Operating Manual Lubrication Device - 8175-9001-032

Operating Manual Lubrication Device - 8175-9001-032

Uploaded by

Michael ToledoCopyright:

Available Formats

Operating Manual Lubrication Device - 8175-9001-032

Operating Manual Lubrication Device - 8175-9001-032

Uploaded by

Michael ToledoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Operating Manual Lubrication Device - 8175-9001-032

Operating Manual Lubrication Device - 8175-9001-032

Uploaded by

Michael ToledoCopyright:

Available Formats

Pos : 1.2 /BA/Standard/00_Titel_R üc ks eite/Titels eite_BAA @ 1\mod_1350385053731_18.

doc x @ 187491 @ @ 1

Instruction manual

Designation: Lubricating device

Model: OLA 1303

No. 8175-9001-032 | Edition 1013

engineering for a better world GEA Mechanical Equipment

8175-9001-032 / 06.03.14

ORIGINAL INSTRUCTION MANUAL

Subject to modification!

The authors are always grateful for comments and sugges-

tions for improving the documentation. These can be ad-

dressed to:

GEA Mechanical Equipment

GEA Westfalia Separator Group GmbH

Werner-Habig-Str. 1, 59302 Oelde, Germany

Tel. +49 2522 77-0, Fax +49 2522 77-2488

www.gea.com

=== Ende der Liste für T extmar ke Titelseite ===

2 GEA Westfalia Separator Group

8175-9001-032 / 06.03.14

1 Safety precautions 4

1.1 Intended use .............................................................................................. 4

1.2 Reasonably foreseeable misuse ............................................................... 4

1.1 Maintenance safety precautions ................................................................ 4

2 Description 6

2.1 Description of unit ...................................................................................... 6

2.2 Installation .................................................................................................. 9

2.3 Requirements to be met by the compressed air supply ............................ 9

3 Operation 10

3.1 Commissioning ........................................................................................ 10

3.2 Adjusting the setting, checking the function ............................................ 10

3.3 Adjusting the oil quantity .......................................................................... 11

3.4 Adjusting the compressed air .................................................................. 11

3.5 Adjusting the solenoid valve (air-oiler valve)) .......................................... 11

3.6 Adjusting the pressure switch .................................................................. 11

3.7 Faults ....................................................................................................... 12

3.8 Plant control and monitoring .................................................................... 12

4 Repair 13

4.1 Maintenance schedule ............................................................................. 13

4.2 Long-term shut-down ............................................................................... 13

Pos : 2 /---Neue Seite--- @ 0\mod_1317283043850_0.doc x @ 550 @ @ 1

3 GEA Westfalia Separator Group

8175-9001-032 / 06.03.14

Pos : 3 /PRU/Standard/00_Ü berschriften/Kapitel/Ü _Sic her hei tshi nweise @ 0\mod_1336640090691_18.doc x @ 108624 @ @ 1

1 Safety precautions

Pos : 4 /___Lini e_Satzs pieg el___ @ 0\mod_1342187982593_0.doc x @ 174868 @ @ 1

Pos : 5 /BA/Standar d/02_Sic herheit/Bes ti mmungsgemäße_Ver wendung/Bes timmungsgemäß e_Ver wendung_Schmi eraggregat @ 0\mod_1335178053588_18.doc x @ 29650 @ 2 @ 1

1.1 Intended use

The intended use is the lubrication of bowl bearings on centrifuges from GEA

Westfalia Separator.

Pos : 6 /BA/Standar d/02_Sic herheit/Vor hers ehbare_F ehl anwendung/Vorhersehbar e_F ehlanwendung_Sc hmieraggregat @ 2\mod_1358931542842_18.doc x @ 219970 @ 2 @ 1

1.2 Reasonably foreseeable misuse

The manual contains instructions for the intended use. Any operation of the lubri-

cating unit that does not fall under the intended use constitutes unintended use and

is considered to be misuse.

Reasonably foreseeable misuses include:

• Use of unsuitable spare parts

• Use of impermissible operating materials

• Operation in incomplete assembly state:

- The required supervisory equipment is not activated.

- The required protective covers are not installed.

• The unit is operated by persons who have not received adequate training.

• Changing the process conditions, operating conditions and environmental condi-

tions without the consent of the manufacturer.

Any misuse of the lubricating unit can lead to severe damage to persons and prop-

erty.

Pos : 7 /BA/Standar d/11_Wartung/Sic her hei t_Wartung/Sicherheit_Wartung_Schmi eraggregat @ 2\mod_1358933505671_18.doc x @ 220138 @ 2 @ 1

1.1 Maintenance safety precautions

Unfavourable operating conditions may require shorter maintenance intervals. The

factors listed below are unfavourable because they either attack the material of the

unit directly or impair the lubrication system.

