Saic-H-2028

Saic-H-2028

Uploaded by

mominCopyright:

Available Formats

Saic-H-2028

Saic-H-2028

Uploaded by

mominOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Saic-H-2028

Saic-H-2028

Uploaded by

mominCopyright:

Available Formats

SAUDI ARAMCO ID/PIEU - 30-Nov-2017- REV. 2017.09.00 (Standards Cutoff - September 30, 2017) Rev. 2017.09.

00 30-Sep-17

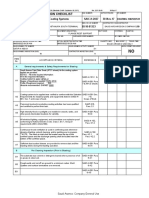

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

In-Process Insp. of Primer or First Coat (Liquid Coating System) SAIC-H-2028 30-Nov-17 COATING- 1402522576

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

UPGRADE FIRE WATER SYSTEM AT RASTANURA SOUTH TERMINAL BI-10-01333 SAUDI ARCHIRODON COMPANY LTD

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

FLANGE REST SUPPORT

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

168-B-XA-864219-003-00-1 & 2

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

08/02/2022 10:30 AM 08/02/2022 10:30 AM SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SATIP-H-100-01 3.2

SAUDI ARAMCO INSPECTION LEVEL

W

CONTRACTOR INSPECTION LEVEL

H

NO

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A General requirements & Safety Requirements for Painting

Saudi Aramco Coating Data Sheet (SAES-H-101V) of the coating system

being applied is provided:

NOTES: Fill in the required information for

Coating System: APCS-3 Primer:Sigma C-200a Coal Tar SAES-H-101V &

Primer Coat: Wet film thickness : 256µm / Reqd. DFT:200 µm

A1 Full System: Wet film thickness :250-300µm / Reqd.DFT:400-600µm

SAES-H-001 Para

Recoat interval (Min / Max):24 Hrs /20 Days.at Steel Temp10 ºC

06 Hrs/ 4 Days e at Steel Temp 30 ºC

4 & APCS Sheets

02 Hrs / 1 Days at Steel Temp 50 ºC

Coating system applied was verified to conform with the project SAES-H-001 Sec.

A2 specification and Selection Requirements for Industrial Plants and 7&

Equipment specified in SAES-H-001, Sec. 7. Scope of Work

Personnel involved in protective coating activities has been qualified and SAEP-316,

A3

certified to perfom their task. Para. 5.1

Safety requirements mandated in SAES-H-102 verified and found to be

acceptable:

1. Work Permits for hot work, cold work, and confined space entry have

been obtained in accordance with GI-0002.100.

2. All electrical lighting, equipment, and connections are explosion proof

conforming to National Electric Code, Class I, Div 1, Group D SAES-H-102

requirements (NEC Article 500). Para. 4.1.4

3. Airless spray equipment and other power tools are properly grounded, Para. 4.1.2

connected, and in good condition. (Grounding wire shall be AWG-4 or Para. 4.2.1

A4

larger). Para. 4.3.2

4. The appropriate personnel protection equipment listed in Para. 4.4.1.2

Table 4-2 of SAES-H-102 is worn Para. 4.4.5.8

5. Continuous forced ventilation is used in confined spaces whenever

abrasive blasting, solvent cleaning, and/or painting are in progress.

**NOTE: The fresh air inlet shall be located near the top of the confined

space whenever practical and the discharge opening shall be located near

the bottom of the confined space.

All personnel entering tanks or vessels after abrasive blasting wear

SAES-H-001 Para

A5 rubber-soled shoes with clean disposable covers, sweat bands and lint-

6.5.5

free gloves.

B Weather Conditions for Painting

Paint shall not be applied during adverse weather conditions such as, but

not restricted to following:

1) Wind is strong enough to blow sand, salt spray or other

foreign matter onto the surface being painted. SAES-H-001 Para

B1

2) Wind is 6.1.1

strong enough to cause dry spay or otherwise seriously

disturb the spray pattern when application is by spray gun.

3) Rain

Paint shall not be applied if one or more of the following conditions exist

(unless paint is specifically formulated for averted condition):

a) Substrate temperature is less than 10°C of the temperature

limit given in the applicable Saudi Aramco Data Sheet SAES-H-001 Para

B2

b) Substrate temperature is more than the temperature limit 6.1.1

given in the applicable Saudi Aramco Data Sheet.

c) Substrate temperature is less than 3°C above the dew point.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Nov-2017- REV. 2017.09.00 (Standards Cutoff - September 30, 2017) Rev. 2017.09.00 30-Sep-17

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

In-Process Insp. of Primer or First Coat (Liquid Coating System) SAIC-H-2028 30-Nov-17 COATING- 1402522576

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

UPGRADE FIRE WATER SYSTEM AT RASTANURA SOUTH TERMINAL BI-10-01333 SAUDI ARCHIRODON COMPANY LTD

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

SAES-H-001,

Relative humidity is over 50% for application & curing of solvent based

B3 APCS-17A, Para.

inorganic zinc primer of APCS-1A/1D/11A/17A.

