Metal Clad SWGR

Metal Clad SWGR

Uploaded by

Shady NasrCopyright:

Available Formats

Metal Clad SWGR

Metal Clad SWGR

Uploaded by

Shady NasrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Metal Clad SWGR

Metal Clad SWGR

Uploaded by

Shady NasrCopyright:

Available Formats

Respon

sibilities

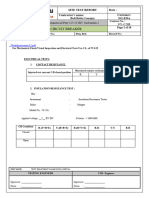

SITE TEST REPORT Date :

Legend

Contractor’s name: Customer:

CSD Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 1 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

Have all relevant safety instructions been followed?

..\WorkInstructions\29.pdf

For Mechanical Check/Visual Inspection and Electrical Tests Use C.L. of W.I.29

Name Plate Details

Make :

Type :

Media of Arc Extinguishing :

Rated Voltage (KV) :

Rated Normal Current (A) :

Rated Frequency (Hz) :

Rated lightning impulse withstand :

Voltage to earth

Rated Short Circuit breaking Current (kA) :

Rated Short Circuit making Current (kA) :

Motor - Aux. Volts - DC :

Auxiliary Volts

Close - DC :

Trip - DC :

Serial No. :

Date of Manufacturer :

1. Bus Continuity & Phasing Test

Testing Instrument :

Procedure : The bus continuity and the phase of the buses are checked at all the CB feeders.

Result :

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 2 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

2. Resistance of Bus Joints

Testing Instrument :

Make : S. No. :

Range :

Calibration Certificate :

Current to be applied : 100A DC

Connections : Both current & voltage leads are connected across a Bus

tapping point and outgoing cable termination points.

Resistance in mille Ohms

Switchgear Remarks

Phase A Phase B Phase C

Cubicle

Wiring Correctness

Testing Instrument

Continuity Tester : 1 No.

Procedure

All external wiring is checked for compliance to the termination schedules.

All Panels wiring correctness will be checked by continuity method as per approved drawing.

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 3 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

3. Resistance of Circuit Breaker - Main Contacts

Panel Designation :

Breaker Reference :

Instrument :

Make :

Model No. / Sl. No. :

Calibration Certificate :

Applied Current : 100 A DC

Circuit Breaker Status : Closed Position

Instrument Connection : i) Current leads & voltage leads connected to

terminals of CB

ii) Repeat for each phase.

Measured Value in Micro- Criteria

Phase REMARKS

Ohm Micro-Ohm

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 4 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

Resistance of Earth Switch – Main Contacts

Panel Reference :

Earth Switch Designation :

Instrument :

Make :

Model No. / Sl. No. :

Calibration Certificate :

Applied Current : 100 A DC

Earth Switch Status : Closed Position

Instrument Connection : i) Current leads & voltage leads connected to terminals of

Earth Switch.

ii) Repeat for each phase.

Measured Value in Micro-Ohm Criteria

Phase Remarks

Micro-Ohm

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 5 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

4. Control Wiring Insulation Resistance Check

Instrument :

Make :

Model No. / Sl. No. :

Voltage applied : 500 V DC

Applied points : Between Auxiliary Control circuits connected together as a whole and

frame of the switchgear.

Control circuits insulation

Resistance : M Ohms

Criteria : > 100 M Ohms

Result :

Note: Auxiliary control circuits shall include complete Switchgear control wiring.

TESTS ON SF6 CIRCUIT BREAKER

FEEDER DESIGNATION:

TESTS ON ANTI-PUMP RELAY

The anti-pump feature in the breakers were tested as follows:

1. The breaker was closed and the control switch was held in CLOSE position. It was ensured that the

breaker closes.

2. The breaker was tripped:

a) Manually b) Electrically

3. It will be noted from the results below that the breaker does not attempt to re-close if a permanent closing

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 6 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

signal is applied.

TRIP SIGNAL BREAKER BREAKER RESUL

ST

OPERATION APPLIED OPERATION STATUS TS

EP

1. Breaker control switch NO Breaker CLOSES Breaker remains

switched to “CLOSE” and CLOSED

held in CLOSE position.