Timely maintenance of the unit and replacement of worn or damaged parts are es-

sential for safe operation of the unit.

Before all maintenance and servicing:

Isolate all electrically supplied equip-

ment from the power supply using the

main switch.

Secure the plant against unintended

restarting with locking devices.

The lubricating unit is pressurised

during operation. It must therefore be

depressurised before commencing

with upgrades, modifications, repairs

etc.

Fig. 1

4 GEA Westfalia Separator Group

8175-9001-032 / 06.03.14

Collect dripping oil to prevent risk of

slipping or infection of the product.

Wait until the bowl has come to a

standstill.

When handling waste oils note:

- Health risks depend on the chemical

composition.

- Dispose of waste oil in accordance

with local regulations.

Fig. 2

Pos : 8 /---Neue Seite--- @ 0\mod_1317283043850_0.doc x @ 550 @ @ 1

5 GEA Westfalia Separator Group

8175-9001-032 / 06.03.14

Pos : 9 /BA/Standar d/00_Übersc hriften/Kapi tel _Ü1_links/Ü 1_li nks _Besc hrei bung @ 2\mod_1359015953942_18.doc x @ 220830 @ @ 1

2 Description

Pos : 10 /___Li nie_Satzs piegel ___ @ 0\mod_1342187982593_0.doc x @ 174868 @ @ 1

Pos : 13 /BA/8000_Zus atz/8175/8418_Autom_Sc hmier ung/03_Beschr eibung/Ar beits weis e/Arbeits weise_8418-010 @ 1\mod_1358331402175_18.doc x @ 218444 @ 2 @ 1

2.1 Description of unit

The oil-air unit is a device for centrifuges for lubricating the bowl bearings with min-

imal quantities.

The finely dosed lubricant is distributed by an air flow in smears on the inner walls

of the lubricating line and is transported to the lubricating point.

The bowl bearings are discontinuously supplied with lubricant in the form of fine

droplets via a discharge nozzle.

The compact unit works in pulses; a lubrication cycle is followed by a pause.

Tasks of the machine control:

• Control of the pause and pulse times

• Monitoring of the filling level in the oil storage vessel

• Monitoring of the air pressure in the individual lubricating lines

The required lubricating quantity can be precisely dosed for each individual lubri-

cating point.

Pos : 14 /---Neue Seite--- @ 0\mod_1317283043850_0.doc x @ 550 @ @ 1

6 GEA Westfalia Separator Group

8175-9001-032 / 06.03.14

Pos : 17 /BA/8000_Zus atz/8175/8418_Autom_Sc hmier ung/03_Beschr eibung/Gesamtpr odukt/Ges amtprodukt_8175-032 @ 9\mod_1390904472112_18.doc x @ 646489 @ 2222 @ 1

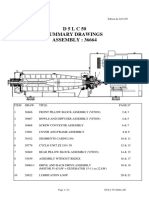

Fig. 3

The oil-air unit consists of the following assemblies:

1 Lubrication vessel with float switch (F)

2 Filler neck for filling the lubricant vessel

3a Adjusting sleeve for the injection oiler, bowl bearing solid side

3b Adjusting sleeve for the injection oiler, not used

3c Adjusting sleeve for the injection oiler, bowl bearing liquid side

4a Lubricating line connection, solid-side outlet

4b Connection lubricating line, sealed

4c Lubricating line connection, fluid-side outlet

5 Oil-air injection oiler

6 Compressed air pressure reducer with pressure gauge and automatic water trap

7 Solenoid valve (air-oiler valve)

9 Sight glass

10 Drain screw

11 Air supply connection (compressed air to be provided by customer)

12 Filling level sensor

7 GEA Westfalia Separator Group

8175-9001-032 / 06.03.14

Fig. 4

8a Pressure switch for minimum air pressure,

inlet to solid-side lubricating point (H)

8b Pressure switch for minimum air pressure,

inlet to fluid-side lubricating point (G)

Pos : 18 /---Neue Seite--- @ 0\mod_1317283043850_0.doc x @ 550 @ 22222222 @ 1

8 GEA Westfalia Separator Group

8175-9001-032 / 06.03.14

Pos : 21 /BA/8000_Zus atz/8175/8418_Autom_Sc hmier ung/06_M ontag e_und_Installation/Schmi erei nrichtung_installieren/Sc hmi erei nrichtung_i nstallieren_8418- 010 @ 1\mod_1358414230830_18.doc x @ 219030 @ 22222222222 @ 1

2.2 Installation

Installation of the electrical components:

• When installing electrical components, local and national guidelines must be

complied with. The unit and individual components such as the tank must be

taken into consideration when carrying out equipotential bonding.

