Chemical Processing Magazine - 012013

Chemical Processing Magazine - 012013

Uploaded by

selereakCopyright:

Available Formats

Chemical Processing Magazine - 012013

Chemical Processing Magazine - 012013

Uploaded by

selereakCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Chemical Processing Magazine - 012013

Chemical Processing Magazine - 012013

Uploaded by

selereakCopyright:

Available Formats

J

A

N

U

A

R

Y

2

0

1

3

PROSPECTS BRIGHTEN FOR

CHEMICAL INDUSTRY

PROPERLY HANDLE

ABNORMAL

SITUATIONS

RETHINK OPTIONS FOR

LARGE DRIVERS

HEAT TRANSFER

FLUIDS AIM FOR

EXTREMES

A variety of signs point to sustained growth by the U. S. chemical makers

BETE...

your one-stop

resource

from

spray lances

to

tank washing

nozzles.

BETE. Your strategic partner for engineered spraying solutions.

CFD Analysis

Distribution

Evaporation

Performance Through Engineering

BETE is your complete single-source supplier of solutions from custom

spray lances and chemical injectors to tank cleaning nozzles. Our in-house

operation includes all aspects of design, fabrication, and performance testing,

ensuring a seamless process from RFQ to delivery.

BETEs integrated engineering, quality, and manufacturing departments

combine to meet a wide variety of code, testing, and inspection requirements.

Request a quote...

BETEs Application Engineers are ready to take your sketch/inquiry and

produce a recommendation and drawing of our proposed solution. Well use

our experience to work with you to improve your process with the right spray

nozzle coupled with custom fabrications designed for your application.

MaxiPass

provides a full cone spray pattern

with even distribution

Retractable

Spray Lance

Made in the USA

BETE Fog Nozzle, Inc.

T(413)772-0846

F(413)772-6729

www.bete.com

MaxiPass

TM

Nozzles

The ultimate in

clog-resistance

with the largest

free passage available

in a full cone nozzle

TF Spiral Nozzles

produce sprays

composed of droplets

signicantly smaller for

quenching and cooling

applications

HydroWhirl Orbitor

is a versatile Clean-In-Place

(CIP) rotating tank cleaning

machine that combines

high-impact cleaning

efciency with extended

operating life, reduced

life cycle costs and simple

on-site service

Conductivity, TDS, and Salt Meter

LCD with Green Light Backlighting

Conductivity, TDS or Salt Measurements

Real Time SD Memory Card Data Logger

(SD Card Included)

Automatic Calibration

(Solutions Sold Separately)

RS232/USB Interface (Optional Cable)

Visit omega.com/cdh-sd1

COPYRIGHT 2012 OMEGA ENGINEERING, INC. ALL RIGHTS RESERVED

omega.com

Liquid R&D Measurement Devices

CDH-SD1

$

450

Benchtop Turbidity, Chlorine

and Color Meter

TRB-3000 Series

Starts at

$

1295

Visit omega.com/trb-3000

OMEGAETTE

TM

pH and Conductivity Testers

PHH-7000 Series

Starts at

$

95

Pre-Mixed pH Calibration

Solutions and Deionized

Water Sold Separately.

Visit

omega.com/pha4_7_10

omega.com/phh-7000

Ultrasonic Flowmeter

Visit omega.com/fdt21

FDT-21

$

1990

Improve your bottom line.

Toll Free: 800-968-7722

www.hapman.com z sales@hapman.com

Perform batch, intermittent, and

continuous operations.

Corvey lree- ard ror-lree-loW|r

bulk materials.

Avoid contamination and explosion hazards.

lrprove |aoor/erery ellc|erc|es.

V|r|r|ze dusl ard |ouse|eep|r cosls.

0|sc|are 100 ol raler|a|.

Minimize cleanup and

producl |oss W|l| our

self-contained dust-

control system.

Simplify oa c|areouls

W|l| your c|o|ce ol |o|sl ard

trolly, or forklift delivery.

Promote safety

|r l|e Wor|p|ace W|l|

easy oa |ard||r.

Improve l|e loW ol

corpacled or d|llcu|l lo

d|sperse raler|a|s W|l|

preural|c oa a|lalor.

Reclaim

your Money

every time

you unload a bag.

Maximize the amount

of material entering your

process with Hapman.

Buying in bulk makes economical sense by

cutting your costs per unit, but only if youre

not leaving valuable product in the bag or on

the shop foor. That's why we've engineered

a heavy-duty unloading system that fully

optimizes your material handling process.

For more information on how Hapman can help you

increase product output, and improve your material

handling process, visit www.hapman.com.

5 CHEMICALPROCESSING.COM O JANUARY 2013

CONTENTS

Chemical Processing (ISSN 0009-2630) is published monthly by Putman Media Inc., 555 West Pierce Road, Suite 301, Itasca, IL 60143. Phone (630) 467-1300. Fax (630) 467-1109. Periodicals postage paid at Itasca, IL,

and additional mailing ofces. POSTMASTER: Send address changes to Chemical Processing, P.O. Box 3434, Northbrook, IL 60065-3434. SUBSCRIPTIONS: Qualied reader subscriptions are accepted from operat-

ing management in the chemical processing industries at no charge. To apply for a qualied subscription, ll in the subscription card. To nonqualied subscribers in the United States, subscriptions are $68 per year.

Single copies are $14. Canadian and foreign annual subscriptions are accepted at $115 surface per year. Single copies are $16. Canada Post International Publications Mail Product Sales Agreement No. 40028661.

Canadian Mail Distributor information: Frontier/BWI, PO Box 1051, Fort Erie, Ontario, Canada, L2A 5N8. Copyright 2013 Putman Media Inc. All rights reserved. The contents of this publication may not be

reproduced in whole or in part without the consent of the copyright owner. REPRINTS: Reprints are available on a custom basis. For price quotation, contact Foster Reprints, (866) 879-9144, www.fostereprints.com.

Putman Media also publishes Control, Control Design, Food Processing, Pharmaceutical Manufacturing and Plant Services. Chemical Processing assumes no responsibility for validity of claims in items reported.

16 29 33

COVER STORY

16 Prospects Brighten for Chemical Industry

Increasing demand from key end users and the competitive

feedstock advantage of shale gas promise to spur growth for

years and lead to an increasing trade surplus in chemicals.

FEATURES

DESIGN AND OPTIMIZATION

23 Rethink Options for Large Drivers

Major developments in high-speed electric motor technology

and improvements in cost and performance of variable speed

drive systems make large electric motor drivers a viable choice.

MAINTENANCE AND OPERATIONS

29 Heat Transfer Fluids Aim For Extremes

Vendors are working to develop new products and support

services to meet the increasing global demand for heat transfer

uids with greater thermal and oxidation stability.

INSTRUMENTATION AND CONTROL

33 Properly Handle Abnormal Situations

An analysis of major incident reports identies some key

challenges and ways to improve development of procedure

management systems that lead to better, safer operations.

MAKING IT WORK

38 Biorenery Beckons

Advanced biofuels are moving toward commercialization with

large-scale bioreneries beginning to sprout around the U.S. A

pioneer plant in Iowa will produce ethanol from corn stover.

COLUMNS

7 From the Editor: Book Targets Chemical

Substitution

9 Chemical Processing Online: Weve

Sealed the Deal

10 Field Notes: Ease Packed-Column

Commissioning

14 Energy Saver: Implement Energy

Eciency Measures, III

15 Compliance Advisor: EPA Keeps Close

Eye on Cadmium

42 Plant InSites: Is Mist a Must?

50 End Point: Chemical Engineering Matters

DEPARTMENTS

11 In Process: Milling Breaks Down Barriers

for MOFs | Sieve Layer Enhances Oxide

Catalyst

41 Process Puzzler: Get Rid Of Problems

Not Just O-Gas

44 Equipment & Services

46 Product Spotlight/Classieds

49 Ad Index

JANUARY 2013 | VOLUME 75, ISSUE 1

Responsibility is part of our DNA

Shale formations in North America may help reduce the continents dependence on imported oil. But recovering oil

and gas from tight rock 10,000 feet under ground requires a lot of skill. Even more than skill, it requires responsibility.

