Professional Documents

Culture Documents

Inspection Report: IR No.: QETO/IR/SUD/110

Inspection Report: IR No.: QETO/IR/SUD/110

Uploaded by

sudipta dasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Report: IR No.: QETO/IR/SUD/110

Inspection Report: IR No.: QETO/IR/SUD/110

Uploaded by

sudipta dasCopyright:

Available Formats

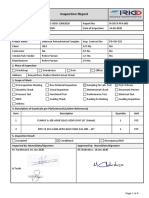

INSPECTION REPORT IR No.

: QETO/IR/SUD/110 Page 01 of 01

VENDOR Associate Manufacturing Industries Corporation DATE 11.06.2020

P.O. NO. 4531038450 Dated 09.11.2019 JOB NO.

ITEMS Hook (capacity 10t), PO Item no.10: 4nos. DRG NO. 11002.50.32.302

QAP NO. Hook_CP3_190058_001 DATASHEET NO.

CLIENT JINDAL STEEL & POWER LIMITED, RAIPUR CLIENT PO NO.

A. INSPECTION ACTIVITIES: INPROCESS / STAGE INSPECTION FINAL INSPECTION

1. Welder Qualification (WPS/PQR/WPQ)- Witness 10. Fit-up / Alignment Check 19. Performance Test 28. Painting Check (DFT)

2. Welder Qualification (WPS/PQR/WPQ)- Review 11. Dimensional Check 20. Noise Level 29. Packing

3. Raw Material Identification 12. Trial Assembly Check 21. Vibration Level 30. Loading / Dispatch

4. Lab Witness of Samples 13. Trial Run Test / Functional Check 22. Strip Test Other Activities (If Any):

5. Non Destructive Test- (NDT)- UT 14. Load Test 23. Visual / Appearance Check 31.

6. Non Destructive Test- (NDT)- RT Review 15. Hardness Test (Other than Lab Witness) 24. Surface Finish Check (Ra) 32.

7. Non Destructive Test- (NDT)- LPT 16. Temperature Rise 25. PMI Test 33.

8. Non Destructive Test- (NDT)- MPT 17. Speed of Rotation 26. Pressure Test (Hydrotest / Pneumatic) 34.

9. Weld Edge Preparation/Bevelling 18. Shaft Run Out / Deflection. 27. Surface Preparation / Blasting 35.

ACTIVITIES PERFORMED (Write down the respective activity numbers from above listed “Inspection Activities”:

B: OBSERVATIONS & DETAILS OF INSPECTION ACTIVITIES CARRIED (Including REMARKS if any):

One forged hook blank (combined forged for all 4pc hook) with integral test piece was offered for identification in heat treated condition (as confirmed by

the supplier). The surface found black forged.

The integral test piece of 100mm thickness is identified with ID mark of QETO stamped on one face (2 locations for 2nos specimen) as

Mill Test Certificate (ingot) is reviewed. The MTC of heat no.1830351 is confirming to 42CrMo4 as per DIN17200 however the drawing calls for any alloy

steel as per IS 4367. The chemistry of the heat is close to 40Cr4Mo3 of IS4367 (only %Mo found 0.18against minimum 0.20).

C: CONCLUSION:

One integral test pieces is identified for mechanical, chemical and metallurgical test. Mill test certificates of the heats reviewed. Clearance/ acceptance is

required for the material grade used from the purchaser.

Name & Sign: Name & Sign: Name & Sign:

For QETO- QUALITY SERVICES For CLIENT / CUSTOMER For VENDOR / SUPPLIER

M/s QETO Quality Services, IR Format No.: DOC-IR-01, R.01

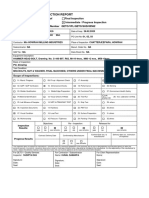

INSPECTION REPORT Page 02 of 02

Continuation Sheet for IR No.: QETO/IR/SUD/109 IR Date: 10.06.2020

B: PHOTOGRAPHS:

Forged bars identified at shop Integral Test piece stamped

C: CONCLUSION:

Two integral test pieces are identified for mechanical, chemical and metallurgical test. Mill test certificates of the heats could not be reviewed as it was

not available at the time of inspection.

