SM CS V7,9,12BKPG

SM CS V7,9,12BKPG

Uploaded by

Redi RiyantoCopyright:

Available Formats

SM CS V7,9,12BKPG

SM CS V7,9,12BKPG

Uploaded by

Redi RiyantoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

SM CS V7,9,12BKPG

SM CS V7,9,12BKPG

Uploaded by

Redi RiyantoCopyright:

Available Formats

Order No.

MAC0205021C2

Multi-Split Air Conditioner

CS-V9BKPG CU-2V14BKP5G CS-V9BKPG CU-2V18BKP5G CS-V9BKPG CU-3V20BKP5G CS-V7BKPG CU-2V19BKP5G CS-V12BKPG

CONTENTS

Page

1 Features 2 Functions 3 Product Specifications 4 Dimensions 5 Refrigeration Cycle Diagram 6 Block Diagram 7 Wiring Diagram 8 Operation Details 9 Operating Instructions 10 Installation Instructions 2 3 6 14 16 18 22 26 34 39 11 Installation and Servicing Air Conditioner Using R410A 12 Servicing Information 13 Troubleshooting Guide 14 Technical Data 15 Exploded View 16 Replacement Parts List 17 Exploded View 18 Replacement Parts List 19 Exploded View 20 Replacement Parts List

Page

49 60 64 66 72 73 74 75 76 77

2002 Matsushita Industrial Corp. Sdn. Bhd. (11969-T). All rights reserved. Unauthorized copying and distribution is a violation of law.

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

21 Exploded View 22 Replacement Parts List 23 Exploded View

78 79 80

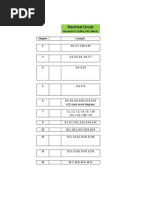

24 Replacement Parts List 25 Electronic Parts List 26 Electronic Circuit Diagram

81 82 83

1 Features

High Efficiency Compact Design Comfort Environment 8 hours of sleep mode operation Air filter with function to reduce dust and smoke Wider range of horizontal discharge air Auto Restart Random auto restart after power failure for safety restart operation Removable and Washable Front Panel Remote Control Self-illuminating Button Catechin Air Purifying Filter Trap dust, tobacco smoke and tiny particles Prevent the growth of bacteria and viruses trapped Solar Refreshing Deodorizing Filter Remove unpleasant odour from the air Operation Improvement Economy mode to reduce electrical power consumption Powerful mode to reach the desired room temperature quickly Long Installation Piping Long piping up to 15 meter 24-hour Timer Setting Environmental Friendly R410A, which does not contain chlorine, is used as its refrigerant, so there is no danger of damage to the ozone layer in stratosphere . Quality Improvement Gas leakage protection Prevent compressor reverse cycle 2-stage OLP to protect compressor Noise prevention during soft dry operation. Anti-dew Formation Control (Cooling & Soft Dry)

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

2 Functions

Remote Control

Self illuminating button

OFF / ON I

Operation OFF / ON

TEMP.

Room Temperature Setting

Cooling, Soft Dry, Air Circulation Operation. Temperature Setting (16C to 30C)

MODE

Operation Mode Selection

AUTO COOL DRY FAN

Automatic Operation Mode Cooling Operation Mode Soft Dry Operation Mode Air Circulation Mode

ON-TIMER OFF-TIMER

Automatic Operation Operation with 2C higher than standard temperature. Operation with standard temperature. Operation with 2C lower than standard temperature.

FAN SPEED

Indoor Fan Speed Selection

FAN FAN FAN AUTO FAN

Low Fan Speed Medium Fan Speed High Fan Speed Automatic Fan Speed

Timer Operation Selection

24-hour, OFF / ON Real Timer Setting.

TIME

Time / Timer Setting

Hours and minutes setting.

AIR SWING

Vertical Airflow Direction Control

AUTO MANUAL

SET CANCEL

Automatic Vertical Airflow Direction Control Vertical Airflow Direction Manual Control (5 stages of adjustment)

Timer Operation Set / Cancel

ON Timer and OFF Timer setting and cancellation.

CLOCK

Clock Setting

Current time setting.

POWERFUL

Powerful Mode Operation OFF/ON Economy Mode Operation OFF/ON

SLEEP

ECONOMY

Sleep Mode Operation OFF / ON

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

Indoor Unit

AUTO OFF / ON

Automatic Operation Button

Press for < 5s to operate Automatic operation mode. (Used when the remote control cannot be used.) Press continuously for 5s or < 10s to operate Test Run/Pump down. Beep sound will be heard at the 5th second. (Used when test running or servicing.) Press continuously for 10s and above to omit or resume the remote control signal receiving sound. Beep, beep sound will be heard at the 10th second.

Random Auto Restart Control

Operation is restarted randomly after power failure at previous setting mode.

Anti-Freezing Control

Anti-Freezing control for indoor heat exchanger. (Cooling and Soft Dry)

Sleep Mode Auto Control

Indoor Fan operates at Low speed. Operation stops after 8 hours.

Operation Indication Lamps (LED)

(Green) ........ Lights up in operation, blinks in Automatic Operation Mode judging. SLEEP (Orange) ........ Lights up in Sleep Mode Operation. TIMER (Orange) ....... Lights up in Timer Setting. POWERFUL (Orange) .. Lights up in Powerful Mode Operation. ECONOMY (Green) ..... Lights up in Economy Mode Operation.

POWER

Indoor Fan Speed Control

High, Medium and Low. Automatic Fan Speed Mode Cooling : Fan rotates at Hi, Me and SLo speed. Deodorizing control is available. Soft Dry: Fan rotates at SLo speed. Deodorizing control is available.

Airflow Direction Control

Automatic air swing and manual adjusted by remote control for vertical airflow. Manually adjusted by hand for horizontal airflow.

Operation Mode

Cooling, Soft Dry, Air Circulation and Automatic Mode.

Starting Current Control

Fan motor is delayed for 1.6 seconds when compressor starts simultaneously.

Powerful Operation

Reaches the desired room temperature quickly.

Time Delay Safety Control

Restarting is inhibited for appro. 3 minutes.

Economy Operation

To reduce electrical power consumption.

7 Minutes Time Save Control

Cooling Operation only.

Anti-Dew Formation Control

Anti-Dew Formation Control for indoor unit discharge area.

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

Outdoor Unit

CU-2V14BK, CU-2V18BK, CU-2V19BK & CU-3V20BK

Compressor Reverse Rotation Protection Control

To protect compressor from reverse rotation when there is a instantaneous power failure.

Overload Protector

2-Stage OLP to protect the compressor. Overload Protector will trip when Temperature of compressor increases to 120C. High temperature or high current flows to compressor. (Refer circuit diagram for OLP characteristic)

60 Secs. Forced Operation Control

Once the compressor is activated, it does not stop within the first 60 secs. However, it stops immediately with remote control stop signal.

Outdoor Fan Operation Control

Temperature Fuse.

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

3 Product Specifications

Unit Power Source Phase V Cycle CS-V9BKPG Single 230 50 CU-2V14BKP5G

Cooling Capacity

kW kcal/h

(1 unit) 3.00 2,580

(2 units) 3.70 3,180

Moisture Removal

l/h Pint/h

(1 unit) 1.7 3.6

(2 units) 2.2 4.6

Airflow Method

OUTLET

SIDE VIEW

TOP VIEW

INTAKE

Air Volume

Indoor Indoor Indoor Indoor

Air Air Air Air

(Lo) (Me) (Hi) (SHi)

m3/min m3/min m3/min m3/min

(cfm) (cfm) (cfm) (cfm)

6.8 (240) 8.0 (280) 9.9 (350) 10.9 (380) High 36, Low 26

High 47

Noise Level

dB (A)

Power level dB

High 49

High 62

Electrical Data

Input

(1 unit) 1,180

(2 units) 1,240

Running Current

(1 unit) 5.3

(2 units) 5.6

EER

W/W kcal/hW A inch inch inch inch mm m inch (mm) inch (mm) inch (mm) lb (kg)

(1 unit) 2.54 2.19 17.8 G ; Half Union 3/8 L ; Half Union 1/4 G (gas side) ; 3/8 L (liquid side) ; 1/4 12 0.7 10 - 13/16 (275) 31 - 15/32 (799) 8 - 9/32 (210) 20 (9.0)

(2 units) 2.98 2.56

Starting Current Piping Connection Port (Flare piping) Pipe Size (Flare piping) Drain Inner diameter Hose Length Dimensions Height Width Depth Net Weight Compressor Type Motor Rated Type Output

G ; 3-way valve 3/8 L ; 3-way valve 1/4 G (gas side) ; 3/8 L (liquid side) ; 1/4 21 - 1/4 (540) 29 - 15/16 (760) 9 - 7/8 (250) 75 (34.0) Rotary (1 cylinder) rolling piston type Induction (2-poles) 830