Especially when the reserves are in close proximity to prime farmland and local communities. Thats why we remain

committed to developing technologies that measure up to the toughest efficiency and safety standards. Because we

know that whats great today can always be improved tomorrow. Its in our nature. Never being satisfied.

Discover more at neversatisfied.statoil.com

Always improving

Never satisfied

7 CHEMICALPROCESSING.COM JANUARY 2013

FROM THE EDITOR

Many companies

agree with these

principles but

dont know how

to implement

them.

THE HAZARDS that certain chemicals may or may

not pose remain a subject of intense debate between

chemical makers, regulators and other interested

parties. Nonetheless, some users of these chemicals

undoubtedly must feel that replacing suspect materi-

als now rather than waiting for an ultimate decision

about their safety is a prudent course of action.

Such rms should take a look at a new 64-page book

called Te Guide to Safer Chemicals, downloadable at

www.bizngo.org/guide.php. It was issued in December

by the Biz-NGO Working Group (www.bizngo.org),

which calls itself a unique collaboration of business and

NGO [nongovernmental organization] leaders who are

creating a roadmap to the widespread use of safer chemi-

cals and sustainable materials in our economy. Some

large manufacturers such as Hewlett-Packard, Dell and

Shaw Industries but no chemical makers as well

as retailers like Staples and Whole Foods are involved.

Previously, Biz-NGO had developed Four Prin-

ciples for Safer Chemicals, namely:

1. Know and disclose chemicals across the lifecycle

of products.

2. Assess and avoid hazards.

3. Commit to continuous improvement.

4. Support public policies and industry standards

that make comprehensive hazards data avail-

able, act to eliminate known risks, and promote

a greener economy.

Te group says that many companies agree with

these principles but dont know how to implement them.

Te Guide is the result of three-plus years

of discussions, pilots and draft versions among

Biz-NGO participants of how to implement the Biz-

NGO Principles for Safer Chemicals, it says.

Te book is not about compliance with laws and

regulations. It assumes companies already comply

and want to move beyond that. Many drivers such

as addressing consumer demands, ensuring product

development stays far ahead of regulations, expand-

ing current markets and capturing new markets, and

guiding innovation can prompt taking a more-pro-

active approach in use of chemicals, notes Biz-NGO.

Te executive summary provides a good overview

of the books purpose and content:

Te Biz-NGO Guide to Safer Chemicals is a

unique resource for downstream users of chemicals.

It is a hands-on guide that charts pathways to safer

chemicals in products and supply chains...

Chemicals are at the core of our materials,

products, and manufacturing systems, and as such

should be at the core of our sustainability programs.

Yet many a downstream business, those organiza-

tions that use chemicals by virtue of the products they

purchase, have avoided starting this journey thinking

that the path to greener and safer chemicals is too

clouded in complexity and uncertainty. Te Guide is

our response to these uncertainties and is intended for

both novices and experts.

Te Guide:

Marks pathways to safer chemicals in products

and supply chains.

Sets relative benchmarks for each of the four Biz-

NGO Principles for Safer Chemicals.

Specines actions for each benchmark.

Presents examples of business practices for each

benchmark.

Illustrates how downstream users are getting

started and advancing on their paths to safer

chemicals.

Users of Te Guide will learn how to:

Measure internal performance, identify areas

of improvement, and track progress to safer

chemicals.

Benchmark performance in comparison to other

organizations.

Communicate to the public their organization's

performance in moving to safer chemicals based

on an independent metric.

Some corporate executives already are applauding

the eort. For instance, Helen Holder, materials man-

ager at Hewlett-Packard, says, Te Guide establishes

clear steps for building a meaningful program for devel-

oping and adopting better materials, and we have found

it to be helpful in communicating across the supply

chain how to implement a green chemistry program.

Te authors admit this initial version has many gaps

in reporting and the benchmarks are imperfect and need

renement. Te Guide is a living resource and will

evolve over time as we learn more about the challenges

and opportunities that organizations face in implement-

ing these benchmarks, they say.

MARK ROSENZWEIG, Editor in Chief

mrosenzweig@putman.net

Book Targets Chemical Substitution

How to guide aims to help companies switch to safer chemicals

Low viscosity = colder temperature start

ups. With a wide operating range from 36 F

to 550 F, this is a non-aromatic/low odor

(not noxious) inherently biodegradable

composition that reduces worker exposure

and environmental issues. Designed for a

variety of applications including batch

reactors, heating and cooling and systems

with cold weather outdoor exposure, this

fluid is tough and durable.

You may want to check/test your system

with a Fluid Analysis. Great for eliminating

any downside risk. Or call and talk with one

of our technical specialists/

engineers over the phone about your

particular application. Contact us

today for real help right away.

Help is here...

wider temperature

range Paratherm MR

heat transfer fluid.

HEAT TRANSFER FLUIDS

31 Portland Road

West Conshohocken PA 19428 USA

800-222-3611

c!J94!49JJ * |+/. c!J94!9!9!

info@paratherm.com

www.paratherm.com

Easy and safe to handle,

an environmentally

friendly alternative to

synthetic aromatic fluids.

In Memory of Julie Cappelletti-Lange,

Vice President 1984-2012

555 West Pierce Road, Suite 301

Itasca, IL 60143

Phone: (630) 467-1300

Fax: (630) 467-1109

www.chemicalprocessing.com

E-mail: cpnews@putman.net

Subscriptions/Customer Service:

(888) 644-1803 or (847) 559-7360

EDITORIAL STAFF

Mark Rosenzweig,

Editor in Chief, x478

mrosenzweig@putman.net

Amanda Joshi,

Managing Editor, x442

ajoshi@putman.net

Traci Purdum,

Senior Digital Editor, x428

tpurdum@putman.net

Sen Ottewell,

Editor at Large

Ireland

sottewell@putman.net

CONTRIBUTING EDITORS

Andrew Sloley,

Troubleshooting Columnist

Lynn L. Bergeson,

Regulatory Columnist

Ven Venkatesan,

Energy Columnist

Dirk Willard, Columnist

DESIGN & PRODUCTION

Stephen C. Herner,

Vice President of Creative Services, x312

sherner@putman.net

Brian Hertel,

Associate Art Director, x413

bhertel@putman.net

Rita Fitzgerald,

Production Manager, x468

rtzgerald@putman.net

EDITORIAL BOARD

Vic Edwards, Kvaerner

Tim Frank, Dow Chemical

Ben Paterson, Eli Lilly

Roy Sanders, Consultant

Ellen Turner, Eastman Chemical

Ben Weinstein, Procter & Gamble

Jon Worstell, Consultant

Sheila Yang, Bayer

PUBLISHER

Brian Marz, Publisher, x411

bmarz@putman.net

EXECUTIVE STAFF

John M. Cappelletti, President/CEO

Jane B. Volland, CFO

Jerry Clark, Vice President of Circulation

Jack Jones, Circulation Director

REPRINTS

Claudia Stachowiak,

Corporate Account Executive

claudias@fosterprinting.com

8-87?-?144 x 121 Fax 21?-51-201?

42?5 5. Obio 5treet, Micbigan City, IN 430

Folio Editorial Excellence Award Winner

9 CHEMICALPROCESSING.COM JANUARY 2013

CHEMICAL PROCESSING ONLINE

Get answers to

sealing problems

that vex you.

AS YOU probably know, weve

been tweaking our Ask The Experts

section to make it more useful. Late

last year we went to a forum format,

which enables readers to add their

insight or ask follow-up questions to

expert answers. We also incorporated

a subscribe feature so you can fol-

low your favorite topics or threads.

Now weve expanded our panel of

experts with a specialist on sealing

technology.

Welcome Peter Petrunich. He is

technical director of the Fluid Seal-

ing Association and has over 30 years

of functional and administrative

experience with the technology and

marketing of f luid sealing products.

Im sure youll want to take advan-

tage of his knowledge.

Right now, because its new, his

forum needs questions. So, its an ideal

opportunity to get answers to sealing

problems that vex you. Your queries

will get him in the groove and make

him feel at home. You can go directly

to his page www.ChemicalProcessing.

com/experts/sealing and click on the

red button to the right that says Pose a

Question to Te Experts.

If you are wondering how we go

about adding new topics, rst we ask

ourselves if theres a need for a certain

area of expertise. In this case, a reader

suggested we add sealing to our roster.

