Professional Documents

Culture Documents

Recycled Plastic Used in Concrete Paver Block

Recycled Plastic Used in Concrete Paver Block

Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Recycled Plastic Used in Concrete Paver Block

Recycled Plastic Used in Concrete Paver Block

Copyright:

Available Formats

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 03 Special Issue: 09 | NCETCE-2014 | June-2014, Available @ http://www.ijret.org 33

RECYCLED PLASTIC USED IN CONCRETE PAVER BLOCK

Ganesh Tapkire

1

, Satish parihar

2

, Pramod Patil

3

, Hemraj R Kumavat

4

1

P.G. Student, Dept of civil Engineering NRI Institute of Research & Technology, Bhopal, Madhya Pradesh India

2

HOD, Dept of civil EngineeringNRI Institute of Research & Technology, Bhopal, Madhya Pradesh India

3

P.G. Student, Dept of civil Engineering SSBTCOE Bambhori, Jalgaon

4

Assistant Professor, Civil Department,RCPIT Shirpur, Maharashtra

Abstract

In this paper Recycled plastic aggregate used in various proportion in concrete mix and check there sutbility .Amount of waste

plastic being accumulated in 21st centuries has created big challenges for their disposal, thus obliging the authorities to invest in

felicitating the use of waste plastic coarse aggregate in a concrete is fundamental to the booming construction industry. Disposal

of plastic waste in an environment is considered to be a big problem due to its very low biodegradability and presence in large

quantities. In recent time use of such, Industrial wastes from plastic bottles, pallets, carry bags; polypropylene (PP) and

polyethylene Terepthalate (PET) were studied as alternative replacements of a part of the conventional aggregates of concrete. If

plastic wastes can be mixed with the concrete mass in some quantity or in some form, without affecting the fundamental and other

properties or slight negotiation in strength the strength of concrete. Industrial wastes from polypropylene (PP) and polyethylene

Terepthalate (PET) were studied as alternative replacements of a part of the conventional aggregates of concrete. Three

replacement levels.10 %, 20 %, 30 by Weight of aggregates were used for the preparation of the concrete.

Keywords: PA: Plastic Aggregate: Polyethylene Terephthalate, LDPE : Low Density Polyethylene HDPE : High

Density Polyethylene, RCA Recycled Plastic Aggregate.PaverBlock.

--------------------------------------------------------------------***----------------------------------------------------------------------

1. INTRODUCTION

The wastes plastic in household is large and increases with

time. In each country the waste composition is different,

since it is affected by socioeconomic characteristics,

consumption patterns and waste management programs, but

generally the level of plastics in waste composition is high.

The largest component of the plastic waste is polyethylene,

followed by polypropylene, polyethylene Terepthalate and

polystyrene. The large volume of materials required for

construction is potentially a major area for the reuse of

waste materials. Recycling in concrete has advantages since

it is widely used and has a long service life, which means

that the waste is being removed from the waste stream for a

long period. Because the amount of mineral aggregates

required in concrete is large, the environmental benefits are

not only related to the safe disposal of bulk waste, but also

to the reduction of environmental impacts arising from the

extraction of aggregates.

1.1 Definition of Plastic

A material which contains one or more number of polymers

having large molecular weight. Solid in its finished state or

same state will manufacturing or processing into finished

articles is known as Plastic. Looking to the global issue of

environmental pollution by post-consumer plastic waste,

research efforts have been focused on consuming this waste

on massive scale in efficient and environmental friendly

manner. Researchers planned to use plastic waste in form of

concrete ingredient as the concrete is second most sought

material by human beings after water. The use of post-

consumer plastic waste in concrete will not only be its safe

disposal method but may also improve the concrete

properties like tensile strength, chemical resistance, drying

shrinkage and creep on short and long term basis.

Why The Plastics:- Polymers have a number of vital

properties, which exploited alone or together, make a

significant and expanding contribution to constructional

needs.

Durable and corrosion resistant.

Good Insulation for cold, heat and sound saving

energy.

It is economical and has a longer life.

