 4.

connector, measure the resistance at

Pin Location 24.

4. Check The Signal Circuit For A OK - All measurements are greater than 5K Ω.

Short Each reading is

greater than 5K Proceed to Test Step 5.

A. The disconnect switch and the Ω.

key start switch remain in the OFF NOT OK - Resistance is less than 5 Ω, a short

position. The governor and Machine exists in the signal circuit.

ECM remain disconnected from the

wiring harness. Repair: Replace the machine harness or repair

the machine harness.

Page 4 of 4

B. Remove the jumper wire that was

installed in the previous Test Step. Note: A resistance that is greater than 5 Ω but

less than 5K Ω would indicate a loose connection

C. Reconnect wire M736-BU(Blue) or a corroded connection in the circuit. A check

to the connector at the governor. of all connector locations within the circuit is

recommended. A resistance measurement that is

D. At the harness connector for the greater than 5K Ω would indicate an open in the

Machine ECM, measure the circuit.

resistance between pin location 24

and all sources of +battery. STOP

OK - The diagnostic code is no longer active.

Repair: The initial diagnostic code could have

been caused by a poor electrical connection or a

short at one of the harness connectors. Resume

normal machine operation.

5. Check If The Diagnostic Code

Remains

STOP

A. Inspect the contacts of the harness

NOT OK - The diagnostic code is active.

connectors and clean the contacts.

Repair: If the cause of the diagnostic code is not

B. Reconnect all harness connectors.

found, the Engine Speed Switch may have failed.

Diagnostic

Since the switch is integrated into the Switch

C. Turn the disconnect switch and code is no

Panel, the entire switch panel must be replaced. If

the key start switch to the ON longer present.

the code continues to be active, the Machine

position.

ECM may have failed.

A failure of the Machine ECM is unlikely. Prior

D. Operate the machine.

to replacing an ECM, always contact the

Technical Communicator for your dealership for

E. Check if diagnostic code is

possible consultation with Caterpillar. This

active.

consultation may effect repair time. If the ECM

requires replacement, see the Troubleshooting,

"ECM - Replace" section of this manual for

additional information.

STOP

Copyright 1993 - 2018 Caterpillar Inc. Sun Dec 9 13:49:32 UTC+0530 2018

All Rights Reserved. j250sgm

Private Network For SIS Licensees.

You might also like

- VERMEER SC852 - MaINTENANCE MANUALDocument98 pagesVERMEER SC852 - MaINTENANCE MANUALAbel NuñzNo ratings yet

- Ef5503 14Document1 pageEf5503 14Rudi Abu ZahraNo ratings yet

- 981 - RTC-80100 IiDocument234 pages981 - RTC-80100 IiHugo GomezNo ratings yet

- Transmission Wiring PDFDocument1 pageTransmission Wiring PDFmarsh2002No ratings yet

- 189-fc 2182Document3 pages189-fc 2182luis zapataNo ratings yet

- 14-SAMSS-534 Oh TransformerDocument8 pages14-SAMSS-534 Oh TransformerHatemS.MashaGbehNo ratings yet

- 923 - 2653BPrecisionCut2-Operator ManualDocument9 pages923 - 2653BPrecisionCut2-Operator ManualJohn Z100% (1)

- 845B Error Codes PDFDocument11 pages845B Error Codes PDFJUNA RUSANDI S100% (2)

- Plano Electrico Cb22bDocument17 pagesPlano Electrico Cb22bRichard Zapata100% (2)

- Plano 815FDocument2 pagesPlano 815FRASMAJONNo ratings yet

- ASC110-150MrCT3 ENDocument10 pagesASC110-150MrCT3 ENDavid Apaza HurtadoNo ratings yet

- Control de Trasm 410g. 2Document2 pagesControl de Trasm 410g. 2davidNo ratings yet

- error Е396Document1 pageerror Е396Aleksey Zhmaev0% (2)

- CP-323C and CS-323C Vibratory Compactor Electrical SystemDocument2 pagesCP-323C and CS-323C Vibratory Compactor Electrical SystemFrederiko MolanNo ratings yet

- CP-433E, CS-423E, and CS-433E Electrical System Vibratory CompactorDocument2 pagesCP-433E, CS-423E, and CS-433E Electrical System Vibratory CompactorHector VallesNo ratings yet

- Codigo 588.09 de d6tDocument4 pagesCodigo 588.09 de d6tericNo ratings yet

- Governor Actuator - Calibrate: Pruebas y AjustesDocument4 pagesGovernor Actuator - Calibrate: Pruebas y AjustesAugusto BellezaNo ratings yet