We agreed that the optimization of

sealing systems oers a signicant op-

portunity to save energy and increase

productivity. Additionally, proper seal

technology can improve plant safety

and environmental compliance, reduce

water consumption, enhance equip-

ment reliability and cut overall mainte-

nance costs.

As a matter of policy we dont

have people from vendors as experts

to avoid any perception that we

favor a particular supplier or that

answers are not impartial. We had

to put our heads together to figure

out who would best fill the expert

shoes. Remembering that Petrunich

wrote an article for us several years

ago (Find the Best Value Seal,

www.ChemicalProcessing.com/arti-

cles/2005/567), Editor Mark Rosenz-

weig asked him to join our team.

We hope you take advantage of

his knowledge in the field of sealing

technology. And remember that we

have nearly 30 experts on call to

answer your questions regarding

everything from combustion and

corrosion to process safety, pumps,

solids processing and everything in

between. Check out all the catego-

ries: www.ChemicalProcessing.com/

experts/. And if you think we are

missing a good topic, let us know.

TRACI PURDUM, Senior Digital Editor

tpurdum@putman.net.

Weve Sealed the Deal

A guru on sealing technology has joined our roster of experts

CHECK OUT SEALING ARTICLES ON

CHEMICALPROCESSING.COM

Specify the Right Slurry Seal www.ChemicalProcessing.com/articles/2012/

specify-the-right-slurry-seal/;

Gas Up Your Sealing Knowledge www.ChemicalProcessing.com/

articles/2006/182/;

New Seals Get Their Turn www.ChemicalProcessing.com/

articles/2007/113/;

Mixer Seal Gets Major Makeover, www.ChemicalProcessing.com/

articles/2011/mixer-seal-gets-major-makeover/.

JANUARY 2013 CHEMICALPROCESSING.COM 10

FIELD NOTES

Velocity controls

gas absorption

but is hard to

manipulate.

THE ACID absorber made weak acid; our scrubbers

were acting as absorbers. For the next few exhaust-

ing hours we stumbled through an ad hoc checklist.

Eventually, we determined a -in. patch of lter

was plugging the absorbers spray nozzle. It probably

escaped our inspection of the vessel bottoms. Packed

towers demand a feedstock free of debris!

First, consider the basics. Velocity controls

gas absorption but is hard to manipulate. Blower

capabilities limit the inuence of gas velocity,

leaving only liquid velocity to adjust. Another

factor is liquid distribution. Te selection of the

nozzle(s) and pump(s) aects this distribution.

Te eectiveness of the spray nozzle(s) and liquid

re-distributor(s) in spreading the liquid over the

packing impact the distribution. Problems will

become apparent during commissioning.

Flush the tower with the spray nozzle(s)

removed. Before starting the pump(s), inspect

the sump, and disassemble and inspect the spray

nozzle(s). Install a coarse basket strainer in the

suction to avoid pump impeller damage from

broken packing; keep the strainer in for several

weeks. Size the mesh to less than half the spray

nozzle orifice. Typically, the f low goes first

through a coarse mesh then a fine mesh; 2 mesh

for coarse and 12 mesh for fine is common. Filter

area should be at least 2.5 times greater than

the pipe f low area. I recommend a differential

pressure gauge and duplex filters. Also, strain

feedstock to prevent spray nozzle fouling.

After ushing for half a day, re-inspect the

sump, and install and set the spray nozzle(s). Te

nozzle-packing distance is crucial. You likely must

rell the packing level because it shrinks, typically

13 feet, after use. Use the time for ushing to

set the levels, test the tank overow capacity, and

adjust the feed ow loop. Youll observe a sudden

drop in the sump level as the packing lls; 815%

is typical. Take care in setting the level trips. On

one job the level was at 50% and tripped the entire

plant o at 45% when the pumps started. Its

important to determine the cavitation point for the

pump during this period.

Te next step is crucial: test the feed ow to

ensure the scrubber or absorber can operate over its

full range. In one startup we were forced to order

a replacement impeller because the pump couldnt

supply enough ow.

Cooling often is used to improve the capture

efficiency of a scrubber where heat of absorption

is exothermic. If the feedstock is cooled, care-

fully check the temperature loop. Its best to test

the loop under high stress conditions; the heat of

summer works best.

Properly setting the spray nozzle(s) is vital to

maximizing the eectiveness of the liquid transfer

coecient. A viewport helps during startup but an

open manway also works although the nozzle(s) will

behave slightly dierently under vacuum. Adjust

the spray nozzle(s) manually so spray touches the

wall without formation of either large droplets or

atomized spray. Record the pressure versus feed-

stock ow. Separate gauges and valves for multiple

nozzles are best.

A common problem with multiple spray nozzles

is interaction. Collision of sprays from dierent

nozzles can create large droplets. Tis can cause

serious distribution problems and eciency losses

because of dry spots, especially in the center of the

tower where the gas velocity is strongest thats

where you want the water to go.

In crucial applications, consider alternate

spray nozzles to avoid poor distribution at the low

and high range of equipment operation. It may

be desirable to adjust the spray pressure accord-

ing to the tower throughput. Also, be aware of

variations in liquid density, viscosity and surface

tension; the process liquid may differ in these

properties from the water used during the test.

Your vendor can run trials to evaluate droplet

formation. Another concern is pump duty; some

pumps serve many duties and this could affect

spray nozzle pressure.

And, nally, theres gas distribution. Ideally,

gas should enter the bottom of the scrubber and be

evenly distributed although usually it isnt. At

best a distributor can spread out the gas. So, per-

form a visual test by running the tower for several

minutes, so the spray nozzle(s) can wet the packing.

Ten, allowing the gas to ow, turn o the water

ow for a time and touch the packing to see if its

still wet in the middle. If the packing is moist in

the center and wet at the walls, the gas distributor

is working well.

DIRK WILLARD, Contributing Editor

dwillard@putman.net

Ease Packed-Column Commissioning

A few steps can avoid problems when starting up a tower lled with random packing

11 CHEMICALPROCESSING.COM JANUARY 2013

IN PROCESS

METAL ORGANIC frameworks (MOFs) are

garnering increasing interest for a variety of appli-

cations including for storing and separating gases

(see, e.g., Chemical Makers Tink Small, www.

ChemicalProcessing.com/articles/2012/chemical-

makers-think-small/, Adsorbent Eases Carbon Cap-

ture, www.ChemicalProcessing.com/articles/2012/

adsorbent-eases-carbon-capture/, Hydrocarbon

Separation Gets Easier, www.ChemicalProcessing.

com/articles/2012/hydrocarbon-separation-gets-

easier/ and Process Speeds Up Enantiomer Separa-

tion, www.ChemicalProcessing.com/articles/2012/

process-speeds-up-enantiomer-separation/). Te

crystalline nanomaterials boast very high surface

area, plus their structure can be tailored for specic

services. However, producing MOFs on a commer-

cial scale in a fast, economical and environmentally

friendly way has posed challenges. Now, researchers

at Queens University, Belfast, U.K., have developed

a manufacturing technique based on milling that

reportedly achieves all three aims (Figure 1).

Now, for the rst time, our patented technology

allows the synthesis of MOFs without using any sol-

vents, even water, and on greatly reduced timescales,

by making use of mechanochemistry, says Stuart

James of the universitys School of Chemistry and

Chemical Engineering. By simply grinding together

two cheap precursors in a basic milling machine, the

MOF material is produced in a matter of minutes, in

a powder form, ready for applications without further

treatment, and without generating solvent waste.

Te approach oers signicant benets even over

techniques that only use water, adds Tom Robinson,

CEO of MOF Technologies, Belfast, a spin-o compa-

ny formed to make MOFs using the milling approach

(www.moftechnologies.com). Water is still a solvent

and needs to be puried for reuse. It also needs to be

removed from the pores of the MOFs after synthesis.

Water-based synthesis can also only be achieved for a

very narrow range of MOFs. Our process is very rapid

compared with these solvent-based techniques and the

process of activation and washing of the MOF after

synthesis (to unlock the pores) is much simpler.

MOF Technologies already has begun small-scale

production and expects to ramp up manufacturing to

commercial scale in a year, he notes.

Start of initial trials at a number of end-users,

for gas storage and separation applications, should

be underway by the end of 2012, Robinson says.