Installation of the pneumatic components:

• Check use of the correct compressed air (see chapter "Compressed air").

• The lubricant vessel must be mounted horizontally so that the oil level in the tank

is uniformly high and can be monitored.

• During installation and operation, refer to the manuals of the centrifuges and the

individual components.

During assembly, there must be no isolated plant components. The oil-air unit may

only be connected via electrostatically conductive pipe or hose systems which

have been taken into consideration when carrying out equipotential bonding.

This oil-air unit is not suitable for use in explosive zones.

Pos : 25 /BA/8000_Zus atz/8175/8418_Autom_Sc hmier ung/06_M ontag e_und_Installation/Anfor der ung en_Druc kl uft/Anfor der ung en_Druc kl uft_8418-010 @ 7\mod_1381393535895_18.doc x @ 435890 @ 22222222222222222222222222222 @ 1

2.3 Requirements to be met by the compressed air supply

Requirement Values

Inlet pressure Min. 0.4 MPa (corresponds to 4 bar)

Max. 0.8 MPa (corresponds to 8 bar)

Required air volume for rating the com- In standard state as per DIN 1343

pressed air supply approx. 3500 l/h in standard state (with

1.013 bar and 0°C) with 4 bar supply

pressure

Based on the compressed air quality grades according to ISO 8573-1

Particle content Class 3

Max. particle size 5 μm

3

Max. particle content 5 mg/m

Class 4

Pressure dew point max. + 3°C

Class 3

3

Oil concentration max. 1 mg/m

Pos : 26 /---Neue Seite--- @ 0\mod_1317283043850_0.doc x @ 550 @ 2222222222222222 @ 1

9 GEA Westfalia Separator Group

8175-9001-032 / 06.03.14

Pos : 27 /BA/Standard/00_Ü berschriften/Kapitel_Ü 1_links /Ü1_links_Betrieb @ 2\mod_1359016610020_18.doc x @ 220864 @ 22222222222222222222222222222222222 @ 1

3 Operation

Pos : 28 /___Li nie_Satzs piegel ___ @ 0\mod_1342187982593_0.doc x @ 174868 @ 2222222222222222222222222222222222222222222222222222222222222222222222 @ 1

Pos : 30 /BA/8000_Zus atz/8175/8418_Autom_Sc hmier ung/08_Inbetriebnahme/Sc hmier einric htung_Inbetriebnahme/Inbetriebnahme_8175-032 @ 10\mod_1391510099229_18.doc x @ 656300 @ 2222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222 @ 1

3.1 Commissioning

• Fill the lubricant vessel through the filler neck 2 up to the maximum mark. Make

sure that no dirt enters the oil storage vessel during filling. Oil quantity and quali-

ty are specified in the "Lubrication and maintenance schedule".

• Check the factory settings of the oil-air unit (see chapter "Adjusting settings").

• Disconnect the oil lines from the bowl bearings.

• The oil-air unit is switched on during start-up of the centrifuge.

- During start-up of the centrifuge, using a sheet of paper, check several times

whether the oil is conveyed to the lubricating points.

- After 10 faulty pulses, the centrifuge is shut down and the control starts the

post-lubrication time. The oil-air unit remains switched on until the post-

lubrication time has expired.

• Connect the oil lines to the bowl bearings.

Pos : 32 /BA/8000_Zus atz/8175/8418_Autom_Sc hmier ung/07_Eins tell ung en/Ei nstellungen_anpass en/Ei nstellung_anpass en_8175- 032 @ 10\mod_1391512583873_18.doc x @ 656335 @ 2222222222222222222222222222222222222222222222222222222222222222222222222222222222222222 @ 1

3.2 Adjusting the setting, checking the function

The oil-air unit runs when the centrifuge is started.

Factory setting

• The oil-air lubrication is adjusted by GEA Westfalia Separator before shipping

the centrifuge.

• The factory setting for the pulsing is specified in the order-specific “Lubrication

and maintenance schedule” in the centrifuge documentation.

• Adjusting the adjusting sleeve for the injection oiler (3): see chapter "Adjusting

the oil quantity".

Adjusting the setting

• The settings of the oil-air unit must be checked and adapted if necessary during

commissioning and inspections.

• The oil quantity fed can be adapted in special cases after consultation with GEA

Westfalia Separator. This is done by altering the pulsing of the unit inside the

control or by adjusting the oil volumes fed into the injection oiler.