Maintenance free (such as painting is minimized)

Hygienic and clean

Ease of processing / installation

Light weight

2. PROPOSED METHODOLOGY

Recycled Plastic Aggregate (RPA) in concrete is acceptable

there are for the making of concrete used coarse aggregate

having size 10mm, natural river sand used for making a

concrete and plastic aggregate used in concrete. Test carried

out on these aggregate density, and sieve analysis., water

absorption, all these test conduct on Recycled plastic

aggregate sample

conventional aggregate and compressive strength of

concrete at 10%, 20%, 30 replacement of plastic aggregate

in concrete.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 03 Special Issue: 09 | NCETCE-2014 | June-2014, Available @ http://www.ijret.org 34

2.1 Material

a) Cement b) coarse aggregate c) Fine aggregate(sand), d)

Recycled Plastic aggregate size less than 10 mm.e) Water.

a) Cement :- Ordinary Portland Cement of 43-grade was

used as it satisfied the requirements of IS: 269- 1969 and

results have been tabulated in table.

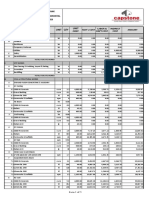

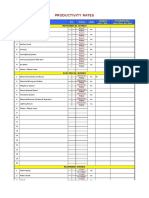

Table.1

Properties of cement

Specific gravity 3.15

Consistency 33%

Fineness 7.5

InitialSetting Time 45 minute

FinalSetting Time 480 nutes

b) Coarse Aggregate:- coarse aggregate shall comply with

the requirement of IS 383 as for as possible crushed

Aggregate shall be used for ensuring adequate durability.

The aggregate used for production of block shall beSound

and free from soft and honeycombed particle the nominal

maxi size of coarse aggregate used in Production of paver

block shall be 10 mm.

c) Fine aggregate:- Fine aggregate shall conform to

requirement of IS 383 For river sand

Table .2

Test

Types of Aggrgate

Coarse Fine Plastic

Specific Gravity 2.60

2.66

1.04

Water Absorption 0.85%

1.0%

Nil

Density (Kg/m3) 1865 kg/M

3

1080 Kg/M

3

640Kg/M

3

Moisture content Nil

1%

Nil

d) Water: - The water used for mixing concrete mix should

be potable drinking water having PH 6 TO 8.

Table .3

As per design M40 Grade Material

Requirement for 1 M

3

Material Quantity in kg

Cement 350

Sand 896

Aggregate 1140

Water 175 lit

2.2 Design Mix

As per design mix M40 grade given table shows the quantity

of material for this reference to take the material quantity for

6 Nos cube each proportion material required.

Table 4

Material proportion in weight batching(All weight in

kg) Kg)

Material 0% 10% 20% 30%

Cement 10 10 10 10

Sand 26 26 26 26

Aggregate Proportion (Kg)

Regular

Aggregate.

33

29.7 26.4 23.1

Plastic

Aggregate.

3.3 6.6 9.9

Total 33 33 33

After the casting the cube remove from the mould after

24hrs and than put the curing tank for curing of 14 days and

28 days after the curing completed .remove from curing tank

and dry to normal atmosphere atlest 2hrs for the surface dry

then to check it for compression testing machine get the

result.

Table 5

Plastic

Aggregate

in %

14 days

cstrength

Avg

strength

28 days

estrength

Avg

strength

0,00

28.80

28.87

39.50

41.10

27.80 42.00

30.00 41.80

10,00

26.80

27.70

39.00

40.07

29.00 40.30

27.30 40.90

20,00

26.00

26.90

38.70

38.97 27.90 39.60

26.80 38.60

30,00

25.00

25.43

37.60

37.77

26.50 38.60

24.80 37.10

In above investigation it is found that the optimum plastic

aggregate was 10% to 20% by weight of coarse aggregate

from the test result it was observed that the compressive

strength of concrete mix satisfy the I.S.456-2000Table no.11

(Clauses 16.1 Md 16.3) acceptanc criteriacomparison of

concrete.

Table 6

Grade

of

concrete

Mean of the group of Non-

overlapping consective test

resultin N/mm2

Individual

test.Result in

N/mm2

M10

(fck + 3N/mm2 ) or

(fck+0825XS.D.)which ever is

greater

Greater than

or Equal to

fck 3

N/mm2

M20

OR

ABOVE

(fck + 4N/mm2)or

(fck+0825XS.D.) (which ever

is greater

Greater than

or Equal to

fck 4

N/mm2

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

_______________________________________________________________________________________

Volume: 03 Special Issue: 09 | NCETCE-2014 | June-2014, Available @ http://www.ijret.org 35

3. CONCLUSIONS

a) The concrete consist of cement, sand, Aggregate and

water. Out of which the aggregate percentage is 60 to 70 %

in concrete and from the above observation, it is computed

to use the 20% Recycled plastic aggregate in concrete which

does not affect the properties of concrete.

b) From the above observation it is possible to use the

plastic in concrete mix up to 20 % weight of coarse

aggregate.

c) Looking in to above aspect we come to the conclusion

that plastic can be in cement concrete mix increase the % in

plastic to decrease the strength of concrete.

d) By using the plastic in concrete mix to reduces the weight

of cube up 15%.

e) From the above observation it is possible to use the

plastic in concrete and bonding admixture in concrete and

also increase the % of plastic in concrete.

f) Lastly, we strongly conclude the use of Recycled plastic

aggregate in concrete which is the best option for the

disposal of plastic & ultimately reduces the plastic pollution

in the Environment.