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

Air Circulation Motor

Fan Speed

Type Material Type Input Rated Output Low Medium High SuperHigh

W W rpm rpm rpm rpm

Heat Exchanger

Description Tube material Fin material Fin Type Row / Stage

FPI Size (W H L) Refrigerant Control Device Refrigeration Oil Refrigerant (R410A) Thermostat Protection Device Capillary Tube

mm (c.c) g (oz)

Air Filter Capacity Control Compressor Capacitor Fan Motor Capacitor

Length Flow Rate Inner Diameter Material Style

mm l/min mm (c.c)

F, VAC F, VAC

Cross-flow Fan Propeller Fan AS + Glass Fiber 20% AS + Glass Fiber 20% Induction (4-poles) Induction (6-poles) 29.3 39.4 15 15 800 940 1,160 795 1,250 Evaporator Condenser Copper Copper Aluminium Aluminium Slit Fin Louver Fin (Plate fin configuration, forced draft) 2 15 1 20 19 17 610 315 25.4 687 508 22 Capillary Tube SUNISO 4GDID or ATMOS M60 (330) 970 (34.2) Electronic Control Overload Protector 615 14.4 1.6 P.P. Honeycomb Capillary Tube 35 F, 400 VAC 1.5 F, 400 VAC 1.0 F, 430 VAC

Specifications are subject to change without notice for further improvement .

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

Unit Power Source Phase V Cycle

CS-V9BKPG Single 230 50

CU-2V18BKP5G

Cooling Capacity

kW kcal/h

(1 unit) 2.73 2,350

(2 units) 5.46 4,700

Moisture Removal

l/h Pint/h

(1 unit) 1.6 3.4

(2 units) 3.0 6.3

Airflow Method

OUTLET

SIDE VIEW

TOP VIEW

INTAKE

Air Volume

Indoor Indoor Indoor Indoor

Air Air Air Air

(Lo) (Me) (Hi) (SHi)

m3/min m3/min m3/min m3/min

(cfm) (cfm) (cfm) (cfm)

6.8 (240) 8.0 (280) 9.9 (350) 10.9 (380) High 36, Low 26

High 55

Noise Level

dB (A)

Power level dB

High 49

High 70

Electrical Data

Input

(1 unit) 860

(2 units) 1,720

Running Current

(1 unit) 3.9

(2 units) 7.8

EER Starting Current Piping Connection Port (Flare piping) Pipe Size (Flare piping) Drain Inner diameter Hose Length Dimensions Height Width Depth Net Weight Compressor Type Motor Rated Type Output

W/W (kcal/hW) A inch inch inch inch mm m inch (mm) inch (mm) inch (mm) lb (kg)

3.17 (2.73) 15.9 G ; Half Union 3/8 L ; Half Union 1/4 G (gas side) ; 3/8 L (liquid side) ; 1/4 12 0.7 10 - 13/16 (275) 31 - 15/32 (799) 8 - 9/32 (210) 20 (9.0) G ; 3-way valve 3/8 L ; 3-way valve 1/4 G (gas side) ; 3/8 L (liquid side) ; 1/4 25 - 21/32 (651) 35 - 3/16 (893) 13 - 19/32 (345) 141 (64) Rotary (1 cylinder) rolling piston type Induction (2-poles) 780

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

Air Circulation Motor

Fan Speed

Type Material Type Input Rated Output Low Medium High SuperHigh

W W rpm rpm rpm rpm

Heat Exchanger

Description Tube material Fin material Fin Type Row / Stage

FPI Size (W H L) Refrigerant Control Device Refrigeration Oil Refrigerant (R410A) Thermostat Protection Device Capillary Tube

mm (c.c) g (oz)

Air Filter Capacity Control Compressor Capacitor Fan Motor Capacitor

Length Flow Rate Inner Diameter Material Style

mm l/min mm (c.c)

F, VAC F, VAC

Cross-flow Fan Propeller Fan AS + Glass Fiber 20% AS + Glass Fiber 20% Induction (4-poles) Induction (6-poles) 29.3 123.0 15 50 800 940 1,160 760 1,250 Evaporator Condenser Copper Copper Aluminium Aluminium Slit Fin Louver Fin (Plate fin configuration, forced draft) 2 15 2 24 19 14 610 315 25.4 560 609.6 44 Capillary Tube SUNISO 4GDID or ATMOS M60 (330) 880 2 (31.0 2) Electronic Control Overload Protector 1,160 7.0 1.4 P.P. Honeycomb Capillary Tube 30 F, 370 VAC 1.5 F, 400 VAC 3.0 F, 450 VAC

Specifications are subject to change without notice for further improvement .

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

Unit

CS-V9BKPG Single Operation (A, B1, B2)

Single Operation (A) (B1 or B2)

CU-3V20BKP5G Double Operation (B1 + B2)

Triple Operation (A + B1 or B2) (A + B1 + B2)

Power Source

Phase V Cycle kW kcal/h l/h Pint/h OUTLET 2.73 2,350 1.6 3.4 2.95 2,540 1.7 3.6

Single 230 50 3.82 3,290 2.2 4.6 TOP VIEW 5.68 4,890 3.1 6.6 6.55 5,630 3.7 7.8

Cooling Capacity Per Unit Moisture Removal

Airflow Method

SIDE VIEW

INTAKE

Air Volume

Indoor Air (Lo) Indoor Air (Me) Indoor Air (Hi) Indoor Air (SHi)

m3/min (cfm) m3/min (cfm) m3/min (cfm) m3/min (cfm) dB (A)

6.8 (240) 8.0 (280) 9.9 (350) 10.9 (380) High 36, Low 26 High 49

Noise Level

High 56

Power level dB Electrical Data Input W

High 71

50

910

1,120

1,200

1,940

1,990

Running Current

0.23

4.1

5.0

5.3

8.6

8.9

EER

W/W (kcal/hW)

3.00 2.58

2.63 2.27

3.18 2.74 (B unit) 17.8 G ; 3-way valve 3/8 L ; 3-way valve 1/4 G (gas side) ; 3/8 L (liquid side) ; 1/4 25 - 21/32 (651) 35 - 3/16 (893) 13 - 19/32 (345) 146 (66) Rotary (1 cylinder) rolling piston type Induction (2-poles)

2.93 2.52

3.29 2.83

Starting Current Piping Connection Port (Flare piping) Pipe Size (Flare piping) Drain Inner diameter Hose Length Dimensions Height Width Depth Net Weight Compressor Type Motor Rated Type Output

A (A unit) 15.9 inch G ; Half Union 3/8 inch L ; Half Union 1/4 inch G (gas side) ; 3/8 inch L (liquid side) ; 1/4 mm 12 m 0.7 inch (mm) 10 - 13/16 (275) inch (mm) 31 - 15/32 (799) inch (mm) 8 - 9/32 (210) lb (kg) 20 (9.0)

(A unit) 780

(B unit) 830

10

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

Air Circulation Motor

Type Material Type Input Rated Output Fan Speed Low Medium High SuperHigh Description Tube material Fin material Fin Type Row / Stage FPI Size (W H L)

W W rpm rpm rpm rpm

Heat Exchanger

Cross-flow Fan AS + Glass Fiber 20% Induction (4-poles) 29.3 15 800 940 1,160 1,250 Evaporator Copper Aluminium Slit Fin 2 15 19 610 315 25.4 Electronic Control P.P. Honeycomb 1.5 F, 400 VAC

Propeller Fan AS + Glass Fiber 20% Induction (6-poles) 123.0 50 760 Condenser Copper Aluminium Louver Fin (Plate fin configuration, forced draft) 2 24 14 756.0 609.6 44 719.5 Capillary Tube SUNISO 4GDID or ATMOS M60 (330, 330) (A unit) 780 (27.5) (B unit) 1,000 (35.3) Overload Protector 780, 645, 950 16.2/13.5, 8.0 1.8, 1.6, 1.4 Capillary Tube 30/35 F, 370 VAC 3.0 F, 450 VAC

mm

Refrigerant Control Device Refrigeration Oil Refrigerant (R410A) Thermostat Protection Device Capillary Length Tube Flow Rate Inner Diameter Air Filter Material Style Capacity Control Compressor Capacitor Fan Motor Capacitor

(c.c) g (oz)

mm l/min mm

F, VAC F, VAC

Specifications are subject to change without notice for further improvement .