Pos : 33 /---Neue Seite--- @ 0\mod_1317283043850_0.doc x @ 550 @ 2222222222222222222222222222222222222222222222222222222 @ 1

10 GEA Westfalia Separator Group

8175-9001-032 / 06.03.14

Pos : 34 /BA/8000_Zus atz/8175/8418_Autom_Sc hmier ung/07_Eins tell ung en/Öl menge_eins tell en/Öl menge_eins tell en_8175- 032 @ 10\mod_1391512898556_18.doc x @ 656371 @ 222222222222222222222222222222222222222222222222222222222222222222222222222222222222222222227 @ 1

3.3 Adjusting the oil quantity

The delivery volume per pulse is adjusted by means of the transparent adjusting

sleeves of the injection oiler.

Pull back the black locking ring.

The delivery volume is reduced stepwise by turning the adjusting sleeve coun-

terclockwise (-).

- It engages 4x per revolution (audibly and tangibly) so that intermediate set-

tings are also possible.

The maximum delivery volume is attained again by turning the adjusting sleeve

clockwise (+) until it hits stop.

Let the black locking ring click into place again.

3

Max. delivery volume / stroke 30 mm

3

1 full left revolution 25 mm

3

2 full left revolutions 20 mm factory setting

3

3 full left revolutions 15 mm

3

4 full left revolutions 10 mm

3

5 full left revolutions 5 mm

3

Over 6 full left revolutions 3 mm

Pos : 35 /BA/8000_Zus atz/8175/8418_Autom_Sc hmier ung/07_Eins tell ung en/Druc kl uft_eins tell en/Druc kl uft_eins tell en_8418-010 @ 1\mod_1358422710037_18.doc x @ 219302 @ 22222222222222222222222222222222222222222222222222222222222222222227 @ 1

3.4 Adjusting the compressed air

At the factory, the air pressure at the compressed air pressure reducer (6) is set to

5 bar.

The air pressure can be altered by turning the handwheel.

The system functions correctly with an air pressure of 4 – 8 bar.

Pos : 36 /BA/8000_Zus atz/8175/8418_Autom_Sc hmier ung/07_Eins tell ung en/Magnetventil _ei nstellen/M agnetventil_eins tell en_8418- 010 @ 1\mod_1358422288546_18.doc x @ 219234 @ 222222222222222222222222222222222222222222222222222227 @ 1

3.5 Adjusting the solenoid valve (air-oiler valve))

The solenoid valve 7 for the air supply is controlled via the machine control.

There are different settings between start phase and operation.

The factory setting is specified in the “Lubrication and maintenance manual”.

Pos : 37 /BA/8000_Zus atz/8175/8418_Autom_Sc hmier ung/07_Eins tell ung en/Druc kschalter_eins tell en/Druc kschalter_einstellen_8418-010 @ 1\mod_1358422526001_18.doc x @ 219268 @ 2222222222222222222222222222222222 @ 1

3.6 Adjusting the pressure switch

The pressure switches for minimum air pressure 8a and 8b for lubricating pulse

monitoring on the bearing housings have been set at the factory to 0.5 bar mini-

mum switching value.

After adjustment, the adjusting screw was secured and sealed against twisting with

lacquer.

Pos : 38 /---Neue Seite--- @ 0\mod_1317283043850_0.doc x @ 550 @ 22222222222222222222222227 @ 1

11 GEA Westfalia Separator Group

8175-9001-032 / 06.03.14

Pos : 40 /BA/8000_Zus atz/8175/8418_Autom_Sc hmier ung/10_Störungen_beheben/Betriebsstörungen/Betriebsstörungen_8418-010 @ 1\mod_1358422950500_18.doc x @ 219336 @ 222222222222222222222 @ 1

3.7 Faults

Note:

• The system is insensitive if too much oil is lubricated in the bearing.

• The bearing temperatures normally rise by only 3° - 5°C.

• If the air pressure is too low, the machine is shut down since the lubricating

points are then no longer adequately supplied with lubricant.

- The switching signal comes directly from the pressure switches on the bearing

housings.

• The setting for monitoring the pressure pulses/lubrication pulses is pre-set in the

control at the factory:

- Oil level in lubricant vessel below minimum

Pos : 41 /---Leer e Z eile--- @ 0\mod_1320741851919_0.doc x @ 9360 @ 222222222277 @ 1

- Mechanical damage to a component

Pos : 42 /BA/8000_Zus atz/8175/8418_Autom_Sc hmier ung/09_Betrieb/Anl agensteuerung_und_Über wachung/Anlag ens teuerung_Über wachung_8418- 010 @ 2\mod_1370340858711_18.doc x @ 255820 @ 222222222222222222777 @ 1

3.8 Plant control and monitoring

If a machine control is delivered by GEA Westfalia Separator, control and monitor-

ing of the operation of the oil-air unit is included in the scope of delivery. Corre-

sponding notes and instructions are given in the manual for the machine control.

