Body, Lock & Security System: Section

Body, Lock & Security System: Section

Uploaded by

Ruhu royCopyright:

Available Formats

Body, Lock & Security System: Section

Body, Lock & Security System: Section

Uploaded by

Ruhu royOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Body, Lock & Security System: Section

Body, Lock & Security System: Section

Uploaded by

Ruhu royCopyright:

Available Formats

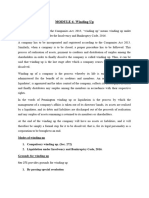

I BODY

B

SECTION

BODY, LOCK & SECURITY SYSTEM C

E

CONTENTS

PRECAUTIONS .......................................................... 4 System Description ................................................. 17 F

Precautions for Supplemental Restraint System OUTLINE ............................................................. 18

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN- Schematic ............................................................... 19

SIONER” .................................................................. 4 Wiring Diagram -D/LOCK- ...................................... 20 G

Precautions for work ................................................ 4 Terminals and Reference Value for BCM ............... 24

Wiring Diagnosis and Trouble Diagnosis ................. 4 Work Flow ............................................................... 24

PREPARATION ........................................................... 5 CONSULT–II Function ............................................ 24

H

Special service tool .................................................. 5 CONSULT–II INSPECTION PROCEDURE ......... 25

Commercial Service Tool ......................................... 5 DATA MONITOR ................................................. 26

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 6 ACTIVE TEST ..................................................... 26

Work Flow ................................................................ 6 Trouble Diagnoses Symptom Chart ....................... 27 BL

CUSTOMER INTERVIEW ..................................... 6 BCM Power Supply and Ground Circuit Check ...... 27

DUPLICATE THE NOISE AND TEST DRIVE ....... 7 Door Switch Check ................................................. 28

CHECK RELATED SERVICE BULLETINS ........... 7 Key Switch (Insert) Check ...................................... 30 J

LOCATE THE NOISE AND IDENTIFY THE Door Lock/Unlock Switch Check ............................ 31

ROOT CAUSE ...................................................... 7 Front Door Lock Assembly LH (Actuator) Check ... 33

REPAIR THE CAUSE ........................................... 7 Front Door Lock Actuator RH Check ...................... 35

K

CONFIRM THE REPAIR ....................................... 8 Rear Door Lock Actuator RH/LH Check ................. 36

Generic Squeak and Rattle Troubleshooting ........... 8 Front Door Lock Assembly LH (Key Cylinder Switch)

INSTRUMENT PANEL .......................................... 8 Check ..................................................................... 37

CENTER CONSOLE ............................................. 8 REMOTE KEYLESS ENTRY SYSTEM ..................... 38 L

DOORS ................................................................. 8 Component Parts and Harness Connector Location... 38

TRUNK .................................................................. 9 System Description ................................................. 39

SUNROOF/HEADLINING ..................................... 9 INPUTS ............................................................... 39 M

OVERHEAD CONSOLE (FRONT AND REAR)..... 9 OPERATED PROCEDURE ................................. 40

SEATS ................................................................... 9 CAN Communication System Description .............. 42

UNDERHOOD ....................................................... 9 Schematic ............................................................... 43

Diagnostic Worksheet ............................................ 10 Wiring Diagram — KEYLES— ................................ 44

HOOD ....................................................................... 12 FIG. 1 ................................................................... 44

Fitting Adjustment .................................................. 12 FIG. 2 ................................................................... 45

CLEARANCE AND SURFACE HEIGHT FIG. 3 ................................................................... 46

ADJUSTMENT .................................................... 13 Terminals and Reference Value for BCM ............... 47

HOOD LOCK ADJUSTMENT ............................. 13 Terminals and Reference Value for IPDM E/R ....... 48

Removal and Installation of Hood Assembly .......... 13 CONSULT-II Function (BCM) ................................. 48

Removal and Installation of Hood Lock Control ..... 14 CONSULT-II Inspection Procedure ......................... 49

REMOVAL ........................................................... 14 “MULTI REMOTE ENT” ....................................... 49

INSTALLATION ................................................... 14 CONSULT-II Application Items ............................... 50

Hood Lock Control Inspection ................................ 15 “MULTI REMOTE ENT” ....................................... 50

POWER DOOR LOCK SYSTEM .............................. 16 Trouble Diagnosis Procedure ................................. 52

Component Parts and Harness Connector Location... 16 Pre-Diagnosis Inspection ........................................ 52

Revision: January 2005 BL-1 2004 Pathfinder Armada

BCM POWER SUPPLY AND GROUND CIRCUIT trol Unit .................................................................. 101

INSPECTION ....................................................... 52 Terminals and Reference Value for BCM .............. 102

Trouble Diagnoses .................................................. 53 Trouble Diagnosis Procedure ................................ 103

SYMPTOM CHART ............................................. 53 Self-Diagnosis Procedures ................................... 103

Key Switch (Insert) Check ...................................... 55 INPUT SIGNAL CHECK MODE ......................... 103

Door Switch Check ................................................. 56 OPERATING CHECK MODE ............................. 103

Keyfob Battery and Function Check ....................... 57 Diagnosis Chart .................................................... 104

Remote Keyless Entry Receiver System Inspection... 58 Back Door Power Supply and Ground Circuit

ACC Power Check .................................................. 60 Inspection .............................................................. 105

IPDM E/R Operation Check .................................... 60 Power Liftgate Switch System Inspection ............. 106

Check Hazard Function .......................................... 62 Back Door Close (Close) Switch System Inspection.107

Check Horn Function .............................................. 62 Back Door Close (Cancel) Switch System Inspec-

Check Headlamp Function ..................................... 62 tion ........................................................................ 108

Check Map Lamp Illumination Function ................. 62 Pinch Strip System Inspection .............................. 109

ID Code Entry Procedure ....................................... 63 Back Door Warning Chime System Inspection ..... 110

KEYFOB ID SET UP WITH CONSULT-II ............ 63 Half-Latch Switch System Inspection .................... 111

KEYFOB ID SET UP WITHOUT CONSULT-II ..... 65 Open Switch System Inspection ........................... 112

Keyfob Battery Replacement .................................. 66 Close Switch System Inspection ........................... 113

VEHICLE SECURITY (THEFT WARNING) SYSTEM... 67 Back Door Handle Switch System Inspection ....... 114

Component Parts and Harness Connector Location... 67 Cinch Latch Motor System Inspection .................. 115

System Description ................................................. 68 DOOR ...................................................................... 116

DESCRIPTION .................................................... 68 Fitting Adjustment ................................................. 116

POWER SUPPLY AND GROUND CIRCUIT ....... 68 FRONT DOOR ................................................... 116

INITIAL CONDITION TO ACTIVATE THE SYS- REAR DOOR ..................................................... 116

TEM ..................................................................... 69 STRIKER ADJUSTMENT .................................. 116

VEHICLE SECURITY SYSTEM ALARM OPER- Removal and Installation ....................................... 117

ATION .................................................................. 69 FRONT DOOR ................................................... 117

VEHICLE SECURITY SYSTEM DEACTIVATION... 69 REAR DOOR ..................................................... 117

PANIC ALARM OPERATION ............................... 70 BACK DOOR ..................................................... 118

CAN Communication System Description .............. 70 FRONT DOOR LOCK .............................................. 119

Schematic ............................................................... 71 Component Structure ............................................ 119

Wiring Diagram -VEHSEC- ..................................... 72 Removal and Installation ....................................... 119