11

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

Unit Cooling Capacity kW kcal/h

One Unit (A) CS-V12BKPG (A) 3.55 (A) 3,050

One Unit (B) CS-V7BKPG (B) 2.10 (B) 1,810

CU-2V19BKP5G (A+B) 5.65 (A+B) 4,860

Moisture Removal

l/h Pint/h

(A) 2.1 4.4

(B) 1.4 3.0

(A+B) 3.1 6.6

Power Source

Phase V Cycle

Single 230 50

Airflow Method

OUTLET

SIDE VIEW

TOP VIEW

INTAKE

Air Volume

Indoor Indoor Indoor Indoor

Air Air Air Air

(Lo) (Me) (Hi) (SHi)

m3/min m3/min m3/min m3/min

(cfm) (cfm) (cfm) (cfm)

7.3 (260) 8.7 (310) 10.2 (360) 10.5 (370) (A) High 39 Low 29 (A) High 52

6.4 7.4 8.5 9.4

(230) (260) (300) (330)

High 55

Noise Level

dB (A)

(B) High 33 Low 26 (B) High 46

Power level dB Electrical Data Input W

High 70

(A) 1,230

(B) 720

(A+B) 1,850

Running Current

(A) 5.5

(B) 3.2

(A+B) 8.3

EER

W/W (kcal/hW) A inch inch inch inch mm m inch (mm) inch (mm) inch (mm) lb (kg)

(A) 2.89 (2.48)

(B) 2.92 (2.51)

(A+B) 3.05 (2.63) (A+B) 30.3 G ; 3-way valve 1/2, 3/8 L ; 3-way valve 1/4, 1/4 G (gas side) ; 1/2, 3/8 L (liquid side) ; 1/4, 1/4 25 - 21/32 (651) 35 - 3/16 (893) 13 - 19/32 (345) 146 (66) Rotary (1 cylinder) rolling piston type Induction (2-poles) (A+B) 1,500 Propeller Fan AS + Glass Fiber 20% Induction (6-poles) 123.0 50 760

Starting Current Piping Connection Port (Flare piping) Pipe Size (Flare piping) Drain Inner diameter Hose Length Dimensions Height Width Depth Net Weight Compressor Type Motor Rated Air Circulation Motor Type Output Type Material Type Input Rated Output Low Medium High SuperHigh

(A) 17.8 (B) 12.5 G ; Half Union 1/2, 3/8 L ; Half Union 1/4, 1/4 G (gas side) ; 1/2, 3/8 L (liquid side) ; 1/4, 1/4 12 0.7 10 - 13/16 (275) 31 - 15/32 (799) 8 - 9/32 (210) 20 (9.0)

Fan Speed

W W rpm rpm rpm rpm

(B) 670 Cross-flow Fan AS + Glass Fiber 20% Induction (4-poles) (A) 28.7 (B) 20.6 15 (A) 900 (B) 800 (A) 1,080 (B) 920 (A) 1,260 (B) 1,050 (A) 1,300 (B) 1,140

(A) 830

12

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

Heat Exchanger

Description Tube material Fin material Fin Type Row / Stage FPI Size (W H L)

mm

Refrigerant Control Device Refrigeration Oil Refrigerant (R410A) Thermostat Protection Device Capillary Tube

(c.c) g (oz)

Air Filter

Length Flow Rate Inner Diameter Material Style

mm l/min mm (c.c)

Capacity Control Compressor Capacitor Fan Motor Capacitor

F, VAC F, VAC

Evaporator Condenser Copper Copper Aluminium Aluminium Slit Fin Louver Fin (Plate fin configuration, forced draft) (A) 2 15 (B) 2 15 2 24 21 19 14 610 315 25.4 756 609.6 44 719.5 Capillary Tube SUNISO 4GDID or ATMOS M60 (330, 330) (A) 1,050 (37.0) (B) 860 (30.3) Electronic Control Overload Protector (A) 1,160 (B) 810 (A) 10.5 (B) 7.0 (A) 1.6 (B) 1.3 P.P. Honeycomb Capillary Tube (A) 35 F, 370 VAC (B) 25 F, 370 VAC 1.5 F, 400 VAC 3.0 F, 450 VAC

Specifications are subject to change without notice for further improvement .

13

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

4 Dimensions

14

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

15

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

5 Refrigeration Cycle Diagram

16

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

17

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

6 Block Diagram

18

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

19

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

20

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

21

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

7 Wiring Diagram

22

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

23

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

24

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

25

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

8 Operation Details

8.1. Cooling Mode Operation

Cooling in operation according to Remote Control setting.

Time Delay Safety Control (3 minutes) When the compressor is stopped by Remote Control, it restarts after 3 minutes when the Remote Control is turned ON. When the setting temperature is reached during cooling operation, the compressor stops and it will not start for 3 minutes. 7 minutes Time Save Control The compressor will start automatically if it has stopped for 7 minutes even if the room temperature is between the compressor ON temperature and OFF temperature.

Starting Current Control When the compressor outdoor fan motor and indoor fan motor are simultaneous ly started, the indoor fan motor will operate 1.6 second later.

Anti-Freezing Control If the temperature of the indoor heat exchanger falls continuously below 2C for 4 minutes or more, the compressor turns off to protect the indoor heat exchanger from freezing. The fan speed setting remains the same. Compressor will restart again when the indoor heat exchanger temperature rises to 10C (Recovery).

3 minutes waiting of Time Delay Safety Control is valid for Cooling Operation.

Compressor Reverse Rotation Protection Control If the compressor is operating continuously for 5 minutes or longer and the temperature difference between intake air and indoor heat exchanger is 2.5C or less for 2 minutes, compressor will stop and restart automatically . (Time Delay Safety Control is valid)

T = Intake air temperature - Indoor heat exchanger temperature This is to protect reverse rotation of the compressor when there is a instantaneou s power failure.

Anti-Dew Formation Control Purpose is to prevent dew formation on indoor unit air discharge area. When the following conditions accur for 30 minutes continuously , anti-dew formation is controlled by indoor fan speed shift to low (CLo to HLo): Indoor intake air temperature is more than 24C and less than 30C. Remote Control setting temperature is less than 25C. Compressor is on. Cooling operation mode. Indoor Fan motor operate at Low fan speed. This control is cancelled immediately when above condition is changed. 26

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

Automatic Fan Speed Mode

When Automatic Fan Speed is selected at Remote Control during cooling operation. Fan speed rotates in the range of Hi to Me. Deodorizing Control.

Cooling Operation Time Diagram

27

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

8.2.

Soft Dry Mode Operation

The unit starts cooling operation until the room temperature reaches the setting temperature set on the Remote Control, and then Soft Dry operation will start. During Soft Dry operation, the Indoor Fan will operate at SLo speed. The operation will be switched on and off for up to 10 minutes ON and 6 minutes OFF. Once Soft Dry operation is turned off, it stops for 6 minutes.

Time Delay Safety Control Once the compressor stops, it will not start for 3 minutes during Cooling operation. Starting Current Control Same as Starting Current Control for Cooling Mode operation. Anti-Freezing Control Same as Anti-Freezing Control for Cooling Mode operation. (For Soft Dry region, 6 minutes waiting is valid during compressor stops.)

Compressor Reverse Rotation Protection Control Same as Compressor Reverse Rotation Protection Control for Cooling Mode Operation. (For Soft Dry region, 6 minutes waiting is valid during compressor stops.)

Anti-Dew Formation Control Same as Anti-Dew Formation Control for Cooling Mode operation. Automatic Fan Speed Mode When Automatic Fan Speed is selected at Remote Control during Soft Dry operation. Fan speed off and on at SLo speed. Deodorizing Control.

28

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

Soft Dry Operation Time Diagram

29

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

8.3.

Air Circulation Mode Operation

When the temperature near the ceiling reaches the setting temperature, Air Circulation Mode operation commences at low airflow volume. It stops when the temperature drops to 2C below the setting temperature. Air Circulation Mode Operation Time Diagram

8.4.

Automatic Mode Operation

Standard for Determining Operation Mode

Indoor fan operates at SLo fan speed for 25 seconds. After judging indoor air temperature, the operation mode is determined and operation continued at the mode determined. After the operation mode has been determined, the mode does not change. However, Soft Dry mode operation includes Cooling mode operation. Room temperature adjustment. The following are added to the setting temperature specified as above.

The mode judging temperature and standard setting temperature can be increased by 2C, by open the circuit of JX1 at indoor electronic controller.

30

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

8.5.

Sleep Mode Auto Operation

Cooling or Soft Dry Operation

Purpose is to obtain a comfortable room temperature while sleeping. When you press the SLEEP Mode, the following movement will start to avoid overcooling. Sleep shift operation starts, when the room temperature reaches the setting temperature or after 1 hour of operation. The setting temperature will be risen by 0.5C at the start of operation and by 0.5C one hour later. The airflow volume will automatically change to Lo fan speed. Sleep Mode operation time is 8 hours, the operation will be stop after 8 hours. When used together with the Timer, the Timer has priority.

8.6.