REFERENCES

[1]. Madam Mohan Reddy, K, Ajitha .B, and Bhavani .R,

Melt-Densified Post Consumer Recycled Plastic Bags Used

as Light Weight Aggregate in Concrete, International

Journal of Engineering Research and Applications (IJERA)

ISSN: 2248-9622 Vol. 2, Issue4, July-August 2012,

pp.1097-1101.

[2]. V. Kasselouri - Rigopoulou, S. Gavela, S. Kolias Use

Of Polymeric Wastes in The Concrete Production Polymers

in concrete: a vision for the 21st century, Cement &

Concrete Composites 21: (1999) 449-452.

[3]. Baboon Rai, S. Tabin Rushad, Bhavesh Kr, and S. K.

Duggal Research Article Study of Waste Plastic Mix

Concrete with Plasticizer International Scholarly Research

Network ISRN Civil Engineering Volume 2012, Article ID

469272, 5 pages doi:10.5402/2012/469272 2005.

[4]. Manual on Cement Concrete & Aggregates Australia

Use of Recycled Aggregates in Construction May

2008Removal and Reuse of Hardened Concrete (ACI 555R-

American Concrete Institute.

[5]. S. Gavela, C. Karakosta , C. Nydriotis , V. Kaselouri-

Rigopoulou , S. Kolias, P. A. Tarantili , C. Magoulas , D.

Tassios and A. Andreopoulos A Study Of Concretes

Containing Thermoplastic Wastes As Aggregates.

[6]. L. R. Bandodkar, A. A. Gaonkar, N. D. Gaonkar, & Y.

P. Gauns Pulverised PET Bottles as Partial Replacement

for Sand International Journal of Earth Sciences and

Engineering 1009 ISSN 0974-5904, Volume 04, No 06 SPL,

October 2011, pp. 1009-1012

[7]. Dr. Prahallada M.C and Dr. Prakash K.B Strength and

Workability Characteristicsof Waste Plastic Fibre

Reinforced Concrete Produced From Recycled Aggregates

International Journal of Engineering Research and

Applications (IJERA) ISSN: 2248-962

[8]. L. R. Bandodkar, A. A. Gaonkar, N. D. Gaonkar, & Y.

P. Gauns Pulverised PET Bottles as Partial Replacement

for Sand International Journal of Earth Sciences and

Engineering 1009 ISSN 0974-5904, Volume 04, No 06 SPL,

October 2011, pp. 1009-1012.

[9]. Dr. Prahallada M.C and Dr. Prakash K.B Strength and

Workability Characteristicsof Waste Plastic Fibre

Reinforced Concrete Produced From Recycled Aggregates

International Journal of Engineering Research and

Applications (IJERA) ISSN: 2248-9622.

[10]. V. Vytlacilov The fibre reinforced concrete with

using recycled aggregates International Journal Of Systems

Applications, Engineering & Development Issue 3, Volume

5, 2011

BIOGRAPHIES

Ganesh v.Tapkire Completed B.E. in civil

Engineering 2008 and M-Tech appear in

Building Construction &Technology in

RGPV University Bhopal (MP).presented

and Publish paper 02 Reaserch paper in

Natinal conference and 01 Internatinal

Journal along with publication author had attened 05

workshop sponsoerd by ISTE. Have two years site

experience in NH-3 Pimpalgaon-dhule BOT Project. From

last two year assistant professor in civil Engineering

department in R.C.Patel.Instute of Techonology Shirpur

Prof. Satish Parihar Pramod S.Patil

Completed B.E. in civil Engineering 2009

and ME appear in Enviormental science&

Engineering North Maharashtra

UniversityJalgaon.presented and Publish

paper 02 Reaserch paper in Natinal

conference and 01 Internatinal Journal along with

publication author had attened 05 workshop sponsoerd by

ISTE. From last two year assistant professor in civil

Engineering department in R.C.Patel.Instute of Techonology

Shirpur

You might also like

- TEN 02 Engineered Wood Products and An Introduction To Timber Structural SystemsDocument7 pagesTEN 02 Engineered Wood Products and An Introduction To Timber Structural Systemsdhanya1995No ratings yet