2.2

SAES-H-001,

Relative humidity is less than 50% for application & curing of water-based

B4 APCS-17B, Para.

inorganic zinc primer of APCS-1A/1D/11A/17B.

2.2

C Paint Preparation

All paint materials for each coating system are supplied by the same

SAES-H-001 Para

C1 Manufacturer. (Exception is when approval was obtained from the

9.2.4

Consulting Services Department.)

Paints has not exceeded the shelf life as stamped/labeled in the SAES-H-001 Para

C2

containers. 11.6

Paint cans showing leakage, gelled paints or skinning are rejected.

SAES-H-001

C3 If sludge is formed at the bottom of the paint container and cannot be

Para6.2.4 & 9.2

dispersed by mixing , the paint shall be rejected.

Partial mixing and use of two-component and multi-component coatings is SAES-H-001 Para

C4

prohibited not used. 9.2.5

Paints are thoroughly mixed until it is homogeneous. Power stirrer is SAES-H-001 Para

C5

used for mixing quantities over 5 liters. 9.2.3

Thinner type (Stock No) and quantity to be added (Percentage)

SAES-H-001 Para

C6 shall be as given in the Saudi Aramco Data Sheet, SAES-H101V.

9.2.3

Thinner is added only when the paint is fully homogeneous mixed.

Blast cleaned surfaces has been inspected for flash rusting prior to

priming or coating.

Note: Flash rusting can occur on blast cleaned surfaces if held for SAES-H-001,

C7

more than 4 hours, in less time during high humidity. Para 8.4.3

D Spray Application of Paint

Paints for immersion service (including vapor zones) are applied by SAES-H-001,

D1

airless spraying equipment. Para 9.1.1

For thick film coatings (600 to 1500 microns DFT) for immersion service,

coating is applied in a single coat "Wet-On-Wet" method to achieve the SAES-H-001 Para

D2

required film thickness. Only airless spraying equipment with higher ratio 9.5.3

pumps (45:1 or higher) shall be used.

A 360° spray gun nozzle with proper tip size shall be used to coat the SAES-H-001,

D3

interior of nozzles and traps inside tanks and vessels. Para. 9.4.4

All weld lines, edges, bolts, nuts and rivets are given brush applied stripe

coat prior to primer or first coat application. Note: When SAES-H-001,

D4

inorganic zinc is used stripe coating should be applied after the first Para. 9.3.2

coating.

Compressed air supply for conventional spray application is not

contaminated with oil, moisture or other contaminants.

SAES-H-001 Para

D5 (NOTE: This is determined by performing a blotter test at start and

6.5.1

mid- point of 8-hour shift.)

Paints to be sprayed are filtered through a 30 to 60-mesh screen prior to SAES-H-001,

D6

use. Para 9.3.7

SAES-H-101V,

Coating nozzle tip size and fluid pressure are verified to be as specified in

D7 Paint

Saudi Aramco Paint Data sheets SAES-H-101V .

Data Sheets

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Nov-2017- REV. 2017.09.00 (Standards Cutoff - September 30, 2017) Rev. 2017.09.00 30-Sep-17

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

In-Process Insp. of Primer or First Coat (Liquid Coating System) SAIC-H-2028 30-Nov-17 COATING- 1402522576

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

UPGRADE FIRE WATER SYSTEM AT RASTANURA SOUTH TERMINAL BI-10-01333 SAUDI ARCHIRODON COMPANY LTD

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Paints shall be continuously agitated with a low-speed stirrer during SAES-H-001,

D8

application. Para 9.3.7

Proper spraying techniques and control of spray pattern are

demonstrated during paint application as follows:

A) Spray Gun is held perpendicular to surface at a distance that will

ensure that a wet layer of paint is deposited on the surface.

SAEP-316,

B) Trigger of the gun is released at the end of each stroke.

Para.

C) Paint is applied in a uniform layer with over lapping at the edges of the

D9 4.4.4 (J) &

spray pattern.

As Referenced

Note 1: Spray application techniques per SSPC-PA 1 Par 7.3.4

(SSPC)

Note 2: Inspectors shall identify poor technique that results in any of

the unacceptable application defects (runs, sags, drips, etc)

Note 3: Corrective action shall be accepted when applications can

be performed without defects in accordance with Data sheets.