Powerful Mode Operation

Purpose of this operation is to obtain the setting temperature quickly. When the Powerful Mode is set, the set temperature will be automatically decreased 3C against the present setting temperature (Lower temperature: 16C). This operation automatically will be running under SHi Fan Speed (Cooling), SLo Fan Speed (Soft Dry). Vertical Airflow Direction:- In Manual setting, the vane will automatically swing down 10 lower than previous setting. - In Auto setting, the vane will automatically swing up and down. However the lower limit will be shifted 10 downward. Powerful Mode will operate for 15 minutes only, after that it will shift back to previous operation mode. Powerful Mode will stop if:- Powerful mode button is pressed again. - Stopped by ON / OFF switch. - Timer OFF activates. - Economy mode button is pressed. - Sleep mode is pressed. - Operation mode button is changed.

8.7.

Economy Mode Operation

Purpose of this operation is to save or reduced electrical power consumption of the room air conditioner. When the Economy Mode is set, the set temperature will be automatically increased 0.5C against the preset setting temperature (Higher temperature: 30C). This operation automatically will be running under SLo Fan Speed. Vertical Airflow Direction:In Manual or Auto setting, the vane will automatically change to Auto Air Swing. Economy Mode will stop if:- Economy Mode button is pressed again. - Stopped by ON / OFF switch. - Timer OFF activates. - Powerful mode button is pressed. - Auto or Manual air swing button is pressed. - Fan Speed control button is pressed. - Sleep Mode button is pressed ON. - Operation Mode is changed.

31

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

8.8.

Random Auto Restart Control

If there is a power failure, operation will be automatically restarted after 3 to 4 minutes when the power is resumed. It will start with previous operation mode and airflow direction. Restart time is decided randomly using 4 parameter:Intake air temperature, setting temperature, fan speed and Air Swing Blade position. Auto Restart Control is not available when Timer or Sleep Mode is set. This control can be omitted by open the circuit of JX2. (Refer Circuit Diagram)

8.9.

Indoor Fan Speed Control

Auto Fan Speed Control When set to Auto Fan Speed, the fan speed is adjusted between maximum and minimum setting as shown in the table. Manual Fan Speed Control Basic fan speed adjustment (3 settings, from Lo to Hi) can be carried out by using the Fan Speed selection button at the remote control.

32

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

8.10. Vertical Airflow Direction Control

Vertical Airflow Direction Auto-Control When set a Airflow Direction Auto-Control with remote control, the louver swings up and down as shown in the diagram. The louver does not swing when the Indoor Fan Motor stops during operation at the upper limit. When stopped with remote control, the discharge vent is reset, and stopped at the closing position.

1. There is no swinging while indoor fan motor is stopped during Cooling and Soft Dry operation. 2. In Air Circulation operation, when the intake air temperature reaches set temperature, the airflow direction is changed from upper limit to lower limit. When the intake air temperature falls to 2C lower than set temperature, the airflow direction is changed from lower limit to upper limit.

Vertical Airflow Direction manual Control When the manual Airflow Direction Selection Button is pressed, the automatic airflow is released and the airflow direction louver move up and down in the range shown in the diagram. The louver can be adjusted by pressing the button to the desired louver position. When the remote control is used to stop the operation, the discharge vent is reset, and stopped at the closing position.

8.11. Delay ON Timer Control

When the Delayed ON Timer is set by using the remote control, the unit will start operate slightly before the set time, so that the room will reach nearly to the set temperature by the desired time. For Cooling and Soft Dry mode, the operation will start 15 minutes before the set time. For Automatic mode, the indoor fan will operate at SLo speed for 25 seconds, 15 minutes before the set time to detect the intake air temperature to determine the operation mode. The operation indication lamp will blink at this time.

8.12. Remote Control Signal Receiving Sound

Long beep sound will be heard when: Stopping the Air Conditioner using ON/OFF switch. Stopping the Sleep Mode. Stopping the Powerful Mode. Stopping the Economy Mode. Short beep sound will be heard for others. To switch off the beep sound:Press the Automatic Operation Button continuously for 10 seconds or more (beep beep will be heard at the 10th second). Repeat the above if you want to switch ON the beep sound.

However, if the Automatic Operation Button has been pressed the Automatic operation will be activated. If you do not require this operation, you may change it by using the remote control.

33

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

9 Operating Instructions

SAFETY PRECAUTIONS

Before operating, please read the following Safety Precautions carefully. To prevent personal injury, injury to others and property damage, the following instructions must be followed. Incorrect operation due to failure to follow instructions will cause harm or damage, the seriousness of which is classified as follow:

Installation Precautions

Operation Precautions

! Warning

Do not install, remove and reinstall the unit by yourself. Improper installation will cause leakage, electric shock or fire. Please engage an authorized dealer or specialist for the installation work.

! Warning

This sign warns of death or serious injury.

Do not share outlet. Do not operate with wet hands. Do not damage or modify the power cord. Do not insert finger or other objects into the indoor or outdoor units. Do not expose directly to cold air for a long period. Use specified power cord.

! Warning

This sign warns of death or serious injury.

! Caution

This room air conditioner must be earthed. Improper grounding could cause electric shock. Ensure that the drainage piping is connected properly. Otherwise, water will leak out. Do not install the unit in a potentially explosive atmosphere. Gas leak near the unit could cause fire.

! Caution

This sign warns of damage to property. The instructions to be followed are classified by the following symbols:

OFF

If abnormal condition (burnt smell, etc.) occurs, switch off the power supply.

! Caution

This sign warns of injury.

Do not wash the unit with water. Do not use for other purposes such as preservation. Do not use any combustible equipment at airflow direction. Do not sit or place anything on the outdoor unit. Switch off the power supply before cleaning. Ventilate the room regularly. Pay attention as to whether the installation rack is damaged after long period of usage.

OFF

This symbol (with a white background) denotes an action that is PROHIBITED.

OFF

These symbols (with a black background) denote actions that are COMPULSORY.

Switch off the power supply if the unit is not used for a long period.

NAME OF EACH PART

Indoor Unit

1 2

Indoor Unit (when the front panel is opened)

1 3

AU UT TO ON OF F

AU UT FA T AN N O AU UT TO DRY

Accessories

Remote Control

CO OL

FA AN N

PO WE MO DE

AIR

RFU

TE

L

MP

2

CHE CK

Ste p

ON OF F

RES ET

SW ING

EC

OF

ON

OM

F/O N

Y SL EE P

2

TIM ER

FAN

SPE

SE T

CA NC EL

ED

CLO CK BAT TER Y

6 5

1 Front Panel 2 Air Intake Vent 3 Air Outlet Vent

3

1 Front Panel 2 Air Filters 3 Air Purifying Filter Remote Control Indication Sticker

Outdoor Unit

CU-2V18BKP5G CU-2V19BKP5G

1 2

4 Vertical Airflow Direction Louver 5 Horizontal Airflow Direction Louver (manually adjusted) 6 Indicator Panel

3 4 5

2 3

ECONOMY POWERFUL

456

7

POWER POWER SLEEP TIMER

Remote Control Holder

1 Auto Operation Button (when the front panel is opened) 2 Economy Mode Indicator 3 Powerful Mode Indicator 4 Power Indicator 5 Sleep Mode Indicator 6 Timer Mode Indicator GREEN ORANGE GREEN ORANGE ORANGE

CU-2V14BKP5G

CU-3V20BKP5G

Two RO3 (AAA) dry-cell batteries or equivalent

Air Purifying Filter 1 Air Intake Vents 2 Ground Terminal (Inside cover) 3 Power Supply Cord 4 Piping (Catechin Air Purifying Filter) (Solar Refreshing Deodorizing Filter) 5 Drain Hose 6 Connecting Cable 7 Air Outlet Vents

34

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

NAME OF EACH PART

Remote Control

1

1 Signal Transmitter 2 Operation Display 3 Powerful Mode Operation Button

How to Insert the Batteries

2

PO WER FUL MO DE AU AIR EC ON TO SW OM IN Y MA G NU AL 2 FAN SP

OF

ON OF F

CH EC K RE SE T

SL E EE D

AUT UTO

COOL DR DRY FAN AN

AUT UTO

4 Room Temperature Setting Button (self-illuminating button) 5 Operation Mode Selection Button

TIM

CL OC K

ER

SE T

CAN CEL

1.5 1.5 V V

ON OFF

AUT UTO FAN AN

6 Economy Mode Operation Button 7 Auto Airflow Direction Button

TEMP

3 4 5 6 7 8 9 0

POWERFUL

OFF/ON

! # $ $ % ^ & * (

8 ON-Timer Button 9 OFF-Timer Button 0 Reset Point (Press with fine-tipped object to clear the memory) ! OFF/ON Button (self-illuminating button) @ Sleep Mode Operation Button # Fan Speed Selection Button $ Manual Airflow Direction Selection Button

1 Slide down the remote control cover completely 2 Insert the batteries

Be sure the direction is correct 12.00 at display - flashing Set the current time (CLOCK) immediately to prevent battery exhaustion. About the batteries Can be used for approximately one year. Observe the following when replacing the batteries Replace with new batteries of the same type. Do not use rechargeable batteries (Ni-Cd). Remove the batteries if the unit is not going to be used for a long period.