Name & Sign: Name & Sign: Name & Sign:

For QETO- QUALITY SERVICES For CLIENT / CUSTOMER For VENDOR / SUPPLIER

M/s QETO Quality Services, IR Format No.: DOC-IR-01, R.01

You might also like

- Pre-Pour Concrete Checklist R00Document2 pagesPre-Pour Concrete Checklist R00Taiwo OshinNo ratings yet

- Hamley Digital InnovationDocument7 pagesHamley Digital InnovationamitNo ratings yet

- Inspection and Test Plan (ITP) WeldingDocument3 pagesInspection and Test Plan (ITP) WeldingMuhammed Abo-Fandood100% (5)

- LTHEDocument5 pagesLTHEMohit Goswami100% (1)

- Principles of Foundry TechnologyDocument7 pagesPrinciples of Foundry TechnologyJeya Vijaya Naveen Vijay54% (13)

- Inspection Report: IR No.: QETO/IR/SUD/115Document2 pagesInspection Report: IR No.: QETO/IR/SUD/115sudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/116Document1 pageInspection Report: IR No.: QETO/IR/SUD/116sudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/114Document2 pagesInspection Report: IR No.: QETO/IR/SUD/114sudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/119Document2 pagesInspection Report: IR No.: QETO/IR/SUD/119sudipta dasNo ratings yet

- Inspection Report: QETO/IR/SUD/104) and Following Are The ObservationDocument2 pagesInspection Report: QETO/IR/SUD/104) and Following Are The Observationsudipta dasNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/118Document2 pagesInspection Report: IR No.: QETO/IR/SUD/118sudipta dasNo ratings yet

- Inspection Report: Page 1 of 3 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 3 Vendor P.O. NOsudipta dasNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- IMIRDocument10 pagesIMIRvizagnucalcuttaNo ratings yet

- Transformer Test ReportDocument46 pagesTransformer Test ReportAkshay GatkalNo ratings yet

- Checklist Fire StopDocument9 pagesChecklist Fire StopAnonymous DMdGdsOENo ratings yet

- Alstom IRDocument4 pagesAlstom IRkasi reddyNo ratings yet

- SurfaceDocument3 pagesSurfacedhaninurhidayat1933No ratings yet

- Pre-Commissioning Format For Reactor: I. General DetailsDocument27 pagesPre-Commissioning Format For Reactor: I. General Detailsmayur dhandeNo ratings yet

- MRIR FOrmDocument1 pageMRIR FOrmssNo ratings yet

- Ir 5073 Ppa 005Document6 pagesIr 5073 Ppa 005ValiNo ratings yet

- Joint Inspection Report MechanicalDocument8 pagesJoint Inspection Report MechanicalRohan SharmaNo ratings yet

- International LTD: Report of Thorough ExaminationDocument1 pageInternational LTD: Report of Thorough ExaminationChisom IkengwuNo ratings yet

- Irn 20.09.2019 Fl-Smidth VoltampDocument2 pagesIrn 20.09.2019 Fl-Smidth VoltampHARI PRASATHNo ratings yet

- NO.: D-2-01-03-01-04: Testing Kit Details Test Perfo Rmed Make Rating / Measu Ring Range Date of Last CalibrationDocument39 pagesNO.: D-2-01-03-01-04: Testing Kit Details Test Perfo Rmed Make Rating / Measu Ring Range Date of Last Calibrationmayur dhandeNo ratings yet

- Procurement Services: Industry & Facilities DivisionDocument6 pagesProcurement Services: Industry & Facilities DivisionVikas Mani TripathiNo ratings yet

- Duqm Refinery Project EPC Package OneDocument22 pagesDuqm Refinery Project EPC Package OnePrashant KumarNo ratings yet

- MDR PT Waduk Tirta Asih 2022.10.26Document264 pagesMDR PT Waduk Tirta Asih 2022.10.26Roxane AlibiNo ratings yet

- 700 QA FRM 0002 in Inspection Notification 042Document1 page700 QA FRM 0002 in Inspection Notification 042sanjeevpatil97No ratings yet

- Ir562 Hmi 28.02.23Document2 pagesIr562 Hmi 28.02.23Pinki Mitra DasNo ratings yet

- DPT of PropellerDocument3 pagesDPT of Propellersushanto.mtbdNo ratings yet

- Fm-dt-58 Spreader Beam Lifting Beam ChecklistDocument2 pagesFm-dt-58 Spreader Beam Lifting Beam ChecklistAkhil100% (1)

- F-02 (Magnetic Particle Test) - (NEW) ..Latest 006Document42 pagesF-02 (Magnetic Particle Test) - (NEW) ..Latest 006Himanshu SinghNo ratings yet

- Inspection Report: 150 MW Dhamangaon Solar Project, MaharashtraDocument6 pagesInspection Report: 150 MW Dhamangaon Solar Project, Maharashtrakaushik21185No ratings yet

- Indian Oil Corporation Limited: ASTM/IP/IS1448)Document3 pagesIndian Oil Corporation Limited: ASTM/IP/IS1448)Arvind DhakaNo ratings yet

- Inspection Report: F-084/09 R-VM23-0012-LV-052 Rev.00Document5 pagesInspection Report: F-084/09 R-VM23-0012-LV-052 Rev.00Navid HashemiNo ratings yet