2. Breaker control switch held YES Breaker trips and Breaker remains

in “CLOSE” position. Electrically does not attempt to OPEN

RECLOSE

3. Breaker control switch NO None Breaker remains

returned to NORMAL. OPEN

4. Breaker control switch NO Breaker CLOSES Breaker remains

switched to “CLOSE” and CLOSED

held in CLOSE position.

5. Breaker control switch held YES Breaker trips and Breaker remains

in “CLOSE” position. mechanically does not attempt to OPEN

RECLOSE

Breaker Insulation Resistance Test:

Instrument :

Make :

Model No. / Sl. No. :

Voltage applied : 5000 V DC

Equipment Status : CB in Closed Position.

Measured IR value

Applied points between Criteria Mega Remarks

( Mega. Ohms )

Ohms

A Phase to Ground > 500 60 sec

B Phase to Ground > 500

C Phase to Ground > 500

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 7 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

CURRENT TRANSFORMER

1. MECHANICAL CHECKS AND VISUAL INSPECTION:

TEST

TEST DESCRIPTION REMARKS

NO

1 Inspect for physical damage or defects.

2 Check nameplate information for correctness.

Check then outdoor secondary wiring terminations are installed in moisture proof

3

enclosures.

4 Check tightness of all bolted connections (torque wrench method).

5 Check that all grounding cables are securely connected.

6 Check secondary wiring is correctly color coded and size of wires is as specified.

7 Check proper lugs have been used on terminations.

Check CT locations physically and secondary terminal labeling has been done

8

correctly.

2. ELECTRICAL TESTS:

TEST

TEST DESCRIPTION REMARKS

NO

1 Insulation resistance test.

2 Winding resistance test.

3 Polarity test or flick test with battery.

4 Ratio test by current primary injection.

5 Magnetizing current test (minimum two points above knee points)

6 Loop resistance measurement test (burden test).

7 Phase identification test.

Verify secondary circuits, terminals, shorting/isolating links by primary injection of

8

CTs

9 Test intercore coupling for all bus differential CTs.

10 Demagnetize CT cores after all tests.

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 8 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

Re

sp

on 1. Insulation Resistance Test :

sibi Instrument :

Make : Model No. / Sl. No. :

Applied Voltage : 500 V DC

Criteria : More than 100 M Ohms

Phase Applied between IR Value in Mega Ohms Result

CORE-1 CORE-2

Primary - Secondary

A Primary - Earth

Secondary - Earth

Primary - Secondary

B Primary - Earth

Secondary - Earth

Primary - Secondary

C Primary - Earth

Secondary - Earth

1. Secondary Winding Resistance Measurement:

Instrument :

Make : Model No. / Sl. No. :

Criteria

Measured value in FAT

Phase CT Ref. Terminal Ohms (...deg.C) RESISTANCE Remarks

AT 75ºC (Ω)

CORE-1 1S1-1S2

A CORE-1 1S1-1S3

A CORE-2 2S1-2S2

CORE-1 1S1-1S2

B CORE-1 1S1-1S3

CORE-2 2S1-2S2

CORE-1 1S1-1S2

C CORE-1 1S1-1S3

CORE-2 2S1-2S2

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 9 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

3. Polarity Test

Tick here if found okay.

CT Ref. Polarity checked and found okay

A B C

4. Ratio Test

Terminal No. Primary Test Sec. Current %

Phase CT Ref. Ratio

Current A measured Error

1S1-1S2

1S1-1S2

A 1S1-1S2

1S1-1S2

1S1-1S3

1S1-1S3

1S1-1S3

1S1-1S3

1S1-1S2

1S1-1S2

B 1S1-1S2

1S1-1S2

1S1-1S3

1S1-1S3

1S1-1S3

1S1-1S3

1S1-1S2

1S1-1S2

C 1S1-1S2

1S1-1S2

1S1-1S3

1S1-1S3

1S1-1S3

1S1-1S3

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 10 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

Ratio Test

Secondry

TERMINAL Primary Test

PHASE CT REF RATIO C.T %Error

No Current (A)

Meas.