MODE

ECONOMY

SLEEP

AIR SWING

AUTO

MANUAL

FAN SPEED

1 ON

OFF

3 SET

CANCEL

TIMER

CHECK RESET CLOCK

Remote Control Signal. Make sure it is not obstructed. Maximum distance : 10 m. Signal received sound. One short beep or one long beep. Notes for Remote Control. Do not throw or drop. Do not get it wet. Certain type of fluorescent lamps may affect signal reception. Consult your dealer.

% Timer Set Button ^ Timer Cancellation Button & Time-Setting Button * Clock Button ( Remote Control Cover

PREPARATION BEFORE OPERATION

Indoor Unit

1

HOW TO OPERATE

Setting Temperature

Knife switch

AU TO

Press 3 to increase or decrease the temperature. The temperature can be set between 16C ~ 30C. Recommended temperature: COOL 26C ~ 28C 1C ~ 2C lower than the room temperature

2 3 5

ON OF F

CH EC K

OFF

ON

HE AT CO OL

AU TO DRY T

FA N

PO WER FUL

MO DE AU AIR EC ON TO SW OM IN Y MA G NU AL 2 FAN SP

AU FA TE TO AN T MP

DRY

OF

F/O

SL EE EE D

Set the knife switch to ON

RE SE T

TIM

CL OC K

ER

SE T

CAN CEL

1 6 4

During AUTO Operation, press 3 to select: Operation with 2C higher than the standard temperature. Operation with the standard temperature. Operation with 2C lower than the standard temperature.

2 6 3

2 3 4 5 6

To start the operation Press 1. POWER indicator (green) on the indoor unit will light up. To stop, press once more. Setting Mode Press 2 to select:AUTO COOL DRY FAN Automatic Operation Cooling Operation Soft Dry Operation Air Circulation Operation

Open the front panel Remove the air filters Fit the air purifying filters in place Insert the air filters Close the front panel

Standard Temperature

Indoor temperature Operation Cooling 23C Soft Dry Standard temperature 25C 22C

Remote Control

To set the current time

AIR SWING

Once the Automatic Operation is selected, the indoor temperature sensor operates automatically to select the desired operation mode with Cooling or Soft Dry. After the operation mode has been selected, the mode does not change.

FAN SPEED

AUTO

MANUAL

1 ON

OFF

3 SET

CANCEL

TIMER

CHECK RESET CLOCK

2 1

1 2 3

Press 1. Then press 2 to increase or decrease the time. Press 1 again. Set time at display will light up.

35

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

Setting the Fan Speed Press 4 to select:FAN Low Fan Speed FAN Medium Fan Speed FAN High Fan Speed AUTO FAN Automatic Fan Speed The speed of the indoor fan is adjusted automatically according to the operation. The indoor fan stops occasionally during cooling operation. Setting the Vertical Airflow Direction Press 5 or 6 to select:COOL / DRY Operation AUTO FAN Operation AUTO

Setting the Horizontal Airflow Direction

Operation Details COOL Cooling Operation To set the room temperature at your preference cooling comfort. AUTO Automatic Operation Sense indoor temperature to select the optimum mode. Temperature is not displayed on the remote control during AUTO operation. DRY Soft Dry Operation A very gentle Cooling Operation, prior to dehumidification. It does not lower the room temperature. During Soft Dry operation, the indoor fan operates at Low fan speed. FAN Air Circulation Operation When the room temperature reaches the set temperature, operation commences at Low airflow volume. It stops when the room temperature drops to 2C below the set temperature. (It is useful when using a heater).

Adjust it manually

Use this air conditioner under the following conditions:

Unit in C DBT: Dry Bulb Temp WBT: Wet Bulb Temp Maximum Temperature Indoor Outdoor

DBT WBT DBT WBT 32 16 23 11 43 16 26 11

36

61

Minimum Temperature

Swing up/down Automatically MANUAL Five stages of adjustment can be made between 14 ~ 36.

Move up or down Automatically MANUAL Five stages of adjustment can be made between 0 ~ 61.

Notes If the unit is not going to be used for an extended period of time, turn off the main power supply. If it is left at the ON position, approximately 2.5 W of electricity will be used even if the indoor unit has been turned off with the remote control. If operation is stopped, then restart immediately, the unit will resume operation only after 3 minutes.

POWERFUL

OFF/ON

CONVENIENCE OPERATION

Sleep Mode Operation Economy Mode Operation

To save electrical power consumption. Please use this mode when the room has reached your desired temperature. Press 7. * Economy mode indicator (green) on the indoor unit will light up. Press once more to cancel this operation.

7 1 5

MODE

ECONOMY

SLEEP

AIR SWING

6 3 4 2

AUTO

MANUAL

FAN SPEED

1 ON

OFF

3 SET

CANCEL

To obtain a comfortable room temperature while sleeping: Press 6. Sleep mode indicator on the indoor unit will light up. To cancel this operation, press once more. Sleep Mode Operation Details When the room temperature reaches the set temperature, the airflow volume will change to low automatically. Sleep Mode Operation time is 8 hours. When used together with the timer, the timer has a priority.

Temperature ST e e tm t p e i r n a g t u r e Approx. 0.5C increase. Sleep Operation button is pressed. 0~1 hour Approx. 0.5C increase.

TIMER

Powerful Mode Operation

To obtain the set temperature quickly. Press 8. * Powerful mode indicator (orange) on the indoor unit will light up. * Powerful mode will operate for 15 minutes only. To cancel this operation, press once more.

CHECK RESET CLOCK

SETTING THE TIMER

Ensure that the current time is correct before setting the timer. The timer cannot be set if the time display is flashing. ON-TIMER Operation To start the air conditioner operation automatically. Press 1 to set the operation. Press 2 to increase or decrease the time. Then press 3. To cancel this operation, press 4. OFF-TIMER Operation To stop the air conditioner operation automatically. Press 5 to set the operation. Press 2 to increase or decrease the time. Then press 3. To cancel this operation, press 4. Timer Mode Operation Details When the ON-Timer is set, operation will start before the actual set time. This is to enable the room temperature reaches the set temperature at the set time.

COOL,DRY, AUTO 15 minutes in advance

Economy / Powerful Mode Operation Details

Economy and Powerful operation cannot be selected simultaneously. The changes of the temperature and airflow volume are automatic. The remote control display remains unchanged. If sleep button or operation mode button is pressed, economy or powerful operation will be cancelled. During FAN Air circulation operation, the powerful and economy operation are not available.

Economy Mode Operation Temperature Airflow volume

Sleep shift operation starts. 1 hour

Cooling or Soft Dry Operation for sleep shift operation will start to avoid overcooling.

Time

after approx. 8 hours of sleep shift operation, it will stop automatically.

COOL / DRY

0.5C higher than set temp.

Super Low

Powerful Mode Operation

Temperature

Airflow volume

COOL / DRY

3C lower than set temp.

Super High

Once the ON-Timer is set, operation will start at the set time everyday. The current time is not displayed when the timers are set. When both timers are used together, the TIMER mode indicator on the indoor unit remains lit even when the operation is stopped by the OFF-TIMER.

36

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

CARE AND MAINTENANCE

Cleaning the Indoor Unit and Remote Control

Wipe gently with a soft, dry cloth. Do not use water hotter than 40C or polishing fluid to clean the unit.

Air Purifying Filters

Pre-season Inspection

Is the discharged air cold? Operation is normal if 15 minutes after the start of operation, the difference between the air intake and outlet vents temperature is:COOL 8C or above

1

Raise the front panel Solar Refreshing Deodorizing Filter Catechin Air Purifying Filter

Cleaning the Air Filter

(Recommendation:- If the unit is operated in a dusty environment, clean the filters every two weeks, continuous use of this dirty filters will reduce cooling efficiency) Remove dirt using a vacuum cleaner. Wash back of the air filter with water. If badly soiled, wash it with soap or a mild household detergent. Let it dry and reinstall it. Be sure the FRONT mark is facing you. * Damaged air filter. Consult the nearest authorized dealer. Part No.: CWD001047. Do not use benzene, thinner, scouring powder or clothes soaked in caustic chemical to clean the unit.

1 2 3 4

Are the air intake or outlet vents of the indoor or outdoor units obstructed? Are the remote control batteries weak? If the remote control display appears weak, replace the batteries.

