Professional Documents

Culture Documents

Section 08630 Metal-Framed Skylight

Section 08630 Metal-Framed Skylight

Uploaded by

MØhãmmed ØwięsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 08630 Metal-Framed Skylight

Section 08630 Metal-Framed Skylight

Uploaded by

MØhãmmed ØwięsCopyright:

Available Formats

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 8 - DOORS AND WINDOWS

SECTION 08630 - METAL-FRAMED SKYLIGHT

PART 1 - GENERAL

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including Conditions of Contract and

Division 1 Specification Sections, apply to this Section.

1.2 SUMMARY

A. Coordinate work of this section with work of other sections as required to properly execute

the work and as necessary to maintain satisfactory progress of the work of other sections,

including:

B. Section includes;

1. Metal Framed Roof Skylight

2. Baked Enamel Finish

3. Glass

4. Glazing Gaskets

5. Fasteners and Accessories

6. Isolation Coating

7. Sealant

1.3 REFERENCES

A. All reference to standards, regulations and requirements of statutory bodies shall mean the

latest published editions at the time of contract. Product manufacture, testing and installation

shall comply with the following references unless otherwise stated in the specification or

otherwise approved.

1. American Architectural Manufacturers Association (AAMA):

a. AAMA 605.2: Voluntary Specification for High Performance Organic Coatings

on Architectural Extrusions and Panels

b. AAMA 1600: Voluntary Specification for Skylights

c. AAMA SDGS-1: Structural Design Guidelines for Aluminium Framed Skylight

2. American Society for Testing and Materials (ASTM):

a. ASTM E283: Test Method for Determining the Rate of Air Leakage through

Exterior Windows, Curtain Walls, and Doors under Specified Pressure

Differences across the Specimen

3. Federal Specifications (FS):

a. TT-S-230: Sealing Compound: Elastomeric Type, Single Component,

Chemically Curing (for Calking, Sealing, and Glazing in Buildings and Other

Structures)

b. TT-S-1543: Sealing Compound: Silicone Rubber Base (for Calking, Sealing,

and Glazing in Buildings and Other Structures)

1.4 REGULATORY REQUIREMENTS

A In addition to the foregoing referenced standards, the regulatory requirements that govern the

work of this Section include the governing codes dictated by Directorate of Civil Defence,

Dubai and/or other local Municipal authorities.

1.5 SUBMITTAL

A. General: Refer to Section 01330 Submittal Procedures for submittal requirements and

procedures.

08630 METAL-FRAMED SKYLIGHT Page 1/4 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 8 - DOORS AND WINDOWS

B. Shop Drawings and Product Data: Submit detailed shop drawings and manufacturer's

product data of the roof skylight, giving sizes, details of fabrication and construction, glass

data, coatings data, colour chart, method of assembly, locations and types of anchors, and

related work.

C. Samples: Submit samples of lengths of coated metal framing, in colour as selected. Colour-

coated metal surfaces require approval of the Engineer.

1.6 DESIGN AND QUALITY ASSURANCE

A. Design and Responsibility: Roof skylight shall be designed, fabricated, and installed by a

skilled and experienced supplier/installer specializing in the design, manufacture, and

installation of custom skylights.

B. Design Criteria: Comply with the hereinbefore specified Reference Standards and the

following:

1. Structural Design Requirements from local Municipal Authority

2. Live Load: 195 kg/sq.m (40 pounds per square foot)

3. Wind Loads: 146 kg/sq.m (30 pounds per square foot), (positive and negative)

4. Seismic Design: Calculations of seismic loading and design for seismic conditions

shall be in accordance with the codes laid by local Municipal authority

5. Thermal Movement: Provide for noiseless expansion and contraction that may be

caused by a temperature range of 37.7 degree Celsius (100 degrees F)

6. Weather-tight Integrity:

a. Water Penetration: None

b. Air Infiltration: Maximum of 2.8 cubic metre per second (0.06 cubic foot per

minute) when tested in accordance with ASTM E283.

7. Glass Safety Factor: 2.5

1.7 GUARANTY

A. In addition to the guaranty requirements specified in the General Conditions, roof skylight and

related flashings shall be guaranteed against leakage, defective materials, and poor work

quality of the completed work. Any such defects or leakage occurring during the period of the

guaranty shall be promptly and completely corrected, including all affected work, at no

additional cost to the Owner.