E Brush/Roller Application

Brush/roller are used when allowed by the paint manufacturer or as SAES-H-101V,

E1

indicated in the paint manufacturer's data sheet in Item A1. Paint Data Sheet

SAES-H-001 Para

E2 The maximum brush size if used for painting is125 mm.

9.3.6

F Final Wet Coat Inspection

Wet coating shall be free of application related defects such as runs, sags, SAES-H-001,

F1

drips, dry spray or foreign matter. Para 9.3.5 b

Coating wet film thickness meets the requirement of Saudi Aramco Paint

SAES-H-101V,

F2 data sheet SAES-H-101V and as listed in Item A1.

Paint Data Sheet

(Refer to Attachment-1 for DFT requirement of Primer)

REMARKS:

ATTACHMENTS:

1. REQUIREMENTS OF SAUDI ARAMCO APPROVED PROPTECTIVE COATING SYSTEMS

REFERENCE DOCUMENTS:

1. SAES-H-001, Coating Selection and Application Requirements for Industrial Plants and Equipment (5 April 2016)

2. SAES-H-102, Safety Requirements for Coating Applications (24 October 2012)

3. SAES-H-101V, Approved Saudi Aramco Data Sheets – Paints and Coatings, ( 9 October 2012 )

4. SAEP-316, Performance Qualification of Coating Personnel (31 July 2016)

5. Steel Structures Painting Council, SSPC-PA 1, June 1996

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: HARSHAD PATIL Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

TALHA Mr. SHANMUGAM GURUSWAMY

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date: MOHAMMEDYASER KHAN Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Nov-2017- REV. 2017.09.00 (Standards Cutoff - September 30, 2017) Rev. 2017.09.00 30-Sep-17

SAUDI ARAMCO INSPECTION CHECKLIST SAIC NUMBER DATE APPROVED QR NUMBER

In-Process Insp. of Primer or First Coat (Liquid Coating System) SAIC-H-2028 30-Nov-17 COATING-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

REQUIREMENTS- SAUDI ARAMCO APPROVED PROTECTIVE COATING SYSTEMS

Specific Requirements for Coating

Application

Each

S.R. No APCS

Coating No. of Coats Coat DFT

Type/Service (Total DFT) Micrometer

#1 #2

Epoxy, Inorg Zinc Primer

Atmospheric Service 3 Coats Min Prime-65-100 Solvent Based Zinc Water Based Zinc

1 APCS-1A

(275-400) Top- 150 Max Primer - RH > 50% Primer - RH < 50%

Epoxy, Epoxy Primer Atmospheric 3 Coats Min Prime-50-100

2 APCS-1B Service (275-400) Top-150 Max

Epoxy, Zinc rich Epx Primer 3 Coats Min Prime-40-75

3 APCS-1C Atmospheric Service (250-375) Top-150 Max

Epoxy/ Polyurethene, Inorg Zinc

Prime-65-100

Primer Atmospheric Service 3 Coats Min Solvent Based Zinc Water Based Zinc

4 APCS-1D Int-100-150

(190-315) Primer - RH > 50% Primer - RH < 50%

Top-25-65

Epoxy/ Polyurethene, Epoxy Primer

Atmospheric Service Prime-50-100

3 Coats Min

5 APCS-1E Int-100-150

(175-315)

Top-25-65

Epoxy/ Polyurethene, Zinc rich

Prime-40-75

Epoxy Primer Atmospheric Service 3 Coats Min

6 APCS-1F Int-125-175

(190-315)

Top-25-65

Phenolic Epoxy Immersion Service Succeeding coats shall Coating thickness

(Self-Priming). be of contrasting within 2 m of anode

3 Coats Min

7 APCS-2A 125 each coat colors. 30% greater

(275-375)

Epoxy Coating Potable Water Succeeding coats shall Coating thickness

Immersion Service (Self-Priming). be of contrasting within 2 m of anode

3 Coats Min

8 APCS-2B 125 each coat colors. 30% greater

(275-375)

Epoxy Coating Immersion Service, Succeeding coats shall Coating thickness

up to 120°C. Prime @ be of contrasting within 2 m of anode

3 Coats Min

9 APCS-2C SAES-H-101V colors. 30% greater

(275-375)

Top-125 Max

Epoxy - Interior of Steel Aviation The total system thickness shall be applied in

Fuel Storage Tank /Piping. 2 Coats Min 2 Coats Min a minimum of two coats of contrasting colors.