Remove the air filters

Cleaning the Front Panel

(Must be removed before washing)

Solar Refreshing Deodorizing Filter Used to remove unpleasant odour and deodorize the air in the room. Reusable. Vacuum, place under direct sunlight for 6 hours and fit it back in place. (Recommended: every 6 months) Catechin Air Purifying Filter The filter is coated with catechin to prevent growth of bacteria and viruses. Reusable. Vacuum and fit it back in place (Recommended: every 6 months) Recommended to change these filters every 3 years. Do not reuse damaged filters. Consult the nearest authorized dealer to purchase a new filter. Catechin Air Purifying Filter No.: CZ-SF70P Solar Refreshing Deodorizing Filter No.: CZ-SFD70P If you operate the air conditioner with dirty filters: Air is not purified Cooling capacity decreases Foul odour is emitted

When the Air Conditioner is Not Used for an Extended Period of Time 1 To dry the internal parts of the indoor unit, operate

the unit for 2 - 3 hours using:FAN operation

1 2

Raise the front panel higher than the horizontal and pull to remove it. Gently wash with water and a sponge. Do not press the front panel too hard when washing. When use kitchen cleaning fluid (neutral detergent), rinse throughly. Do not dry the front panel under direct sunlight. To fix the front panel, raise the front panel horizontally, match the protruding portion on the indoor unit to the fulcrum and push into place.

Stop the operation by remote control and switch off the knife switch. Note: If the unit is not switched off by the remote control, it will start operating when the knife switch is switched to ON (because the unit is equipped with Auto Restart Control). Remove the remote control batteries.

Recommended Inspection

After used over several seasons, the unit will become dirty and thus decreases the units performance. Depending on the operation conditions, a dirty unit may produce odour and dust may pollute dehumidification system. Therefore, a seasonal inspection is recommended in addition to regular cleaning. (Consult an authorized dealer).

Fulcrum

Protruding portion on indoor unit

HELPFUL INFORMATION

Auto Operation Button Auto Restart Control If power is resumed after a power failure, the operation will restart automatically after 3 - 5 1/2 minutes. Operation will be restarted automatically under the previous operation mode and airflow direction when power is resumed as the operation is not stopped by the remote control. Timer Setting When power failure occurs, the timer setting will be cancelled. Once power is resumed, reset the timer. Thunder and Lightning This air conditioner is equipped with a built-in surge protective device. However, in order to further protect your air conditioner from being damaged by abnormally strong lightning activity, you may switch off the knife switch.

ENERGY SAVING AND OPERATION HINTS

Setting the Temperature Approximately 10% of electricity can be saved. Set the temperature 1C higher than the desired temperature. Air Filters and Air Purifying Filters Clean the air filters every 2 weeks and the Air Purifying Filters every 6 months. Dirty filters may reduces cooling efficiency. Keep All Doors and Windows Closed Otherwise, cooling performance will be reduced and electricity cost is wasted. Outdoor Unit Do not block the air outlet vents. Otherwise, it will lower the cooling performance. Timer and Sleep Mode To prevent wastage of electricity, use sleep mode when sleeping or Timer when going out. Avoid Direct Sunlight Keep curtains or drapes closed to avoid direct sunlight during cooling operation.

Confirm the knife switch at ON

ECONOMY POWERFUL POWER SLEEP TIMER

Raise the front panel and press Automatic Operation If the remote control fails to function or has been misplaced, press the Auto Operation button to start the Automatic operation. The Automatic operation will be activated immediately once the Auto operation button is pressed. However, temperature cannot be adjusted in this operation. The power indicator on the indoor unit will blink until the operation mode is selected automatically. To cancel this operation, press once more. Remote Control Signal Receiving Sound To switch off the beep (Signal Receiving Sound), press the Auto Operation button for 10 seconds continuously or longer. Beep, beep sound will be heard at the tenth seconds. Note: Beep sound will be heard at the fifth seconds; However please press continuously until you heard beep, beep sound. Repeat the above steps if you want to switch on the Signal Receiving Sound. (This is for Servicing purposes only) Note: If you press this button continuously for 5 to 10 seconds, Test Run operation will be performed. A beep sound will be heard at the fifth seconds indicating the Test Run starts to operate.

37

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

TROUBLESHOOTING

Normal Operation

Is it okay?

Air conditioner has been restarted, but does not operate for 3 minutes. A sound like water flowing can be heard. It seems that fog is coming out from the air conditioner. The room has a peculiar odour. During Automatic Airflow setting, indoor fan stops occasionally. The outdoor unit emits water or steam.

Call the Dealer Immediately

This is the answer

This is to protect the air conditioner. Wait until the air conditioner begins to operate. This is the sound of refrigerant flowing inside the air conditioner. Condensation occurs when the airflow from the air conditioner cools the room. This may be a damp smell emitted by the wall, carpet, furniture or clothing in the room. This is to remove smell emitted by the surroundings. In COOL/DRY operation, moisture in the air condenses into water on the cool surface of outdoor unit piping that causes dripping.

If the following conditions occur, turn off the main power supply, and then call the dealer immediately. Abnormal noise is heard during operation. Water or foreign material gets into the remote control by mistake. Water leak from the indoor unit. Switches or buttons do not operate properly. The circuit breaker switches off frequently. Power supply cord become unusually warm.

Abnormal Operation

Is it okay? The air conditioner does not operate. Air conditioner produces loud noise during operation. The air conditioner does not cool effectively. Please check

Has the circuit breaker been tripped? Is the timer being used correctly? Is the installation work slanted? Is the front grille closed properly? Has the temperature been set incorrectly? Are the filters dirty? Are the intake or outlet vents of the outdoor unit obstructed? Are all windows and doors closed?

38

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

10 Installation Instructions

1. Philips screw driver 2. Level gauge Required tools for Installation Works 5. Spanner 9. Gas leak detector 6. Pipe cutter 10. Measuring tape 13. Multimeter 14. Torque wrench 18 N.m (1.8 kgf.m) 42 N.m (4.2 kgf.m) 55 N.m (5.5 kgf.m) 15. Vacuum pump 16. Gauge manifold

3. Electric drill, hole core drill 7. Reamer (70 mm) 4. Hexagonal wrench (4 mm) 8. Knife

11. Thermometer 12. Megameter

10.1. Safety Precautions

Read the following SAFETY PRECAUTIONS carefully before installation. Electrical work must be installed by a licensed electrician. Be sure to use the correct rating of the power plug and main circuit for the model to be installed. The caution items stated here must be followed because these important contents are related to safety. The meaning of each indication used is as below. Incorrect installation due to ignoring of the instruction will cause harm or damage, and the seriousness is classified by the following indications.

This indication shows the possibility of causing death or serious injury.

This indication shows the possibility of causing injury or damage to properties only.

The items to be followed are classified by the symbols:

Symbol with background white denotes item that is PROHIBITED from doing.

Carry out test running to confirm that no abnormality occurs after the installation. Then, explain to user the operation, care and maintenance as stated in instructions. Please remind the customer to keep the operating instructions for future reference.

1. Engage dealer or specialist for installation. If installation done by the user is defective, it will cause water leakage, electrical shock or fire. 2. Install according to this installation instruction strictly. If installation is defective, it will cause water leakage, electrical shock or fire. 3. Use the attached accessories parts and specified parts for installation. Otherwise, it will cause the set to fall, water leakage, fire or electrical shock. 4. Install at a strong and firm location which is able to withstand the sets weight. If the strength is not enough or installation is not properly done, the set will drop and cause injury. 5. For electrical work, follow the local national wiring standard, regulation and this installation instruction. An independent circuit and single outlet must be used. If electrical circuit capacity is not enough or defect found in electrical work, it will cause electrical shock or fire. 6. Use the specified cable (1.5 mm 2) and connect tightly for indoor/outdoor connection. Connect tightly and clamp the cable so that no external force will be acted on the terminal. If connection or fixing is not perfect, it will cause heat-up or fire at the connection. 7. Wire routing must be properly arranged so that control board cover is fixed properly. If control board cover is not fixed perfectly, it will cause heat-up at connection point of terminal, fire or electrical shock. 8. When carrying out piping connection, take care not to let air substances other than the specified refrigerant go into refrigeration cycle. Otherwise, it will cause lower capacity, abnormal high pressure in the refrigeration cycle, explosion and injury. 9. When connecting the piping, do not allow air or any substances orther than the specified refrigerant (R410A) to enter the refrigeration cycle. Otherwise, this may lower the capacity, cause abnormally high pressure in the refrigeration cycle, and possibly result in explosion and injury. (V7BKPG, V9BKPG, V12BKPG) 10. When connecting the piping, do not use any existing (R22) pipes and flare nuts. Using such same may cause abnormally high pressure in the refrigeration cycle (piping), and possibly result in explosion and injury. Use only R410A materials. Thickness of copper pipes used with R410A must be more than 0.8 mm. Never use copper pipes thinner than 0.8 mm. It is desirable that the amount of residual oil is less than 40 mg/10 m. (V7BKPG, V9BKPG, V12BKPG) 11. Do not modify the length of the power supply cord or use of the extension cord, and do not share the single outlet with other electrical appliances. Otherwise, it will cause fire or electrical shock.