Core-2 2S1-2S2

A

Core-2 2S1-2S2

B

Core-2 2S1-2S2

C

Instruments:

1. Primary Injection Kit

Make : Model / Sl. No :

2. Tong Tester / Multimeter

Make : Model / Sl. No. :

5. Magnetization Curve Measurement:

Instruments:

Make : Model / Sl. No. :

Calibration certificate Ref.:

Criteria : The % error for magnetizing Current shall be within + 5% of the factory test report

.

Note: All CT cores shall be demagnetized after the tests are carried out.

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 11 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

CT Analyzer test results will be attached.

Magnetization Curve Measurement:

Measurement to be carried out at 8 points along the magnetization curve and

2 points above knee point voltage at maximum Tap.

Measured Values

Phase Description

1 2 3 4 5 6 7 8

CORE-1 Voltage (V)

Ratio:

Current (mA)

Terminal Nos.

Current from

magnetizing

Curve (mA)

CORE-1 Voltage (V)

Ratio:

A Current (mA)

Terminal Nos.

Current from

magnetizing

Curve (mA)

CORE-2

Voltage (V)

Ratio:

Current (mA)

Terminal Nos. Current from

magnetizing

Curve (mA)

CORE-2

Ratio: Voltage (V)

Current (mA)

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 12 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

Terminal Current from

Nos. magnetizing

Curve (mA)

Measured Values

Phase Description

1 2 3 4 5 6 7 8

CORE-1 Voltage (V)

Ratio:

Current (mA)

Current from

Terminal Nos.

magnetizing

Curve (mA)

CORE-1 Voltage (V)

B Ratio: Current (mA)

Current from

Terminal Nos.

magnetizing

Curve (mA)

CORE-2 Voltage (V)

Ratio:

Current (mA)

Current from

Terminal Nos. magnetizing

Curve (mA)

CORE-2

Ratio: Voltage (V)

Current (mA)

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 13 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

Current from

magnetizing

Terminal Curve (mA)

Nos.

Measured Values

Phase Description

1 2 3 4 5 6 7 8

Voltage (V)

CORE-1

Ratio:

Current (mA)

Current from

Terminal Nos.

magnetizing

Curve (mA)

Voltage (V)

CORE-1

C Ratio: Current (mA)

Current from

Terminal Nos.

magnetizing

Curve (mA)

CORE-2 Voltage (V)

Ratio:

Current (mA)

Current from

Terminal Nos. magnetizing

Curve (mA)

CORE-2

Ratio: Voltage (V)

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 14 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

Current (mA)

Current from

Terminal magnetizing

Nos. Curve (mA)

6. Burden Test

Instrument:

Current Injection Kit

Make :

Model / Sl. No. :

Rated Burden : CORE-1; 1S1-1S3= Ratio ; VA= UAL>=; Protection

CORE-2; 2S1-1S2= Ratio; VA= ; Metering

Calculated Burden Design

Measured

Phase CT Ref. (V x I) Burden

Volts

(VA)

A

CORE-1

CORE-2

B

CORE-1

CORE-2

C

CORE-1

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 15 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

CORE-2

7. PRIMARY INJECTION TEST

C.T. No. Application:

Core No.

Injected Measured Secondary Current (mA)

Current (A) R Y B N

Phase Identification Check (by shorting secondary terminal during primary injection) :

Note: All CT cores shall be demagnetized after the tests are carried out.

VOLTAGE TRANSFORMER

1. MECHANICAL CHECKS AND VISUAL INSPECTION:

TEST

TEST DESCRIPTION REMARKS

NO

1 Inspect for physical damage or defects.

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 16 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

TEST

TEST DESCRIPTION REMARKS

NO

2 Check nameplate information for correctness.

3 Check tightness of all bolted connection.

4 Check that the HV connection does not transfer stress to the HV terminal.

5 Check that all grounding cables are securely connected.

Check mechanical clearances and proper operation of all isolation and grounding

6

devices (as applicable).