B. Said guaranty shall be in effect for a period of five years from the date of Certificate of

Substantial Completion. The guaranty shall be signed by the skylight installer and

countersigned by the Contractor, and shall be submitted to the Engineer prior to acceptance

of the skylight work.

C. In addition, submit coating system manufacturer's standard twenty (20) year warranty for the

fluoropolymer baked-enamel finish as herein specified.

PART 2 - PRODUCTS

2.1 MATERIALS

A. Skylight Type: Skylight shall be custom-designed and -fabricated, metal-framed roof skylight,

conforming to the details and dimensions indicated.

B. Baked-Enamel Finish:

1. Coating System: Exposed metal framing shall be coated and finished with a baked

fluoropolymer (PVDF) enamel coating system or PE-SDF coating system. Colour shall

be a standard colour as selected and approved by the Engineer from manufacturer's

standards.

a. Heads of exposed fasteners shall be coated to match colour of adjacent baked

enamel finish.

08630 METAL-FRAMED SKYLIGHT Page 2/4 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 8 - DOORS AND WINDOWS

2. Coating Performance: Final coating shall conform to the ASTM performance and test

requirements specified in AAMA 605.2.

C. Glass: Comply with requirements indicated.

D. Glazing Gaskets: Extruded synthetic rubber, continuous glazing gaskets, tape, or strip, as

recommended by the skylight manufacturer.

E. Fasteners and Accessories: Furnish anchors and fasteners, washers, straps, and

accessories required for a complete and finished installation. Fasteners connecting framing

members and fasteners exposed to weather shall be Type 304 or Type 316 stainless steel.

Interior fasteners shall be stainless steel with heads coated to match baked-enamel finish.

Fasteners shall have rubber gaskets or washers under heads, nuts, and metal washers.

F. Isolation Coating: Framing members to be in contact with concrete, wood, plaster, or

dissimilar metals shall be painted with a heavy coat of alkali-resistant bituminous paint.

G. Sealant: Silicone synthetic rubber elastomeric sealant that cures at normal temperature to a

flexible firm rubber, tack free, and designed for adhesion to the surfaces to which it will be

applied. Sealant shall meet or exceed the minimum requirements of Fed. Spec. TT-S-230 or

Fed. Spec. TT-S-1543, as applicable.

2.2 FABRICATION

A. Roof skylight shall be custom designed and fabricated to suit building conditions and roof

opening, of sizes and configurations indicated.

B. Sizes and design characteristics of the framing members shall be as required by opening

spans to carry a minimum live load of 195kg/sq.m (40 pounds per square foot) with a

maximum fibre stress of 914 kg/sq.cm(13,000 pounds per square inch) and maximum

deflection of 1/240 at centre of span and as specified in Article 1.04.C.

C. Metal framing shall be prefabricated and preassembled in the factory or shop as far as

practicable. Welding shall be performed in the shop by qualified welders. Welds exposed to

view shall be ground and dressed smooth.

D. Provide for expansion and contraction in the fabrication and assembly of metal framing.

E. Provide for drainage of condensation to the exterior. Curbs shall be provided with

condensation weep holes.

F. Glass shall be continuously supported on glazing gaskets or tape at all bearing surfaces, top

and bottom. Gaskets or tape shall be compressed a minimum of 15 percent all around to

form a tight seal. There shall be no glass surfaces bearing on metal. Gaskets and sealing

tape shall be continuous and shall seal glass and metal watertight. Provide for 16mm (5/8-

inch) minimum grip of glass and for expansion and contraction of glass.

PART 3 - EXECUTION

3.1 INSTALLATION

A. Skylight shall be installed and glazed by the manufacturer or its authorized representative as

indicated and in accordance with the approved shop drawings and the manufacturer's

installation instructions and recommendations, using only workers skilled and experienced in

this type of work.

B. Ample provisions shall be made in flashings and assemblies for expansion and contraction.

Skylight shall be watertight after installation and completion of the work.

C. Skylight assembly shall be set on curb in continuous bead of sealant. Skylight assembly and

flashings shall be calked and sealed with sealant as required for a watertight installation.