Plants without control:

In the case of machine controls ordered by the plant operator, the following must

be taken into account for the control of the oil-air unit:

• The pulse and pause time is controlled:

The times are given in the order-specific "Lubrication and maintenance schedule”.

The following is monitored:

• The lubrication pulse

- The pressure switches (8) check at both bearing points whether the minimum

air pressure is achieved during the lubrication pulse and whether it subse-

quently decreases.

- Faulty lubrication pulses are counted up.

- Completed pulses are counted down but not below 0.

- In the case of 5 faulty pulses, a warning and collective alarm are output as a

message.

- In the case of 10 faulty pulses, the machine is shut down.

• The filling level in the lubricant vessel

- A warning signal is given first. If no oil has been topped up after 25000 sec-

onds, the centrifuge is switched off.

Pos : 43 /---Neue Seite--- @ 0\mod_1317283043850_0.doc x @ 550 @ 2322227 @ 1

12 GEA Westfalia Separator Group

8175-9001-032 / 06.03.14

Pos : 44 /BA/Standard/00_Ü berschriften/Kapitel_Ü 1_links /Ü1_links_Ins tandsetzung @ 2\mod_1359017366804_18.doc x @ 221000 @ 22322222222777 @ 1

4 Repair

Pos : 45 /___Li nie_Satzs piegel ___ @ 0\mod_1342187982593_0.doc x @ 174868 @ 2223222223222222222237777 @ 1

Pos : 47 /BA/8000_Zus atz/8175/8418_Autom_Sc hmier ung/11_Wartung/Wartungspl an/Wartungspl an_8175- 032 @ 10\mod_1391691582494_18.doc x @ 660385 @ 2223333333333337 @ 1

4.1 Maintenance schedule

Oil-air lubricating units need little maintenance.

Repair work may only be carried out on a unit which has been de-energised be-

CAUTION

forehand by trained personnel.

Work on energised units can lead to personal injury.

The lubricating unit is pressurised during operation. It must therefore be de-

pressurised before commencing with repairs.

Check regularly:

Machine component Action Operator

Check entire lubricating Operator

for leakage

unit

Carry out a visual inspection for leakage, paying particular Operator

attention to the connecting parts at the bearing points. The

Oil lines

latter are exposed to the machine vibrations.

Re-seal untight connections.

Fill in oil up to the maximum mark on the filling level indica- Operator

tor.

• The required oil is specified in the order-specific "Lubrication

Lubricant vessel and maintenance schedule" in the machine documentation.

• To avoid mistakes, it is recommended to attach a label speci-

fying the lubricant used to the lubricant vessel.

• Holding capacity: max. 3 litres oil.

Cleaning:

As required, the compact unit can be cleaned with mild, material-compatible de-

tergents (non-alkaline, no soap).

Cables and hoses should remain connected if possible. Openings must be

closed to prevent detergents from entering the inside.

Given a normal operating mode and the use of the lubricants listed in the “Lubri-

cation and maintenance schedule”, cleaning of the interior is not necessary.

If an incorrect or contaminated lubricant has been filled in by mistake, the inside

of the lubricant vessel must be cleaned. For this purpose, consult GEA Westfalia

Separator.

Pos : 50 /BA/8000_Zus atz/8175/8418_Autom_Sc hmier ung/13_Außer betriebnahme/Langfristige_Auß erbetri ebnahme/Langfristige_Auß erbetriebnahme_8418- 010 @ 1\mod_1358426385696_18.doc x @ 219404 @ 2 @ 1

4.2 Long-term shut-down

Disconnect the power from the oil-air unit.

Fill the lubricant vessel with oil to avoid corrosion.

Store in a dry and dust-free environment.

=== Ende der Liste für T extmar ke Inhalt ===

- The ambient temperatures must be between 10 – 60°C.

13 GEA Westfalia Separator Group

Pos : 53 /BA/Standard/00_Ti tel _Rüc ks eite/Ruec ks eite @ 0\mod_1342013267033_18.doc x @ 173244 @ @ 1

We live our values-

Excellence • Passion • Integrity • Responsibility • GEA-versity

GEA Group is a global engineering company with multi-billion euro sales and operations

in more than 50 countries. Founded in 1881, the company is one of the largest providers of innova-

tive equipment and process technology. GEA Group is listed in the STOXX® Europe 600 Index.