10 APCS-2D

(200-250) (200-250)

Solvent Free Phenolic Epoxy Succeeding coats shall Coating thickness

General Immersion Service be of contrasting within 2 m of anode

Min 1 Coat

11 APCS-2E (Self-Priming). colors. 30% greater

(500-600)

Saudi Aramco: Company General Use

Glass Flake Polyester General The total system thickness is applied in a

Immersion Service single coat or two coats wet on wet. Use

contrasting colors if the second coat is to be

Max 2 Coat applied within the allowed re-coating

12 APCS-2F intervals. Also Stripe coat sharp corners

(600-1000)

Glass Flake Vinyl Ester Heavy-Duty Coating thickness

Immersion Service Max 2 Coat within 2 m of anode

13 APCS-2G 30% greater

(600-1000)

100% Solid, Glass Flake Epoxy Coating thickness

Immersion Service up to 105C. One Coat within 2 m of anode

14 APCS-2H 30% greater

(30-40 mils)

Ceramic/Inorganic Filled Epoxy- Coating thickness

Phenolic/Novolac Coating - One Coat within 2 m of anode

15 APCS-2I Immersion Service up to 150C 30% greater

(20-40 mils)

Coal Tar Epoxy Immersion Service Succeeding coats shall coating concrete,

and buried (steel and concrete) be of contrasting thickness-not less

Min Two Coats

16 APCS-3 300 max /Coat colors. than 720 microns

(400-600)

Aluminum - Pigmented Alkyd

Coating Prime-50/coat,

Atmospheric 3 Coats Min (min prime 75)

17 APCS-4

(115-118) Top-40

Max/coat

Heat Radiant Insulating Coating

System Total System

18 APCS-5A

300 – 500

Hot Insulating Coating System -

carbon steel and stainless steel

Depend on Design

service 500 Micron

19 APCS-5B Req & Substrate

reduces 40°F

temperature

Alkyd Enamel Coating System. Prime-50/coat,

3 Coats Min (min prime 75)

20 APCS-6

(125-200) Top-50Max/

coat

Rust Conversion Primer/Alkyd Aluminum alkyds Alkyd enamels

Topcoat System 37-75 micrometers 50-100 above

Rust Convertor above thickness of thickness of rust

one coat min rust converte convertar

(SAES-H-

21 APCS-7 3 Coats Min

101V)

Top-One or

more coat

Chlorinated Rubber Coating System

2 Coats Min Prime-50-75

22 APCS-9

(100-175) Top-50-100

Bituminous Paint Moderate

Temperature, Buried or Immersion

Service Thickness per

Buried: 750 min

coat and No. of

23 APCS-10 Immersed:

coats. @ SAES-

1150 min

H-101V

Saudi Aramco: Company General Use

High Temp System Atmospheric Solvent Based Zinc Water Based Zinc

Service 150°C-400°C (with Primer - RH > 50% Primer - RH < 50%

Inorganic Zinc Primer). Two coats Prime-25-65

24 APCS-11A

(40-105) Top-15-40

Very High Temp System

Atmospheric Service 400-540°C. Two coats Prime-15-40

25 APCS-11B

(30-80) Top-15-40

Air-Drying, single component, high Protective Coating for Pitting Corrosion and

heat external coating for bare and Stress Corrosion Cracking bare and

insulated carbon steel & austenitic System 2: Hot insulated Austenitic 300 Series Stainless

System 1:

stainless Steel Steel

Ambient Steel

Application

Application

(300-500F)

26 APCS-11C Two Coat:

Three Coat: 5-6

5-6 mils/Coat

mils/Coat

Total DFT: 10-12

Total DFT: 15-

mils

18 mils

Nonskid aggregate added into the next to last

topcoat while it is still wet. A final topcoat

Prime-50-100 shall be applied over the aggregate sealing it

Nonskid Epoxy Coating System for 3 Coats Min

27 APCS-12 Top-150

Floors and Decks (275-400)

Max/coat

Relative humidity >50% during application

and curing.

norganic Zinc Primer, Solvent- One Coat

28 APCS-17A

Based. (65-100)

Relative humidity <50% during application

and curing.

One Coat

29 APCS-17B norganic Zinc Primer, Water-Based.

(65-100)

Splash Zone Compound, Hand One Coat

30 APCS-19A

Applied Grade (2500 Min)

Splash Zone Compound, Spray One Coat

31 APCS-19B

Applied Grade (2500 Min)

Maintenance

New Construction: Coating

Glass Flake Reinforced Polyester/

Two coats @ 750 Existing

32 APCS-19C Epoxy Systems for Offshore

per coat -total of Structures: One

Structural Steel at Splash Zone.

1500 Coat @ 750 –

1000 microns

Entrapped air, entrapped sand or other

foreign matter, wrinkles, sags and dry spots

2 layers of glass in the coating shall be removed and the

cloth with a 3:1 affected area repaired.

