07 02 PQR

07 02 PQR

Uploaded by

Mo ZeroCopyright:

Available Formats

07 02 PQR

07 02 PQR

Uploaded by

Mo ZeroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

07 02 PQR

07 02 PQR

Uploaded by

Mo ZeroCopyright:

Available Formats

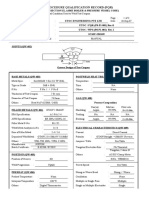

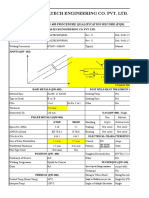

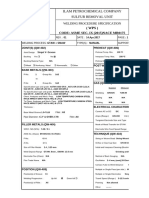

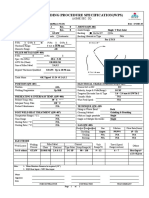

WELDING PROCEDURE QUALIFICATION RECORD (PQR)

OneBase

According To ASME Code SectionVIII Div.1 and IX-ED:2015

Sheet 1 of 2

PQR NO.: 001 WPS NO.: WA-WPS-001 Rev 0 Process : Date

JOINT DESIGN (QW-402)

Joint Design

Backing Material (Type)

BASE METAL (QW-403) 75 ± 5

P NO. : 1 GROUP NO. : 1 To P NO. 1 GROUP NO. 1

Specification Type & Grade

Thickness

Maximum Pass thickness t

11.07 mm

Diameter 5 6

4

2mm

FILLER METAL (QW-404) 3

2

Process GTAW SMAW 1

SFA NO.

AWS Classification

F No 3-5mm

A No

Size of Filler Metals

Filler Metal product form

Max. Deposited weld Metal

Other :

POSITION (QW-405) : PREHEAT (QW-406)

Positions of Groove: preheat Temp.

Welding Progression : Max. Interpass Temp.

Other Other

POST WELD HEAT TREATMENT (QW-407) GAS (QW-408)

Heating Rate Gas Description Mixture(%) Flow Rate Remarks

Temperature Range Shielding

Holding Time Backing

Cooling Rate Trailing

ELECTRICAL CHARACTERISTIC (QW-409)

Type of Current

Amps Range

TECHNIQUE (QW-410)

String / Weave

Orifice Cup Diameter (GTAW) Initial and Interpass Cleaning

Oscilation ( M/C or Automatic ) Method of back gouging

Peening Manual / Automatic / Machine

Multiple or Single Pass per Side Welding Champer ( GTAW )

Multiple or Single Electrode Use of thermal process

Current Voltage Heat Input

Bead No. Process AMP. Range Filler Metal Type Diam.(mm) Remarks

Type Polarity Range J/mm

WA Q. C. Manual Exhibit No. (07-02) Rev.: 0 Date: 17/09/2023

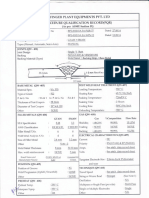

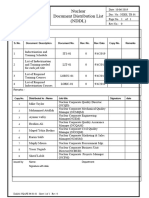

PROCEDURE QUALIFICATION RECORD (PQR)

According To ASME Code SectionVIII Div.1 and IX-ED:2015

Sheet 2 of 2

PQR NO.: 001 WPS NO./Rev. Energya-WPS-001 Rev. 0 Process : GTAW/SMAW Date : 10/06/2016

Qualification Test's Results (1) (2)

TENSILE TESTS

Ultimate Total Load Ultimate Strength Type of Failure &

Specimen No. Width Thickness Area Remarks

(KN) (Mpa) location

GUIDED BEND TESTS

Specimen No. TYPE Result Remarks

TOUGHNESS TEST

Notch Type

Notch Specimen Impact Values Lateral Expantion

Specimen No. Test Temp. Drop wieght Break

Location Size Absorbed Energy ( J ) % Shear Distance (mm)

HARDNESS TEST

Hardness Value ( HV )

Indentation No. Location Remarks

I II III IV V VI Average

OTHER TESTS

Test Result: Report No. Performed By Remarks

Notes

1) Mechanical Tests conducted in : El-Nasr Steel pipes & Fittings Co.