FIG. 1 ................................................................... 72 REMOVAL .......................................................... 119

FIG. 2 ................................................................... 73 INSTALLATION .................................................. 121

FIG. 3 ................................................................... 74 Disassembly and Assembly .................................. 121

FIG. 4 ................................................................... 75 DOOR KEY CYLINDER ASSEMBLY ................. 121

FIG. 5 ................................................................... 76 REAR DOOR LOCK ................................................ 122

Terminals and Reference Value for BCM ................ 77 Component Structure ............................................ 122

Terminals and Reference Value for IPDM E/R ........ 77 Removal and Installation ....................................... 122

CONSULT-II Function ............................................. 78 REMOVAL .......................................................... 122

CONSULT-II INSPECTION PROCEDURE .......... 78 INSTALLATION .................................................. 122

CONSULT-II APPLICATION ITEM ....................... 79 BACK DOOR LOCK ................................................ 123

Trouble Diagnosis ................................................... 80 Power Back Door Opener ..................................... 123

WORK FLOW ...................................................... 80 REMOVAL ......................................................... 123

Preliminary Check .................................................. 81 INSTALLATION ................................................. 123

Symptom Chart ....................................................... 82 Door Lock Assembly ............................................. 124

Diagnostic Procedure 1 .......................................... 83 REMOVAL ......................................................... 124

Diagnostic Procedure 2 .......................................... 86 INSTALLATION ................................................. 124

Diagnostic Procedure 3 .......................................... 87 NVIS(NISSAN VEHICLE IMMOBILIZER SYSTEM-

Diagnostic Procedure 4 .......................................... 88 NATS) ...................................................................... 125

Diagnostic Procedure 5 .......................................... 88 Component Parts and Harness Connector Location.125

Diagnostic Procedure 6 .......................................... 88 System Description ............................................... 126

AUTOMATIC BACK DOOR SYSTEM ....................... 89 System Composition ............................................. 126

Component Parts and Harness Connector Location... 89 ECM Re-communicating Function ........................ 127

System Description ................................................. 89 Wiring Diagram — NATS — .................................. 128

OPERATION DESCRIPTION .............................. 90 Terminals and Reference Value for BCM .............. 129

Schematic ............................................................... 95 CONSULT-II .......................................................... 129

Wiring Diagram -B/CLOS- ...................................... 96 CONSULT-II INSPECTION PROCEDURE ........ 129

Terminals and Reference Value for Back Door Con- CONSULT-II DIAGNOSTIC TEST MODE FUNC-

Revision: January 2005 BL-2 2004 Pathfinder Armada

TION .................................................................. 130 Body Sealing ........................................................ 158

HOW TO READ SELF-DIAGNOSTIC RESULTS. 131 DESCRIPTION .................................................. 158 A

NVIS (NATS) SELF-DIAGNOSTIC RESULTS Body Construction ................................................ 161

ITEM CHART .................................................... 131 BODY CONSTRUCTION .................................. 161

Work Flow ............................................................ 132 Body Alignment .................................................... 162 B

Trouble Diagnoses ............................................... 133 BODY CENTER MARKS ................................... 162

SYMPTOM MATRIX CHART 1 ......................... 133 PANEL PARTS MATCHING MARKS ................. 164

SYMPTOM MATRIX CHART 2 ......................... 134 DESCRIPTION .................................................. 165

DIAGNOSTIC SYSTEM DIAGRAM .................. 134 ENGINE COMPARTMENT ................................ 166 C

Diagnostic Procedure 1 ........................................ 135 UNDERBODY ................................................... 168

Diagnostic Procedure 2 ........................................ 136 PASSENGER COMPARTMENT ....................... 171

Diagnostic Procedure 3 ........................................ 137 REAR BODY ..................................................... 176 D

Diagnostic Procedure 4 ........................................ 138 Handling Precautions for Plastics ......................... 178

Diagnostic Procedure 5 ........................................ 139 HANDLING PRECAUTIONS FOR PLASTICS . 178

Diagnostic Procedure 6 ........................................ 142 LOCATION OF PLASTIC PARTS ...................... 179 E

How to Replace NATS Antenna Amp. .................. 143 Precautions in Repairing High Strength Steel ....... 181

HOMELINK UNIVERSAL TRANSCEIVER ............. 144 HIGH STRENGTH STEEL (HSS) USED IN NIS-

Wiring Diagram — TRNSCV — ........................... 144 SAN VEHICLES ................................................ 181

Trouble Diagnoses ............................................... 145 Foam Repair ......................................................... 183 F

DIAGNOSTIC PROCEDURE ............................ 145 URETHANE FOAM APPLICATIONS ................ 183

CAB AND REAR BODY ......................................... 147 FILL PROCEDURES ......................................... 183

Body Mounting ..................................................... 147 Replacement Operations ...................................... 184 G

BODY REPAIR ........................................................ 148 DESCRIPTION .................................................. 184

Body Exterior Paint Color ..................................... 148 HOODLEDGE ................................................... 187

Body Component Parts ........................................ 149 FRONT PILLAR ................................................. 188 H

UNDERBODY COMPONENT PARTS .............. 149 CENTER PILLAR .............................................. 191

BODY COMPONENT PARTS ........................... 151 OUTER SILL ..................................................... 193

FRAME COMPONENT PARTS ......................... 153 REAR FENDER ................................................. 194

BL

Corrosion Protection ............................................ 155 REAR SIDE MEMBER ...................................... 196

DESCRIPTION .................................................. 155 REAR FLOOR REAR ........................................ 197

ANTI-CORROSIVE WAX .................................. 156 CRUSH HORN .................................................. 198

UNDERCOATING ............................................. 157 J

Revision: January 2005 BL-3 2004 Pathfinder Armada

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER” EIS0027P

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

● To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

● Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for work EIS0027Q

● After removing and installing the opening/closing parts, be sure to carry out fitting adjustments to check

their operation.

● Check the lubrication level, damage, and wear of each part. If necessary, grease or replace it.

Wiring Diagnosis and Trouble Diagnosis EIS0027R

When you read wiring diagrams, refer to the following:

● GI-15, "How to Read Wiring Diagrams"

● PG-4, "POWER SUPPLY ROUTING CIRCUIT"

When you perform trouble diagnosis, refer to the following:

● GI-11, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES"

● GI-27, "How to Perform Efficient Diagnosis for an Electrical Incident"

Check for any Service bulletins before servicing the vehicle.

Revision: January 2005 BL-4 2004 Pathfinder Armada

PREPARATION

PREPARATION PFP:00002

A

Special service tool EIS0027S

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number B

(Kent-Moore No.) Description

Tool name

— Locating the noise C

(J-39570)

Chassis ear

SIIA0993E

E

— Repairing the cause of noise F

(J-43980)

NISSAN Squeak and Rat-

tle Kit

G

SIIA0994E H

BL

— Used to test keyfobs

(J-43241)

Remote Keyless Entry

Tester J

LEL946A K

Commercial Service Tool EIS0027T

(Kent-Moore No.)

Description

M

Tool name

(J-39565) Locating the noise

Engine ear

SIIA0995E

Revision: January 2005 BL-5 2004 Pathfinder Armada

SQUEAK AND RATTLE TROUBLE DIAGNOSES

SQUEAK AND RATTLE TROUBLE DIAGNOSES PFP:00000

Work Flow EIS003OJ

SBT842

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer to GW-9, "Diagnostic Worksheet" . This information is necessary to duplicate the

conditions that exist when the noise occurs.