Fiberglass Reinforced Coatings,

33 APCS-20A ratio of resin:

Hand Lay-Up.

reinforcement by

weight

Entrapped air, entrapped sand or other

Glass Flake/Chopped Fiberglass foreign matter, wrinkles, sags and dry spots

34 APCS-20B Reinforced Coatings (Spray in the coating shall be removed and the

Applied) affected area repaired.

Saudi Aramco: Company General Use

Epoxy Coating for Application onto Two coats

35 APCS-22A 200 Max /Coat

Damp Steel Surfaces (300-400)

Atmospheric

Epoxy Coating for Application onto 350-400

36 APCS-22B One Coat

Damp Steel Surfaces Splash Zn

400-575

Thickness per

High Temperature Mastic Paint for

coat and No. of Total system

37 APCS-23 Buried or Immersion Service (Self-

coats. @ SAES- 500

Priming)

H-101V

Two or more coats 150-200 Each

38 APCS-26 Epoxy Mastic Coating (Self-Priming)

(300-400) Coat

Use when added gloss color retention, and

abrasion resistance are required.

Epoxy Mastic/Polyurethane Coating Two coats Prim- 250-300

39 APCS-26T

System (290-360) Top-40-60

The total dry film Use contrasting

thickness shall be colors if the second

applied in a single coat coat is to be applied

Solvent Free Two-component Ultra or two coats (wet on within the allowed re-

One or Two wet). coating intervals.

40 APCS-27 Hybrid Epoxy Coating Immersion

(600-1000)

Service up to 150ºC.

Saudi Aramco: Company General Use

R NUMBER

OATING-

ONTRACTOR

ements for Coating

lication

#2

Water Based Zinc

Primer - RH < 50%

Water Based Zinc

Primer - RH < 50%

Coating thickness

within 2 m of anode

30% greater

Coating thickness

within 2 m of anode

30% greater

Coating thickness

within 2 m of anode

30% greater

kness shall be applied in

ats of contrasting colors.

Coating thickness

within 2 m of anode

30% greater

Saudi Aramco: Company General Use

kness is applied in a

ats wet on wet. Use

he second coat is to be

owed re-coating

coat sharp corners

coating concrete,

thickness-not less

than 720 microns

Alkyd enamels

50-100 above

thickness of rust

convertar

Saudi Aramco: Company General Use

Water Based Zinc

Primer - RH < 50%

or Pitting Corrosion and

n Cracking bare and

c 300 Series Stainless

Steel

dded into the next to last

wet. A final topcoat

the aggregate sealing it

0% during application

0% during application

pped sand or other

es, sags and dry spots

e removed and the

d.

pped sand or other

es, sags and dry spots

e removed and the

d.

Saudi Aramco: Company General Use

oss color retention, and

ance are required.

Use contrasting

colors if the second

coat is to be applied

within the allowed re-

coating intervals.

Saudi Aramco: Company General Use

You might also like

- Applicable Codes & Standards For Aramco Projects (Piping)Document107 pagesApplicable Codes & Standards For Aramco Projects (Piping)momin100% (11)

- Hydrostatic Testing ProcedureDocument7 pagesHydrostatic Testing Proceduremomin67% (3)

- Saic S 4057Document5 pagesSaic S 4057Engr IrfanNo ratings yet

- Non-Conformance Control ProcedureDocument12 pagesNon-Conformance Control Proceduremomin100% (2)

- Contact Details Modification Form Federal BankDocument16 pagesContact Details Modification Form Federal BankSidhi Kodur0% (1)

- SAIC-H-2032 Rev 7Document4 pagesSAIC-H-2032 Rev 7Satheesh Rama SamyNo ratings yet

- Saic H 1004Document4 pagesSaic H 1004NASIR SYEDNo ratings yet

- Saic-H-2027Document3 pagesSaic-H-2027momin0% (1)

- Saudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Document5 pagesSaudi Aramco Inspection Checklist: Top Coating Application (Intumescent Fireproofing Matls) 15-Nov-17Abdul HannanNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 15-Nov-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 15-Nov-17 MechAbdul HannanNo ratings yet

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocument3 pagesSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliNo ratings yet

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CDocument2 pagesSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyNo ratings yet

- Satr-H-2006 3.3Document3 pagesSatr-H-2006 3.3mominNo ratings yet

- SAIC-B-2003 Rev 2Document2 pagesSAIC-B-2003 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- SATIP-B-006-01 Fireproofing ConcreteDocument2 pagesSATIP-B-006-01 Fireproofing ConcreteprakashNo ratings yet