7 Check integrity of primary fuses.

8 Check insulation liquid level (if applicable).

2. ELECTRICAL TESTS:

TEST

TEST DESCRIPTION REMARKS

NO

1. Winding resistance test.

Insulation resistance test HV TO G, LV TO G and HV TO LV using a one KV

2.

Insulation tester.

3. Ratio test.

4. Polarity test.

5. Primary and secondary fuses rating checks for 11 kv VTs and above (if applicable).

6. Check VT HV Neutral is solidly grounded.

7. Check electrical operation of all isolating and grounding devices (if applicable).

8. Check phase sequence, for the final three phase assembly.

9. Verify secondary circuits, terminal to terminal for correctness and tightness.

10. Loop resistance test and burden test.

11. Check gaps of protective flashover devices (if applicable).

12. Insulation power factor test, 10 kv and above.

13. Back energization test at rated voltage for 15 minutes

1. Winding Resistance (Secondary side)

Instrument :

Make :

Model No. / Sl. No. :

Phase Core Measured value in Ohms (C) FAT Remarks

RESISTANCE AT

75º C(Ω)

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 17 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

A 1

2

B 1

2

C 1

2

Formula to convert winding resistance to reference temperature at 75 C for copper winding.

NOTE: 1.

Rc = Calculated value at 75 C

Rm = Measurement value which contained a measurement cable.

NOTE: 2

Calculated 75 C Rc = (Rm-Rx) x (234.5+75)

(234.5+Ta)

Rx = Resistance value of the measurement cable.

Ta = Ambient Temperature C

NOTE: 3

Resistance value of measurement cable Rx = _______ Ω

2. Insulation Resistance Test:

Instrument :

Make :

Model No. / Sl. No. :

Applied Voltage : 500 V DC

Criteria : More than 10 M Ohms

Sl.No. Applied between IR Value in Mega Ohms Remarks

A Phase B Phase C Phase

Primary - Secondary - 1

1 Primary - Ground

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 18 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

Secondary-1 - Ground

Primary - Secondary-2

2 Secondary-2 - Ground

3 Secondary-1 – Secondary –2

3.Ratio test.

Terminal No. Primary Test Current A Sec. Current %

Phase CT Ref. Ratio

measured Error

1S1-1S2

1S1-1S2

A 1S1-1S2

1S1-1S2

1S1-1S3

1S1-1S3

1S1-1S3

1S1-1S3

1S1-1S2

1S1-1S2

B 1S1-1S2

1S1-1S2

1S1-1S3

1S1-1S3

1S1-1S3

1S1-1S3

1S1-1S2

1S1-1S2

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 19 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

C 1S1-1S2

1S1-1S2

1S1-1S3

1S1-1S3

1S1-1S3

1S1-1S3

TERMINAL Pry Test Sec. CT

PHASE CT REF RATIO %Error

No Current A Meas.

Core-2 2S1-2S2

A

Core-2 2S1-2S2

B

Core-2 2S1-2S2

C

Result:

4. Polarity Test

Instrument 1. Multimeter

2. Battery

Tick here if found okay

Polarity checked

Phase Core & found okay

A 1

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 20 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

2

B 1

2

C 1

2

5. Burden Test

Instrument:

Multimeter

Make :

Model / Sl. No. :

Calibration

Certificate ref. :

Voltage Current Burden Rated Burden

Phase Secondary Remarks

Applied Measured VxI

A 1

B 1

C 1

6. Back Energization Test at Rated Voltage

Instruments:

1. Three Phase Dimmerstat

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 21 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

Make :

Model / Sl. No. :

2. Multimeter (AC Voltmeter range) = 2 Nos.

Make :

Model / Sl. No. :

Calibration Certificate ref. :

3. Procedure

a) Remove the 13.8kV side HRC fuses of the potential transformers in all the three phases to

ensure that the primary induced voltage is not fed to the switchgear bus or the other equipments.

b) The voltage is applied at the Secondary terminals of the PT in the LV

Compartment through the 3 phase Dimmer stat. The voltage is increased from zero

To 115 V gradually and is stabilized at this value for 15 minutes.