- 22m High Wall at Durga Temple With PECDocument5 pages22m High Wall at Durga Temple With PECGerald TanNo ratings yet

- Recycled Plastic Used in Concrete Paver Block PDFDocument3 pagesRecycled Plastic Used in Concrete Paver Block PDFRusel ZahrawNo ratings yet

- Minor Project Synopsis Civil FinalDocument9 pagesMinor Project Synopsis Civil FinalAceNo ratings yet

- Plastic Roads A Recent Advancement in Waste Management IJERTV5IS090574Document5 pagesPlastic Roads A Recent Advancement in Waste Management IJERTV5IS090574SahityaNo ratings yet

- Plastic Road ReportDocument53 pagesPlastic Road ReportSunny Prajapati100% (1)

- Plastic Mixed Reinforced ConcreteDocument10 pagesPlastic Mixed Reinforced ConcreteUmange RanasingheNo ratings yet

- USE OF Plastic Waste in Road ConstructionDocument19 pagesUSE OF Plastic Waste in Road ConstructionAbhishek PawarNo ratings yet

- Final Project PPT AquebDocument20 pagesFinal Project PPT AquebKlien ParkerNo ratings yet

- Seminar Report Plastic Road PDFDocument13 pagesSeminar Report Plastic Road PDFAbhinav YadavNo ratings yet

- Seminar ReportDocument29 pagesSeminar ReportSreelakshmi Mohan100% (1)

- Green ConcreteDocument12 pagesGreen Concretevaishnavi yedur100% (1)

- PPTDocument28 pagesPPTRama Arul SakthiNo ratings yet

- Plastic Road ReportDocument6 pagesPlastic Road ReportsrivinaymnNo ratings yet

- Building Materials Final Solution After Cor.Document64 pagesBuilding Materials Final Solution After Cor.TarunNo ratings yet

- 1.1 Concrete: "Partial Replacement of Coarse Aggregate With Ceramic Tile in Concrete"Document11 pages1.1 Concrete: "Partial Replacement of Coarse Aggregate With Ceramic Tile in Concrete"Naveen SNo ratings yet

- Plastic RoadsDocument16 pagesPlastic RoadsAbhinav Yadav100% (1)

- Concrete Using Coconut Fiber - An AlternativeDocument4 pagesConcrete Using Coconut Fiber - An AlternativeSenthil KumarNo ratings yet

- Ready Mix Concrete: Technical Seminar Report OnDocument7 pagesReady Mix Concrete: Technical Seminar Report OnadityaNo ratings yet

- ABM Seminar ReportDocument24 pagesABM Seminar Reportmd MuzammilNo ratings yet

- Project - PPT - 3308-1 FinalDocument47 pagesProject - PPT - 3308-1 FinalsNo ratings yet

- Use of Waste Plastic in Bituminous RoadsDocument27 pagesUse of Waste Plastic in Bituminous Roadssachin palNo ratings yet

- Animesh Kashyap PPT On Plastic RoadDocument23 pagesAnimesh Kashyap PPT On Plastic RoadANIMESH KASHYAPNo ratings yet

- Effects of Glass Waste On Compressive Strength of ConcreteDocument21 pagesEffects of Glass Waste On Compressive Strength of ConcreteRachit SharmaNo ratings yet

- USE OF Plastic Waste in Road ConstructionDocument19 pagesUSE OF Plastic Waste in Road ConstructionAbhishek PawarNo ratings yet

- "Soil Stabilization Using Plastic Waste": A Technical Seminar Presentation OnDocument27 pages"Soil Stabilization Using Plastic Waste": A Technical Seminar Presentation OnAkhilesh B.MNo ratings yet

- COconut Shell PaperDocument10 pagesCOconut Shell PaperPeer MohamedNo ratings yet

- Use of Waste Plastic in Flexible Pavements-Green RoadsDocument13 pagesUse of Waste Plastic in Flexible Pavements-Green RoadsNaveen JatavNo ratings yet

- Plastic RoadsDocument7 pagesPlastic Roadsprithvi biswasNo ratings yet

- 12.project Report IDocument52 pages12.project Report IsrinivasanNo ratings yet

- A Review Paper On Replacement of Fine AggregateDocument5 pagesA Review Paper On Replacement of Fine AggregateIJRASETPublicationsNo ratings yet