● The customer may not be able to provide a detailed description or the location of the noise. Attempt to

obtain all the facts and conditions that exist when the noise occurs (or does not occur).

● If there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer

is concerned about. This can be accomplished by test driving the vehicle with the customer.

● After identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

● Squeak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard sur-

faces = higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

● Creak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch

dependent on materials/often brought on by activity.

● Rattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

● Knock —(Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

● Tick—(Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

● Thump—(Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

● Buzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

● Often the degree of acceptable noise level will vary depending upon the person. A noise that you may

judge as acceptable may be very irritating to the customer.

● Weather conditions, especially humidity and temperature, may have a great effect on noise level.

Revision: January 2005 BL-6 2004 Pathfinder Armada

SQUEAK AND RATTLE TROUBLE DIAGNOSES

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on A

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli- B

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine. C

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer. D

● Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

● If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body. E

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom. F

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

G

1. Narrow down the noise to a general area.To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

H

● removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be bro-

ken or lost during the repair, resulting in the creation of new noise.

BL

● tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

● feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the J

noise.

● placing a piece of paper between components that you suspect are causing the noise.

● looking for loose components and contact marks. K

Refer to GW-7, "Generic Squeak and Rattle Troubleshooting" .

REPAIR THE CAUSE L

● If the cause is a loose component, tighten the component securely.

● If the cause is insufficient clearance between components:

– separate components by repositioning or loosening and retightening the component, if possible. M

– insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through your authorized NISSAN

Parts Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100×135 mm (3.94×5.31 in)/76884-71L01: 60×85 mm (2.36×3.35 in)/76884-71L02: 15×25

mm (0.59×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50×50 mm (1.97×1.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

50×50 mm (1.97×1.97 in)

INSULATOR (Light foam block)

Revision: January 2005 BL-7 2004 Pathfinder Armada

SQUEAK AND RATTLE TROUBLE DIAGNOSES

80845-71L00: 30 mm (1.18 in) thick, 30×50 mm (1.18×1.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15×25 mm (0.59×0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle Troubleshooting EIS003OK

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

Revision: January 2005 BL-8 2004 Pathfinder Armada

SQUEAK AND RATTLE TROUBLE DIAGNOSES

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner. A

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment B

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

C

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING D

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder E

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape. F

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

G

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

H

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS BL

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise. J

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame K

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component L

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then M

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: January 2005 BL-9 2004 Pathfinder Armada

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Diagnostic Worksheet EIS003OL

LIWA0276E

Revision: January 2005 BL-10 2004 Pathfinder Armada

SQUEAK AND RATTLE TROUBLE DIAGNOSES

BL

SBT844

Revision: January 2005 BL-11 2004 Pathfinder Armada

HOOD

HOOD PFP:F5100

Fitting Adjustment EIS0028K

LIIA2161E

1. Hood hinge 2. Hood stay 3. Hood lock assembly

4. Hood assembly 5. Front grille 6. Headlamp

7. Front fender 8. Cowl grille A. 8.0 mm (0.315 in.)

Revision: January 2005 BL-12 2004 Pathfinder Armada

HOOD

B. 2.0 mm (0.08 in) C. 8.0 mm (0.31 in.) D. 0.8 mm (0.03 in)

E. 3.5 mm ( 0.14 in) F. 8.8 mm ( 0.35 in) A

CLEARANCE AND SURFACE HEIGHT ADJUSTMENT

1. Remove the hood lock assembly and adjust the height by rotating the bumper rubber until the hood clear- B

ance of hood and fender becomes 1 mm (0.04 in) lower than fitting standard dimension.

2. Temporarily tighten the hood lock, and position it by engaging it with the hood striker. Check the lock and

striker for looseness, and tighten the hood lock assembly bolt to the specified torque.

C

3. Adjust the clearance and surface height of hood and fender according to the fitting standard dimension by

rotating right and left bumper rubbers.

CAUTION:

D

Adjust right/left gap between hood and each part to the following specification.

Hood and headlamp (B–B) : Less than 8.0 mm

HOOD LOCK ADJUSTMENT E

1. Move the hood lock to the left or right so that striker center is vertically aligned with hood lock center

(when viewed from vehicle front).

2. Make sure the secondary latch is properly engaged with the sec- F

ondary striker with hood's own weight by dropping it from

approx. 200 mm (7.87 in) height or by pressing it lightly approx.

3 kg (29 N, 7lb). G

CAUTION:

Do not drop the hood from 300 mm (11.81 in) height or

higher. H

3. After adjusting hood lock, tighten the hood lock assembly bolts

to the specified torque.

PIIA3806E

BL

Removal and Installation of Hood Assembly EIS0028L

LIIA1078E

1. Support the hood striker with a proper material to prevent it from falling.

WARNING:

Body injury may occur if no supporting rod is holding the hood open when removing the damper

stay.

2. Remove the nuts from the hood to remove the hood assembly.

CAUTION:

Operate with two workers, because of its heavy weight.

Installation is in the reverse order of removal.

Revision: January 2005 BL-13 2004 Pathfinder Armada

HOOD

Removal and Installation of Hood Lock Control EIS0028M

LIIA1080E

1. Hood lock assembly 2. Hood lock cable

REMOVAL

1. Remove the front grill. Refer to EI-17, "FRONT GRILLE" .

2. Remove the front fender protector (LH). Refer to EI-21, "FENDER PROTECTOR" .

3. Disconnect the hood lock cable from the hood lock, and unclip it from the radiator core support upper and

hood ledge.

4. Remove the bolt and the hood opener.

5. Remove the grommet from the lower dash and pull the hood lock cable toward the passenger room.

CAUTION:

While pulling, be careful not to damage the outside of the hood lock cable.

INSTALLATION

1. Pull the hood lock cable through the lower dash into to the engine room.

Revision: January 2005 BL-14 2004 Pathfinder Armada

HOOD

Be careful not to bend the cable too much, keeping the radius

100mm (3.94 in) or more. A

2. Make sure the cable is not offset from the positioning grommet,

and push the grommet into the panel hole securely.

3. Apply the sealant to the grommet (at * mark) properly. B

PIIA0173E

D

4. Install the cable securely to the lock.

5. After installing, check the hood lock adjustment and hood

opener operation. E

G

PIIA0174E

Hood Lock Control Inspection EIS0028N

H

CAUTION:

If the hood lock cable is bent or deformed, replace it.

1. Make sure the secondary latch is properly engaged with the sec- BL

ondary striker with hood's own weight by dropping it from

approx. 200 mm (7.87 in) height.

2. While operating the hood opener, carefully make sure the front

end of the hood is raised by approx. 20 mm (0.79 in). Also make J

sure the hood opener returns to the original position.

PIIA1086E

L

3. Check the hood lock lubrication condition. If necessary, apply

“body grease” to the points shown in the figure. M

PIIA0176E

Revision: January 2005 BL-15 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

POWER DOOR LOCK SYSTEM PFP:24814

Component Parts and Harness Connector Location EIS0028O

WIIA0572E

Revision: January 2005 BL-16 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

System Description EIS0028P

A

Power is supplied at all times

● through 50A fusible link (letter f, located in the fuse and fusible link box)

● to BCM terminal 70 and B

● through 15A fuse [No. 22, located in the fuse block (J/B)]

● to BCM terminal 57.