08630 METAL-FRAMED SKYLIGHT Page 3/4 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 8 - DOORS AND WINDOWS

Calking and sealing work shall conform to applicable requirements of Section 07920 Joint

Sealants.

3.2 TESTS

A. Skylight installation shall be watertight, and water jet tests to prove this shall be conducted by

the Contractor, under the observation of the Engineer. Water jet tests shall be performed in

conjunction with roofing water tests. Tests shall be performed before work is started on

interior finishes.

END OF SECTION 08630

08630 METAL-FRAMED SKYLIGHT Page 4/4 Rev.1 - 02 Aug 2015

You might also like

- 08 4400 - Curtain Wall and Glazed Assemblies - FinalDocument50 pages08 4400 - Curtain Wall and Glazed Assemblies - FinalAbdullah NajjarNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- 3 Part Spec Sliding Over Roof SkylightDocument5 pages3 Part Spec Sliding Over Roof Skylightmahmoud morsyNo ratings yet

- ACP SpecsDocument8 pagesACP SpecsJana jerodyNo ratings yet

- Guide Specification - SDP 200: GeneralDocument10 pagesGuide Specification - SDP 200: GeneralhbookNo ratings yet

- Aluminum FramesDocument5 pagesAluminum Frameseromax1No ratings yet

- ArcWall ACM SpecDocument6 pagesArcWall ACM SpecRam CaceresNo ratings yet

- Asm XDocument6 pagesAsm XAlijihad2001aoNo ratings yet

- Section 077100 - Roof SpecialtiesDocument6 pagesSection 077100 - Roof SpecialtiesWENDING HUNo ratings yet

- M - Series Specification 02 - 2018Document5 pagesM - Series Specification 02 - 2018Ahsan KhanNo ratings yet

- SpecDocument9 pagesSpecمعاذ محمدNo ratings yet

- Joint Sealants - MSTDocument9 pagesJoint Sealants - MSTwafikmh4No ratings yet

- Standing Seam Metal Roof Panels Fabral Stand N Seam 2Document9 pagesStanding Seam Metal Roof Panels Fabral Stand N Seam 2TomNo ratings yet

- Section 09220 Portland Cement PlasterDocument9 pagesSection 09220 Portland Cement PlasterMØhãmmed ØwięsNo ratings yet

- 08 63 00 PDFDocument11 pages08 63 00 PDFAnonymous hk1fhAkwyNo ratings yet

- SF - Glass-Fiber-Reinforced Concrete (GFRC)Document6 pagesSF - Glass-Fiber-Reinforced Concrete (GFRC)SunilNo ratings yet

- GFRCDocument11 pagesGFRCMhmd AbdoNo ratings yet

- 04 3023 01Document5 pages04 3023 01U MariappanNo ratings yet

- Section 07 42 13 - Corrugated Metal Façade Panels Part 1 - General 1.01 Related DocumentsDocument8 pagesSection 07 42 13 - Corrugated Metal Façade Panels Part 1 - General 1.01 Related DocumentsSharlette SaulNo ratings yet

- Tieback Anchors - 1.24.11Document7 pagesTieback Anchors - 1.24.11xcvNo ratings yet

- 09 28 13 Cement Board CeilingsDocument6 pages09 28 13 Cement Board CeilingsWagih NabihNo ratings yet

- Product Guide Specification: Masterformat 2004 Edition in Parentheses. Delete Version Not RequiredDocument10 pagesProduct Guide Specification: Masterformat 2004 Edition in Parentheses. Delete Version Not RequiredmanishNo ratings yet

- Mw07620-Sheet Metal Flashing and TrimDocument8 pagesMw07620-Sheet Metal Flashing and TrimBanner BruceNo ratings yet

- Section 10200 Louvers and VentsDocument3 pagesSection 10200 Louvers and VentsMØhãmmed ØwięsNo ratings yet

- Section 09514Document7 pagesSection 09514motaz alzoubiNo ratings yet

- Part 1 GeneralDocument6 pagesPart 1 GeneralCamilo Eduardo Celis MeloNo ratings yet

- PlasterDocument12 pagesPlasterAhmed GhariebNo ratings yet

- FL - Aluminum Doors and WindowsDocument9 pagesFL - Aluminum Doors and WindowsAmro Ahmad AliNo ratings yet