- Plastic Bricks PPT First ReviewDocument18 pagesPlastic Bricks PPT First Review19TUCV038 SHUHAIL AKTHAR.ANo ratings yet

- Green Concrete: BY Amal JamalDocument16 pagesGreen Concrete: BY Amal JamalAMAL JAMAL BITNo ratings yet

- Minor Project 1 PDFDocument42 pagesMinor Project 1 PDFSumit JoshiNo ratings yet

- Final Year ProjectDocument50 pagesFinal Year ProjectDanish KaiserNo ratings yet

- To Find The Strength of Concrete Block Using Waste Material Project ReportDocument49 pagesTo Find The Strength of Concrete Block Using Waste Material Project ReportSahil Bali100% (1)

- Partial Repacement of Plastic in BitumenDocument5 pagesPartial Repacement of Plastic in BitumenSri HariNo ratings yet

- Utilisation of Waste Plastic in Bituminous Mixes For Road ConstructionDocument26 pagesUtilisation of Waste Plastic in Bituminous Mixes For Road Constructionshiva5059No ratings yet

- D D Khedkar Evaluation of Suitability of Ambanala Water, Amravati, For IrrigationDocument4 pagesD D Khedkar Evaluation of Suitability of Ambanala Water, Amravati, For IrrigationDr. Dinesh D KhedkarNo ratings yet

- 7th Sem Minor ProjectDocument13 pages7th Sem Minor ProjectRajesh Nayak100% (1)

- On Plastic Roads by RAIS SHAIKHDocument21 pagesOn Plastic Roads by RAIS SHAIKHRais ShaikhNo ratings yet

- Studies On Quarry Dust As Partial Replacement of Fine Aggregates in ConcreteDocument3 pagesStudies On Quarry Dust As Partial Replacement of Fine Aggregates in ConcreteEditor IJLTEMASNo ratings yet

- Mohamed Elfatih - TechnicalDocument11 pagesMohamed Elfatih - Technical6qwhnq9z4h100% (1)

- Rajarajeswari College of EngineeringDocument23 pagesRajarajeswari College of Engineeringchetan maitriNo ratings yet

- Yash Bulbule Seminar Report On Concrete RoadDocument38 pagesYash Bulbule Seminar Report On Concrete RoadBulbule Yash MadhavNo ratings yet

- Analysis of Compressive Strength of M-25 Grade Concrete Using Fly Ash As Partial Replacement of CementDocument49 pagesAnalysis of Compressive Strength of M-25 Grade Concrete Using Fly Ash As Partial Replacement of CementRais AlamNo ratings yet

- Geo Polymer ConcreteDocument17 pagesGeo Polymer ConcreteAshutosh RungtaNo ratings yet

- Project ReportDocument41 pagesProject ReportAashu chaudhary100% (1)

- Use of Plastic Waste in Road ConstructionDocument15 pagesUse of Plastic Waste in Road ConstructionbavawilNo ratings yet

- Experimental Study of Compressive Strength of Concrete by Partial Replacement of Fine Aggregate With Copper SlagDocument12 pagesExperimental Study of Compressive Strength of Concrete by Partial Replacement of Fine Aggregate With Copper SlagIJRASETPublicationsNo ratings yet

- Green Concrete: WWW - SeminarDocument12 pagesGreen Concrete: WWW - SeminarSuraj Deb BarmaNo ratings yet

- Utilzation of Waste Plastic in Manufacturing of Bricks Along With Quarry Dust and M-SandDocument8 pagesUtilzation of Waste Plastic in Manufacturing of Bricks Along With Quarry Dust and M-SandPeeyush MishraNo ratings yet

- HarishDocument15 pagesHarishhp0195877100% (1)

- Study of Light Weight Fibre Reinforced Concrete by Partial Replacement of Coarse Aggregate With Pumice StoneDocument10 pagesStudy of Light Weight Fibre Reinforced Concrete by Partial Replacement of Coarse Aggregate With Pumice StoneMohammed Sohel AhmedNo ratings yet

- Paper On Plastic To RoadDocument6 pagesPaper On Plastic To RoadSumskrutha Kosgi ShroffNo ratings yet

- A Study On Use of Waste Polyethylene in Bituminous Paving MixingDocument106 pagesA Study On Use of Waste Polyethylene in Bituminous Paving Mixingpraveen100% (1)