- SA-P-011 Instrument TransformerDocument4 pagesSA-P-011 Instrument TransformerSathiya SeelanNo ratings yet

- Native Inspection - Report - CleanedDocument6 pagesNative Inspection - Report - CleanedPrathamesh OmtechNo ratings yet

- Box Up All Lighting CircuitDocument2 pagesBox Up All Lighting CircuitHafiz YunusNo ratings yet

- SARENS HEAVY CalibarationDocument2 pagesSARENS HEAVY CalibarationSusil Kumar Sahoo100% (1)

- Annexure 3 - Indicative Inspection Test PlanDocument3 pagesAnnexure 3 - Indicative Inspection Test PlanBob Kmn0% (1)

- PR RepairDocument1 pagePR Repairaxis inspection solutionsNo ratings yet

- TTR NR - VD - 20.05.2022Document41 pagesTTR NR - VD - 20.05.2022AdarshNo ratings yet

- SARENS (SLI & Anemometer Calibration)Document2 pagesSARENS (SLI & Anemometer Calibration)Susil Kumar SahooNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationKorneliusNo ratings yet

- Gpti Qicl J931 Mut 019Document3 pagesGpti Qicl J931 Mut 019uselessinstaid52No ratings yet

- Measurement of Payment (Electrical Work)Document14 pagesMeasurement of Payment (Electrical Work)Steven JosephNo ratings yet

- Inspection Test Plan For Eot CraneDocument4 pagesInspection Test Plan For Eot CraneBikash ShreshthaNo ratings yet

- Ppap Part No 1c004396Document36 pagesPpap Part No 1c004396Mandar DivekarNo ratings yet

- AB-005-2020 Dated 10.09.2020 (SKF-Prestine)Document3 pagesAB-005-2020 Dated 10.09.2020 (SKF-Prestine)AliasgarNo ratings yet

- Visit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoDocument4 pagesVisit Report: TUV Control No.: TUV SAP No: 8115236437 (Branch: Report NoVinay YadavNo ratings yet

- G2206070002 0001 Test ReportDocument12 pagesG2206070002 0001 Test Reportrakesh kumarNo ratings yet

- Failure Analysis ReportDocument14 pagesFailure Analysis ReportpramodkumarNo ratings yet

- Annexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Document15 pagesAnnexure-I For Gem Bid No:Gem/2021/B/1451378 Dated: 19-08-2021Sravan DasariNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- 100 KLPD of 2G Ethanol From Biomass at Iocl PanipatDocument7 pages100 KLPD of 2G Ethanol From Biomass at Iocl PanipatSuraj ShettyNo ratings yet

- Kolkata: Calibration: Ofcalibration: IDocument4 pagesKolkata: Calibration: Ofcalibration: IjamilNo ratings yet

- Man Rider Winch VisualDocument6 pagesMan Rider Winch VisualRanjithNo ratings yet

- Qeto - Quality Services: Ultrasonic Test ReportDocument1 pageQeto - Quality Services: Ultrasonic Test Reportsudipta dasNo ratings yet

- Revised Rate List Under The West Bengal Health Scheme, 2008 (Notification No. 796-F (MED) Dated 31-01-2011)Document110 pagesRevised Rate List Under The West Bengal Health Scheme, 2008 (Notification No. 796-F (MED) Dated 31-01-2011)sudipta dasNo ratings yet

- West Bengal Health Scheme, 2008: Engineering Institute For Junior ExecutivesDocument3 pagesWest Bengal Health Scheme, 2008: Engineering Institute For Junior Executivessudipta dasNo ratings yet

- Qeto - Quality Services: Penetrant Test ReportDocument1 pageQeto - Quality Services: Penetrant Test Reportsudipta dasNo ratings yet

- Qeto - Quality Services: Ultrasonic Test ReportDocument1 pageQeto - Quality Services: Ultrasonic Test Reportsudipta dasNo ratings yet

- Qty - 366 Nos Material - UNS F33100 / ASTM A536 65-45-12: Z002BX0D A Ecn NoDocument1 pageQty - 366 Nos Material - UNS F33100 / ASTM A536 65-45-12: Z002BX0D A Ecn Nosudipta dasNo ratings yet

- Inspection Report: Page 1 of 3 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 3 Vendor P.O. NOsudipta dasNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Total Qty - 4 Nos Material - UNS F33100 / ASTM A536 65-45-12Document1 pageTotal Qty - 4 Nos Material - UNS F33100 / ASTM A536 65-45-12sudipta dasNo ratings yet

- Ingot Crack: Presentation By: Sudipta DasDocument19 pagesIngot Crack: Presentation By: Sudipta Dassudipta dasNo ratings yet