2) Welder name : Taha Ahmed Taha Welder No. : W001

WE CERTIFY THAT THE STATEMENTS IN THIS RECORD ARE CORRECT AND THAT THE TEST WELDS WERE PREPARED, WELDED

AND TESTED IN ACCORDANCE WITH THE REQUIREMENTS OF ASME IX Ed. 2015

Prepared By Reviewed By Reviewed By

Name : Name : Name

Title : Title : Title

Signature Signature Signature

Date Date Date

HICC Q. C. Manual Exhibit No. (07-02) Rev.: 0 Date:01/05/2016

You might also like

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Saes A 134Document13 pagesSaes A 134Mohamed Soliman100% (1)

- Catalogo FMC - Link Belt - Belt Conveyors IdlersDocument124 pagesCatalogo FMC - Link Belt - Belt Conveyors IdlersErich Thomas100% (1)

- PQR Editable SampleDocument2 pagesPQR Editable SampleKoya ThangalNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- Assassin's Creed III Crafting GuideDocument7 pagesAssassin's Creed III Crafting GuideHasbiallah YusufNo ratings yet

- U.G WPS 006Document5 pagesU.G WPS 006arefpiriNo ratings yet

- QW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Document3 pagesQW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Alesol EquipmentNo ratings yet

- WPS 07 SDDocument2 pagesWPS 07 SDPravesh TiwariNo ratings yet

- Final PQRDocument130 pagesFinal PQRAhamed Naufal CaNo ratings yet

- WpsDocument3 pagesWpsPankaj KumarNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- U.G WPS 005Document8 pagesU.G WPS 005arefpiriNo ratings yet

- WPS & PQR - LTM - QW - PipeDocument7 pagesWPS & PQR - LTM - QW - PipeKAMALNo ratings yet

- Metals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Document6 pagesMetals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Luis MuñozNo ratings yet

- P1 to P1 GTAW 5265 (1)Document7 pagesP1 to P1 GTAW 5265 (1)iswarkumarsahoo894No ratings yet

- PQR A106 HAL-1Document1 pagePQR A106 HAL-1Budi Setia RahmanNo ratings yet

- GMCo - WPSDocument8 pagesGMCo - WPSMohamed AtefNo ratings yet

- Procedure Qualification RecordDocument6 pagesProcedure Qualification RecordGaurang PandyaNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Tips Wps FormatDocument5 pagesTips Wps FormatWaqas WaqasNo ratings yet

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 pagesIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- PQR 03 2014Document2 pagesPQR 03 2014vinuNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- PQR 77Document14 pagesPQR 77BIIS QAQC Babu SivaNo ratings yet

- QW 483 - PQR (Gtaw+smaw) 04.01.17Document8 pagesQW 483 - PQR (Gtaw+smaw) 04.01.17Srikant GanjiNo ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Wps 18Document2 pagesWps 18Avishek GuptaNo ratings yet

- U.G WPS 007Document8 pagesU.G WPS 007arefpiriNo ratings yet

- PQR TipsDocument2 pagesPQR TipsWaqas WaqasNo ratings yet

- WPS PQR XLSXDocument4 pagesWPS PQR XLSXMd Sahabul IslamNo ratings yet

- PQWDocument3 pagesPQWcorey jacobsNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Document2 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Vaibhav GuptaNo ratings yet

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (2)

- Wps FormatDocument2 pagesWps FormatParminder SinghNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- Request For Welding Procedure ApprovalDocument18 pagesRequest For Welding Procedure Approvalecsuperal100% (1)

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDocument2 pagesWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraNo ratings yet

- Verspec WPS WPQDocument6 pagesVerspec WPS WPQgtsi.draftsmanNo ratings yet

- Form PQR 1 AsmeDocument6 pagesForm PQR 1 AsmeZam Zam NoorNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document2 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- RK PWPS PC 001Document2 pagesRK PWPS PC 001SudeepDPoojaryNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)attaullaNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- Smaw E316-16 (WPS+PQR) EditableDocument5 pagesSmaw E316-16 (WPS+PQR) Editablek v swarna deelipanNo ratings yet