● through 10A fuse [No. 19, located in the fuse block (J/B)] C

● to key switch terminal 3

With ignition key inserted, power is supplied

● through key switch terminal 4 D

● to BCM terminal 37.

Ground is supplied to terminal 67 of BCM through body grounds M57, M61 and M79.

When the door is locked or unlocked with main power window and door lock/unlock switch, ground is supplied E

● to CPU of main power window and door lock/unlock switch

● through main power window and door lock/unlock switch terminal 17

F

● through grounds M57, M61 and M79.

Then main power window and door lock/unlock switch operation signal is supplied.

● to BCM terminal 22 G

● through main power window and door lock/unlock switch terminal 14.

When the door is locked or unlocked with power window and door lock/unlock switch RH, ground is supplied

● to CPU of power window and door lock/unlock switch RH H

● through power window and door lock/unlock switch RH terminal 11

● through grounds M57, M61 and M79.

BL

Then power window and door lock/unlock switch RH operation signal is supplied

● to BCM terminal 22

● through power window and door lock/unlock switch RH terminal 16.

J

When the door is locked with front door lock assembly LH, ground is supplied

● to main power window and door lock/unlock switch terminal 4

● through key cylinder switch terminals 1 and 5 K

● through grounds M57, M61 and M79.

Then key cylinder switch operation signal is supplied

● to BCM terminal 22 L

● through main power window and door lock/unlock switch terminal 14.

When the door is unlocked with front door lock assembly LH, ground is supplied

M

● to main power window and door lock/unlock switch terminal 6

● through key cylinder switch terminals 6 and 5

● through grounds M57, M61 and M79.

Then key cylinder switch operation signal is supplied

● to BCM terminal 22

● through main power window and door lock/unlock switch terminal 14.

BCM is connected to main power window and door lock/unlock switch and power window and door lock/unlock

switch RH through a serial link.

When the front door switch LH is ON (door is open), ground is supplied

● to BCM terminal 47

● through front door switch LH terminal 2

● through front door switch LH case ground.

When the front door switch RH is ON (door is open), ground is supplied

● to BCM terminal 12

● through front door switch RH terminal 2

Revision: January 2005 BL-17 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

● through front door switch RH case ground.

When the rear door switch LH is ON (door is open), ground is supplied

● to BCM terminal 48

● through rear door switch LH terminal 2

● through rear door switch LH case ground.

When the rear door switch RH is ON (door is open), ground is supplied

● to BCM terminal 13

● through rear door switch RH terminal 2

● through rear door switch RH case ground.

When the back door switch is ON (door is open), ground is supplied

● to BCM terminal 43

● through back door switch terminal 3

● through back door switch terminal 1

● through grounds B7 and B19.

OUTLINE

Functions available by operating the door lock and unlock switches on driver door and pas-

senger door

● Interlocked with the locking operation of door lock and unlock switch, door lock actuators of all doors are

locked.

● Interlocked with the unlocking operation of door lock and unlock switch, door lock actuators of all doors

are unlocked.

Functions available by operating the key cylinder switch on driver door

● Interlocked with the locking operation of door key cylinder, door lock actuators of all doors are locked.

● When door key cylinder is unlocked, front door lock assembly LH is unlocked.

● When door key cylinder is unlocked for the second time within 5 seconds after the first operation, door

lock actuators on all doors are unlocked.

Key reminder door system

When door lock and unlock switch is operated to lock doors with ignition key in key cylinder and any door

open, all door lock actuators are locked and then unlocked.

Revision: January 2005 BL-18 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

Schematic EIS0028Q

BL

WIWA0192E

Revision: January 2005 BL-19 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

Wiring Diagram -D/LOCK- EIS0028R

WIWA0182E

Revision: January 2005 BL-20 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

BL

WIWA0193E

Revision: January 2005 BL-21 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

WIWA0194E

Revision: January 2005 BL-22 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

BL

WIWA0195E

Revision: January 2005 BL-23 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

Terminals and Reference Value for BCM EIS0028S

Termi- Wire Voltage (V)

Item Condition

nal Color (Approx.)

12 R/L Front door switch RH Door open (ON) → Door close (OFF) 0 → Battery voltage

13 R/W Rear door switch RH Door open (ON) → Door close (OFF) 0 → Battery voltage

When ignition switch is ON or power

22 W/V Anti–pinch serial link

window timer operates

PIIA2344E

Key inserted in IGN key cylinder (ON) →

37 B/R Key switch (insert) Key removed from IGN key cylinder Battery voltage → 0

(OFF)

39 W CAN-H — —

40 R CAN-L — —

Back door switch (without auto-

matic back door system) or back

43 R/B Door open (ON) → Door close (OFF) 0 → Battery voltage

door latch actuator (with auto-

matic back door system)

47 SB Front door switch LH Door open (ON) → Door close (OFF) 0 → Battery voltage

48 R/Y Rear door switch LH Door open (ON) → Door close (OFF) 0 → Battery voltage

57 Y/R Battery power supply — Battery voltage

Front door lock assembly LH Driver door lock knob

59 G 0 → Battery voltage

(unlock) (locked → unlocked)

65 V All door lock actuators (lock) Driver door lock knob (neutral → lock) 0 → Battery voltage

Front door lock actuator RH,

rear door lock actuators LH/RH Door lock and unlock switch (locked →

66 G/Y 0 → Battery voltage

and back door lock actuator unlocked)

(unlock)

67 B Ground — —

70 W/B BAT power supply — Battery voltage

Work Flow EIS0028T

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to BL-17, "System Description" .

3. According to the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer to BL-27,

"Trouble Diagnoses Symptom Chart" .

4. Does power door lock system operate normally? OK: GO TO 5, NG: GO TO 3.

5. INSPECTION END.

CONSULT–II Function EIS0028U

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

BCM diagnosis Inspection item, self–diagnosis

Content

part mode

Data monitor Displays BCM input data on real–time basis.

Door lock

Active test Sends drive signals to door lock actuator to perform operation check.

Revision: January 2005 BL-24 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

CONSULT–II INSPECTION PROCEDURE

"DOOR LOCK" A

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carries out CAN communication. B

1. Turn ignition switch OFF.

2. Connect “CONSULT-II” and "CONSULT-II CONVERTER" to the

data link connector. C

E

BBIA0369E

3. Turn ignition switch ON. F

4. Touch “START (NISSAN BASED VHCL)”.

BCIA0029E BL

5. Touch “BCM”.

If "BCM" is not indicated, refer to GI-38, "CONSULT-II Data Link

J

Connector (DLC) Circuit" .

BCIA0030E

M

6. Touch “DOOR LOCK”.

LIIA1137E

Revision: January 2005 BL-25 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

7. Select diagnosis mode.

“DATA MONITOR” and “ACTIVE TEST” are available.

BCIA0031E

DATA MONITOR

Monitor item "OPERATION" Content

KEY ON SW "ON/OFF" Indicates [ON/OFF] condition of key switch.

CDL LOCK SW "ON/OFF" Indicates [ON/OFF] condition of lock signal from lock/unlock switch LH and RH.

CDL UNLOCK SW "ON/OFF" Indicates [ON/OFF] condition of unlock signal from lock/unlock switch LH and RH.

KEY CYL LK-SW "ON/OFF" Indicates [ON/OFF] condition of lock signal from key cylinder.