Hi-Pot Test on Switchgear

Test Instruments

Make : Sl. No. :

Range : Calibration Certificate :

Procedure: : Test voltage to be applied is between phase and earth for 1

minute. The other two phases not under test are shorted and

earthed.

Breakers shall be tested in closed and in service position.

Test Voltage : 80 % of power frequency withstand voltage (Dry)

= 0.8 x 38 = 30kV RMS

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 22 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

Leakage (mA) Criteria Remarks

Phases

No Breakdown

A

No Breakdown

B

No Breakdown

C

Hi-Pot Test on Switchgear

IR Value Criteria

(mega Ohms) Mega Ohms Result

Phases

After

Before Hi-pot Test

Hi-pot Test

A > 1000

B > 1000

C > 1000

Functional Checks:

Sl. No. Criteria of Acceptance

Check to be performed Result

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 23 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

1. Checks for Circuit Breaker

i) Spring charging time .......... s Factory Test Result

ii) Motor current .......... A

at Rated Control Voltage

2. Functional check of Circuit Breaker Operation counter Proper Operation

Circuit Breaker Timing Test

3. Factory Test Result

A Ph. B Ph. C Ph.

i) Closing Time ......

ii) Opening Time for Closing Time

a) Trip Coil – 1 <75 ms

b) Trip Coil – 2 Opening Time

<65 ms

Verification of terminal to terminal CT secondary circuits.

4. As per approved drawing

Check for CT & PT Star point Ground connections.

Proper Grounding

5.

Verification of PT phases sequence and terminal to terminal

secondary circuits. As per approved drawing

6.

Minimum Control Voltage Trip & Close Operation

Sl. No. Description Criteria Measured

1. Minimum Trip coil pick up voltage < 70 V Trip Coil # 1 :

Trip Coil # 2 :

2. Minimum closing coil pick up < 90 V

voltage

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

SITE TEST REPORT Date :

Contractor’s name: Customer:

Hadi Haider Company NG-EOA

Contract No. :

Name of substation: Contruction of Mardumah 115/13.8kV 20BD 564-C31

Page 24 of 24

METAL CLAD SWITCHGEAR

Panel/Bay No: Equip. No.: Dwg. Ref.: Record No.:

Functional Test

Space Heater and Thermostat

Sl.No. Description Criteria Remarks

1. Supply Voltage 220 V AC

2. Thermostat Operation

Heater Circuit ON 55 ± 5 º F

Heater Circuit OFF 70 ± 5 º F

3. Heater Current ( A )

( Single Phase )

TEST DATE: TEST EQUIPMENT CALIB.DATE & DETAIL

TESTING ENGINEER CSD- Engineer

Signature: ________________ Signature: ________________

Name : ________________ Name : ________________

You might also like

- Checklist For Commissioning of CCTV SystemDocument2 pagesChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- 6.2 Why The Future Does Not Need UsDocument15 pages6.2 Why The Future Does Not Need UsCarolyn Elizabeth Barcemo93% (15)

- Checklist For T&C of CCTV SystemDocument2 pagesChecklist For T&C of CCTV Systemsheb_khaleelNo ratings yet

- MCB of Acdb Test ReportDocument1 pageMCB of Acdb Test Reportganeshapec8No ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Units: WashingtonDocument4 pagesUnits: WashingtonYunior Rodriguez100% (2)

- DISCONNECT&GROUNDING SWITCHEsDocument5 pagesDISCONNECT&GROUNDING SWITCHEsShady NasrNo ratings yet

- Site Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 1Document21 pagesSite Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 1Jayabal GnanaprakasamNo ratings yet

- Site Test Report: Contractor's NameDocument3 pagesSite Test Report: Contractor's NameJayabal GnanaprakasamNo ratings yet

- Site Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationDocument7 pagesSite Test Report Ng-Sa Name of Substation: Al-Tawdihiyah 132/33KV SubstationSyed Abbas100% (1)