- Esquema Eletrico Geral Pc200-8Document3 pagesEsquema Eletrico Geral Pc200-8Egon HenriqueNo ratings yet

- Desarmado & Armado Eje Trasero 426BDocument14 pagesDesarmado & Armado Eje Trasero 426BAbelardo Pina100% (2)

- Sistema HidraulicoDocument4 pagesSistema Hidraulicojulio peña limaNo ratings yet

- Diag Elect Kenr3518kenr3518 01Document2 pagesDiag Elect Kenr3518kenr3518 01julio cesar100% (1)

- Fallo Psid 96 NiveladoraDocument1 pageFallo Psid 96 NiveladoraAlfonso BerRamNo ratings yet

- 95ZV 2 (EU Trouble)Document111 pages95ZV 2 (EU Trouble)Halil KaraNo ratings yet

- Fault Code 253 Engine Oil Level - Data Valid But Below Normal Operational Range - Most Severe LevelDocument4 pagesFault Code 253 Engine Oil Level - Data Valid But Below Normal Operational Range - Most Severe LevelAhmedmahNo ratings yet

- Illustration 1 g03326191 Schematic of The Action AlarmDocument3 pagesIllustration 1 g03326191 Schematic of The Action AlarmJuan LopezNo ratings yet

- Failure Code (DXA0KA) PC-EPC Sol Open Circuit: SEN01887-02 40 TroubleshootingDocument2 pagesFailure Code (DXA0KA) PC-EPC Sol Open Circuit: SEN01887-02 40 Troubleshootingale ale0% (1)

- 46.2 Classification of Failure and Troubleshooting: 46. Trouble Shooting (By Error Codes)Document3 pages46.2 Classification of Failure and Troubleshooting: 46. Trouble Shooting (By Error Codes)Luis M. Quilca0% (1)

- 330 GC - Plano HidráulicoDocument12 pages330 GC - Plano Hidráulicojgonzalesm83No ratings yet

- Anulador Del NeutralizadorDocument3 pagesAnulador Del NeutralizadormartinaguilarespinoNo ratings yet

- Safety Hints TransportationDocument261 pagesSafety Hints TransportationJosé PinzonNo ratings yet

- Manual Cat 320lDocument2 pagesManual Cat 320lRaphael BuenoNo ratings yet

- Dokumen - Tips - Diagrama Electrico Grua TerexDocument14 pagesDokumen - Tips - Diagrama Electrico Grua TerexLeopoldo Grajales BistrainNo ratings yet

- Manual de Taller sk350 PDFDocument31 pagesManual de Taller sk350 PDFLeo Perez100% (1)

- FAULT CODE 3137 - Metering Unit - Open LoadDocument5 pagesFAULT CODE 3137 - Metering Unit - Open LoadGarcia CruzNo ratings yet

- SM-VOLVO BM L90C WHEEL LOADER Service Repair Manual pt.1Document19 pagesSM-VOLVO BM L90C WHEEL LOADER Service Repair Manual pt.1jose cuevas100% (2)

- Esquema Electrico Cargador Caterpillar 938g II PDFDocument32 pagesEsquema Electrico Cargador Caterpillar 938g II PDFDarwing A. RodriguesNo ratings yet

- 966H Special Tool ListDocument12 pages966H Special Tool Listford62bNo ratings yet

- Diagrama Electrico 950GDocument2 pagesDiagrama Electrico 950GpercyNo ratings yet

- Esquema Cat 320l - 2 PDFDocument2 pagesEsquema Cat 320l - 2 PDFAdrian Martin100% (1)

- 621E & 623E Wheel Tractor-Scrapers Electrical System: Machine Harness Connector and Component LocationsDocument2 pages621E & 623E Wheel Tractor-Scrapers Electrical System: Machine Harness Connector and Component LocationsGilvan JuniorNo ratings yet

- S570 Elec Acs-Sjc-Op 7210761 PDFDocument15 pagesS570 Elec Acs-Sjc-Op 7210761 PDFEvert Vargas TorrezNo ratings yet

- Plano ElectricoDocument25 pagesPlano ElectricoJoseAntonioQuintanillaPoncedeLeon100% (1)

- FX-375 ServiceDocument21 pagesFX-375 ServiceMauro PerezNo ratings yet

- Ec300d Bric Hyd Eng-Gb20025147b HDocument30 pagesEc300d Bric Hyd Eng-Gb20025147b Hgamalsuam9No ratings yet

- SD160, SD200: Volvo Single Drum CompactorsDocument4 pagesSD160, SD200: Volvo Single Drum CompactorstoufikNo ratings yet