- Mid Term Presentation of RaminderDocument43 pagesMid Term Presentation of RaminderAndrea DeleonNo ratings yet

- Project Report On Self Compacting ConcreteDocument94 pagesProject Report On Self Compacting ConcreteSunilkumar Ce100% (3)

- Replacement of Waste Material in Concrete Using Recycled PlasticDocument6 pagesReplacement of Waste Material in Concrete Using Recycled Plasticsinghal siddhant100% (1)

- Experimental Investigation On The Compressive Strength of Concrete With Plastic PET Bottle Aggregate As Fine Aggregate.Document7 pagesExperimental Investigation On The Compressive Strength of Concrete With Plastic PET Bottle Aggregate As Fine Aggregate.abhishek bellary100% (1)

- Waste Plastic GoooodDocument12 pagesWaste Plastic GoooodAngel AngelNo ratings yet

- Aisi 4140 PHDocument1 pageAisi 4140 PH123vigenNo ratings yet

- Ceramic, Polymer and Composite MaterialsDocument39 pagesCeramic, Polymer and Composite MaterialsYasir ArafatNo ratings yet

- M-30 Boiler Feed Water Piping Diagram PDFDocument11 pagesM-30 Boiler Feed Water Piping Diagram PDFАндрей ХмелярчукNo ratings yet

- MS 01 140 PDFDocument69 pagesMS 01 140 PDFshahzadNo ratings yet

- ChassisDocument30 pagesChassisRavi KiranNo ratings yet

- Valve StandardsDocument15 pagesValve Standardsabdu100% (1)

- NanoGrout CFGDocument3 pagesNanoGrout CFGimzee25100% (2)

- Grade Guide A36 SteelDocument3 pagesGrade Guide A36 SteelBayar DiyarNo ratings yet

- 011 Besi BajaDocument34 pages011 Besi BajaMFA nounNo ratings yet

- Dental Amalgam: by Kazhan Omer AbdulrahmanDocument32 pagesDental Amalgam: by Kazhan Omer AbdulrahmanSyedMubeenYaserNo ratings yet

- ACI Column SheetDocument51 pagesACI Column SheetRajveer SinghNo ratings yet

- NIA IgbarasDocument11 pagesNIA IgbarasBernardo Rasimo100% (1)

- QP10-Q-611 Rev0 Typical Cross Section For Roads and TrafficDocument1 pageQP10-Q-611 Rev0 Typical Cross Section For Roads and TrafficnawajhaNo ratings yet

- Bolt Depot - Bolt Grade Markings and Strength ChartDocument2 pagesBolt Depot - Bolt Grade Markings and Strength ChartAvishkar100% (1)

- PR Concrete RecycleDocument4 pagesPR Concrete RecycleAnonymous z4Fe39jNo ratings yet

- SPAN Noted 2 Part 2 2013Document32 pagesSPAN Noted 2 Part 2 2013wan marzukiNo ratings yet

- Cast Cat 2013Document360 pagesCast Cat 2013megatornadoNo ratings yet

- List of ClientsDocument3 pagesList of ClientsanujNo ratings yet

- Sample EstimatesDocument157 pagesSample EstimatesyogeshNo ratings yet

- Light Transmitting ConcreteDocument29 pagesLight Transmitting ConcreteAnvesh Jakke67% (3)

- Proposed Four Storey Building: Sub-Total Civil Works B. Structural WorksDocument7 pagesProposed Four Storey Building: Sub-Total Civil Works B. Structural WorksEl LlacunaNo ratings yet

- API 572 Study Guide: Practice QuestionsDocument10 pagesAPI 572 Study Guide: Practice QuestionsRizwan Nazir100% (1)

- Building Construction LDocument55 pagesBuilding Construction LRoland CepedaNo ratings yet

- Bill of MaterialsDocument2 pagesBill of MaterialsJonathan SilayaNo ratings yet

- Equipment ProductivityDocument13 pagesEquipment Productivitymuhammad75makeNo ratings yet

- Basement ConstructionDocument1 pageBasement ConstructiondinendraNo ratings yet

- Spot Detail: Key PlanDocument1 pageSpot Detail: Key PlanMJian VergaraNo ratings yet

- Pipe Support Design GuidelinesDocument9 pagesPipe Support Design GuidelineskarunaNo ratings yet

- BOQ HUBER HOLLYDocument11 pagesBOQ HUBER HOLLYSUNIL PATELNo ratings yet