KEY CYL UN-SW "ON/OFF" Indicates [ON/OFF] condition of unlock signal from key cylinder.

IGN ON SW "ON/OFF" Indicates [ON/OFF] condition of ignition switch.

DOOR SW–DR "ON/OFF" Indicates [ON/OFF] condition of front door switch LH.

DOOR SW–AS "ON/OFF" Indicates [ON/OFF] condition of front door switch RH.

DOOR SW–RR "ON/OFF" Indicates [ON/OFF] condition of rear door switch RH.

DOOR SW–RL "ON/OFF" Indicates [ON/OFF] condition of rear door switch LH.

BACK DOOR SW "ON/OFF" Indicates [ON/OFF] condition of back door switch.

ACTIVE TEST

Test item Content

This test is able to check all door lock actuators lock operation. These actuators lock when

ALL LOCK/UNLOCK

"ON" on CONSULT–II screen is touched.

This test is able to check front door lock assembly LH unlock operation.These actuators lock

DR UNLOCK

when "ON" on CONSULT–II screen is touched.

This test is able to check door lock actuators (except front door lock assembly LH) unlock

OTHER UNLOCK

operation.These actuators unlock when "ON" on CONSULT–II screen is touched.

Revision: January 2005 BL-26 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

Trouble Diagnoses Symptom Chart EIS0028V

A

Symptom Repair order Refer to page

1. Door switch check BL-28

Key reminder door function does not operate

2. Key switch (Insert) check BL-30 B

properly.

3. Replace BCM. BCS-21

Power door lock does not operate with door lock

and unlock switch on main power window and C

1. Door lock/unlock switch check BL-31

door lock/unlock switch or power window and

door lock/unlock switch RH

Front door lock assembly LH does not operate. 1. Door lock actuator check (Front LH) BL-33 D

1. Door lock actuator check (Front RH, Rear LH/

Specific door lock actuator does not operate. BL-35

RH)

1. Front door lock assembly LH (key cylinder E

Power door lock does not operate with front door BL-37

switch) check

key cylinder LH operation.

2. Replace BCM. BCS-21

Power door lock does not operate. 1. BCM power supply and ground circuit check BL-27 F

2. Door lock/unlock switch check BL-31

1. Door switch check (Back door)

Back door opener does not operate G

2. Back door lock actuator check

BCM Power Supply and Ground Circuit Check EIS0028W

H

1. CHECK FUSE

● Check the following BCM fuse and fusible link.

BL

Component Parts Terminal No. (SIGNAL) Ampere No. Location

BCM 57 (BAT power supply) 10A 22 Fuse block (J/B)

BCM 70 (BAT power supply) 50A f Fuse and fusible link box J

NOTE:

Refer to BL-16, "Component Parts and Harness Connector Location" .

OK or NG K

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of problem before installing new fuse, refer to PG-4,

"POWER SUPPLY ROUTING CIRCUIT" . L

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF. M

2. Disconnect BCM.

3. Check voltage between BCM connector M20 terminals 57, 70

and ground.

Terminals

(Wire color) Voltage (V)

Connector

(Approx.)

(+) (-)

57 (Y/R)

M20 Ground Battery voltage

70 (W/B)

OK or NG

OK >> GO TO 3. LIIA1039E

NG >> Repair or replace harness.

Revision: January 2005 BL-27 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

3. CHECK GROUND CIRCUIT

Check continuity between BCM connector M20 terminal 67 and

ground.

Terminals

Connector (Wire color) Continuity

(+) (-)

M20 67 (B) Ground Yes

OK or NG

OK >> Power supply and ground circuit is OK.

NG >> Repair or replace harness. LIIA1040E

Door Switch Check EIS0028X

1. CHECK DOOR SWITCHES INPUT SIGNAL

With CONSULT-II

Check door switches ("DOOR SW-DR", "DOOR SW-AS", "DOOR SW-RL", "DOOR SW-RR") in DATA MONI-

TOR mode with CONSULT–II.Refer to BL-26, "DATA MONITOR" .

● When any doors are open:

DOOR SW-DR :ON

DOOR SW-AS :ON

DOOR SW-RL :ON

DOOR SW-RR :ON

BACK DOOR SW :ON

● When any doors are closed:

DOOR SW-DR :OFF

DOOR SW-AS :OFF LIIA0665E

DOOR SW-RL :OFF

DOOR SW-RR :OFF

BACK DOOR SW :OFF

Without CONSULT-II

Check voltage between BCM connector M18 or M19 terminals 12, 13, 43, 47, 48 and ground.

Connec- Terminals (Wire color) Voltage (V)

Item Condition

tor (+) (–) (Approx.)

Back door

43 (R/B)

switch

Front door

M19 47 (SB)

switch LH

Open 0

Rear door

48 (R/Y) Ground ↓ ↓

switch LH

Closed Battery voltage

Front door

12 (GR/L) LIIA1041E

switch RH

M18

Rear door

13 (O/B)

switch RH

OK or NG

OK >> System is OK.

NG >> GO TO 2.

Revision: January 2005 BL-28 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

2. CHECK DOOR SWITCH CIRCUIT A

1. Turn ignition switch OFF.

2. Disconnect door switch and BCM.

3. Check continuity between door switch connector B8 (Front LH), B108 (Front RH), B18 (Rear LH), B118 B

(Rear RH) terminal 2 or D709 (Back) terminal 3 and BCM connector M18, M19 terminals 12, 13, 43, 47

and 48.

2 (SB) - 47 (SB) :Continuity should exist C

2 (R/L) - 12 (R/L) :Continuity should exist

2 (R/Y) - 48 (R/Y) :Continuity should exist

D

2 (R/W) - 13 (R/W) :Continuity should exist

3 (R/B) - 43 (R/B) :Continuity should exist

4. Check continuity between door switch connector B8 (Front LH), E

B108 (Front RH), B18 (Rear LH), B118 (Rear RH) terminal 2 or

D709 (Back) terminal 3 and ground.

LIIA1139E F

2 (SB, R/L, R/Y or R/W) - :Continuity should not exist

Ground

3 (R/B) - Ground :Continuity should not exist

G

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness. H

3. CHECK DOOR SWITCHES

● Disconnect door switch harness. BL

● Check continuity between door switch connector terminals.

Terminal Condition Continuity J

Door switch (front Open Yes

2 – Ground

and rear Closed No

Open Yes

K

Door switch (back) 3 – Ground

Closed No

OK or NG L

OK >> Check door switch case ground condition (front and rear

door) or ground circuit (back door).

LIIA1146E

NG >> Replace door switch. M

Revision: January 2005 BL-29 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

Key Switch (Insert) Check EIS0028Z

1. CHECK KEY SWITCH INPUT SIGNAL

With CONSULT-II

Check key switch "KEY ON SW" in DATA MONITOR mode with CONSULT–II.Refer to BL-26, "DATA MONI-

TOR" .

● When key is inserted to ignition key cylinder:

KEY ON SW :ON

● When key is removed from ignition key cylinder:

KEY ON SW :OFF

LIIA0169E

Without CONSULT-II

Check voltage between BCM connector M18 terminal 37 and

ground.

Connec- Terminal (Wire color)

Condition Voltage (V)

tor (+) (–)

Key is inserted. Battery voltage

M18 37 (B/R) Ground

Key is removed. 0

OK or NG

OK >> System is OK.

NG >> GO TO 2. LIIA0567E

2. CHECK KEY SWITCH (INSERT)

Check continuity between key switch connector terminals.