- Alfanar Co.: Respon Sibilities Legend CSDDocument4 pagesAlfanar Co.: Respon Sibilities Legend CSDJayabal GnanaprakasamNo ratings yet

- 17.22 DC Supervision RXSF1Document3 pages17.22 DC Supervision RXSF1jayabalNo ratings yet

- Alfanar Co.: Respon Sibilities Legend CSDDocument4 pagesAlfanar Co.: Respon Sibilities Legend CSDjayabalNo ratings yet

- Respon Sibilities Legend CSD: Alfanar CoDocument3 pagesRespon Sibilities Legend CSD: Alfanar CojayabalNo ratings yet

- Surge ArresterDocument3 pagesSurge Arresterوليد موسىNo ratings yet

- Respon Sibilities Legend CSD: Site Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 1Document2 pagesRespon Sibilities Legend CSD: Site Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 1jayabalNo ratings yet

- Current TransformerDocument12 pagesCurrent TransformerSyed AbbasNo ratings yet

- VBHDocument7 pagesVBHJayabal GnanaprakasamNo ratings yet

- 9 LorDocument2 pages9 LorThameemul BuhariNo ratings yet

- Alfanar Co.: Site Test Report Sec-Eoa Name of Substation: Dammam Housing 115/13.8KV Substation # 1Document7 pagesAlfanar Co.: Site Test Report Sec-Eoa Name of Substation: Dammam Housing 115/13.8KV Substation # 1Jayabal GnanaprakasamNo ratings yet

- Alfanar Co.: Site Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 1Document3 pagesAlfanar Co.: Site Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 1jayabalNo ratings yet

- Alfanar Co.: Respon Sibilities Legend CSDDocument5 pagesAlfanar Co.: Respon Sibilities Legend CSDjayabalNo ratings yet

- 8.directional O.C Relay REQ650Document7 pages8.directional O.C Relay REQ650jayabalNo ratings yet

- 16 MVTPDocument3 pages16 MVTPjayabalNo ratings yet

- Alfanar Co.: Site Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 3 Aux - Relay (Rxmb1) TestDocument2 pagesAlfanar Co.: Site Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 3 Aux - Relay (Rxmb1) Testjayabal100% (1)

- Alfanar Co.: Respon Sibilities Legend CSDDocument1 pageAlfanar Co.: Respon Sibilities Legend CSDjayabalNo ratings yet

- Alfanar Co.: Site Test Report Sec-Eoa Name of Substation: Dammam Housing 115/13.8KV Substation # 1Document2 pagesAlfanar Co.: Site Test Report Sec-Eoa Name of Substation: Dammam Housing 115/13.8KV Substation # 1jayabalNo ratings yet

- Breaker Fail Relay REQ650Document6 pagesBreaker Fail Relay REQ650Jayabal Gnanaprakasam100% (1)

- 17.8 Omron MM4XPDocument2 pages17.8 Omron MM4XPjayabalNo ratings yet

- Alfanar Co.: Site Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 3Document2 pagesAlfanar Co.: Site Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 3jayabalNo ratings yet

- Potential TransformerDocument8 pagesPotential TransformerSyed AbbasNo ratings yet

- T-602 Test ReportDocument31 pagesT-602 Test Reportnaveendevi13No ratings yet

- LG Energy Test. RM3Document5 pagesLG Energy Test. RM3salmanNo ratings yet

- 36.6tv-Avr ZivDocument3 pages36.6tv-Avr ZivVinod KumarNo ratings yet

- Commissioning Check List For Access Control SystemDocument1 pageCommissioning Check List For Access Control SystemmohammadNo ratings yet

- 1414-PVB-FCC-ICL-PVSK-007-01 LV Panel TestDocument10 pages1414-PVB-FCC-ICL-PVSK-007-01 LV Panel TestNoorNo ratings yet

- Alfanar Co.: Site Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 1Document15 pagesAlfanar Co.: Site Test Report Ng-Sa Name of Substation: Dammam Housing 115/13.8KV Substation # 1Jayabal GnanaprakasamNo ratings yet

