Mozzle Repad Design Tool

Uploaded by

Siddiqui Muhammad AshfaqueMozzle Repad Design Tool

Uploaded by

Siddiqui Muhammad Ashfaque1

2 Pressure Vessel Engineering Ltd.

3 Finite Element Analysis ASME Code Calculations

4 Canadian Vessel Registration Vessel Modeling and Drafting

5

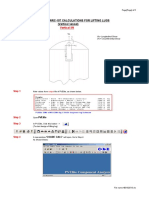

6 Nozzle and Repad Design Tool ver E4.01 Page 1 of 2

7 Nozzle Description

8 Shell Inputs:

9 SA-240 304 Material

10 20,000 Sv [psi] - allowable stress

11 1.00 E1 - efficiency of shell at nozzle

12 24.000 Ds [in] - inside diameter of shell

13 0.204 nt [in] - nominal shell wall thickness

14 0.015 Treq [in] - required shell wall thickness

15 0.015 sca [in] - shell corrosion allowance

16 Nozzle Inputs:

17 SA-312 304 Material

18 20,000 Sn [psi] - allowable stress

19 1.00 E - nozzle efficiency

20 4.000 Do [in] - outside diameter of nozzle

21 0.160 Nwall [in] - nominal wall thickness of nozzle

22 1.000 Lp [in] - exterior projection of nozzle

23 1.000 Ip [in] - interior projection of nozzle

24 0.015 nca [in] - nozzle corrosion allowance

25 12.5% UTP [%] - undertolerance allowance

26 50.0 Pn [psi] - interior pressure

27 Reinforcement:

28 SA-240 304 Material

29 20,000 Sp [psi] - allowable stress of repad

30 0.250 te [in] - repad thickness

31 6.000 Dp [in] - outside diameter

32 0.200 Leg41 [in] - fillet size

33 0.200 Leg42 [in] - fillet size

34 0.200 Leg43 [in] - fillet size

35 0.250 LegG [in] - depth of groove

36 Variables:

37 UT [in] = Nwall*UTP 0.16*0.1 = 0.020

38 Rn [in] = Do/2 - (Nwall-nca) + UT 4/2 - (0.16-0.015) + 0.02 = 1.875

39 ti [in] = Nwall-2*nca 0.16-2*0.015 = 0.130

40 h [in] = MIN(Ip-sca,2.5*nt,2.5*ti) MIN(1-0.015,2.5*0.204,2.5*0.13) = 0.325

41 tn [in] = Nwall-nca 0.16-0.015 = 0.145

42 d [in] = Do-2*tn 4-2*0.145 = 3.710

43 Required Thickness: UG-27(c)(1,2)

44 TreqN [in] = (Pn*Rn)/(Sn*E - 0.6*Pn)+nca ~~ required minimum thickness

45 (50*1.875)/(20000*1 - 0.6*50)+0.015 = 0.020

46 CheckTreqN = TreqN <= Nwall 0.02 <= 0.16 = Acceptable

47 Minimum thickness per UG-45 [in] = Acceptable 0.078

1 Area Replacement:

2 Ar [in^2] = 1*d*Treq*1+2*tn*Treq*1*(1-fr1) ~~ required Area

3 1*3.71*0.015*1+2*0.145*0.015*1*(1-1) = 0.056

4 A1 [in^2] = max(d, 2*(nt+tn)) * (E1*nt-1*Treq)-2*tn*(E1*nt-1*Treq)*(1-fr1)

5 MAX(3.71, 2*(0.204+0.145)) * (1*0.204-1*0.015)-2*0.145*(1*0.204-1*0.015)*(1-1) = 0.701

6 A2 [in^2] = min((tn-trnR)*fr2*min(5*nt,2*Lp),(tn-trnR)*(Min(2.5*tn+te,2*Lp)*fr2*2))

7 MIN((0.145-0.005)*1*MIN(5*0.204,2*1),(0.145-0.005)*(MIN(2.5*0.145+0.25,2*1)*1*2)) = 0.143

8 A3 [in^2] = Min(5*nt*ti*fr2,5*ti*ti*fr2,2*h*ti*fr2)

9 MIN(5*0.204*0.13*1,5*0.13*0.13*1,2*0.325*0.13*1) = 0.085

10 A5 [in^2] = (Dp-d-2*tn)*te*fr4 (6-3.71-2*0.145)*0.25*1 = 0.500

11 A41 [in^2] = Leg41^2*fr3 0.2^2*1 = 0.040

12 A42 [in^2] = Leg42^2*fr4 0.2^2*1 = 0.040

13 A43 [in^2] = (Leg43-nca)^2*fr2 (0.2-0.015)^2*1 = 0.034

14 Aa [in^2] = A1+A2+A3+A5+A41+A42+A43 ~~ actual area

15 0.701+0.143+0.085+0.5+0.04+0.04+0.034 = 1.543

16 CheckA = Aa >= Ar ~~ check area replacement 1.543 >= 0.056 = Acceptable

17 The UG-16(b) minimum thickness requirement has not been taken into consideration here.

18 The required weld size is not checked on this sheet

19 This sheet cannot be used to check for allowable exterior pressure loads.

20 This sheet is for educational use only - use at your own risk.

21 Pressure Vessel Engineering Ltd.