39

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

1. This equipment must be earthed. It may cause electrical shock if grounding is not perfect. 2. Do not install the unit at place where leakage of flammable gas may occur. In case gas leaks and accumulates at surrounding of the unit, it may cause fire. 3. Carry out drainage piping as mentioned in installation instructions. If drainage is not perfect, water may enter the room and damage the furniture.

1. Selection of the installation location. Select a installation location which is rigid and strong enough to support or hold the unit, and select a location for easy maintenance. 2. Power supply connection to the room air conditioner. Connect the power supply cord of the room air conditioner to the mains using the following method. Power supply connection to a circuit breaker for the permanent connection. Use an approved 16A circuit breaker for the permanent connection. It must be a double pole switch with a minimum 3 mm contact gap. 3. Do not release refrigerant. Do not release refrigerant during piping work for installation, reinstallation and during repairing a refrigeration parts. Take care of the liquid refrigerant, it may cause frostbite. 4. Installation work. It may need two people to carry out the installation work. 5. Do not install this appliance in a laundry room or other location where water may drip from the ceiling, etc.

40

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

Attached accessories

Indoor/Outdoor Unit Installation Diagram

Applicable piping kit CZ-3F5, 7AEN (CS-V7BKPG, CS-V9BKPG) CZ-4F5, 7, 10AN (CS-V12BKPG)

SELECT THE BEST LOCATION INDOOR UNIT There should not be any heat source or steam near the unit. There should not be any obstacles blocking the air circulation. A place where air circulation in the room is good. A place where drainage can be easily done. A place where consideration . noise prevention is taken into

Do not install the unit near the door way. Ensure the spaces indicated by arrows from the wall, ceiling, fence or other obstacles. Recommended installation height for indoor unit shall be at least 2.3 m. OUTDOOR UNIT If an awning is built over the unit to prevent direct sunlight or rain, be careful that heat radiation from the condenser is not obstructed. There should not be any animal or plant which could be affected by hot air discharged. Keep the spaces indicated by arrows from wall, ceiling, fence or other obstacles. Do not place any obstacles which may cause a short circuit of the discharged air. If piping length is over the common length, additional refrigerant should be added as shown in the table.

41

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

10.2. INDOOR UNIT

10.2.1. SELECT THE BEST LOCATION (Refer to Select the best location section) 10.2.2. HOW TO FIX INSTALLATION PLATE

The mounting wall is strong and solid enough to prevent it from the vibration.

10.2.3. TO DRILL A HOLE IN THE WALL AND INSTALL A SLEEVE OF PIPING

1. Insert the piping sleeve to the hole. 2. Fix the bushing to the sleeve. 3. Cut the sleeve until it extrudes about 15 mm from the wall. Caution

When the wall is hollow, please be sure to use the sleeve for tube assy to prevent dangers caused by mice biting the connecting cable.

4. Finish by sealing the sleeve compound at the final stage.

with putty or caulking

The centre of installation plate should be at more than 450 mm at right and left of the wall. The distance from installation plate edge to ceiling should more than 67 mm. From installation plate left edge to units left side is 47 mm. From installation plate right edge to units right is 73 mm.

: For left side piping, piping connection for liquid should be about 14 mm from this line. : For left side piping, piping connection for gas should be about 56 mm from this line. : For left side piping, piping connecting cable should be about 785 mm from this line.

10.2.4. INDOOR UNIT INSTALLATION

1. For the right rear piping

1. Mount the installation plate on the wall with 5 screws or more. (If mounting the unit on the concrete wall consider using anchor bolts.) Always mount the installation plate horizontally by aligning the marking-off line with the thread and using a level gauge. 2. Drill the piping plate hole with 70 mm hole-core drill. Line according to the arrows marked on the lower left and right side of the installation plate. The meeting point of the extended line is the centre of the hole. Another method is by putting measuring tape at position as shown in the diagram above. The hole centre is obtained by measuring the distance namely 150 mm and 125 mm for left and right hole respectively. Drill the piping hole at either the right or the left and the hole should be slightly slanted to the outdoor side.

2. For the right and right bottom piping

42

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

3. For the embedded piping

(This can be used for left rear piping & left bottom piping also.)

43

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

10.2.5. CONNECT THE CABLE TO THE INDOOR UNIT

1. The inside and outside connecting cable can be connected without removing the front grille. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloropre ne sheathed 4 1.5 mm 2 flexible cord, type designation 245 IEC 57 or heavier cord. Ensure the color of wires of outdoor unit and the terminal Nos. are the same to the indoors respectively. Earth lead wire shall be longer than the other lead wires as shown in the figure for the electrical safety in case of the slipping out of the cord from the anchorage.

Secure the cable onto the control board with the holder (clamper).

INSTALLATION OF AIR PURIFYING FILTERS 1. Open the front panel. 2. Remove the air filters. 3. Put air purifying filters (left) and solar refreshing deodorizing filter (right) into place as shown in illustration below.

44

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

HOW TO TAKE OUT FRONT GRILLE Please follow the steps below to take out front grille if necessary such as when servicing. 1. Set the vertical airflow direction louver to the horizontal position. 2. Slide down the two caps on the front grille as shown in the illustration below, and then remove the two mounting screws. 3. Pull the lower section of the front grille towards you to remove the front grille.

When reinstalling the front grille, first set the vertical airflow direction louver to the horizontal position and then carry out above steps 2 - 3 in the reverse order.

10.3. OUTDOOR UNIT

10.3.1. SELECT THE BEST LOCATION (Refer to Select the best location section) 10.3.2. INSTALL THE OUTDOOR UNIT

After selecting the best location, start installation according to Indoor/Outdoor Unit Installation Diagram. 1. Fix the unit on concrete or rigid frame firmly and horizontally by bolt nut. (10 mm). 2. When installing at roof, please consider strong wind and earthquake. Please fasten the installation stand firmly with bolt or nails.

AUTO SWITCH OPERATION The below operations will be performed by pressing the AUTO switch. 1. AUTO OPERATION MODE The Auto operation will be activated immediately once the Auto Switch is pressed. 2. TEST RUN OPERATION (FOR PUMP DOWN/SERVICING PURPOSE) The Test Run operation will be activated if the Auto Switch is pressed continuously for more than 5 sec. to below 10 sec.. A pep sound will occur at the fifth sec., in order to identify the starting of Test Run operation 3. REMOTE CONTROLLER RECEIVING SOUND ON/OFF The ON/OFF of Remote Controller receiving sound can be change over by pressing the AUTO Switch continuously for 10 sec. and above. A pep, pep sound will occur at the tenth sec., in order to indicate the ON/OFF change over of remote control receiving sound.

10.3.3. CONNECTING THE PIPING

Connecting the Piping to Indoor Unit Please make flare after inserting flare nut (locate at joint portion of tube assembly) onto the copper pipe. (In case of using long piping) Connect the piping Align the center of piping and sufficiently tighten the flare nut with fingers. Further tighten the flare nut with torque wrench in specified torque as stated in the table.

MODEL CS-V7BKPG CS-V9BKPG CS-V12BKPG

Piping size Gas 3/8 (42 N.m) 3/8 (42 N.m) 1/2 (55 N.m)

(Torque) Liquid 1/4 (18 N.m) 1/4 (18 N.m) 1/4 (18 N.m)

45

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

Connecting the Piping to Outdoor Unit 1. Align the center of the piping and sufficiently tighten the flare nut with fingers. 2. Finally, tighten the flare nut with torque wrench until the wrench clicks. When tightening the flare nut with torque wrench, ensure the direction for tightening follows the arrow on the wrench. Caution

The CU-3V20BKP5G/V9B KPG have different cooling capacities depending on the connection to A1, A2 and/or B on CU3V20BKP5G individually. (Refer to SPECIFICATIONS on CATALOG) 1. The Cooling Capacity of Indoor Unit connecting B on CU-3V20BKP5G (Called B unit) is different from that of A1 and A2 Units. 2. A1 and A2 Units share the same compressor, their cooling capacities thus change depending on whether one, the other, or both of the units is in use. 3. Reflect the B or A (A1 and/or A 2) on the Indoor Unit for later reference.

CUTTING AND FLARING THE PIPING 1. Please cut using pipe cutter and then remove the burrs. 2. Remove the burrs by using reamer. If burrs is not removed, gas leakage may be caused. Turn the piping end down to avoid the metal powder entering the pipe. 3. Please make flare after inserting the flare nut onto the copper pipes.