- 5.avr Relay Tapcon260Document9 pages5.avr Relay Tapcon260jayabalNo ratings yet

- 3 Rxba4Document2 pages3 Rxba4Thameemul BuhariNo ratings yet

- Current TransformerDocument10 pagesCurrent TransformerShady NasrNo ratings yet

- CT of AcdbDocument3 pagesCT of Acdbmaheshknm100% (1)

- 1414-Pvb-Fcc-Icl-Pvsk-001-01 MV TXDocument4 pages1414-Pvb-Fcc-Icl-Pvsk-001-01 MV TXNoorNo ratings yet

- Surge Arrester Test ReportDocument4 pagesSurge Arrester Test ReportAmr ElkadyNo ratings yet

- Respon Sibilities Legend CSD: Name of Substation: AC Distribution PanelsDocument2 pagesRespon Sibilities Legend CSD: Name of Substation: AC Distribution PanelsrohitduraiNo ratings yet

- Endira: Site Acceptance Test 17SAT-CB-002 HV-Circuit Breaker 1Document1 pageEndira: Site Acceptance Test 17SAT-CB-002 HV-Circuit Breaker 1Bravery DamanikNo ratings yet

- 1.station - Service TransformerDocument10 pages1.station - Service TransformerThameemul BuhariNo ratings yet

- Mvaj205 Test 4400003962/00 Sec - Coa: Description: Contract No.Document2 pagesMvaj205 Test 4400003962/00 Sec - Coa: Description: Contract No.wazakifyNo ratings yet

- Auxiliary Contactors Test FormatDocument1 pageAuxiliary Contactors Test FormatHumayun Ahsan100% (1)

- 19.station - Service TransformerDocument9 pages19.station - Service TransformerThameemul BuhariNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Power Transformer TestDocument24 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Power Transformer TestabderrahmaneNo ratings yet

- Mvaj205 Test 4400003962/00 Sec - Coa: Description: Contract No.Document2 pagesMvaj205 Test 4400003962/00 Sec - Coa: Description: Contract No.wazakifyNo ratings yet

- Ammeter, Voltmeter Testing Not Applicable For This PanelDocument3 pagesAmmeter, Voltmeter Testing Not Applicable For This Paneleswaran005100% (1)

- CVT ReportDocument7 pagesCVT ReportAmr ElkadyNo ratings yet

- 1 AcdbDocument9 pages1 AcdbmaheshknmNo ratings yet

- Site Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoaDocument2 pagesSite Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoawazakifyNo ratings yet

- Dry TR TestDocument9 pagesDry TR Testamjaad100% (1)

- Site Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoaDocument2 pagesSite Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoawazakifyNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Instrument TransformersDocument4 pagesSaudi Aramco Pre-Commissioning Form: Instrument TransformersJithuRaj0% (1)

- Site Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoaDocument2 pagesSite Inspection and Test Record: Mvaj205 Test 4400003962/00 Sec - CoawazakifyNo ratings yet

- Site Inspection and Test Record: Al - Babtain S/S 8715 (132/13.8 KV)Document3 pagesSite Inspection and Test Record: Al - Babtain S/S 8715 (132/13.8 KV)m khNo ratings yet

- Form Test - 001-015Document51 pagesForm Test - 001-015RadityaDoriRevanoskySitorusNo ratings yet

- MVAX31Document6 pagesMVAX31Shady NasrNo ratings yet

- INDOOR CIRCUITBREAKERsDocument10 pagesINDOOR CIRCUITBREAKERsShady NasrNo ratings yet

- Current TransformerDocument10 pagesCurrent TransformerShady NasrNo ratings yet

- HVPD - CIRED 2013 - Combined Power Quality and Condition Monitoring of Offshore NetworksDocument4 pagesHVPD - CIRED 2013 - Combined Power Quality and Condition Monitoring of Offshore NetworksShady NasrNo ratings yet

- DQ - Autoclave FDocument5 pagesDQ - Autoclave Fgayatri maldhureNo ratings yet

- Macionis GlobalizationDocument4 pagesMacionis GlobalizationPoinsithia OrlandaNo ratings yet