GEA Mechanical Equipment

GEA Westfalia Separator Group GmbH

Werner-Habig-Str. 1, 59302 Oelde, Germany

Tel. +49 2522 77-0, Fax +49 2522 77-2488

www.gea.com

=== Ende der Liste für T extmar ke Ruec ks eite ===

You might also like

- SB 9727-5 LubricantsDocument4 pagesSB 9727-5 LubricantsHumberto Betto Bravo100% (1)

- Panx-350 SPCDocument64 pagesPanx-350 SPCbhaskar reddyNo ratings yet

- Bfa8013 - en 2023-01-24Document123 pagesBfa8013 - en 2023-01-24John Alexander Sandoval Alfonso100% (1)

- List of Materials Lot4Document4 pagesList of Materials Lot4Reny SitorusNo ratings yet

- Aldec 10+Document2 pagesAldec 10+epebeNo ratings yet

- CD 518 HV VFD Brochure Rev 2Document6 pagesCD 518 HV VFD Brochure Rev 2Nurullah BöğüşNo ratings yet

- Separator Manual High Speed Separator: MMB 305S-11Document164 pagesSeparator Manual High Speed Separator: MMB 305S-11Bima Surya Utama100% (1)

- HSS Range Poster - A3 PDFDocument1 pageHSS Range Poster - A3 PDFJulian De la CruzNo ratings yet

- IB Chemistry Topic 1 NotesDocument5 pagesIB Chemistry Topic 1 NotesCristian AlamosNo ratings yet

- 9077-305 Vse 40-02-007Document1,032 pages9077-305 Vse 40-02-007gcd2008No ratings yet

- Lynx 20-200 Atex Oim ManualDocument243 pagesLynx 20-200 Atex Oim ManualGiorgiana RosuNo ratings yet

- P32684_maint_uk_00911221_00911321Document118 pagesP32684_maint_uk_00911221_00911321mboyievNo ratings yet

- 0820 9001 000 - Moc515 Moc8015Document58 pages0820 9001 000 - Moc515 Moc8015gaby2003100% (1)

- Alfa Laval - Foodec 100, Leaflet PDFDocument2 pagesAlfa Laval - Foodec 100, Leaflet PDFImad MhannaNo ratings yet

- D5LC50 Summary Drawings ASSEMBLY: 36664: Edition Du 14/11/03Document21 pagesD5LC50 Summary Drawings ASSEMBLY: 36664: Edition Du 14/11/03Lionel TabeauNo ratings yet

- 518 HV VFD (ATEX) - Equipment Data Sheet (Rev 06)Document2 pages518 HV VFD (ATEX) - Equipment Data Sheet (Rev 06)Gerard HoffardNo ratings yet

- G-CENTRI FORCE PLC's ManualDocument19 pagesG-CENTRI FORCE PLC's ManualShahaji ChavanNo ratings yet

- 040 - 2052 9001 041Document170 pages040 - 2052 9001 041babubhaiyya4211No ratings yet

- Service & Maintenance Manual High Speed Separator: Product No. 881039-12-01/1 Book No. 568854-02 Rev. 2Document133 pagesService & Maintenance Manual High Speed Separator: Product No. 881039-12-01/1 Book No. 568854-02 Rev. 2امير الموسوي100% (1)

- Haldiram BBRPX610 MRMDocument136 pagesHaldiram BBRPX610 MRMSales Sarthak EngineeringNo ratings yet

- Gears - Parts List - 2016Document14 pagesGears - Parts List - 2016Centrifugal SeparatorNo ratings yet

- v00 - Sparepart Catalogue - 5129150 SPC ESDocument75 pagesv00 - Sparepart Catalogue - 5129150 SPC ESconanellbarbaro1No ratings yet

- 5500 Centrifuge Hydraulic Backdrive Operations ManualDocument138 pages5500 Centrifuge Hydraulic Backdrive Operations ManualTaher Yusuf0% (1)

- Disk Stack Compressing DeviceDocument22 pagesDisk Stack Compressing Deviceаа аааNo ratings yet

- Alfa-Laval 3.5 DD Parts From Rev Tech L.CDocument2 pagesAlfa-Laval 3.5 DD Parts From Rev Tech L.CMonthep Rodthai100% (1)

- Alpha Laval Emmie Oil SeparatorDocument2 pagesAlpha Laval Emmie Oil SeparatorADITYA_PATHAKNo ratings yet

- PX 65 LeafletDocument2 pagesPX 65 LeafletrinthusNo ratings yet

- Verti-G and CVG Quick Reference Guide - Rev B - 6499975 - 01Document44 pagesVerti-G and CVG Quick Reference Guide - Rev B - 6499975 - 01farhad iqbalNo ratings yet

- HH 1448HD BrakeSmart Centrifuge - Operations Manual - 2005Document120 pagesHH 1448HD BrakeSmart Centrifuge - Operations Manual - 2005Centrifugal SeparatorNo ratings yet

- Centriquip - 2002 - BrochureDocument5 pagesCentriquip - 2002 - BrochureCentrifugal SeparatorNo ratings yet