- Suria Engineering: Procedure Qualification Record (PQR)Document2 pagesSuria Engineering: Procedure Qualification Record (PQR)suria qaqcNo ratings yet

- WPS&PQR FormsDocument4 pagesWPS&PQR FormsArab WeldersNo ratings yet

- WPS-ASME-007-1 Rev0Document1 pageWPS-ASME-007-1 Rev0Ahmed LepdaNo ratings yet

- Request For Welding Procedure ApprovalDocument13 pagesRequest For Welding Procedure ApprovalecsuperalNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- 05-04 MarkingName Plate For U' StampDocument2 pages05-04 MarkingName Plate For U' StampMo ZeroNo ratings yet

- NQAP-16.01 Corrective Action ProcedureDocument7 pagesNQAP-16.01 Corrective Action ProcedureMo ZeroNo ratings yet

- Exhibit NQAME 06.01.01nuclear Document Distribution List TR01Document1 pageExhibit NQAME 06.01.01nuclear Document Distribution List TR01Mo ZeroNo ratings yet

- APQ-01 Audit PlanDocument1 pageAPQ-01 Audit PlanMo ZeroNo ratings yet

- Acl Apq 01Document2 pagesAcl Apq 01Mo ZeroNo ratings yet

- QA-02 Audit ReportDocument2 pagesQA-02 Audit ReportMo ZeroNo ratings yet

- 11 V 04abDocument5 pages11 V 04abMo ZeroNo ratings yet

- 20 V 08Document5 pages20 V 08Mo ZeroNo ratings yet

- 09-Sec 4 - Material ControlDocument6 pages09-Sec 4 - Material ControlMo ZeroNo ratings yet

- DC-01 Audit ReportDocument2 pagesDC-01 Audit ReportMo ZeroNo ratings yet

- 11-Sec 6 - NCRDocument2 pages11-Sec 6 - NCRMo ZeroNo ratings yet

- TR-01 Audit ReportDocument2 pagesTR-01 Audit ReportMo ZeroNo ratings yet

- 11 V 01Document5 pages11 V 01Mo ZeroNo ratings yet

- Data Sheet: EnpplDocument2 pagesData Sheet: EnpplMo ZeroNo ratings yet

- 10 V 05Document5 pages10 V 05Mo ZeroNo ratings yet

- 14 V 02Document5 pages14 V 02Mo ZeroNo ratings yet

- 16-Sec 11 - Authorized InspectorDocument1 page16-Sec 11 - Authorized InspectorMo ZeroNo ratings yet

- Data Sheet: EnpplDocument2 pagesData Sheet: EnpplMo ZeroNo ratings yet

- RealDocument4 pagesRealMo ZeroNo ratings yet

- Data Sheet: EnpplDocument2 pagesData Sheet: EnpplMo ZeroNo ratings yet

- Data Sheet: EnpplDocument2 pagesData Sheet: EnpplMo ZeroNo ratings yet

- 10 V 04Document5 pages10 V 04Mo ZeroNo ratings yet

- Data Sheet: EnpplDocument2 pagesData Sheet: EnpplMo ZeroNo ratings yet

- Data Sheet: EnpplDocument2 pagesData Sheet: EnpplMo ZeroNo ratings yet

- Hyster-H5 0FTDocument16 pagesHyster-H5 0FTMo ZeroNo ratings yet

- Modulate Action Datasheet Leser Type 431 433 327071Document20 pagesModulate Action Datasheet Leser Type 431 433 327071Mo ZeroNo ratings yet

- Relief 5Document5 pagesRelief 5Mo ZeroNo ratings yet

- Asme BPVC - Ii.a-2021 Sa-350/sa-350mDocument1 pageAsme BPVC - Ii.a-2021 Sa-350/sa-350mMo ZeroNo ratings yet

- Global GPDocument2 pagesGlobal GPMo ZeroNo ratings yet

- UCS-67 Impact Tests of Welding Procedures: ASME BPVC - VIII.1-2021 UCS-66 - UCS-67Document1 pageUCS-67 Impact Tests of Welding Procedures: ASME BPVC - VIII.1-2021 UCS-66 - UCS-67Mo ZeroNo ratings yet

