Aisc 34

Uploaded by

Stephanie ScottAisc 34

Uploaded by

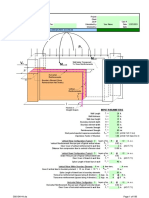

Stephanie ScottPROJECT: STEEL BUILDING DESIGN CASE STUDY SUBJECT: Bracing connection, gusset plate design.

Brace line B1, second floor.

= resistance factor Fy = specified (ASTM) minimum yield stress Fu = specified (ASTM) minimum tensile strength Rn = strength t = thickness of connected part Pu = factored load to be resisted d = diameter of the bolt eb = one-half the depth of the beam, in. ec = one-half the depth of the column, in. db = depth of the beam, in. dc = depth of the column, in. w.p. = working point. N = horizontal distance of gusset plate, in. V = vertical distance of gusset plate, in. = distance from the face of the column flange to the centroid of the gusset-to-beam connection, in. = distance from the face of the beam flange to the centroid of the gusset-to-column connection, in. Aw =cross section area of the whitmore section

SHEET 122 of 131

Pu = B C D

127.0 k 96 k

Elevation View

13

A 30 Plan View Member A-E, Interior floor girder: W24x68 ASTM 992 db = 23.7 in Fy = 50 ksi Fu = 65 ksi Member A-B, Interior column: W10x49 ASTM 992 dc = 9.98 in Fy = 50 ksi Fu = 65 ksi Member A-C, Brace: 2L6x4x1/2LLBB A36 Fy = 36 ksi Fu = 58 ksi

W.P.

Column W10x49 Gusset Plate

Brace 2L6x4x1/2

13 15

Girder W24x68

Red font indicates user input

PROJECT: STEEL BUILDING DESIGN CASE STUDY SUBJECT: Bracing connection, gusset plate design. Use A325-N bolts in standard holes,3/4 in diameter. Design shear strength of one bolt, double shear (LRFD Table 7-10) Check bearing strength @ each bolt hole: Rn = (2.4 * d * t * Fu) = ( = 0.75) 45.7 kips > 31.8 kips

SHEET 123 of 131

Rn = 31.8 k

OK!

Check tension yielding on the Whitmore section:

Column Brace

13 15 Whitmore section

Gusset Plate

Girder

y = tan 30o * 6 = y

3.5

in

30

6

*Note: Assume simplified Whitmore section (double dashed area) for the purpose of this lab. This design will be more conservative. OK!

Rn = (Fu * Aw) = 248.0 kips > 127.0 kips ( = 0.9) Aw = (y + y + 2.5(Perp. distance between center of holes))*0.5

Red font indicates user input

PROJECT: STEEL BUILDING DESIGN CASE STUDY SUBJECT: Bracing connection, gusset plate design. Distribution of brace force to beam and column: (Uniform force method) From the member and frame geometry eb = db/2 = ec = dc/2 = tan = 11.85 4.99 1.154 in in 15

SHEET 124 of 131

13

in order to remain free of moments on the connection interfaces, the following expression must be satisfied:

tan * eb - ec = - * tan - * tan = 8.68 in

N

Column

0.5

allow 1/2 in. between gusset and column for the setback

Brace

13 15

Gusset Plate

ec

Girder

eb

W.P.

Try a gusset plate : 1/2 = = in. x 20 1/8 in. horizontally x in in 16.414 in OK! (If Less Than One) = 6.7 in 13 3/4 in. vertically

16.5 6.7

' = tan * eb - ec + * tan = ' = Use = N= V= 0.09 in

16.5 in and 20 1/8 in 13 3/4 in

Red font indicates user input

You might also like

- Shear Strength Controls 21.65 Kips/bolt: Section at ANo ratings yetShear Strength Controls 21.65 Kips/bolt: Section at A4 pages

- Notes: Proposed Ids Workshop Oilfields Supply Center LTDNo ratings yetNotes: Proposed Ids Workshop Oilfields Supply Center LTD1 page

- Design of Flush Extended End Plate ConnectionsNo ratings yetDesign of Flush Extended End Plate Connections3 pages

- Assume A Plate Girder of The Following Properties: Span of Beam (L)No ratings yetAssume A Plate Girder of The Following Properties: Span of Beam (L)10 pages

- 42-42 DETAIL-42 41-41 DETAIL-41 40-40 DETAIL-40: NotesNo ratings yet42-42 DETAIL-42 41-41 DETAIL-41 40-40 DETAIL-40: Notes1 page

- Atasehir Gardens Podium OF: Member: LocationNo ratings yetAtasehir Gardens Podium OF: Member: Location7 pages

- Design of Lacing: 2.5% of Axial Load Force in Each Lacing Bar (Flac)No ratings yetDesign of Lacing: 2.5% of Axial Load Force in Each Lacing Bar (Flac)4 pages