- SECTION 03490 Glass Fiber Reinforced Concrete (GFRC)Document17 pagesSECTION 03490 Glass Fiber Reinforced Concrete (GFRC)SunilNo ratings yet

- Glazed Aluminum Curtain WallsDocument22 pagesGlazed Aluminum Curtain Wallsnvdinh511No ratings yet

- Section 09260 Gypsum Board AssembliesDocument10 pagesSection 09260 Gypsum Board AssembliesMØhãmmed ØwięsNo ratings yet

- W2700 Window Wall Specification FinalDocument11 pagesW2700 Window Wall Specification FinalSharlette SaulNo ratings yet

- 0421 IMP Guide Specification Foam Roof Panel IBC 2018Document8 pages0421 IMP Guide Specification Foam Roof Panel IBC 2018thomsonNo ratings yet

- Flexospan 07 42 13fleDocument23 pagesFlexospan 07 42 13fleAashish MuraliNo ratings yet

- Metal Duct WorkDocument9 pagesMetal Duct WorkSyed Waqas HussainNo ratings yet

- 2500 SpecificationDocument5 pages2500 SpecificationMelissa ArandaNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 09250-1 Gypsum BoardDocument5 pagesITCC in Riyadh Residential Complex J10-13300 09250-1 Gypsum BoarduddinnadeemNo ratings yet

- Section 07950 Expansion ControlDocument5 pagesSection 07950 Expansion ControlMØhãmmed ØwięsNo ratings yet

- 09 51 00 - Suspended Ceiling PDFDocument6 pages09 51 00 - Suspended Ceiling PDFmasoodaeNo ratings yet

- Plastic SkylightsDocument5 pagesPlastic Skylightsmohamed fathiNo ratings yet

- Uniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionDocument10 pagesUniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionTaher AmmarNo ratings yet

- 04 3020 00Document4 pages04 3020 00Phạm Khắc HảiNo ratings yet

- P.O. Number: 7200018725Document6 pagesP.O. Number: 7200018725sethu1091No ratings yet

- Metal Framed SkylightsDocument13 pagesMetal Framed SkylightsLloyd R. PonceNo ratings yet

- Asphalt Shingles - MSTDocument13 pagesAsphalt Shingles - MSTwafikmh4No ratings yet

- 800 Spec 877 Rev 9 DocDocument3 pages800 Spec 877 Rev 9 DockhuNo ratings yet

- Aluminum Composite Pannel LimitsDocument7 pagesAluminum Composite Pannel LimitsRex SirilanNo ratings yet

- Section 07 4000 - Metal Panel SystemDocument20 pagesSection 07 4000 - Metal Panel SystemMuhammad AbuBakarNo ratings yet

- CEMENT PLASTER SPECS H Proc Notices Notices 030 K Notice Doc 28847 860093827Document17 pagesCEMENT PLASTER SPECS H Proc Notices Notices 030 K Notice Doc 28847 860093827Carlos VelardeNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 05810-1 Expansion Joint Cover AssembliesDocument5 pagesITCC in Riyadh Residential Complex J10-13300 05810-1 Expansion Joint Cover AssembliesuddinnadeemNo ratings yet

- TerracottaDocument11 pagesTerracottaDiaszNo ratings yet

- Tensile Membrane Structures: Name of Project Page - of - July 9, 2013Document18 pagesTensile Membrane Structures: Name of Project Page - of - July 9, 2013jackNo ratings yet

- Spec DoorDocument6 pagesSpec DoorvomquyNo ratings yet

- Trellis SpecDocument3 pagesTrellis Spectroyel99No ratings yet

- OpeningsDocument159 pagesOpeningssadoonNo ratings yet

- SECTION 09 23 00 Gypsum PlasteringDocument12 pagesSECTION 09 23 00 Gypsum PlasteringRima Baz FadousNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 09515 - 1 Cement Board CeilingDocument5 pagesITCC in Riyadh Residential Complex J10-13300 09515 - 1 Cement Board CeilinguddinnadeemNo ratings yet