- Satr H 2004Document1 pageSatr H 2004ravi ajithNo ratings yet

- Saic B 1002Document3 pagesSaic B 1002jerinNo ratings yet

- SAIC-H-2010 Rev 7Document1 pageSAIC-H-2010 Rev 7Satheesh Rama SamyNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002Sajid ShaikhNo ratings yet

- Saic A 1010Document1 pageSaic A 1010Naushad AlamNo ratings yet

- Saic Q 1039Document4 pagesSaic Q 1039Basir AhmadNo ratings yet

- Saic-S-1004 Rev 7 (Final)Document2 pagesSaic-S-1004 Rev 7 (Final)ryann mananquilNo ratings yet

- SATR-W-2020 Rev 8Document4 pagesSATR-W-2020 Rev 8محمد علي النويصرNo ratings yet

- TCS-Q-113.04 (Rev 00)Document24 pagesTCS-Q-113.04 (Rev 00)Safeer TpNo ratings yet

- Saudi Aramco Inspection Checklist: Structural Steel Materials Receiving Inspection SAIC-M-1021 1-Nov-09 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Structural Steel Materials Receiving Inspection SAIC-M-1021 1-Nov-09 CivilWaleed MedhatNo ratings yet

- Satr S 4002Document1 pageSatr S 4002Noor Mohamed AzeezNo ratings yet

- 09 Samss 101Document9 pages09 Samss 101GOSP3 QC MechanicalNo ratings yet

- Saic Q 1028Document2 pagesSaic Q 1028Qays YousefNo ratings yet

- Saic A 1017Document1 pageSaic A 1017jerinNo ratings yet

- 09 Samss 071Document6 pages09 Samss 071inatt101100% (1)

- QMIS RFI RaisedDocument2 pagesQMIS RFI RaisedSulman YounasNo ratings yet

- Saudi Aramco Inspection Checklist: Surface Preparation and Formwork Inspection SAIC-Q-1053 1-Nov-09 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Surface Preparation and Formwork Inspection SAIC-Q-1053 1-Nov-09 CivilWaleed MedhatNo ratings yet

- 175 100100 PDFDocument2 pages175 100100 PDFThaksenNo ratings yet

- Incr - XXXDocument2 pagesIncr - XXXsadik coolsadyNo ratings yet

- Pages From SAES-H-001-5Document1 pagePages From SAES-H-001-5mohammed s fawab100% (1)

- Satip M 0011111Document14 pagesSatip M 0011111Afzal HussainNo ratings yet

- Satip A 104 03eeDocument10 pagesSatip A 104 03eeRijwan MohammadNo ratings yet

- SATIP-H-002-06 Coating For Submerged Services-APCS 113 ABCDocument2 pagesSATIP-H-002-06 Coating For Submerged Services-APCS 113 ABChossamalsherbinyNo ratings yet

- 09 Samss 103Document8 pages09 Samss 103azhar enggNo ratings yet

- 175 091300Document2 pages175 091300Abu Anas M.SalaheldinNo ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 MechDocument15 pagesSaudi Aramco Inspection Checklist: Inspection of Structural Alignment During Erection SAIC-M-2007 30-Apr-13 Mechpookkoya thangalNo ratings yet

- SATIP-H-002-01 Rev 7Document4 pagesSATIP-H-002-01 Rev 7Satheesh Rama SamyNo ratings yet

- SATIP-H-100-01 Rev 7Document2 pagesSATIP-H-100-01 Rev 7Satheesh Rama SamyNo ratings yet

- SATIP-T-492-01 Ver 08Document1 pageSATIP-T-492-01 Ver 08thezaidNo ratings yet

- Inspection & Testing RequirementsDocument1 pageInspection & Testing RequirementsMuhammad RizwanNo ratings yet

- Saes Q 010Document4 pagesSaes Q 010Noor Alam JanNo ratings yet

- Saudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilDocument3 pagesSaudi Aramco Inspection Checklist: Soil Sampling, Testing and Review of Test Reports SAIC-A-1001 24-Mar-16 CivilSajid ShaikhNo ratings yet

- Internal NCR Log For Satellite 30aug18Document4 pagesInternal NCR Log For Satellite 30aug18GA JonNo ratings yet

- Saic-M-1012 Rev 7 (Final)Document3 pagesSaic-M-1012 Rev 7 (Final)Satheesh Rama SamyNo ratings yet

- 1 Scope: SAEP-302Document8 pages1 Scope: SAEP-302nasirNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanMoghal AliNo ratings yet

- SATIP Q 010 01 Cement Based Non Shrink GroutingDocument2 pagesSATIP Q 010 01 Cement Based Non Shrink GroutingAhmed GamalNo ratings yet