- Dokumen - Tips Using The 1u5470 Engine Pressure GroupDocument11 pagesDokumen - Tips Using The 1u5470 Engine Pressure Grouppedro sosaNo ratings yet

- Sistema Electrico Paystar 2008 Conectores S08326bDocument160 pagesSistema Electrico Paystar 2008 Conectores S08326bJohn Fredy Palacio G.No ratings yet

- Isuzu - 4JJ1 Tier 4 (2011)Document12 pagesIsuzu - 4JJ1 Tier 4 (2011)Ebied YoussefNo ratings yet

- Circuito Hidraulico Trasmision CAT 966GDocument17 pagesCircuito Hidraulico Trasmision CAT 966GhectorNo ratings yet

- Ef3602 9Document2 pagesEf3602 9AwanNo ratings yet

- Diagrama Hidráulico CA512Document16 pagesDiagrama Hidráulico CA512SAMİ ENİS ARIOĞLUNo ratings yet

- GROUP 12 PROLIX SWITCH (Up To # 0062) : 1. Operating Principle Wiring DiagramDocument1 pageGROUP 12 PROLIX SWITCH (Up To # 0062) : 1. Operating Principle Wiring DiagramSaidi JalelNo ratings yet

- 821 C Circuito HidráulicoDocument1 page821 C Circuito HidráulicoMauricio SimonNo ratings yet

- Transmission Diagnostic Trouble Codes F343-F348Document2 pagesTransmission Diagnostic Trouble Codes F343-F348Lupin GonzalezNo ratings yet

- Diagrama Electrico de Transmcion 160HDocument3 pagesDiagrama Electrico de Transmcion 160HJuan CarlosNo ratings yet

- Test 924G, Pilot System PressureDocument3 pagesTest 924G, Pilot System Pressuremijael1393100% (1)

- Cummins: Fault Code: 141 PID: P100 SPN: 100 FMI: 4Document4 pagesCummins: Fault Code: 141 PID: P100 SPN: 100 FMI: 4Enrrique Lara100% (2)

- 287 - 288 Codes - Window Wiper Delay TestDocument5 pages287 - 288 Codes - Window Wiper Delay TestDibas BaniyaNo ratings yet

- Troubleshooting 320D-2 WBYDocument110 pagesTroubleshooting 320D-2 WBYasyuzwarNo ratings yet

- Alarm - Test: TroubleshootingDocument8 pagesAlarm - Test: TroubleshootingMbahdiro Kolenx100% (1)

- 1440 - 2265 - 2266 Codes Sensor TestDocument8 pages1440 - 2265 - 2266 Codes Sensor TestDibas BaniyaNo ratings yet

- 287 - 288 Codes - Window Wiper Delay TestDocument5 pages287 - 288 Codes - Window Wiper Delay TestDibas BaniyaNo ratings yet

- DibasDocument138 pagesDibasDibas BaniyaNo ratings yet

- 17 - 374 - 581 - 598 - 735 - 1160 - 1525 - 1590 Codes - Solenoid TestDocument7 pages17 - 374 - 581 - 598 - 735 - 1160 - 1525 - 1590 Codes - Solenoid TestDibas BaniyaNo ratings yet

- Fluid MechanicsDocument114 pagesFluid MechanicsDibas BaniyaNo ratings yet

- Champi MaiDocument3 pagesChampi MaiDibas BaniyaNo ratings yet

- ZF Trans-1Document42 pagesZF Trans-1Dibas BaniyaNo ratings yet

- Electrical SchematicDocument14 pagesElectrical SchematicDibas BaniyaNo ratings yet

- Hanuman ConstructionDocument3 pagesHanuman ConstructionDibas BaniyaNo ratings yet

- Nepalgung PPT - DEC'022Document15 pagesNepalgung PPT - DEC'022Dibas BaniyaNo ratings yet

- Mahankal First 250hrsDocument3 pagesMahankal First 250hrsDibas BaniyaNo ratings yet

- Maintenance Chart and PriceDocument21 pagesMaintenance Chart and PriceDibas BaniyaNo ratings yet

- Astha Nirman SewaDocument3 pagesAstha Nirman SewaDibas BaniyaNo ratings yet

- SudanDocument1 pageSudanDibas BaniyaNo ratings yet

- 1104C-E44 System Operaton Testing AdjustingDocument64 pages1104C-E44 System Operaton Testing AdjustingDibas BaniyaNo ratings yet

- Vacancy Notice 2079 PDFDocument8 pagesVacancy Notice 2079 PDFDibas BaniyaNo ratings yet

- Senior Technician (A & C), Level 5Document7 pagesSenior Technician (A & C), Level 5Dibas BaniyaNo ratings yet