Terminals Condition Continuity

Key is inserted. Yes

3–4

Key is removed. No

OK or NG

OK >> Repair or replace harness.

NG >> Replace key switch.

LIIA1044E

Revision: January 2005 BL-30 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

Door Lock/Unlock Switch Check EIS00290

1. CHECK DOOR LOCK/UNLOCK SWITCH INPUT SIGNAL A

With CONSULT-II

Check door lock/unlock switch ("CDL LOCK SW", "CDL UNLOCK SW") in DATA MONITOR mode in CON- B

SULT–II. Refer to BL-26, "DATA MONITOR"

● When door lock/unlock switch is turned to LOCK:

C

CDL LOCK SW :ON

● When door lock/unlock switch is turned to UNLOCK:

CDL UNLOCK SW :ON D

PIIA6538E F

Without CONSULT-II

G

1. Remove key from ignition key cylinder.

2. Check the signal between BCM connector M18 terminal 22 and ground with oscilloscope when door lock/

unlock switch is turned to LOCK or UNLOCK.

H

3. Make sure the signals which are shown in the figure below can be detected during 10 seconds just after

the door lock/unlock switch is turned to LOCK or UNLOCK.

Terminal (Wire color) BL

Connector Voltage (V)

(+) (–)

M18 22 (W/V) Ground

K

PIIA1297E

PIIA6379E

OK or NG L

OK >> Door lock and unlock switch circuit is OK.

NG >> GO TO 2.

M

2. CHECK BCM OUTPUT SIGNAL

Check ("POWER WINDOW DOWN") in ACTIVE TEST mode for

"REMOTE KEYLESS ENTRY SYSTEM" with CONSULT–II. Refer to

BL-50, "Active Test" .

When "ACTIVE TEST" is performed, are the front win-

dows lowered?

OK or NG

OK >> GO TO 3.

NG >> Replace BCM.

PIIA3080E

Revision: January 2005 BL-31 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

3. CHECK DOOR LOCK/UNLOCK SWITCH GROUND HARNESS

1. Turn ignition switch OFF.

2. Disconnect main power window and door lock/unlock switch or power window and door LOCK/UNLOCK

switch RH

3. Check continuity between main power window and door lock/

unlock switch connector D8 terminal 17 and ground.

17 (B) - Ground : Continuity should exist.

LIIA0392E

4. Check continuity between power window and door lock/unlock

switch RH connector D105 terminal 11 and ground

11 (B) - Ground : Continuity should exist.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

LIIA1140E

Revision: January 2005 BL-32 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

4. CHECK POWER WINDOW SERIAL LINK CIRCUIT A

1. Disconnect BCM.

2. Check continuity between BCM connector M18 terminal 22 and main power window and door lock/unlock

switch connector D7 terminal 14. B

22 (W/V) - 14 (LG/W) : Continuity should exist.

E

LIIA0394E

3. Check continuity between BCM connector M18 terminal 22 and power window and door lock/unlock F

switch RH connector D105 terminal 16.

22 (W/V) - 16 (LG/W) : Continuity should exist.

OK or NG G

OK >> Replace main power window and door lock/unlock

switch or power window and door lock/unlock switch

RH. H

NG >> Repair or replace harness.

BL

LIIA0395E

Front Door Lock Assembly LH (Actuator) Check EIS003NU J

1. CHECK DOOR LOCK ACTUATOR SIGNAL

1. Turn ignition switch OFF. K

2. Check voltage between BCM connector M20 terminals 59, 65

and ground.

L

Terminals

(Wire color) Voltage (V)

Connector Condition

(Approx.)

(+) (-)

M

Driver door lock/unlock

59 (G) switch is turned to 0 → Battery voltage

M20 Ground UNLOCK

Driver door lock/unlock

65 (V) 0 → Battery voltage

switch is turned to LOCK LIIA1046E

OK or NG

OK >> GO TO 2.

NG >> Replace BCM. Refer to BCS-21, "Removal and Installation of BCM" .

Revision: January 2005 BL-33 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

2. CHECK DOOR LOCK ACTUATOR HARNESS

1. Disconnect BCM and front door lock assembly LH (actuator).

2. Check continuity between BCM connector M20 terminals 59, 65

and front door lock assembly LH (actuator) connector D14 termi-

nals 2, 3.

Terminals Terminals

Connector Connector Continuity

(Wire color) (wire color)

59 (G) 2 (G) Yes

M20 D14

65 (V) 3 (V) Yes

3. Check continuity between BCM connector M20 terminals 59, 65

and ground.

LIIA1574E

Connector Terminals (Wire color) Continuity

59 (G) No

M20 Ground

65 (V) No

OK or NG

OK >> Replace front door lock assembly LH (actuator).

NG >> Repair or replace harness.

Revision: January 2005 BL-34 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

Front Door Lock Actuator RH Check EIS003NV

1. CHECK FRONT DOOR LOCK ACTUATOR RH SIGNAL A

1. Turn ignition switch OFF.

2. Check voltage between BCM connector M20 terminals 65, 66 B

and ground.

Terminals

(Wire color) Voltage (V) C

Connector Condition

(Approx.)

(+) (-)

Door lock/unlock switch is 0 → Battery voltage D

65 (V)

turned to LOCK for 300 ms

M20 Ground

Door lock/unlock switch is 0 → Battery voltage

66 (G/Y)

turned to UNLOCK for 300 ms

LIIA1048E

E

OK or NG F

OK >> GO TO 2.

NG >> Replace BCM. Refer to BCS-21, "Removal and Installation of BCM" .

2. CHECK DOOR LOCK ACTUATOR HARNESS G

1. Disconnect BCM and front door lock actuator RH.

2. Check continuity between BCM connector M20 terminals 65, 66 H

and front door lock actuator RH D114 terminals 2, 3.

Terminal Continuity

BL

65 (V) 3 (V) Yes

66 (G/Y) 2 (G/Y) Yes

3. Check continuity between BCM connector M19 terminals 65, 66 J

and ground.

Terminals (Wire color) Continuity

LIIA1479E

K

65 (V) No

Ground

66 (G/Y) No

L

OK or NG

OK >> Replace front door lock actuator RH.

NG >> Repair or replace harness. M

Revision: January 2005 BL-35 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

Rear Door Lock Actuator RH/LH Check EIS003NW

1. CHECK DOOR LOCK ACTUATOR SIGNAL

1. Turn ignition switch OFF.

2. Check voltage between BCM connector M20 terminals 65, 66

and ground.

Terminals

(Wire color) Voltage (V)

Connector Condition

(Approx.)

(+) (-)

Door lock/unlock switch 0 → Battery voltage

65 (V)

is turned to LOCK for 300 ms

M20 Ground

Door lock/unlock switch 0 → Battery voltage

66 (G/Y)

is turned to UNLOCK for 300 ms

LIIA1048E

OK or NG

OK >> GO TO 2.

NG >> Replace BCM. Refer to BCS-21, "Removal and Installation of BCM" .

2. CHECK DOOR LOCK ACTUATOR HARNESS

1. Disconnect BCM and each door lock actuator.

2. Check continuity between BCM connector M20 terminals 65, 66

and rear door lock actuator RH/LH connectors terminals 2, 3.

Terminal Continuity

65 (V) 3 (V) Yes

66 (G/Y) 2 (G/Y) Yes

3. Check continuity between BCM connector M20 terminals 65, 66

and ground.