Tailoring of the material properties will be the next

step after initial trials. We will look at dierent MOF

structures as well as functionalization, for example

through postsynthetic modication.

If the trials meet expectations, the materials may

gain industrial use within the next 12 months, he

Milling Breaks Down Barriers for MOFs

Solvent-free approach promises low-cost, environmentally friendly large-scale production

METAL ORGANIC FRAMEWORK

Figure 1. Milling approach enables making MOFs from

precursors that arent soluble. Source: MOF Technologies.

Nov 11 Dec 11 Jan 12 Feb 12 Mar 12 Apr 12 May 12 June 12 July 12 Aug 12 Sep 12 Oct 12

$

M

i

l

l

i

o

n

79.0

78.0

77.0

76.0

75.0

%

Shipments (NAICS S325) Capacity utilization

80.0

Chemical Activity Barometer

61,000

62,000

63,000

64,000

65,000

90.0

89.0

88.0

87.0

86.0

%

91.0

Shipments and the CAB continued to rise but capacity utilization slipped.

Source: American Chemistry Council.

ECONOMIC SNAPSHOT

JANUARY 2013 CHEMICALPROCESSING.COM 12

IN PROCESS

believes. Te rst commercial applications likely will

be for separations. Te uniformity and tunability of

the pore size and structure of these materials make

them well suited to these applications. Tere are huge

potential energy savings over distillation, for example,

Robinson notes.

A bed of MOF material can be used for adsorp-

tive separations, for example in a pressure-swing

adsorption process. Here, the selective adsorption of

the material is the key property. However, they can

also be used in membranes, where molecular sieving

dominates. Here, the well-dened and tunable pore

size/shape of MOFs is advantageous, he explains.

As an example, acetylene/methane selectivities of

more than 700 have been reported. Pore volume also

is important. MOFs have higher pore volumes and,

therefore, higher capacities than other solid adsorbents

such as zeolites, Robinson adds.

MOF Technologies expects to oer MOFs tuned

for hydrocarbon separations within the next year. It

plans to sell a general line of MOFs for such services

as well as custom versions for particular end-users.

While the rm will produce commercial quanti-

ties of the materials, it also is looking to license the

technology for large-volume applications, he notes.

We believe that mechanochemistry in general is a

scalable, environmentally friendly platform technique

that can replace solvent-based processes for the produc-

tion of a wide range of materials, Robinson stresses.

Sieve Layer Enhances

Oxide Catalyst

A PROCESS that encapsulates particles in a sieve-

like lm to block unwanted reactants could improve

the reactivity and selectivity of oxide catalysts say

researchers from Northwestern University, Evanston,

Ill., and Agronne National Laboratory, Lemont, Ill.

Tey foresee it resulting in greener, more ecient

conversion of biomass and glucose into fuels and

other ne chemicals.

Te ability to conduct these reactions in a selec-

tive way opens doors to new applications in green

chemistry and sustainability, says Justin Notes-

tein, assistant professor of chemical and biological

engineering at Northwesterns McCormick School of

Engineering. Unlike current processes, which may

require enzymes or precious metals, our method relies

only on harmless, inert oxides.

Te researchers focused on photocatalytic oxida-

tions to test their method. Tey deposited a template

on a core particle of titanium dioxide and applied a

nanometer-thick lm of aluminum oxide around but

not on the template using atomic layer deposition.

Removing the template then left the lm with tiny

holes, or nanocavities, less than two nanometers in

diameter (see Figure 2).

Te coating acts like a sieve, allowing only the

smaller reactants in a mixture to slip through the

holes and react with the titanium oxide, while larger

reactants were blocked. Te result was much higher

selectivity (up to 9:1) toward the less hindered reac-

tants. More details can be found in a recent article in

Nature Chemistry.

Research is ongoing and the next step is to expand

the application, in particular, using more traditional

redox-active and acidic oxides, and develop alternate

synthesis methods, including those that do not use

atomic layer deposition, says Notestein.

We expect that within two years we will have

developed a number of targeted versions of this rst,

proof-of-concept catalyst system, he adds.

Te process was conducted at room temperature

and required only a low-power light source. In fact,

temperature limits are likely those of the phase trans-

formations of the oxides composing the catalyst, says

Notestein. Although not discussed in the published

manuscript, these materials are well behaved after

a typical calcination step at 500C. He also notes

that other researchers at Northwestern and Argonne

have developed a related technique that helps stabilize

supported metal catalysts against coking and high-

temperature sintering.

Notestein says that because the sieving layer

Figure 2. A sieve-like surface allows access only to molecules

small enough to penetrate the <2nm-diamater supermicropo-

rous cavities. Source: Christian Canlas, Northwestern University.

NANOCAVITIES

Template grafting

p-tertbutylcalix[4]arene

(CAL)

adamantane

carboxylic acid

(ACA)

ditertbutyl catechol

(TBC)

Atomic layer deposition

of oxide

Template removal by O

3

1-2 mm

IN PROCESS

More than

three-quarters of

respondents say their

companies follow-

through on safety.

41.7%

Always

35.4%

Most of the

time

4.2%

Rarely

10.4%

Some of

the time

8.3%

Never

Responses (%)

Does your company walk the walk not just talk the talk

when it comes to safety?

TO PARTICIPATE IN THIS MONTHS POLL,

GO TO CHEMICALPROCESSING.COM.

is only as thick as a single molecule, they havent

experienced any clogging in the traditional sense, but

like any other catalyst, it can be poisoned by strong

chemisorption.

Optimizing catalyst formulations for specic

applications will remain the primary challenge for

some time. We expect that some of the more reactive

catalyst surfaces will have challenges in template

selection and lm growth.

Notestein believes the chemical compatibility

of the sieving layer with the reactants and solvent is

likely the biggest limitation, but also the greatest op-

portunity. If an oxide used as the parent catalyst or

the sieving layer is incompatible with the solvent, for

example, an additional layer can be added to passivate

most of the surface, he explains.

Te team expects the materials to serve as drop-in

replacements for other oxide catalysts and to oer

comparable service lives for the particular applica-

tion. We hope that by improving selectivity we will

decrease coking, improving catalyst lifetime before

regeneration is needed, says Notestein.

To further control and improve selectivity, the team

is looking into template molecules that are smaller or

have larger aspect ratios. Like a zeolite, we hypothesize

that closer approach to molecular dimensions will im-

prove reactant and product selectivity, says Notestein.

Te researchers have no immediate plans for pilot-

scale testing.

Join the no-valve

metering revolution

No valves, no ancillaries, no vapor lock

Accurate, linear and repeatable flows

Up to 5000:1 flow control to 8.0 GPH at 100 psi

ReNu pumphead technology: fully sealed for safe,

tool-free maintenance

qdospumps.com

800-282-8823

Industrial Division

Watson-Marlow MasoSine Bredel

JANUARY 2013 CHEMICALPROCESSING.COM 14

ENERGY SAVER

Implement Energy Efciency Measures, III

Continuous monitoring of energy costs offers added benets

Monitoring

energy cost

shouldnt be a

rst or last step,

but a continuous

action.

IMPLEMENTATION ISNT the nal action in

energy management. With gradually rising energy

costs, eciency becomes a moving scale. When the

scale shifts, the energy management cycle repeats

again with new concepts and new technologies. So,

in a continuously running plant theres no end for

energy eciency measures; they only reach a new

level in the eciency scale.

An interesting example explains this cycle: No

traveler can miss the yellowish mountains around

Johannesburg, the city of gold mines in South Africa.

When the price of gold was $300/ounce, extracting

gold at levels below 7 g from a ton of mined rock was

uneconomical, and so several yellowish mountains

grew. But today, when golds market price is over

$1,500/ounce, the once-dumped mine rocks are

fenced and protected for additional extraction in the

future. So, an energy-savings opportunity ignored

in the past could suddenly become a hot favorite to

top management. Because energy management is a

continuous improvement process, monitoring after

implementation is a very essential step plant engineers

shouldnt ignore.

Many plants dont pay much attention to energy

management projects once implemented unless some-

thing goes wrong. Such a situation rarely happens; so

managers are satised with a one-time performance

assessment of the implemented project. However,

post-implementation monitoring can help:

1. Conrm a good, sustained performance that

gives the plant operating personnel and energy engineer

condence to explore other processes for possible energy

savings. Tis also can motivate other plant personnel

who were hesitant to improve energy cost savings.