- 09 Samss 087 PDFDocument8 pages09 Samss 087 PDFMohamed SolimanNo ratings yet

- 175 011000 PDFDocument2 pages175 011000 PDFAbu Anas M.SalaheldinNo ratings yet

- QC Notes Revised 12 PagesDocument12 pagesQC Notes Revised 12 PagesTaimoor Abbass100% (1)

- Nitomortar TC2000Document3 pagesNitomortar TC2000talatzahoorNo ratings yet

- Saudi Aramco Test ReportDocument2 pagesSaudi Aramco Test ReportMoghal AliNo ratings yet

- Saic-Q-1065 Rev 1 (Final)Document2 pagesSaic-Q-1065 Rev 1 (Final)ryann mananquilNo ratings yet

- Saic A 1005.Document5 pagesSaic A 1005.Fazal HaqNo ratings yet

- Satip S 070 01 Rev 7 (Final)Document2 pagesSatip S 070 01 Rev 7 (Final)Zuhaib Khan100% (2)

- SAIC-A-1014 - Preweld Qualification of HDPE WelderDocument1 pageSAIC-A-1014 - Preweld Qualification of HDPE WelderwalidNo ratings yet

- Liquid CoatingsDocument12 pagesLiquid CoatingsSUNIL RAJPUTNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 30-Apr-13 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 30-Apr-13 Mechpookkoya thangalNo ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 Mechkarthi51289No ratings yet

- 0001Document1 page0001mominNo ratings yet

- Part.1 Issued For Construction (Fire Protection)Document322 pagesPart.1 Issued For Construction (Fire Protection)mominNo ratings yet

- IMS ManualDocument6 pagesIMS ManualmominNo ratings yet

- Ba090211 005Document1 pageBa090211 005mominNo ratings yet

- SOP - Permit To Work SystemDocument3 pagesSOP - Permit To Work Systemmomin100% (2)

- Management Review 2020Document2 pagesManagement Review 2020mominNo ratings yet

- Project Quality Plan (JFJS-788)Document18 pagesProject Quality Plan (JFJS-788)mominNo ratings yet

- Sep Mgse CM SCM 0031 Procedure For Valve Testing and InstallationDocument6 pagesSep Mgse CM SCM 0031 Procedure For Valve Testing and InstallationmominNo ratings yet

- Magnetic Particle Testing ProcedureDocument11 pagesMagnetic Particle Testing ProceduremominNo ratings yet

- Ba090205 001Document1 pageBa090205 001mominNo ratings yet

- Alf Piping 117 009Document6 pagesAlf Piping 117 009mominNo ratings yet

- Saudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechDocument8 pagesSaudi Aramco Inspection Checklist: Review of SIS For Air Cooled Heat Exchanger SAIC-E-2004 15-Nov-17 MechmominNo ratings yet

- Mgse T Sep Sa 0029Document1 pageMgse T Sep Sa 0029mominNo ratings yet

- Saic-H-2029Document12 pagesSaic-H-2029mominNo ratings yet

- Satr-H-2006 3.3Document3 pagesSatr-H-2006 3.3mominNo ratings yet

- Saudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechDocument7 pagesSaudi Aramco Inspection Checklist: Storage Handling & Presevation of Heat Exchangers. SAIC-E-2003 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechDocument13 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Air-Cooled Heat Exchanger SAIC-E-2005 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechDocument1 pageSaudi Aramco Inspection Checklist: Nitrogen and Pearlite Application On BAHE Frame SAIC-E-2011 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Inspection Checklist: Inspect Assembly of Air-Cooled Heat Exchanger ComponentsDocument12 pagesSaudi Aramco Inspection Checklist: Inspect Assembly of Air-Cooled Heat Exchanger ComponentsmominNo ratings yet

- Saudi Aramco Inspection Checklist: Re-Instatement of Air Cooled Heat Exchanger SAIC-E-2008 15-Nov-17 MechDocument5 pagesSaudi Aramco Inspection Checklist: Re-Instatement of Air Cooled Heat Exchanger SAIC-E-2008 15-Nov-17 MechmominNo ratings yet

- SATIP-S-060-08 Rev 8 Copper Piping FinalDocument2 pagesSATIP-S-060-08 Rev 8 Copper Piping FinalmominNo ratings yet

- Saic-H-2030Document9 pagesSaic-H-2030mominNo ratings yet

- Saudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechDocument3 pagesSaudi Aramco Inspection Checklist: Internal Cleanliness Inspection of Heat Exchangers SAIC-E-2009 15-Nov-17 MechmominNo ratings yet

- Saudi Aramco Typical Inspection PlanDocument10 pagesSaudi Aramco Typical Inspection PlanmominNo ratings yet

- SATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalDocument2 pagesSATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalmominNo ratings yet