- Fort ListDocument14 pagesFort ListAbhijit B. BagulNo ratings yet

- TP - Penology & Victimologgy - Jan-May-2022Document13 pagesTP - Penology & Victimologgy - Jan-May-2022sachet12No ratings yet

- EGEC Market Report Update ONLINEDocument24 pagesEGEC Market Report Update ONLINELia Badea100% (1)

- s958-Stpm Computing SyllabusDocument30 pagess958-Stpm Computing SyllabusjackNo ratings yet

- 10 SPWLA D 11 00183 Improved Formation Evaluation While Drilling With A New Heavy Gas DetectorDocument12 pages10 SPWLA D 11 00183 Improved Formation Evaluation While Drilling With A New Heavy Gas DetectorpendexxNo ratings yet

- Redapt Hazardous Area GuideDocument11 pagesRedapt Hazardous Area Guidescribd8421100% (1)

- Review of LiteratureDocument78 pagesReview of Literaturesm_bolke_422802317No ratings yet

- Introduction To AiDocument13 pagesIntroduction To Aisuryakant barkadeNo ratings yet

- WEEK 7 Introduction To Mechanical EngineeringDocument42 pagesWEEK 7 Introduction To Mechanical EngineeringRahim AssaniNo ratings yet

- Silabus AI 1Document7 pagesSilabus AI 1Aisyah Nadiatul HikmahNo ratings yet

- Friday VerniceDocument47 pagesFriday VerniceNastase Daniela EcaterinaNo ratings yet

- Calculate Density of A PowderDocument6 pagesCalculate Density of A PowderPrathyusha RamadurgamNo ratings yet

- ALSA Academic Publications Guidebook 2021 2022Document12 pagesALSA Academic Publications Guidebook 2021 2022Đồng Hoài NamNo ratings yet

- Instant Download Test Bank For Chemistry The Science in Context, Fourth Edition PDF All ChapterDocument36 pagesInstant Download Test Bank For Chemistry The Science in Context, Fourth Edition PDF All Chaptergeralpara53No ratings yet

- Motovolt E BrochureDocument36 pagesMotovolt E BrochurehemprasadbadgujarNo ratings yet

- Directions For The User: Northern Mindanao Colleges, IncDocument7 pagesDirections For The User: Northern Mindanao Colleges, IncBrian Reyes GangcaNo ratings yet

- Slide Trí Tuệ Nhân Tạo - Lecture04 - CSP - Phạm Bảo Sơn - UETDocument40 pagesSlide Trí Tuệ Nhân Tạo - Lecture04 - CSP - Phạm Bảo Sơn - UETNgocNo ratings yet

- EHSDP0120.9 Crane Operation Pre-Lift ChecklistDocument1 pageEHSDP0120.9 Crane Operation Pre-Lift Checklistshravani mangalpalliNo ratings yet

- Adobe Scan 18 Jan 2023Document10 pagesAdobe Scan 18 Jan 2023亗AYUSH彡0% (1)

- May 2015 Che Board ExaminationDocument12 pagesMay 2015 Che Board ExaminationIvan Jio Revilla SanchezNo ratings yet

- MDWG-63-2 April I, 1963: GPO Price $Document306 pagesMDWG-63-2 April I, 1963: GPO Price $Mihaela NastaseNo ratings yet

- Transport Phenomena 1Document8 pagesTransport Phenomena 1Al- DhaheriNo ratings yet

- Risk Assessment in Block Cave Mining: Ingles Tecnico IiDocument8 pagesRisk Assessment in Block Cave Mining: Ingles Tecnico IiRossana AngelesNo ratings yet

- English For Acad Quarter 1 Module 1Document3 pagesEnglish For Acad Quarter 1 Module 1Rovelyn FigueroaNo ratings yet

- GSP LettersDocument11 pagesGSP LettersRHYSLYN RUFIN SALINASNo ratings yet

- A Social Media Plan For The Ultimate Fighting ChampionshipDocument36 pagesA Social Media Plan For The Ultimate Fighting Championshiplwalker1545No ratings yet