22 120 Randall Drive, Suite B

23 Waterloo, Ontario, Canada, N2V 1C6

24 www.pveng.com (519) 880-9808

You might also like

- Horizontal Pressure Vessel Calculation (Eng)No ratings yetHorizontal Pressure Vessel Calculation (Eng)59 pages

- TM.P. S.p.A. Termomeccanica Pompe: Pump PerformancesNo ratings yetTM.P. S.p.A. Termomeccanica Pompe: Pump Performances1 page

- Local Stress Calculation Sheet - Edition 4-July-15No ratings yetLocal Stress Calculation Sheet - Edition 4-July-1515 pages

- Ellipsoidal HEAD THICKNESS CALCULATION FOR INTERNAL PRESSURENo ratings yetEllipsoidal HEAD THICKNESS CALCULATION FOR INTERNAL PRESSURE3 pages

- Design Calculation Sheet: H2So4 Neutralization TankNo ratings yetDesign Calculation Sheet: H2So4 Neutralization Tank43 pages

- WRC-107 Lifting Lugs - Vert. Vessel Vertical LiftNo ratings yetWRC-107 Lifting Lugs - Vert. Vessel Vertical Lift5 pages

- Vessel Calculation Sheet: Internal Pressure DesignNo ratings yetVessel Calculation Sheet: Internal Pressure Design7 pages

- Saddle v1-5: Fixed Saddle Sliding SaddleNo ratings yetSaddle v1-5: Fixed Saddle Sliding Saddle9 pages

- PV Elite (Construccion de Recipiente) MDMTNo ratings yetPV Elite (Construccion de Recipiente) MDMT8 pages

- What Is An ASME Appendix 2 Flange Design PDFNo ratings yetWhat Is An ASME Appendix 2 Flange Design PDF1 page

- Design Sheet: WELDING CHECK (Nozzle To Repad)No ratings yetDesign Sheet: WELDING CHECK (Nozzle To Repad)5 pages

- Pipe&Shell - Design - Tool Pipe and ShellNo ratings yetPipe&Shell - Design - Tool Pipe and Shell1 page

- Pressure Vessel Nozzle Calc - ASME VIII Div 1100% (1)Pressure Vessel Nozzle Calc - ASME VIII Div 120 pages

- Using The ASME VIII-1 Nozzle F Factor (UG-37)No ratings yetUsing The ASME VIII-1 Nozzle F Factor (UG-37)7 pages

- Solid Works Model For The Pressure VesselNo ratings yetSolid Works Model For The Pressure Vessel16 pages

- TM.P. S.p.A. - Termomeccanica Pompe: 20 AP 20 Pump Size: Performance CurvesNo ratings yetTM.P. S.p.A. - Termomeccanica Pompe: 20 AP 20 Pump Size: Performance Curves1 page

- Engineering Services Related To Process Study: SRU RevampNo ratings yetEngineering Services Related To Process Study: SRU Revamp16 pages

- Design of Tall Towers Deflection Calculation As Per Megassy Contactor Tower (Cl-1001)No ratings yetDesign of Tall Towers Deflection Calculation As Per Megassy Contactor Tower (Cl-1001)1 page

- ISO 15189 Accreditation: Benita I.Haines Corporate Compliance and Quality Manager For Valley Health July 19, 2009No ratings yetISO 15189 Accreditation: Benita I.Haines Corporate Compliance and Quality Manager For Valley Health July 19, 200915 pages

- Specialized Cte Industry Certification ListNo ratings yetSpecialized Cte Industry Certification List14 pages

- Tackling Disablist Language Based Bullying in School: A Teacher's GuideNo ratings yetTackling Disablist Language Based Bullying in School: A Teacher's Guide28 pages

- 18 Propositional Logic First Order Logic 27-02-2024No ratings yet18 Propositional Logic First Order Logic 27-02-202425 pages

- On The Use Non-Stationary Penalty Functions T o Solve Nonlinear Constrained Optimization Problems With GA'sNo ratings yetOn The Use Non-Stationary Penalty Functions T o Solve Nonlinear Constrained Optimization Problems With GA's6 pages

- H.K. Moffatt - Cosmic Dynamos: From Alpha To OmegaNo ratings yetH.K. Moffatt - Cosmic Dynamos: From Alpha To Omega5 pages