Terminals (Wire color) Continuity

LIIA1480E

65 (V) No

Ground

66 (G/Y) No

OK or NG

OK >> Replace door lock actuator.

NG >> Repair or replace harness.

Revision: January 2005 BL-36 2004 Pathfinder Armada

POWER DOOR LOCK SYSTEM

Front Door Lock Assembly LH (Key Cylinder Switch) Check EIS003NX

1. CHECK DOOR KEY CYLINDER SWITCH LH A

With CONSULT-II

Check front door lock assembly LH (key cylinder switch) ("KEY CYL LK-SW") and ("KEY CYL UN-SW) in B

DATA MONITOR mode in CONSULT–II. Refer to BL-26, "DATA MONITOR" .

● When key inserted in front key cylinder is turned to LOCK:

C

KEY CYL LK-SW : ON

● When key inserted in front key cylinder is turned to UNLOCK:

KEY CYL UN-SW : ON D

LIIA0188E

F

Without CONSULT-II

Check voltage between main power window and door lock/unlock

switch connector D7 terminals 4, 6 and ground. G

Terminals (Wire

color) Voltage (V)

Connector Condition

(Approx.) H

(+) (–)

Neutral/Unlock 5

4 (L)

Lock 0

BL

D7 Ground

Neutral/Lock 5

6 (R)

Unlock 0 LIIA0566E

J

OK or NG

OK >> Front door lock assembly LH (key cylinder switch) signal is OK.

NG >> GO TO 2. K

2. CHECK DOOR KEY CYLINDER SWITCH LH

1. Turn ignition switch off. L

2. Disconnect front door lock assembly LH (key cylinder switch).

3. Check continuity between front door lock assembly LH (key cyl-

M

inder switch) connector terminals 1, 5 and 6.

Terminals Condition Continuity

1–5 Key is turned to LOCK. Yes

6–5 Key is turned to UNLOCK. Yes

OK or NG

OK >> Check the following.

● Front door lock assembly LH (key cylinder switch)

ground circuit. LIIA1573E

● Harness for open or short between main power win-

dow and door lock/unlock switch and front door lock assembly LH (key cylinder switch).

NG >> Replace front door lock assembly LH (key cylinder switch).

Revision: January 2005 BL-37 2004 Pathfinder Armada

REMOTE KEYLESS ENTRY SYSTEM

REMOTE KEYLESS ENTRY SYSTEM PFP:28596

Component Parts and Harness Connector Location EIS00295

WIIA0571E

Revision: January 2005 BL-38 2004 Pathfinder Armada

REMOTE KEYLESS ENTRY SYSTEM

System Description EIS00296

INPUTS A

Power is supplied at all times

● to BCM terminal 70

B

● through 50A fusible link (letter f , located in the fuse and fusible link box).

● to BCM terminal 57

● through 15A fuse [No. 22, located in the fuse block (J/B)].

C

When the key switch is ON, power is supplied

● to BCM terminal 37

● through key switch terminals 3 and 4 D

● through 10A fuse [No. 19, located in the fuse block (J/B)].

When the key switch is ACC or ON, power is supplied

● to BCM terminal 11 E

● through 10A fuse [No. 4, located in the fuse block (J/B)].

When the key switch is ON or START, power is supplied

F

● to BCM terminal 38

● through 10A fuse (No. 59, located in the fuse and relay box).

When the front door switch LH is ON (door is OPEN), ground is supplied G

● to BCM terminal 47

● through front door switch LH terminal 2

● to front door switch LH case ground. H

When the front door switch RH is ON (door is OPEN), ground is supplied

● to BCM terminal 12

● through front door switch RH terminal 2 BL

● to front door switch RH case ground.

When the rear door switch LH is ON (door is OPEN), ground is supplied

J

● to BCM terminal 48

● through rear door switch LH terminal 2

● to rear door switch LH case ground. K

When the rear door switch RH is ON (door is OPEN), ground is supplied

● to BCM terminal 13

● through rear door switch RH terminal 2 L

● to rear door switch RH case ground.

When the back door switch is ON (door is OPEN), ground is supplied

● to BCM terminal 43 M

● through back door switch terminal 3,

● through back door switch terminal 1,

● to body grounds B7 and B19.

Keyfob signal is inputted to BCM from the remote keyless entry receiver.

The remote keyless entry system controls operation of the

● power door lock

● back door opener

● interior lamp and step lamps

● panic alarm

● hazard and horn reminder

● keyless power window down (open)

● auto door lock operation

Revision: January 2005 BL-39 2004 Pathfinder Armada

REMOTE KEYLESS ENTRY SYSTEM

OPERATED PROCEDURE

● When the keyfob is operated, the signal from the keyfob is sent and the remote keyless entry receiver

receives the signal and sends it to the BCM. The BCM only locks/unlocks the doors if the ID number

matches. (Remote control entry functions)

● Using the keyfob, the transmitter sends radio waves to the remote keyless entry receiver, which then

sends the received waves to the BCM. Only if the ID number matches does the BCM lock/unlock the

doors. (Remote control door function)

● Unless the key is inserted into the ignition key cylinder or one of the doors is opened within 1 minute after

the UNLOCK switch on the keyfob is pressed, all the doors are automatically locked. (Auto lock function)

● When a door is locked or unlocked, the vehicle turn signal lamps flash and the horn sounds to verify oper-

ation. (Active check function)

● When the key is in the ignition key cylinder (when the key switch is ON) and one of the doors is open, the

door lock function does not work even when the door lock is operated with the keyfob.

● Keyfob ID set up is available.

● If a keyfob is lost, a new keyfob can be set up. A maximum of 5 IDs can be set up simultaneously.

Remote Control Entry Functions

Operation Description

● When a button on the keyfob is operated, the signal is sent from the keyfob and received by the keyless

remote entry receiver.

● The received signal is sent to the BCM and compared with the registered ID number.

● If the ID number matches, the BCM uses communication to send the lock/unlock signal to each door lock

actuator.

● When the door lock actuators receive this communication, each operates to lock/unlock its door.

Remote control entry operation conditions

Keyfob operation Operation condition

● With key removed (key switch: OFF)

Door lock operation (locking)

● Closing all doors (door switch: OFF)

Door lock operation (unlocking) With key removed (key switch: OFF)

Auto Lock Function

Operation Description

● Unless the key is inserted into the ignition key cylinder, one of the doors is opened, or the keyfob is oper-

ated within 1 minute after a door lock is unlocked by keyfob operation, all the doors are automatically

locked.

The 1 minute timer count is executed by the BCM and after 1 minute, the BCM sends the lock signal to all

doors.

Lock operations are the same as for the remote control entry function.

Remote Control Automatic Back Door Function (Vehicles With Automatic Back Door System)

Switching from all closed to all open

● When a button on the keyfob is operated, the signal is sent from the keyfob and received by the remote

keyless entry receiver.

● The received signal is sent to the BCM and compared with the registered ID number.

● If the ID number matches, the BCM uses power window serial link communication to send the back door

open signal to the back door control unit

● When the back door control unit receives the back door open signal for 0.5 continuous seconds, if the

remote control automatic back door operation enable conditions are met, the warning chime is sounded

and the back door unlock signal is sent to the back door latch using communication.

● When the back door latch receives the back door unlock signal, it operates the release actuator and

releases to back door latch.