2. Verify that problematic issues are corrected. A

below-par performance would force the plant person-

nel, energy engineer and the vendor (if involved) to

nd out what went wrong and apply the necessary

corrective measures.

3. Indicate performance variations due to changes

in processing conditions and the seasons. Once

the performance variation is correlated with these

changes, optimization will be much easier.

4. Establish the nancial performance of the

energy project. Only then would the energy engineers

credibility and requests for future funding be seriously

considered.

Te energy engineer who initiated the project, the

manager who approved the funds and the operating

personnel should be interested in post-implementation

monitoring. Hence, its necessary to dene the monitor-

ing methodology as well as the project scope. Sometimes

the existing metering system may suce; occasionally,

additional metering provisions may be required.

In one renerys successful energy management

project, the rst step was to restart the Energy & Loss

Index calculations and report these data to manage-

ment monthly. Te results were phenomenal and were

sustained month after month with only marginal

improvements. No big capital investments were made

in the rst year, but the monthly monitoring led to

more saleable fuels released to the market.

Current information technology provides several

options for improved monitoring through data

collection, data analysis and better reporting for-

mats. Industries dier in their energy-performance-

monitoring methodologies. Tus, its essential for

an energy engineer to be aware of improvement

processes in other industries. Whatever the method,

internal or external experts should review data peri-

odically to enable global comparison and to include

technological developments.

Te most common key performance indicators

(KPIs) relate to consumption of a specic fuel or elec-

tricity per unit of output. Boiler eciency is a globally

comparable KPI, while Btu/lb of ammonia is specic

to the plant. Tese KPIs also could be extended

or modied to include dierent processing routes.

In addition, it may be worth modifying older data

processing methods with newer, faster methods that

could generate energy-related KPIs directly, as well as

correlate KPIs to cost. Vendors are a good source for

learning about the latest technical developments.

When choosing the data processing method, its

essential that it be capable of:

1. Acquiring data from the plant control database

on a real-time basis.

2. Setting eciency targets and evaluating the

deviation between the actual and target.

3. Incorporating cost elements that are correlated

from KPI.

4. Storing at least three years real-time data.

Tough this column stresses monitoring energy

cost as a post-implementation action, it shouldnt be a

rst or last step, but a continuous action.

VEN V. VENKATESAN, Energy Columnist

vvenkatesan@putman.net

Paul Episcopo

VIP Plumbing

Macedonia, Ohio

www.ViegaProPress.us | 1-800-976-9819

Think fameless

Viega ProPress for copper and stainless

The gl obal l eader

i n pl umbi ng, heat i ng

and pi pe j oi ni ng syst ems

Meeting the strictest standards

in North America, Viega ProPress

makes secure connections in

less than seven seconds.

Versatile and reliable,

Viega ProPress is available

from " to 4" in copper or

304 and 316 stainless steel.

More than one million viega

press fttings installed every day

around the world

Patented Smart Connect

feature

ensures no ftting is left unpressed

Choice of sealing elements to customize

for nearly any application

No fame is required to install viega ProPress, eliminating

noxious fumes, hot work permits and fre watches

By using Viega ProPress

, Royal Chemical

didnt have to shut down and it was easier to

get the pressing tool into smaller spaces where

welding would not have been an option.

CUSTOMER: Royal Chemical

APPLlCATlON: Chemical transport lines

LOCATlON: Macedonia, OH

CONTRACTOR: vlP Plumbing

2012 viega LLC

VIP Plumbing, in Cleveland, OH, installed

approximately 3,000 feet of Viega stainless steel

pipe for chemical processing equipment at Royal

Chemicals Macedonia, OH plant using the

Viega ProPress for stainless system.

When Royal Chemical wanted to replace existing

process piping for chemical transport between

storage tanks and mixing tanks with stainless

steel pipe, as well as add additional processing

lines, vlP Plumbing was able to offer quick,

fameless installation of stainless steel pipe and

fttings using Viega ProPress.

Viega ProPress uses press fttings to make

water-tight and air-tight connections. The system is

comprised of stainless steel pipe, valves and fttings

in sizes up to 4". lt takes less than seven seconds

to make a pressed connection. The patented

Smart Connect

feature, available on all Viega

ProPress systems, helps installers easily identify

unpressed connections.

"By pressing, Royal Chemical didn't have to shut

down and it was easy to get the pressing tool into

smaller spaces where welding would not have been

an option," said Paul Episcopo, President of vlP

Plumbing. Purchasing the pressing tool was a good

investment and its opened our capabilities to include

stainless systems.

Viega ProPress

for

stainless opens doors

to new markets for

VIP Plumbing

VIP Plumbing installed 2" to 2" 316 stainless steel

lines for fve mixing tanks and used approximately

130 fttings including three-piece ball valves. The

new valve features three-piece construction with a

full-port ball that is able to be removed for repair and

maintenance without removing the press ends from

the system.

The new three-piece ball valve was perfect for

the caustic chemicals, like nitric acid, said Rocky

Iammarino, the plumber who installed Viega ProPress

at Royal Chemical.

We worked with our Viega representative to make

sure that the sealing elements were approved for

use with the specifc chemicals in those lines,

explained Episcopo. vlP Plumbing used fttings with

the standard EPDM and FKM sealing elements for

increased chemical resistance.

The security against leaks is important with chemical

transport. The Smart Connect feature ensures that no

ftting is left unpressed, and when we pressure tested

the lines there were no leaks, said Iammarino.

Viega ProPress allowed VIP Plumbing to not only

complete the installation of the chemical transport

lines, but also established the companys capabilities

in the industrial market.

We are looking forward to getting involved with

additional projects that involve stainless and may not

have been in our repertoire prior to our experience

with viega ProPress for stainless," said Episcopo.

For more information on Viega ProPress for

stainless, visit www.ViegaProPress.us or call

toll free: 800-976-9819.

15 CHEMICALPROCESSING.COM JANUARY 2013

COMPLIANCE ADVISOR

For many

reasons, this

rule is troubling.

EPA Keeps Close Eye on Cadmium

Precedent-setting rule requires manufacturers to submit health and safety studies

ON DECEMBER 3, 2012, the U.S. Environ-

mental Protection Agency (EPA) continued its

use of the Toxic Substances Control Act (TSCA)

to regulate products not just chemicals in

publishing a final rule adding cadmium and

cadmium compounds to the TSCA Section 8(d)

rule. In so doing, manufacturers and importers

of cadmium must submit unpublished health

and safety studies to the EPA (including use in

materials that have been or are reasonably likely

to be incorporated into consumer products). This

article summarizes the rule and its implications.

BACKGROUND

In 2010, several petitioners asked the EPA and

the U.S. Consumer Product Safety Commission

(CPSC) to address their concern with the pres-

ence and safety of cadmium in toy metal jewelry.

They requested the CPSC to restrict the use of

the material to prevent childrens exposure to

cadmium from such products, and the EPA to

seek health and safety data and to limit cadmium

in toy metal jewelry.

Since then, ASTM International has issued a

voluntary standard addressing CPSCs concerns. Te

nal rule reects the EPAs response to the petition-

ers request. TSCA Section 8(d) authorizes the EPA

to issue rules requiring manufacturers (including

importers), processors, or distributors of targeted

chemical substances to submit health and safety stud-

ies pertinent to such substances.

Under the rule, companies that in the ten

years preceding the date a chemical substance is

listed either have proposed to manufacture or im-

port or have manufactured or imported the listed

substance must submit to the EPA a copy of each

health and safety study thats in their possession.

The same requirement applies to manufacturers

or importers that at the time the chemical sub-

stance is listed propose to manufacture or import,

or are manufacturing or importing the listed

chemical substance. The studies must be submit-

ted to the EPA by March 4, 2013.

Manufacturers and importers must submit a

copy of all unpublished health and safety stud-

ies, as well as any studies showing measurable

content of cadmium or cadmium compounds in

consumer products.

WHY THIS RULE IS IMPORTANT

This rule is precedent-setting for several reasons.

First, the scope of the rule is vast. Consumer

products is broadly defined to include items used

in and around homes, schools, recreational areas

and temporary residences. The rule applies to

cadmium at any measurable level. This sweeps

in a huge cross section of consumer products. It

does exclude products where cadmium only ap-

pears as an impurity.