- ACS Specs GFRC1Document10 pagesACS Specs GFRC1Chrill DsilvaNo ratings yet

- Matrix Series Metal Wall PanelsDocument10 pagesMatrix Series Metal Wall PanelsBrendan PrattNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Section 12500 FurnitureDocument5 pagesSection 12500 FurnitureMØhãmmed ØwięsNo ratings yet

- St-104 - Overall Ground Floor PlanDocument1 pageSt-104 - Overall Ground Floor PlanMØhãmmed ØwięsNo ratings yet

- ST 1100 Excavation Layout Plan Layout1Document1 pageST 1100 Excavation Layout Plan Layout1MØhãmmed ØwięsNo ratings yet

- St-006 - Block Wall Restraint Details and Lintel Schedule Sheet-1Document1 pageSt-006 - Block Wall Restraint Details and Lintel Schedule Sheet-1MØhãmmed ØwięsNo ratings yet

- St-03 - General Notes Sheet-2Document1 pageSt-03 - General Notes Sheet-2MØhãmmed ØwięsNo ratings yet

- Section 12494 Roller ShadesDocument5 pagesSection 12494 Roller ShadesMØhãmmed ØwięsNo ratings yet

- Section 09960 Protective CoatingsDocument17 pagesSection 09960 Protective CoatingsMØhãmmed ØwięsNo ratings yet

- Section 09910 PaintingDocument13 pagesSection 09910 PaintingMØhãmmed ØwięsNo ratings yet

- Section 12800 Interior Plants and PlantersDocument10 pagesSection 12800 Interior Plants and PlantersMØhãmmed ØwięsNo ratings yet

- Division 12 Furnishing - Table of ContentsDocument1 pageDivision 12 Furnishing - Table of ContentsMØhãmmed ØwięsNo ratings yet

- Section 12090 UpholsteryDocument4 pagesSection 12090 UpholsteryMØhãmmed ØwięsNo ratings yet

- Section 09680 CarpetDocument7 pagesSection 09680 CarpetMØhãmmed ØwięsNo ratings yet

- Section 12430 Decorative LampsDocument3 pagesSection 12430 Decorative LampsMØhãmmed ØwięsNo ratings yet

- Section 10520 Fire Protection SpecialitiesDocument7 pagesSection 10520 Fire Protection SpecialitiesMØhãmmed ØwięsNo ratings yet

- Section 09260 Gypsum Board AssembliesDocument10 pagesSection 09260 Gypsum Board AssembliesMØhãmmed ØwięsNo ratings yet

- Section 10200 Louvers and VentsDocument3 pagesSection 10200 Louvers and VentsMØhãmmed ØwięsNo ratings yet

- Section 09720 Wall CoveringsDocument4 pagesSection 09720 Wall CoveringsMØhãmmed ØwięsNo ratings yet

- Section 09300 TilesDocument11 pagesSection 09300 TilesMØhãmmed Øwięs100% (1)

- Section 09220 Portland Cement PlasterDocument9 pagesSection 09220 Portland Cement PlasterMØhãmmed ØwięsNo ratings yet

- Section 09380 Dimension Stone TilesDocument9 pagesSection 09380 Dimension Stone TilesMØhãmmed ØwięsNo ratings yet

- Section 08800 GlazingDocument17 pagesSection 08800 GlazingMØhãmmed ØwięsNo ratings yet

- Section 08113 Custom Steel Door FramesDocument6 pagesSection 08113 Custom Steel Door FramesMØhãmmed ØwięsNo ratings yet

- Section 08710 Door HardwareDocument22 pagesSection 08710 Door HardwareMØhãmmed ØwięsNo ratings yet

- Section 07810 Applied FireproofingDocument4 pagesSection 07810 Applied FireproofingMØhãmmed ØwięsNo ratings yet

- Section 07141 Cold Fluid Applied WaterproofingDocument6 pagesSection 07141 Cold Fluid Applied WaterproofingMØhãmmed ØwięsNo ratings yet

- Section 07210 Building InsulationDocument7 pagesSection 07210 Building InsulationMØhãmmed ØwięsNo ratings yet

- Section 08100 Metal Doors and FramesDocument4 pagesSection 08100 Metal Doors and FramesMØhãmmed ØwięsNo ratings yet

- Managerial Economics - Economic Planning and Development ModelsDocument13 pagesManagerial Economics - Economic Planning and Development ModelsDr Linda Mary Simon100% (1)