- Project Title: Revision: Sheet: Project No.: Designed By: Date: Subject: Checked By: DateNo ratings yetProject Title: Revision: Sheet: Project No.: Designed By: Date: Subject: Checked By: Date4 pages

- Staircase-3: A A Note: All Connection Design and Fabrication To Be Responsible by Contractor'S DesignerNo ratings yetStaircase-3: A A Note: All Connection Design and Fabrication To Be Responsible by Contractor'S Designer1 page

- Concrete Special Structural Wall ACI 318-08No ratings yetConcrete Special Structural Wall ACI 318-08188 pages

- Vertical Weld Design Bolt Design'!A1 Deflection!A1 Material Data'!a1 Index!a1 TrangNo ratings yetVertical Weld Design Bolt Design'!A1 Deflection!A1 Material Data'!a1 Index!a1 Trang7 pages

- Handrail For Staircase-3: DET - 145 E040 TYP DET - 145 E040 TYPNo ratings yetHandrail For Staircase-3: DET - 145 E040 TYP DET - 145 E040 TYP1 page

- Design of Non Composite Beams With Large OpeningsNo ratings yetDesign of Non Composite Beams With Large Openings73 pages

- Isolated Footing Schedule: Size of PedestalNo ratings yetIsolated Footing Schedule: Size of Pedestal1 page

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionNo ratings yetRean'S Building 5/24/2002 Angle Plate Design: Framed Beam Connection11 pages

- Column Interaction Diagram Units: KN, KN-M: English MetricNo ratings yetColumn Interaction Diagram Units: KN, KN-M: English Metric5 pages

- Built - Up Column Design ("Effectiveness of Various Built-Up Columns") Section PropertiesNo ratings yetBuilt - Up Column Design ("Effectiveness of Various Built-Up Columns") Section Properties2 pages

- Characterstic Strength:: Annexure-Vc Structural Design of Combined Footing For ColumnNo ratings yetCharacterstic Strength:: Annexure-Vc Structural Design of Combined Footing For Column2 pages

- Client Name: Prepared By: Date: A Project Name: Location: DescriptionNo ratings yetClient Name: Prepared By: Date: A Project Name: Location: Description1 page

- Sectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)No ratings yetSectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)49 pages

- Anchor Bolt + Base Plate Design Joint 8 - v2No ratings yetAnchor Bolt + Base Plate Design Joint 8 - v24 pages

- Rectangular Pad Footing Design: (Provied)No ratings yetRectangular Pad Footing Design: (Provied)6 pages

- Design of Members For Flexure Using The Steel Construction Manual (13th Ed.)No ratings yetDesign of Members For Flexure Using The Steel Construction Manual (13th Ed.)4 pages

- Beam-Column Hunch-End Plate Moment Conn PDFNo ratings yetBeam-Column Hunch-End Plate Moment Conn PDF11 pages

- Steel Overhead Ground Wire and Stranded Steel Guy Wire: Overhead Conductors Electric UtilityNo ratings yetSteel Overhead Ground Wire and Stranded Steel Guy Wire: Overhead Conductors Electric Utility1 page

- Steel Overhead Ground Wire and Steel Guy Wire: Overhead Conductors Electric UtilityNo ratings yetSteel Overhead Ground Wire and Steel Guy Wire: Overhead Conductors Electric Utility1 page

- Torque-Tension Chart For A307 Gr5 Gr8 Gr9 PDFNo ratings yetTorque-Tension Chart For A307 Gr5 Gr8 Gr9 PDF1 page

- ACI 421.1R-99: Reported by Joint ACI-ASCE Committee 421No ratings yetACI 421.1R-99: Reported by Joint ACI-ASCE Committee 42115 pages

- Torque-Tension Chart For A307 Gr5 Gr8 Gr9 PDFNo ratings yetTorque-Tension Chart For A307 Gr5 Gr8 Gr9 PDF1 page

- Mobile Elevated Work Platforms (MEWP) Program: Provo, UtahNo ratings yetMobile Elevated Work Platforms (MEWP) Program: Provo, Utah14 pages

- Key - Section: Advanced Building ConstructionNo ratings yetKey - Section: Advanced Building Construction8 pages

- Design of Bracing Connections in Concentrically Braced Frames100% (1)Design of Bracing Connections in Concentrically Braced Frames43 pages

- 10.2 Bridge Loading Test 10.2.1 GeneralNo ratings yet10.2 Bridge Loading Test 10.2.1 General69 pages

- Behaviour of Block Shear Failure in Different Connections: Jagdish R. Dhanuskar & Laxmikant M. GuptaNo ratings yetBehaviour of Block Shear Failure in Different Connections: Jagdish R. Dhanuskar & Laxmikant M. Gupta15 pages