Second, health and safety studies include

any data that bear on the effects of a chemical

substance on health or the environment. . . .

Studies showing any measurable content of cad-

mium or cadmium compounds are reportable.

Third, the requirement applies not just to the

chemical, but to the product in which the chemi-

cal is embedded regardless of whether theres any

potential for the cadmium to be bioavailable or

present an exposure risk.

Finally, its unclear whether the rule imposes

a duty to determine whether a product includes

cadmium or if cadmium is reasonably likely

to be incorporated into a consumer product.

The rule offers no guidance on what this means

or how to assess whether cadmium is reason-

ably likely to be incorporated into a consumer

product.

For all these reasons, this rule is troubling.

Its issuance raises a raft of procedural concerns

beyond the scope of this article. The rule extends

TSCAs reach under Section 8(d) well beyond

chemicals to products. Because cadmium is found

in thousands of consumer products, especially

electronics, many entities subject to the rule may

be unaware of its application. Its all the more

troubling that a rule with so many precedent-

setting implications wasnt subject to standard

notice and comment rulemaking.

LYNN BERGESON, Regulatory Editor

lbergeson@putman.net

Lynn is managing director of Bergeson & Campbell, P.C.,

a Washington, D.C.-based law firm that concentrates on

chemical industry issues. The views expressed herein are

solely those of the author. This column is not intended to

provide, nor should be construed as, legal advice.

JANUARY 2013 CHEMICALPROCESSING.COM 16

GROWTH WAS eeting in 2012, especially in China and

in other emerging markets. In Europe, a crisis turned into an

outright recession, which at the close of the year still showed

no signs of abating. In the United States, a typical business

cycle recovery has yet to emerge in many sectors. Although

U.S. gross domestic product (GDP) surpassed its pre-reces-

sion peak, growth was painfully slow in 2011 and 2012.

Te atmosphere in Washington about issues such as the

scal cli has undermined business condence, impacting

investments and hiring. Recent regional surveys and other

indicators suggest the strong manufacturing recovery in the

United States has lost momentum and factory activity has

peaked, hopefully temporarily. Moreover, the recession in

Europe and weakness in Asia is hindering export sales, a

pillar of growth during 20092011.

At this point, the consumer bolstered both by

lower debt and the apparently sustainable recovery in

housing is taking over from the business sector in

providing foundational support for the U.S. economy.

One short-term indicator to watch is the Chemical Activ-

ity Barometer (CAB), which is a composite index of eco-

nomic indicators that track the activity of the U.S. chemical

industry (see: How Will Te U.S. Economy Fare?, www.

ChemicalProcessing.com/articles/2012/how-will-the-u-s-

economy-fare/). Tis activity generally occurs early in the

supply chain, so the CAB provides a leading indicator for the

overall economy and can reveal potential turning points. Te

CAB is signaling slow, tentative economic growth in early

2013 (see Economic Snapshot, p. 11).

Te consensus forecast (our base case scenario) for U.S.

GDP is for continued but anemic growth in 2013 about

2.0%, which is well below the long-term trend (Table 1).

Tis presumes Washington avoided going over the scal

cli, which it hadnt done at press time. If so, economic

growth should return to long-term trend levels in 2014. If

not, the economy could shrink nearly 0.5% this year.

A variety of signs point to sustained

growth by the U. S. chemical makers

By Thomas Kevin Swift and Martha Gilchrist Moore,

American Chemistry Council

PROSPECTS

BRIGHTEN FOR

CHEMICAL

INDUSTRY

17 CHEMICALPROCESSING.COM JANUARY 2013

CHEMICALS OUTLOOK

Many major end-use markets especially those tied to

exports and business investment have recovered in the

United States. However, others remain below their 2007

peaks. Growth in the manufacturing sector, which is the

largest consumer of chemicals, abated in 2012 after gains

from mid-2009 to 2011.

Te two-speed manufacturing sector that emerged in 2011

(What Will 2012 Bring?, www.ChemicalProcessing.com/ar-

ticles/2012/what-will-2012-bring/) continues. Oil and gas, light

vehicles and aircraft, as well as iron and steel remain strong.

Light vehicles represent an important market for chemicals

(nearly $3,650 per vehicle), and production continues to in-

crease. U.S. light vehicle sales are expected to rise in 2013 and

in 2014 as pent-up demand, improving employment (and in-

come) prospects, and better availability of credit foster growth.

Housing, another large consumer of chemicals (over $15,000

per start), shows very encouraging signs, and was perhaps the

major economic news of 2012. Housing activity will start to

stir in 2013 and 2014. Shortages have emerged in some local

markets and prices have begun to rise nationwide. Moreover,

demographic factors are re-emerging as a driving force. Activ-

ity will remain well below the previous peak of 2.07 million

units in 2005 but by mid-decade will approach the long-term

underlying demand of 1.5 million units per year as suggested

by demographics and replacement needs.

Overall, the spotty manufacturing recovery has damp-

ened domestic chemical demand while the recession in

Europe and weakness elsewhere have hindered exports. In

general, inventories along the supply chain have become only

slightly imbalanced and, barring a major recession, a large

correction isnt expected.

Te weakness in exports to Europe and China has been

partially oset by gains in other regions. Meanwhile, imports

declined, as industrial demand weakened. In 2012, exports

rose 1.8% to $190.2 billion while imports slipped 0.8%

JANUARY 2013 CHEMICALPROCESSING.COM 18

to $189.5 billion. Tus, the U.S. chemical industry en-

joyed a modest trade surplus, a welcome reversal from

2011 when it suered a decit.

Tis year the American Chemistry Council (ACC)

expects trade in chemicals to continue to expand

at moderate rates as global manufacturing activity

remains fragile (Table 2). Exports will grow 4.7%

to $199.7 billion in 2013 and then 6.6% to $212.8

billion in 2014. Imports will rise by 4.1% to $197.3

in 2013 and then 6.2% to $209.6 billion in 2014. As

a result, the trade surplus in chemicals will expand

to $2.4 billion in 2013 and $3.3 billion in 2014. (All

totals in the table, including the 2014 surplus, reect

import and export values before they were rounded.)

Renewed competitiveness due to shale gas (and the

resulting disconnect between U.S. natural gas prices and

global oil prices) is prompting new investments we

count over 50 projects announced in the last two years,

representing aggregate capital spending exceeding $40

billion that will boost exports in the years ahead.

Te large surpluses in basic chemicals will continue to

expand, as will surpluses in specialties and consumer

products. Tese gains will more than oset continuing

trade decits in pharmaceuticals and agricultural chemi-

cals, and result in growing trade surpluses.

Te consensus is that U.S chemical output will

improve during 2013. Volume of chemicals, exclud-

ing pharmaceuticals, will increase 1.9% in 2013 and

2.3% in 2014. Strong growth is expected in plastic

resins as export markets revive. Demand from end-use

markets, most notably light vehicles and housing,

will drive production of specialty chemicals. Gains

in consumer products, which were strong last year,

will moderate in 2013 and 2014. After a weak 2012,

demand for agricultural chemicals will revive. In the

long term, growth in U.S. chemicals will outpace that

of the overall U.S. economy. Pharmaceuticals eventu-

ally will emerge as a growth segment.

Although projected year-on-year growth rates

for most segments during the next few years ap-

pear good, they must be considered in the context

of the exceptionally sharp declines seen in 2008 and

continuing into 2009. It may take years for activity

to recover from these steep declines and exceed past

peaks. Another factor is that these projections reect

the consensus; mainstream forecasters models largely

are demand-driven. Te signicant investment in

shale gas is a supply-side response and suggests a much

higher growth prole, as well discuss later. Tus, the

consensus outlook likely is too low.

Te industry is sensitive to a number of risks. High

and volatile energy costs are paramount in this regard,

as are potential adverse regulatory and other policy ini-

tiatives. Fiscal squabbles in Washington could dampen

domestic industrial activity, while an even weaker world

economy would adversely aect exports.

With a stalling of volumes, overall operating rates

slipped during 2012. Looking forward, modest gains

in chemical industry production volumes and stable

capacity suggest improving operating rates this year;

strengthening production volumes could boost capac-

ity utilization even higher in 2014 and beyond. Te

more than 50 projects already announced will result

in fairly strong gains in capacity through 2017.