- Aldec PDFDocument4 pagesAldec PDFJoice AlvesNo ratings yet

- 2 Gear Drive Decanters 010807Document4 pages2 Gear Drive Decanters 010807banerjeeamlanNo ratings yet

- Decanter Panx750 OmDocument249 pagesDecanter Panx750 OmGerardo CheNo ratings yet

- TD WaterMaster CF 6000Document2 pagesTD WaterMaster CF 6000Song Nguyen Nguyen100% (1)

- Alfa Laval MAB206 PDFDocument196 pagesAlfa Laval MAB206 PDFThái Mai ĐìnhNo ratings yet

- Technical Documentation: Technische DokumentationDocument524 pagesTechnical Documentation: Technische DokumentationAndhityas Piscessandhy PutraNo ratings yet

- ALDEC G2-95 - Manual - 2010Document104 pagesALDEC G2-95 - Manual - 2010Centrifugal Separator100% (1)

- MAB 206 Separator - O&M (Centrifuse TG) PDFDocument196 pagesMAB 206 Separator - O&M (Centrifuse TG) PDFadarsh_saxena262775% (4)

- ESS-1450HD2 - 2020 - BrochureDocument4 pagesESS-1450HD2 - 2020 - BrochureCentrifugal SeparatorNo ratings yet

- CD 600 VFDDocument409 pagesCD 600 VFDJavier PabonNo ratings yet

- Decanter Centrifuge: Alfa Laval Alfa LavalDocument30 pagesDecanter Centrifuge: Alfa Laval Alfa LavalYousef AlipourNo ratings yet

- SPX Seital Separation Technology - ApplicationDocument44 pagesSPX Seital Separation Technology - ApplicationmikafazNo ratings yet

- Shell Cardium® Fluid EP: Premium Performance Open Gear and Wire Rope FluidDocument1 pageShell Cardium® Fluid EP: Premium Performance Open Gear and Wire Rope FluidRaghavendra MurthyNo ratings yet

- Brozh Dekantertsentrifuugid PDFDocument4 pagesBrozh Dekantertsentrifuugid PDFNima AhvaziNo ratings yet

- DA 45 WI Part Katalog Tanpa Bowl DiscDocument72 pagesDA 45 WI Part Katalog Tanpa Bowl DiscMuhammad ArifNo ratings yet

- Offering Letter:: HA Decanter DDI 4743 ForDocument4 pagesOffering Letter:: HA Decanter DDI 4743 ForMuhammad ArifNo ratings yet

- Introduction of DecanterDocument6 pagesIntroduction of DecanterJega Yuvan100% (1)

- Cavex ManualDocument20 pagesCavex ManualQuinn Golden100% (1)

- CCB - Rev 04Document102 pagesCCB - Rev 04Alok SinghNo ratings yet

- InstalacionDocument36 pagesInstalacionHumberto Betto BravoNo ratings yet

- Electrical Load - Full Operation ModeDocument14 pagesElectrical Load - Full Operation ModeAris KancilNo ratings yet

- PSS 3.2-1040 - Parts List - 2017Document10 pagesPSS 3.2-1040 - Parts List - 2017Centrifugal SeparatorNo ratings yet

- PSS 1.2 - 3.2 - 3.3 - 5.2 - Operating Manual - Vol. 1 - 2020 - ESDocument43 pagesPSS 1.2 - 3.2 - 3.3 - 5.2 - Operating Manual - Vol. 1 - 2020 - ESCentrifugal SeparatorNo ratings yet

- Shell Rhodina Grease SDX 2: Calcium Grease For Industrial ApplicationsDocument2 pagesShell Rhodina Grease SDX 2: Calcium Grease For Industrial ApplicationsKuhnNo ratings yet

- Specification of GCF-G-210FMDocument7 pagesSpecification of GCF-G-210FMShahaji ChavanNo ratings yet

- RSE70 Spare Parts CatalogDocument120 pagesRSE70 Spare Parts Cataloggcd2008No ratings yet

- Decanter UCD 205Document4 pagesDecanter UCD 205Itamar HiteNo ratings yet

- Decanter CentrifugeDocument224 pagesDecanter Centrifugeagsan.algabh2718No ratings yet

- Slicer: VS12D, VS12CD, VS12D-R, VS12D-V, VS12D-V/RDocument74 pagesSlicer: VS12D, VS12CD, VS12D-R, VS12D-V, VS12D-V/Rsakysrus2No ratings yet

- Three-Phase Asynchronous Motor Series 1R.5/1S.5: Operating Instructions Edition 03.2011Document284 pagesThree-Phase Asynchronous Motor Series 1R.5/1S.5: Operating Instructions Edition 03.2011Mamadou NdongoNo ratings yet