- TT TRT 2000 - CTCDocument4 pagesTT TRT 2000 - CTCDibas BaniyaNo ratings yet

- DGS Paper Authorization Form English - FillableDocument1 pageDGS Paper Authorization Form English - FillableDibas BaniyaNo ratings yet

- Propel G20 ProtectedDocument82 pagesPropel G20 ProtectedDibas BaniyaNo ratings yet

- Detuned, Series Filter Reactor: For Power Factor Correction CapacitorDocument4 pagesDetuned, Series Filter Reactor: For Power Factor Correction Capacitorctxd758n100% (1)

- Lvis09axsfy23 5c300sa002sDocument1 pageLvis09axsfy23 5c300sa002sVishal SharmaNo ratings yet

- Design Software 1 PDFDocument2 pagesDesign Software 1 PDFalok bhatnagarNo ratings yet

- Terminacion AbbDocument28 pagesTerminacion AbbAnonymous oKr1c2WNo ratings yet

- As 60947.5.1-2004 Low-Voltage Switchgear and Controlgear Control Circuit Devices and Switching Elements - EleDocument10 pagesAs 60947.5.1-2004 Low-Voltage Switchgear and Controlgear Control Circuit Devices and Switching Elements - EleSAI Global - APACNo ratings yet

- ch19 DCMotors PDFDocument38 pagesch19 DCMotors PDFmehralsmenschNo ratings yet

- Am CircuitsDocument14 pagesAm CircuitsIngkz Jerae100% (1)

- PHD Thesis Raghbendra TiwariDocument189 pagesPHD Thesis Raghbendra Tiwariraghbendrat3884No ratings yet

- Morphy Richards Mwo 25 CG ManualDocument2 pagesMorphy Richards Mwo 25 CG Manualn4895413No ratings yet

- N-Channel 0 V (D-S) Mosfet: Features Product SummaryDocument8 pagesN-Channel 0 V (D-S) Mosfet: Features Product SummarySajjad HussainNo ratings yet

- Review: What Are The Values of The Following Resistors?Document19 pagesReview: What Are The Values of The Following Resistors?Ahmed Abdelaziz AtallahNo ratings yet

- Parts Numbers TV SonyDocument30 pagesParts Numbers TV SonyHernando SalamancaNo ratings yet

- Sec12 - Electric MotorsDocument12 pagesSec12 - Electric MotorsYusufNo ratings yet

- TWDLMDA20DTK DATASHEET WW en-GBDocument8 pagesTWDLMDA20DTK DATASHEET WW en-GBتقانة المعلوماتNo ratings yet

- Ficha Tecnica de Gabinete En2850Document4 pagesFicha Tecnica de Gabinete En2850Alexis Cordero100% (1)

- Towing Bar ElectricalDocument5 pagesTowing Bar ElectricalCosminNo ratings yet

- Ti 19551580 83 enDocument2 pagesTi 19551580 83 enolivier.bigouretNo ratings yet

- 200 Amp Automatic Transfer SwitchDocument44 pages200 Amp Automatic Transfer SwitchHaytham BafoNo ratings yet

- 15 PPT Common HazardDocument13 pages15 PPT Common HazardAxl Pyro PalisocNo ratings yet

- ElectDocument188 pagesElectMeet Joshi100% (1)

- Experment of LDRDocument7 pagesExperment of LDRBlue JasmineNo ratings yet

- KBP200 (1) Puente RectificadorDocument4 pagesKBP200 (1) Puente RectificadorCesar Stevens Gonzalez CespedesNo ratings yet

- 7je6 Electricity at HomeDocument2 pages7je6 Electricity at HomeAriellaNo ratings yet

- 00543000Document172 pages00543000Dhilip AnNo ratings yet

- Verilog-A Implementation of SOI MOSFET-Based Amplifier and RingDocument9 pagesVerilog-A Implementation of SOI MOSFET-Based Amplifier and RingAdib ShadmanNo ratings yet

- Types of RelaysDocument24 pagesTypes of RelayselmerNo ratings yet

- Novel Zero-Current-Transition PWM Converters: Eric X. CDocument6 pagesNovel Zero-Current-Transition PWM Converters: Eric X. Ccarlos_eqnNo ratings yet

- Thyristor Firing Circuit: Rs = 10-22 Ω Rg = 1 kΩ Cg = 0.01 μF - 0.1μFDocument10 pagesThyristor Firing Circuit: Rs = 10-22 Ω Rg = 1 kΩ Cg = 0.01 μF - 0.1μFAnil Kumar SinghNo ratings yet

- Deogarh Court Boq Garden LightDocument7 pagesDeogarh Court Boq Garden Lighttsadkans59No ratings yet