INVESTMENT CLIMATE

U.S. investments in chemicals surged 19.8% in 2011.

Tese gains continued into 2012; capital spending

grew 15.5% to about $38.1 billion last year.

Capital spending cycles generally lag cycles of

industry activity prots and operating rates serve

as leading determinants of spending. (Other factors

inuencing the level of investment include the busi-

ness cycle, long-term business expectations, taxation

policies, the cost of capital, the burden of debt, the

supply of credit, and mandated expenditures, e.g.,

% change is year/year unless

noted otherwise

2009 2010 2011 2012 2013 2014 2015 2016 2017

Gross domestic product -3.1 2.4 1.8 2.1 2.0 3.0 3.2 3.0 2.9

Consumer spending -1.9 1.8 2.5 1.9 2.0 2.8 2.8 2.6 2.5

Business investment -18.1 0.7 8.6 7.3 3.7 6.4 6.8 5.1 4.9

Industrial production -7.0 5.4 4.1 3.8 2.3 3.1 3.5 3.0 2.8

Light vehicle sales, millions 10.4 11.6 12.7 14.4 14.7 15.1 15.7 15.9 15.8

Housing starts, millions 0.55 0.59 0.61 0.79 0.96 1.36 1.51 1.61 1.61

Consumer prices -0.3 1.7 3.1 2.1 1.9 2.1 2.2 2.2 2.2

10-year Treasury notes, % 3.26 3.21 2.79 1.84 2.11 2.67 3.46 4.21 4.71

Unemployment rate, % 9.3 9.6 9.0 8.1 7.8 7.6 7.0 6.4 5.9

Exchange rate, $/ 1.39 1.33 1.39 1.28 1.24 1.24 1.26 1.28 1.31

PROSPECTS FOR CHEMICALS

Table 1. Growth will return to long-term levels in 2014.

due to regulations.) In general, improving production

and utilization rates, cost containment from earlier

cost-reduction eorts, low feedstock and other raw

material costs (compared to Europe and Northeast

Asia) and higher selling prices resulted in a strong

recovery of prots from 2010 into 2012. Given the

new dynamics from shale gas, the current upswing in

prots possibly will last longer than in recent cycles.

In addition, utilization rates have risen, although they

remain below the levels of several years ago and the

long-term average.

With improving operating rates and prot margins,

and a low cost of capital, the U.S. chemical industry

will increase investment in new plant and equipment.

Te need to replace worn-out and outdated assets

is apparent and will spur some spending. However,

improved U.S. competitiveness resulting from shale gas

will be the most important driver. Te industrys invest-

ment cycle clearly has re-engaged; capital spending

quickly has surpassed the most recent peak.

Te recovery will strengthen into an expansion by

mid-decade, with greater capital spending for capacity

additions expected during the next ve years. Tanks

to shale gas, the United States is becoming an increas-

ingly preferred location for plants. Substantial new

investments in petrochemicals and derivatives will

arise from shale gas developments. Basic olens capac-

ity will increase by 35% to 40%, various industry

consultants estimate. Double-digit gains are expected

through 2015 with only a minor slowdown in capital

spending after that. By 2017, capital spending by the

U.S. chemical industry will reach $64.5 billion, more

than double the level at the start of this decade.

SHALE GAS DEVELOPMENTS

Te availability of gas from shale is possibly the most

important domestic energy development of the past

50 years. Following a decade of high and volatile

natural gas prices that destroyed industrial demand

and led to the closure of many gas-intensive manu-

facturers, shale gas oers a new era of American

competitiveness that will lead to greater investment,

industry growth and employment.

Increasing domestic shale gas production is help-

ing to reduce U.S. natural gas prices and create a more

stable supply of natural gas for fuel and power. It

CLEANER TANKS IN LESS TIME.

LET US SHOW YOU HOW.

One of our local tank cleaning experts will

visit your plant to:

E.oluote ]uu| cu||ert cleorir aet|uJs

Suest wo]s tu cleor tor|s au|e t|u|uu|l],

|eJuce wote| orJ c|eaicol use orJ |etu|r tor|s

tu se|.ice au|e (uic|l]

RecuaaerJ w|ic| u uu| wiJe |ore u tor|

cleore|s will Jeli.e| t|e ue|u|aorce ]uu reeJ

||u.iJe o uo]|oc| orol]sis

l ]uu'|e cleorir tor|s uu tu 1JJ' ir Jio., we

|o.e t|e erue|tise orJ tor| cleore| ]uu reeJ.

|lus, we'|e ir ]uu| o|eo - o lucol soles eriree|

|ua ure u uu| 9J soles uces is reo||].

Call 1-800-95-SPRAY

or visit TankJet.com to

request your FREE tank

cleaning evaluation.

TankJet

JcJ |i|lauoct

Tank Cleaner

S|uwr let tu |i|t. Tor|Jet

//19J Mutu|i/eJ Tor|

Cleaner; TankJet 6353 Tank

Cleorir lu//le, Tor|Jet cJ

Tor| Cleore| orJ Tor|Jet

1cJ 0i|ectiurol Tor| Cleore|.

also is leading to more-aordable supplies of natural

gas liquids (NGLs), including ethane, which is a key

petrochemical feedstock.

As weve already noted, U.S. chemical makers

have announced more than 50 projects in the past

two years to capitalize on the competitive advantage

of abundant supplies of natural gas and NGLs. Such

projects include new ethylene crackers as well as units

for derivative products (i.e., polyethylene, ethylene

oxide, etc.), methanol, ammonia and on-purpose

ethylene co-products.

To illustrate the potential of these investments,

Figure 1 shows ACCs estimates of the incremental

production from the 50 projects (in orange) overlaid on

top of our baseline forecast (blue). Including production

from new investments, growth likely will average 4.6%

per year through 2017, more than double the 2.2%

average annual growth of the consensus forecast.

Further development of the nations shale gas and

ethane can drive an even greater expansion in domes-

tic manufacturing capacity that goes well beyond the

chemical industry provided policymakers develop

balanced regulatory policies and permitting practices.

(ACC supports a comprehensive energy policy that

maximizes all domestic energy sources, including re-

newables, alternatives, coal and nuclear as well as oil and

natural gas; places priority on greater energy eciency

in industrial facilities as well as homes and buildings;

and relies on sound economic approaches to encourage

the adoption of diverse energy sources, including energy

recovery from plastics and other materials and renewable

sources. Te United States must ensure its regulatory

policies allow capitalizing on shale gas as a vital energy

source and manufacturing feedstock, while protecting

our water supplies and environment.)

EMPLOYMENT SITUATION

Following a decade of job losses, the chemical

industry added jobs for the second year in a row in

2012. Total employment rose to 798,500, up 1.3%

from 2011. Tis in large part reects increasing

production of comparatively more-labor-intensive

JANUARY 2013 CHEMICALPROCESSING.COM 20

% change is year/year

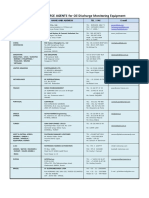

unless noted otherwise

2009 2010 2011 2012 2013 2014 2015 2016 2017

Total Production Volumes -11.3 3.4 0.5 -0.5 1.9 2.8 3.3 3.3 3.3

Pharmaceuticals -6.0 -7.3 -1.5 -3.3 1.8 3.5 4.2 4.4 4.3

Chemicals, excluding pharmaceuticals -12.1 10.3 1.5 1.5 1.9 2.3 2.6 2.5 2.5

Consumer products -9.1 1.0 12.5 5.0 2.4 1.8 2.1 2.0 1.9

Agricultural chemicals 5.1 4.3 -1.8 -0.9 0.7 2.0 1.7 1.6 1.3

Specialties -14.2 10.7 4.2 6.2 2.9 2.6 2.9 2.8 2.8

Basic chemicals -16.1 17.5 -2.6 0.7 1.6 2.3 2.6 2.5 2.5

Other Indicators:

Exports, $ billions 145.5 171.2 187.3 190.7 199.7 212.8 227.8 242.9 259.7

Imports, $ billions 145.7 166.6 191.1 189.5 197.3 209.6 223.6 237.6 253.3

Trade balance, $ billions -0.1 4.6 -3.7 1.2 2.4 3.3 4.2 5.2 6.4

Capacity, % change -5.9 -6.5 -2.4 0.3 0.8 1.5 2.5 3.0 3.5

Capacity utilization, % 68.0% 75.2% 77.5% 76.9% 77.7% 78.6% 79.2% 79.4% 79.4%

Shipments, $ billions 628.9 697.8 776.8 765.1 794.2 833.1 878.9 927.2 978.2

% change -14.9 14.5 11.3 -1.5 3.8 4.9 5.5 5.5 5.5

Capital spending, $ billions 26.56 27.52 32.96 38.08 43.40 48.75 54.00 59.30 64.50

% change -9.2 8.4 19.8 15.5 14.0 12.3 10.8 9.8 8.8

Employment, thousands 804.1 786.5 788.3 798.5 797.0 803.0 805.0 806.0 807.0

% change -5.1 -2.2 0.2 1.3 -0.2 0.8 0.2 0.1 0.1

PRODUCTION EXCLUDING PHARMACEUTICALS

Table 2. The U.S. chemical industry now enjoys a trade surplus and this should grow. Note: Entries are rounded but totals reect numbers before rounding.

plastic resins, synthetic rubbers and manmade bers.