● The back door control unit operates the back door motor to open the back door. (At this time, speed con-

trol, input reverse, and overload reverse control are executed.)

● When the back door is opened to the fully open position, the full-open position is detected with the rotation

sensor, the back door motor is stopped.

Revision: January 2005 BL-40 2004 Pathfinder Armada

REMOTE KEYLESS ENTRY SYSTEM

● The door held by the back door stays at the full open position.

Full open → full closed operation A

● When a button of the keyfob is operated, the signal is sent from the keyfob and received by the remote

keyless entry receiver.

● The received signal is sent to the BCM and compared with the registered ID number. B

● If the ID number matches, the BCM uses communication to send the back door close request signal to the

back door control unit.

● When the back door control unit receives the back door close request signal for 0.5 continuous seconds, if C

the remote control automatic back door operation enable conditions are met, the warning chime is

sounded and the back door motor begins closing the back door.

● The back door control unit operates the magnetic clutch and the back door motor to close the back door. D

(At this time, the back door control unit executes speed control, input reverse, and overload reverse con-

trol.)

● When the back door comes to the half-latch state, the back door latch detects the half-latch state through E

half-latch switch operation. The back door latch latches the back door.

For the automatic back door system operation enable conditions, refer to BL-89, "AUTOMATIC BACK DOOR

SYSTEM" . F

Active Check Function

Operation Description

When a door is locked or unlocked by keyfob operation, the vehicle turn signals flash and the horn sounds to G

verify operation.

● When a button on the keyfob is operated, the signal is sent from the remote controller and received by the

keyless remote entry receiver. H

● The received signal is sent to the BCM and compared with the registered ID number.

● If the ID number matches, the BCM uses communication to send the turn signal flashing and horn signal

to the IPDM E/R. BL

● The IPDM E/R flashes the turn signal lamps and sounds the horn for each keyfob operation.

Operating function of hazard and horn reminder

J

C mode S mode

Keyfob operation Lock Unlock Lock Unlock

Hazard warning lamp K

Twice Once Twice —

flash

Horn sound Once — — —

L

Hazard and Horn Reminder

BCM output to IPDM E/R for horn reminder signal as DATA LINE (CAN H line and CAN L line).

The hazard and horn reminder has C mode (horn chirp mode) and S mode (non-horn chirp mode).

How to change hazard and horn reminder mode M

With CONSULT-II

Hazard and horn reminder can be changed using “WORK SUPPORT” mode in “MULTI ANSWER BACK SET".

Without CONSULT-II

Refer to Owner's Manual for instructions.

Interior Lamp Operation

When the following input signals are both supplied:

● all door switches are in the OFF position. (when all the doors are closed);

● interior lamp switch is in DOOR position.

Remote keyless entry system turns on interior lamp and ignition illumination (for 30 seconds) with input of

UNLOCK signal from keyfob.

For detailed description, refer to LT-126, "ROOM LAMP TIMER OPERATION" .

Panic Alarm Operation

When key switch is OFF (when ignition key is not inserted in key cylinder), remote keyless entry system turns

on and off horn and headlamp intermittently with input of PANIC ALARM signal from keyfob.

Revision: January 2005 BL-41 2004 Pathfinder Armada

REMOTE KEYLESS ENTRY SYSTEM

The alarm automatically turns off after 25 seconds or when BCM receives any signal from keyfob.

Keyless Power Window Down (open) Operation

When keyfob unlock switch is turned ON with ignition switch OFF, and the switch is detected to be on continu-

ously for 3 seconds, the driver's door and passenger's door power windows are simultaneously opened.

Power window is operated to open and the operation continues as long as the keyfob unlock switch is

pressed.

CAN Communication System Description EIS00297

Refer to LAN-5, "CAN COMMUNICATION" .

Revision: January 2005 BL-42 2004 Pathfinder Armada

REMOTE KEYLESS ENTRY SYSTEM

Schematic EIS00298

BL

WIWA0196E

Revision: January 2005 BL-43 2004 Pathfinder Armada

REMOTE KEYLESS ENTRY SYSTEM

Wiring Diagram — KEYLES— EIS00299

FIG. 1

LIWA0427E

Revision: January 2005 BL-44 2004 Pathfinder Armada

REMOTE KEYLESS ENTRY SYSTEM

FIG. 2

A

BL

WIWA0197E

Revision: January 2005 BL-45 2004 Pathfinder Armada

REMOTE KEYLESS ENTRY SYSTEM

FIG. 3

WIWA0233E

Revision: January 2005 BL-46 2004 Pathfinder Armada

REMOTE KEYLESS ENTRY SYSTEM

Terminals and Reference Value for BCM EIS0029A

A

Wire Voltage (V)

Terminal Item Condition

Color (Approx.)

11 O Ignition switch (ACC) Ignition switch in ACC Battery voltage B

12 R/L Front door switch RH Door close (OFF) → Open (ON) Battery voltage → 0

13 R/W Rear door switch RH Door close (OFF) → Open (ON) Battery voltage → 0

C

18 P Ground — 0

Remote keyless entry receiver

19 V/W — 5

power supply

D

Remote keyless entry receiver E

20 G/W —

signal

F

Key inserted in IGN key cylinder →

37 B/R Key switch Battery voltage → 0

Key removed from IGN key cylinder

38 W/L Ignition switch (ON) Ignition switch ON Battery voltage

G

39 W CAN H — —

40 R CAN L — — H

42 GR Glass hatch ajar switch Glass close (OFF) → Open (ON) Battery voltage → 0

43 R/B Back door switch Door close (OFF) → Open (ON) Battery voltage → 0

47 SB Front door switch LH Door close (OFF) → Open (ON) Battery voltage → 0 BL

48 R/Y Rear door switch LH Door close (OFF) → Open (ON) Battery voltage → 0

Battery saver Battery saver does operated →

56 R/G Battery voltage → 0 J

(Interior lamp) Does not operated (ON → OFF)

57 Y/R Power source (BAT) — Battery voltage

Door lock & unlock switch

59 G Driver door lock actuator 0 → Battery voltage K

(Neutral → Unlock)

When doors are locked or unlocked

60 G/B Turn signal LH 0 → Battery voltage

using keyfob (OFF → ON) *2

L

When doors are locked or unlocked

61 G/Y Turn signal RH 0 → Battery voltage

using keyfob (OFF → ON) *2

Step lamp ON 0

62 R/W Step lamp LH and RH M

Step lamp OFF Battery voltage

Room lamp ON *1 Battery voltage

63 L Room lamp

Room Lamp OFF *1 0

Door lock & unlock switch

65 V Door lock actuators 0 → Battery voltage

(Neutral → Lock)

Passenger and rear doors lock Door lock & unlock switch

66 G/Y 0 → Battery voltage

actuator (Neutral → Unlock)

67 B Ground — 0

69 W/R Power window power source — Battery voltage

70 W/B Power source (BAT) — Battery voltage

● *1: when room lamp switch is in "DOOR" position.

● *2: when hazard reminder is ON.

Revision: January 2005 BL-47 2004 Pathfinder Armada

REMOTE KEYLESS ENTRY SYSTEM

Terminals and Reference Value for IPDM E/R EIS0029B

Wire Voltage (V)

Terminal Item Condition

Color (Approx.)

38 B Ground — 0

39 W CAN H — —

40 R CAN L — —

When doors locks are operated

45 G/W Horn relay Battery voltage → 0

using keyfob (OFF → ON) *