- Astn A194 - 2018Document12 pagesAstn A194 - 2018Danny TriwibowoNo ratings yet

- Ref Centrifuge CL 21R PDFDocument83 pagesRef Centrifuge CL 21R PDFAshari EndraNo ratings yet

- Simgas PRMS SimulationDocument9 pagesSimgas PRMS Simulationmatteo2009No ratings yet

- Solutions Practice Test: Multiple ChoiceDocument7 pagesSolutions Practice Test: Multiple Choicesana iqbalNo ratings yet

- Applications of Dampers For RCC Building To Reduce Seismic RiskDocument3 pagesApplications of Dampers For RCC Building To Reduce Seismic RiskSaurabh PednekarNo ratings yet

- Basic Barcelona Model - Géotechnique40 AlonsoDocument26 pagesBasic Barcelona Model - Géotechnique40 AlonsoYorch FirstoneNo ratings yet

- Dupont Pyralux Apr: All-Polyimide With Embedded Resistor Foil, Flexible LaminateDocument8 pagesDupont Pyralux Apr: All-Polyimide With Embedded Resistor Foil, Flexible LaminateAyrton PatiñoNo ratings yet

- Raghu MahajanDocument2 pagesRaghu MahajanNayan SharmaNo ratings yet

- Thermodynamics Lecture 1Document15 pagesThermodynamics Lecture 1Shahla GondalNo ratings yet

- Welding of Copper AlloysDocument24 pagesWelding of Copper AlloysSgk ManikandanNo ratings yet

- CH 3 Atoms and Molecules 1Document52 pagesCH 3 Atoms and Molecules 1SHIVAKUMAR H PNo ratings yet

- (Chapman & Hall - CRC Applied Mathematics & Nonlinear Science) Chen, Yi-Tung - Li, Jichun-Computational Partial Differential Equations Using MATLAB-CRC Press (2008)Document14 pages(Chapman & Hall - CRC Applied Mathematics & Nonlinear Science) Chen, Yi-Tung - Li, Jichun-Computational Partial Differential Equations Using MATLAB-CRC Press (2008)Santiago Del Rio OliveiraNo ratings yet

- IBIA Glossary of TerminologyDocument65 pagesIBIA Glossary of TerminologyJohn GreenNo ratings yet

- poorhaydariWJ 2005 10 s149 PDFDocument7 pagespoorhaydariWJ 2005 10 s149 PDFCristiana GusmãoNo ratings yet

- Activation of (Na, Ca) - Bentonites With Soda and Mgo and Their Utilization As Drilling MudDocument8 pagesActivation of (Na, Ca) - Bentonites With Soda and Mgo and Their Utilization As Drilling MudTaufiqTaufiqNo ratings yet

- GIbbs Energy Regular Solution NotesDocument13 pagesGIbbs Energy Regular Solution Notessaurabh kumarNo ratings yet

- Diatomic Molecule Partition FunctionDocument18 pagesDiatomic Molecule Partition FunctionAnimasahun Olamide HammedNo ratings yet

- Word Problems YMASDocument37 pagesWord Problems YMASKim Gerald MenesesNo ratings yet

- Datasheet sx01dn PDFDocument10 pagesDatasheet sx01dn PDFarielfilthNo ratings yet

- Handout 05 (16 Aug 2022) Structure of Ionic Solids and CeramicsDocument32 pagesHandout 05 (16 Aug 2022) Structure of Ionic Solids and CeramicssandeepNo ratings yet

- Physics Exit 3q1718 .Document16 pagesPhysics Exit 3q1718 .Mikaella Tambis0% (1)

- Chapter One: 1 Bio-Oil Plant DesignDocument55 pagesChapter One: 1 Bio-Oil Plant DesignJomed Barallas100% (1)

- Characterization of Chemically Synthesized Cds NanoparticlesDocument7 pagesCharacterization of Chemically Synthesized Cds Nanoparticlesaditya singhNo ratings yet

- Amd Treat DsDocument1 pageAmd Treat DsirfanNo ratings yet

- An Analysis of Extended and exponentially-Fed-Batch CulturesDocument9 pagesAn Analysis of Extended and exponentially-Fed-Batch CulturesScourge BlackthornNo ratings yet

- QTN 1807120Document4 pagesQTN 1807120SanthoshMBSanthuNo ratings yet

- Class 12 Allen Jee ElectrochemistryDocument5 pagesClass 12 Allen Jee Electrochemistrybooksuse.neet.20250% (1)

- Simulating Half Life MakeupDocument2 pagesSimulating Half Life MakeupKris GribecNo ratings yet

- KeresaHaughtion Lab1Document3 pagesKeresaHaughtion Lab1KayenNo ratings yet