46

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

10.3.4. EVACUATION OF THE EQUIPMENT

WHEN INSTALLING AN AIR CONDITIONER, BE SURE TO EVACUATE THE AIR INSIDE THE INDOOR UNIT AND PIPES in the following procedure. 1. Connect a charging hose with a push pin to the Low and High side of a charging set and the service port of the 3-way valve. Be sure to connect the end of the charging hose with the push pin to the service port. 2. Connect the center hose of the charging set to a vacuum pump with check valve, or vacuum pump and vacuum pump adaptor. 3. Turn on the power switch of the vacuum pump and make sure that the needle in the gauge moves from 0 cmHg (0 MPa) to -76 cmHg (-0.1 MPa). Then evacuate the air approximatel y ten minutes. 4. Close the Low side valve of the charging set and turn off the vacuum pump. Make sure that the needle in the gauge does not move after approximatel y five minutes. Note: BE SURE TO FOLLOW THIS PROCEDURE IN ORDER TO AVOID REFRIGERANT GAS LEAKAGE. 5. Disconnect the charging hose from the vacuum pump and from the service port of the 3-way valve. 6. Tighten the service port caps of the 3-way valve at torque of 18 N.m with a torque wrench. 7. Remove the valve caps of both of the 2-way valve and 3way valve. Position both of the valves to OPEN using a hexagonal wrench (4 mm). 8. Mount valve caps onto the 2-way valve and the 3-way valve. Be sure to check for gas leakage.

CAUTION

If gauge needle does not move from 0 cmHg (0 MPa) to -76 cmHg (-0.1 MPa), in step 3 above take the following measure: If the leak stops when the piping connections are tightened further, continue working from step 3. If the leak does not stop when the connections are retightened, repair the location of leak. Do not release refrigerant during piping work for installation and reinstallation. Take care of the liquid refrigerant, it may cause frostbite.

10.3.5. CONNECT THE CABLE TO THE OUTDOOR UNIT

1. Remove the control board cover from the unit by loosening the screw. 2. Connecting cable between indoor unit and outdoor unit shall be approved polychloropre ne sheathed flexible cord, type designation 245 IEC 57 or heavier cord (4 1.5 mm 2). Power supply cord cable use 3 1.5 mm 2 flexible cord, type designation 245 IEC 57 or heavier cord.

47

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

3. Secure the cable onto the control board with the holder (clamper). 4. Confirm the SW1 Switch at AUTO position. (CU-2V14BKP5G, CU-3V20BKP5G) 5. Attach the control board cover back to the original position with the screw.

10.3.6. PIPE INSULATION

1. Please carry out insulation at pipe connection portion as mentioned in Indoor/Outdoor Unit Installation Diagram. Please wrap the insulated piping end to prevent water from going inside the piping. 2. If drain hose or connecting piping is in the room (where dew may form), please increase the insulation by using POLY-E FOAM with thickness 6 mm or above.

CHECK THE DRAINAGE Open front panel and remove air filters. (Drainage checking can be carried out without removing the front grille.) Pour a glass of water into the drain tray-styrofoam. Ensure that water flows out from drain hose of the indoor unit.

NOTE:

These equipment shall be connected to a suitable mains network with a main impedance less than the following: CS-V9BKPG / CU-2V14BKP5G: 0.35 CS-V9BKPG / CU-3V20BKP5G: 0.19 CS-V7BKPG, CS-V12BKPG / CU-2V19BKP5G: 0.20 CS-V9BKPG / CU-2V18BKP5G: 0.21

CHECK ITEMS

Is there any gas leakage at flare nut connections? Has the heat insulation been carried out at flare nut connection? Is the connecting cable being fixed to terminal board firmly? Is the connecting cable being clamped firmly?

EVALUATION OF THE PERFORMANCE Operate the unit at cooling operation mode for fifteen minutes or more. Measure the temperature of the intake and discharge air. Ensure the difference between the intake temperature and the discharge is more than 8C.

Is the drainage OK? (Refer to Check the drainage section) Is the earth wire connection properly done? Is the indoor unit properly hooked to the installation plate? Is the power supply voltage complied with rated value? Is there any abnormal sound? Is the cooling operation normal? Is the thermostat operation normal? Is the remote controls LCD operation normal? Is the air purifying filter installed?

48

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

11 Installation and Servicing Air Conditioner Using R410A

11.1. OUTLINE

11.1.1. About R410A Refrigerant

1. Converting air conditioners to R410A Since it was declared in1974 that chlorofluorocarbons (CFC), hydro chlorofluorocarbons (HCFC) and other substances pose a destructive danger to the ozone layer in the earths upper stratosphere (20 to 40 km above the earth), measures have been taken around the world to prevent this destruction. The R22 refrigerant which has conventional ly been used in ACs is an HCFC refrigerant and, therefore, possesses this ozonedestroying potential. International regulations (the Montreal Protocol Ozone-Damaging Substances) and the domestic laws of various countries call for the early substitution of R22 by a refrigerant which will not harm the ozone layer. In ACs, the HFC refrigerant which has become the mainstream alternative called R410A.Compared with R22, the pressure of R410A is approximatel y 1.6 times as high at the same refrigerant temperature, but the energy efficiency is about the same. Consisting of hydrogen (H), fluorine (F) and carbon (C), R410A is an HFC refrigerant. Another typical HFC refrigerant is R407C. While the energy efficiency of R407C is some what inferior to that of R410A, it offers the advantage of having pressure characteristic s which are about the same as those of R22, and is used mainly in packaged ACs. 2. The characteristic s of HFC (R410A) refrigerants a. Chemical characteristic s The chemical characteristic s of R410A are similar to those of R22 in that both are chemically stable, non-flammable refrigerants with low toxicity. However, just like R22, the specific gravity of R410A gas is heavier than that of air. Because of this, it can cause an oxygen deficiency if it leaks into a closed room since it collects in the lower area of the room. It also generates toxic gas when it is directly exposed to a flame, so it must be used in a well ventilated environment where it will not collect.

Table 1 Physical comparison of R410A and R22 R410A R32/R125 (50/50) -51.4 1.56 Mpa (15.9 kgf/cm2) 64.0 kg/m 3 Non-flammable 0 1730

Composition (wt%) Boiling point (C) Vaporizing pressure (25C) Saturated vapor density Flammability Ozone- destroying point (ODP) Global- warming point (GWP)

R22 R22 (100) -40.8 0.94 Mpa (9.6 kgf/cm 2) 44.4 kg/m 3 Non-flammable 0.005 1700

b. Compositional change (pseudo-aze otropic characteristic s) R410A is a pseudo-azeotropic mixture comprising the two components R32 and R125. Multi-component refrigerants with these chemical characteristic s exhibit little compositiona l change even from phase changes due to vaporization 9or condensation), which means that there is little change in the circulating refrigerant composition even when the refrigerant leaks from the gaseous section of the piping. Accordingly, R410A can be handled in almost the same manner as the single-component refrigerant R22. However, when charging, because there is a slight change in composition between the gas phase and the liquid phase inside a cylinder or other container, charging should basically begin with the liquid side. c. Pressure characteristic s As seen in Table 2, the gas pressure of R410A is approximatel y 1.6 times as high as that of R22 at the same refrigerant temperature, which means that special R410A tools and materials with high-pressure specifications must be used for all refrigerant piping work and servicing.

Table 2 Comparison of R410A and R22 saturated vapor density Unit: MPa Refrigerant Temperature (C) R410A -20 0.30 0 0.70 20 1.35 40 2.32 60 3.73 65 4.15

R22 0.14 0.40 0.81 1.43 2.33 2.60

49

CS-V9BK PG CU-2 V14B KP5G / CS-V9BKP G CU-2 V18B KP5G / CS-V9BKP G CU-3 V20B KP5G / CS-V7BKP G CU-2 V19B KP5G / CS-V12B KPG

d. R410A refrigerating machine oil Conventiona lly, mineral oil or a synthetic oil such as alkylbenzene has been used for R22 refrigerating machine oil. Because of the poor compatibility between R410A and conventional oils like mineral oil, however, there is a tendency for the refrigerating machine oil to collect in the refrigerating cycle. For this reason, polyester and other synthetic oils which have a high compatibility with R410A are used as refrigerating machine oil. Because of the high hygroscopic property of synthetic oil, more care must be taken in its handling than was necessary with conventional refrigerating machine oils. Also, these synthetic oils will degrade if mixed with mineral oil or alkylbenzene , causing clogging in capillary tubes or compressor malfunction. Do not mix them under any circumstances.

11.1.2. Safety Measure When Installing / Receiving Refrigerant Piping