- Cables and Wires CatalogueDocument16 pagesCables and Wires CatalogueVENITHA K100% (1)

- Australian Critical Minerals ProspectusDocument68 pagesAustralian Critical Minerals ProspectusBill LiNo ratings yet

- AWS A5.15-90 Cast Iron Welding ElectrodesDocument30 pagesAWS A5.15-90 Cast Iron Welding ElectrodesElias Jagiello50% (2)

- Hints and Tips For Plastic ModelingDocument52 pagesHints and Tips For Plastic ModelingDan100% (2)

- Prospekt 95R EnglischDocument2 pagesProspekt 95R EnglischAbdoOmarNo ratings yet

- BCT 604 Task 1 Sharifah Nur Atiqah (2020963365) Ap256 5aDocument11 pagesBCT 604 Task 1 Sharifah Nur Atiqah (2020963365) Ap256 5asharifah atiqahNo ratings yet

- Cutting Aws C5.3 2000 R2011Document33 pagesCutting Aws C5.3 2000 R2011Serkan AkşanlıNo ratings yet

- Pinacle Welder - ManualDocument24 pagesPinacle Welder - ManualnoreenNo ratings yet

- Iso 2341-1986Document8 pagesIso 2341-1986Azadeh AliabadiNo ratings yet

- Final year report on BAMBOO SLICING MACHINE444(1)Document48 pagesFinal year report on BAMBOO SLICING MACHINE444(1)Sudip AcharyaNo ratings yet

- Chemical MachiningDocument26 pagesChemical MachiningKAMALJEET SINGHNo ratings yet

- Non Traditional MachiningDocument33 pagesNon Traditional MachiningCaleb QuaynorNo ratings yet

- 20 Green Sand Casting Defects and Their Suggested RemediesDocument4 pages20 Green Sand Casting Defects and Their Suggested RemediesPatil Amol PandurangNo ratings yet

- WMP Lab Manual-2023 Aiml-ADocument78 pagesWMP Lab Manual-2023 Aiml-ASentinel PlaysNo ratings yet

- SUNTUF 8000 5000 Spandek Industrial Installation GuideDocument3 pagesSUNTUF 8000 5000 Spandek Industrial Installation GuideRaja RajanNo ratings yet

- Iron and Steel January 2018 PDFDocument2 pagesIron and Steel January 2018 PDFMarc Benedict TalamayanNo ratings yet

- You Will Learn: Cast Iron Structure and Properties of White Cast IronDocument13 pagesYou Will Learn: Cast Iron Structure and Properties of White Cast IronamitNo ratings yet

- Engine Stand PlansDocument23 pagesEngine Stand PlansJoey WilletNo ratings yet

- High Frequency Packaging and RFdevicesDocument25 pagesHigh Frequency Packaging and RFdevicespoubellebox01No ratings yet

- CSWIP 3 2 Senior Welding Inspector WIS10Document418 pagesCSWIP 3 2 Senior Welding Inspector WIS10Mohammed Shamil100% (3)

- 066 069 PDFDocument4 pages066 069 PDFAnonymous UoHUagNo ratings yet

- Procedures and Guidelines For Coa Exemption Condition Procedures RemarksDocument4 pagesProcedures and Guidelines For Coa Exemption Condition Procedures RemarksHawa AzizNo ratings yet

- Iso 683-17 - 2014Document11 pagesIso 683-17 - 2014George LituNo ratings yet

- 4.co - DMB 2243 Welding Process 2Document6 pages4.co - DMB 2243 Welding Process 2azmi yusofNo ratings yet

- Monthly Scrap - MayDocument1 pageMonthly Scrap - MayAmirHakimRusliNo ratings yet

- Steel Frame ConstructionDocument47 pagesSteel Frame Constructionapi-386384775No ratings yet

- Process Technology Level 2: © University of Teesside 2005Document31 pagesProcess Technology Level 2: © University of Teesside 2005Murad ZareebahNo ratings yet