In 2013, productivity gains, which typically average

around 2.5% per year, will outpace output growth.

Tus, employment will slip by 0.2% this year before

expanding by 0.8% in 2014.

However, the graying manufacturing workforce

and decades of young people turning away from ca-

reers in manufacturing and the trades raise concerns

about the quality and quantity of workers that will

be available. Government and industry likely will

work together to ensure the American workforce is

prepared for the jobs required in an emerging manu-

facturing renaissance.

Moreover, the retirements of baby boomers

the average age of a chemical industry employee

is over 50 present challenges for retaining

institutional knowledge. Today, many companies

are ratcheting up efforts to avoid knowledge and

skill losses (see: Keep Know-how in Place, www.

ChemicalProcessing.com/articles/2009/114/).

They increasingly are using information tech-

nology and other media to capture and store

institutional knowledge, and transferring that

knowledge via project debriefings, mentoring,

communities of practice, etc. In addition, theyre

taking deliberate steps in career development

Call: 800.836.7068 www.materialtransfer.com

Drum Discharger

Bulk Bag Filler

Container

Discharger

Bulk Bag

Discharger

Lift & Dump

Container Discharger

MATERIAL HANDLING SOLUTIONS

Bulk Bag

Conditioner

Production volume from Incremental Production (left)

Production volume (left)

% change in volume from Incremental Production (right)

% change in volume (right)

120

100

80

60

40

20

0

10

5

0

-5

-10

-15

% change

year/year

Index

(2007=100)

2

0

0

3

2

0

0

4

2

0

0

5

2

0

0

6

2

0

0

7

2

0

0

8

2

0

0

9

2

0

1

1

2

0

1

0

2

0

1

2

2

0

1

3

2

0

1

4

2

0

1

5

2

0

1

6

2

0

1

7

CONSENSUS OUTLOOK

Figure 1. New plants spurred by shale gas will boost production of chemicals excluding

pharmaceuticals.

and succession planning, and employing phased

retirements, etc.

Fortunately, the supply of new chemical engineers

is on the upswing. After declining in the mid-2000s,

chemical engineering enrollments now are increas-

ing, somewhat alleviating what could be a critical

challenge. Greater cooperation between industry and

academia is playing a role.

PROMISING PROSPECTS

Te global recovery stalled in 2012 with Europe

slipping back into recession and manufacturing in

China slowing sharply. In the U.S., uncertainty

about the election, the scal cli, and the overall

pace of recovery curbed growth. More than three

years since the o cial end of the recession, the

majority of manufacturing industries remain below

their pre-recession peak. However, while growth

slowed in developed countries, emerging market

economies continued to expand. Tis year, growth

will accelerate across most regions of the world.

Low-cost shale gas will enable U.S. chemical mak-

ers to emerge as global low-cost suppliers of many

petrochemical and plastic products. As balance

sheets continue to improve and the nations shale

resources are developed further, chemical producers

and other manufacturers are bringing investment

back to the U.S. Tis manufacturing renaissance

oers huge potential, not only to the millions of

American workers it will employ, but also to the

U.S. economy as a whole.

THOMAS KEVIN SWIFT is chief economist and managing

director of the American Chemistry Council, Washington, D.C.

MARTHA GILCHRIST MOORE is senior director, policy analy-

sis and economics, for the American Chemistry Council. E-mail

them at Kevin_Swift@americanchemistry.com and Martha_Moore@

americanchemistry.com.

Which static mixer is right

for you? Let me show you.

Ross offers expert support and the worlds broadest selection

of static mixers for applications involving turbulent or laminar

flow. With no moving parts, our heavy duty LPD, LLPD and

ISG designs are ideal for sanitary and non-sanitary mixing,

9+6*%*1+%'5(147.64#g.19#0&70.+/+6'&8+5%15+6;T

For a free white paper, visit StaticMixers.com/Learn

Or call Christine Banaszek today: 1-800-243-ROSS

Christine Banaszek

Applications Engineer

Employee Owner

Scan to learn more.

Free Tag Reader: http://gettag.mobi

RELATED CONTENT ON CHEMICALPROCESSING.COM

How Will The U.S. Economy Fare?, www.ChemicalProcessing.com/articles/2012/how-will-the-u-s-economy-fare/

What Will 2012 Bring?, www.ChemicalProcessing.com/articles/2012/what-will-2012-bring/

Chemical Industry Bounces Back, www.ChemicalProcessing.com/articles/2011/chemical-industry-bounces-back/

Keep Know-how in Place, www.ChemicalProcessing.com/articles/2009/114/

23 CHEMICALPROCESSING.COM JANUARY 2013

Variable-speed electric motors can offer signicant advantages

By Amin Almasi, WorleyParsons Services Pty. Ltd.

ADVANCES IN high-speed electric mo-

tor technology along with improvements

in the cost and the performance of vari-

able speed drive (VSD) systems make di-

rect coupling of a gearless electrical mo-

tor to a turbocompressor or pump worth

considering for many services requiring

large drivers. Brushless synchronous mo-

tors with two-pole rotors often suit high

performance duties. Special applications

may benet from other options such as

induction electric motors.

When using an electric motor driver,

full power is available instantly over the

entire site ambient temperature range and

train speed range (including startup). Te

number of successive and cumulative start/

stop and load cycles generally isnt critical.

Variable-speed electric motors in the

upper-megawatt power ranges (say, over

20 MW) usually have energy eciencies

exceeding 97% over the entire useful

speed range (typically 70105% of the

rated speed). In a combined-cycle power

plant, the electric drives eciency gener-

ally is 1525% better than that of typical

heavy-frame gas turbine drivers. In addi-

tion, some of todays electric motors dont

need scheduled maintenance for periods

of up to 6 years of continuous operation

and even after that dont require replace-

ment of costly parts.

Large electric

drives always are

custom engineered

for an application,

allowing, e.g., a

turbocompressor to

be optimized in capacity and

speed for the process, rather

than being limited by a given

gas turbine rating. Te rotor

design and overall features of

the motors closely match those

of electrical generators; design

and manufacturing of large

(over 100 MW) generators is

well established, and numerous

units are operating successfully.

However, motors are variable

speed while generators usually

are constant speed, and motors

suer from oscillating shaft torques

during operation (particularly when

starting).

MOTOR ISSUES

When designing large high-speed elec-

tric motors, mechanical and dynamic

problems must be solved carefully. Me-

chanical stresses, vibration level, losses

and cooling restrictions can limit

the capacity and the maximum

speed of a large electrical motor.

Rethink Options for

LARGE

DRIVERS

JANUARY 2013 CHEMICALPROCESSING.COM 24

In any high-speed electric motor drive applica-

tion, mechanical excitations, electrical pulsations,

rotor dynamics issues, balance problems and

mechanical-dynamic considerations in general are

of paramount importance in ensuring a smooth-

running rotating train over the entire speed range

and during all normal and transient operations.

Also, prior to ordering, its essential to know the

behavior of the train during any electrical fault

conditions (the most severe probably being a short

circuit at the electric motor terminals). VSD-fed

electric motors continuously produce some small

torque oscillations over the entire speed range. So,