- SATIP-S-060-02 Rev 8 Electric Drinking Water Coolers FinalDocument2 pagesSATIP-S-060-02 Rev 8 Electric Drinking Water Coolers FinalmominNo ratings yet

- CH 4 Kinematic Analysis of Parallel Kinematic Manipulators - Inverse and Forward KinematicsDocument21 pagesCH 4 Kinematic Analysis of Parallel Kinematic Manipulators - Inverse and Forward KinematicsMbuso MadidaNo ratings yet

- ANNOTATED Lumbera Tax Tables Forecast 2023Document12 pagesANNOTATED Lumbera Tax Tables Forecast 2023Cassie GacottNo ratings yet

- Research Proposal On Empirical Analysis of Validity of Capital Assets Pricing ModelDocument14 pagesResearch Proposal On Empirical Analysis of Validity of Capital Assets Pricing ModelNepal Bishal ShresthaNo ratings yet

- Why CDocument9 pagesWhy CMuhammedNo ratings yet

- Anderson I. - Chess Visualization Course Book 1 Part 1Document168 pagesAnderson I. - Chess Visualization Course Book 1 Part 1Willy Martinez100% (2)

- Fire Testing of Upholstered Furniture: Standard Test Method ForDocument22 pagesFire Testing of Upholstered Furniture: Standard Test Method ForSTAFFORDNo ratings yet

- Lesson Plan in Bookkeeping For DemoDocument5 pagesLesson Plan in Bookkeeping For DemoJudy BalaseNo ratings yet

- StellarRotation Jean LouisTassoul PDFDocument273 pagesStellarRotation Jean LouisTassoul PDFMoisésNo ratings yet

- Climate Control CompressorsDocument8 pagesClimate Control CompressorsrobertNo ratings yet

- CGC Activities On Climate Change Issues: Ahsan Uddin AhmedDocument12 pagesCGC Activities On Climate Change Issues: Ahsan Uddin AhmedSuhan ChowdhuryNo ratings yet

- CB by Fin: Component Location ManualDocument13 pagesCB by Fin: Component Location ManualvinayNo ratings yet

- Tseamcet - 2021 - Last Ranks - Special - RoundDocument3 pagesTseamcet - 2021 - Last Ranks - Special - RoundmnrNo ratings yet

- Dinesh Rajput Resume ShihoriDocument2 pagesDinesh Rajput Resume Shihorinajit143nNo ratings yet

- ISYS6300 Business Process Fundamental: Week 7 The Production CycleDocument39 pagesISYS6300 Business Process Fundamental: Week 7 The Production CycleEdwar ArmandesNo ratings yet

- Car Scanner OBD2Document104 pagesCar Scanner OBD2joejondNo ratings yet

- Output LogDocument8 pagesOutput LogBlackPanterNo ratings yet

- CH 4 - The Meaning of Interest RatesDocument46 pagesCH 4 - The Meaning of Interest RatesAysha KamalNo ratings yet

- Anamnesis and HypomnesisDocument12 pagesAnamnesis and HypomnesisMartin M. MoralesNo ratings yet

- 1216.0 Required Gas Piping SizeDocument70 pages1216.0 Required Gas Piping SizeHu Hin AngNo ratings yet

- Math 10 - Q3 M10Document12 pagesMath 10 - Q3 M10Bien DivinaflorNo ratings yet

- Avishkar Poster Krishna Menon - 2023 DecemberDocument1 pageAvishkar Poster Krishna Menon - 2023 DecemberKrishna MenonNo ratings yet

- Richardson v. Greg Ward (Sheriff) Et Al (INMATE2) - Document No. 3Document3 pagesRichardson v. Greg Ward (Sheriff) Et Al (INMATE2) - Document No. 3Justia.comNo ratings yet

- SPEC-0100500 Non-Dairy CreamerDocument1 pageSPEC-0100500 Non-Dairy CreamerharnoNo ratings yet

- MPH Hbook 200221Document75 pagesMPH Hbook 200221Sykat ZamanNo ratings yet

- The Essential Guide To ReinsuranceDocument51 pagesThe Essential Guide To Reinsurancefireblastrer100% (1)

- A Complete Guide To Painting Miniatures 1Document140 pagesA Complete Guide To Painting Miniatures 1marko.greguric92No ratings yet

- Chapter-9-Soil VIIDocument8 pagesChapter-9-Soil VIIPreeti BansalNo ratings yet

- Local Media6021450079784218265Document27 pagesLocal Media6021450079784218265Winnie AriolaNo ratings yet

- Genetics Activities StudentDocument78 pagesGenetics Activities StudentupmzamoNo ratings yet