- BBPS PresentationDocument11 pagesBBPS PresentationRajkot academyNo ratings yet

- Chap 001Document41 pagesChap 001ms_cherriesNo ratings yet

- Drew 1997Document15 pagesDrew 1997Supriya.G. JakatiNo ratings yet

- Nxivm Doc 475: Lauren Salzman Pleads GuiltyDocument2 pagesNxivm Doc 475: Lauren Salzman Pleads GuiltyTony OrtegaNo ratings yet

- Japanese Milk Bread Recipe - NYT CookingDocument3 pagesJapanese Milk Bread Recipe - NYT CookingAravind ShadyNo ratings yet

- Stepping Off The Karmic WheelDocument3 pagesStepping Off The Karmic WheelticutzaNo ratings yet

- 2 - Parathyroid GlandDocument21 pages2 - Parathyroid Glandtaha55860No ratings yet

- Ecaade2012 Vol 1 LowresDocument770 pagesEcaade2012 Vol 1 Lowreslmn_grssNo ratings yet

- Film ProductionDocument13 pagesFilm ProductionHannah JonesNo ratings yet

- Schneider Electric - R&D Job Description - 2023 BatchDocument9 pagesSchneider Electric - R&D Job Description - 2023 BatchSushiNo ratings yet

- QuizDocument3 pagesQuizYousaf SaleemNo ratings yet

- Tutorial of WRC 107 For Lifting LugsDocument20 pagesTutorial of WRC 107 For Lifting LugsPeterWayNo ratings yet

- Name: Bitrus Atang Reg No: AKP/ENG/EET/HND 2008/019 Course: Digital Communication IIIDocument9 pagesName: Bitrus Atang Reg No: AKP/ENG/EET/HND 2008/019 Course: Digital Communication IIIPatrick AfefohNo ratings yet

- ITP For Access Control SystemTesting and CommissioningDocument1 pageITP For Access Control SystemTesting and CommissioningTamer Eid0% (1)

- Fluiten Plan APIDocument71 pagesFluiten Plan APImontsegran100% (1)

- Answers For Power & DistributionDocument60 pagesAnswers For Power & DistributionkuchowNo ratings yet

- BALANCE ENE, Nov Cash Flow DI ANTESDocument41 pagesBALANCE ENE, Nov Cash Flow DI ANTESMaría ElisaNo ratings yet

- SPPU Question Paper II On Marketing-Strategy-Pattern-2019Document2 pagesSPPU Question Paper II On Marketing-Strategy-Pattern-2019Sandeep ChaudharyNo ratings yet

- Cat World October 2018Document84 pagesCat World October 2018Friedrich NietzscheNo ratings yet

- Spanish Versification 2015Document4 pagesSpanish Versification 2015Sam PurnellNo ratings yet

- DC 09Document44 pagesDC 09Avaa AmgaaNo ratings yet

- CLASS PROGRAM 5 Michael Dos Tres 2022 23Document1 pageCLASS PROGRAM 5 Michael Dos Tres 2022 23Sassa IndominationNo ratings yet

- Solar Power Manager Series (EN)Document1 pageSolar Power Manager Series (EN)fukaboriNo ratings yet

- Yu Gi Oh SoloDocument4 pagesYu Gi Oh SoloEDURGNo ratings yet

- Ag Policy KenyaDocument41 pagesAg Policy KenyaGladys WambuiNo ratings yet

- Criminal Procedure - Case DigestDocument1 pageCriminal Procedure - Case DigestLykah HonraNo ratings yet

- Sales Letter: Submitted by Femina FredyDocument19 pagesSales Letter: Submitted by Femina FredyAntondeepakNo ratings yet

- Huawei GSM-R: Future Proof, Flexible and Reliable: Norman FRISCHDocument18 pagesHuawei GSM-R: Future Proof, Flexible and Reliable: Norman FRISCHCharles SedilloNo ratings yet

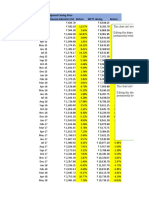

- Britannia Industries Historical Closing Price Data-FinalDocument48 pagesBritannia Industries Historical Closing Price Data-FinalSourabh ChiprikarNo ratings yet