- Bestscope 6010TR-Specs-280619-DF&BFDocument1 pageBestscope 6010TR-Specs-280619-DF&BFsudipta dasNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- 23-Dalalpukur-Axioscope Specs MAT With C-DIC & 305Document2 pages23-Dalalpukur-Axioscope Specs MAT With C-DIC & 305sudipta dasNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument3 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/118Document2 pagesInspection Report: IR No.: QETO/IR/SUD/118sudipta dasNo ratings yet

- Become A Digital Marketing ManagerDocument10 pagesBecome A Digital Marketing ManagerMr George YadiNo ratings yet

- Mata Kuliah Bisnis Internasional Chapter 15 Resume "Exporting, Importing, & Countertrade" Nama: Syamil Jihad NPM: 1906387436Document3 pagesMata Kuliah Bisnis Internasional Chapter 15 Resume "Exporting, Importing, & Countertrade" Nama: Syamil Jihad NPM: 1906387436BegeraNo ratings yet

- Sustainability PackagingDocument3 pagesSustainability Packagingdong.quan.1705No ratings yet

- Continuous Improvement - ModelDocument12 pagesContinuous Improvement - Modelmuneerpp100% (2)

- Module 5 Executive PresentationDocument15 pagesModule 5 Executive Presentationapi-621467446No ratings yet

- EM531 531 RathodH 2Document60 pagesEM531 531 RathodH 2Santosh Kumar SurineediNo ratings yet

- Competition To Enter Shoe Market in EgyptDocument4 pagesCompetition To Enter Shoe Market in Egyptrohan shethNo ratings yet

- Diehl Doreen WHU Diss 2012Document118 pagesDiehl Doreen WHU Diss 2012Archit VermaNo ratings yet

- Non-Tariff Measures, Trade Remedies, and Rules of Origin: Exercise 2Document7 pagesNon-Tariff Measures, Trade Remedies, and Rules of Origin: Exercise 2Hằng TừNo ratings yet

- TKL Te040 Test Script Inv v2.0Document32 pagesTKL Te040 Test Script Inv v2.0Enrico Chatigan100% (1)

- KPIDocument7 pagesKPIMushfika MuniaNo ratings yet

- Chapter 9 (Cleaning and Fettling of Castings), 2003Document32 pagesChapter 9 (Cleaning and Fettling of Castings), 2003Desalegn DgaNo ratings yet

- Lesson 1 BPO 1 - ELEC 1Document3 pagesLesson 1 BPO 1 - ELEC 1Angela MagtibayNo ratings yet

- CPD Unit I Notes Introduction To Product Design & Development 2022Document38 pagesCPD Unit I Notes Introduction To Product Design & Development 2022Shankar PawarNo ratings yet

- SIS Life Cycle Activities and DocumentsDocument6 pagesSIS Life Cycle Activities and DocumentsMohamed Ali BoumarafNo ratings yet

- Dabur - Social Media Centre of ExcellenceDocument8 pagesDabur - Social Media Centre of ExcellenceAshish KothariNo ratings yet

- PP CmiDocument1 pagePP CmiCagri EfilNo ratings yet

- MAT 510 Business Statistics Week 1 To 11Document7 pagesMAT 510 Business Statistics Week 1 To 11morgan mugoNo ratings yet

- Kalyan Pharma LTD.: Presented by - Group 5Document11 pagesKalyan Pharma LTD.: Presented by - Group 5Saumitra NandaNo ratings yet

- Analysis of Consumer Electronics Industry With Porter S FiveDocument11 pagesAnalysis of Consumer Electronics Industry With Porter S FiveGREAT Alikhan0% (1)

- MGT 361Document5 pagesMGT 361Debrah BetingNo ratings yet

- Analysis of Perfectly Competitive MarketDocument10 pagesAnalysis of Perfectly Competitive MarketSharif HassanNo ratings yet

- EATON - Handbook - Panelbuilder - PG 16-37Document21 pagesEATON - Handbook - Panelbuilder - PG 16-37septiyan widiantoNo ratings yet

- Six SigmaDocument9 pagesSix SigmaJitendra SutarNo ratings yet

- Dhanalakshmi College of Engineering Department of Mechanical Engineering Me 6302 Manufacturing Technology - 1 (Question Bank)Document10 pagesDhanalakshmi College of Engineering Department of Mechanical Engineering Me 6302 Manufacturing Technology - 1 (Question Bank)arulNo ratings yet

- BRC ManualDocument14 pagesBRC ManualRuel GarduqueNo ratings yet

- Training Record 2Document15 pagesTraining Record 2subhanmusadiqNo ratings yet

- Levis XBMHDocument33 pagesLevis XBMHBalabaskaran BaskaranNo ratings yet