Material Composition General

Material Composition General

Uploaded by

Balaji RGCopyright:

Available Formats

Material Composition General

Material Composition General

Uploaded by

Balaji RGOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Material Composition General

Material Composition General

Uploaded by

Balaji RGCopyright:

Available Formats

Page 1 of 1

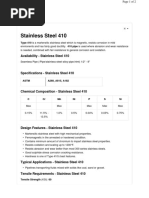

Steel Type Grade Summary of Properties Nominal Chemical Analysis % Related Standards

C Mn Cr Mo Ni V Mb Cu N & Specifications

Carbon LF2 Standard carbon flange steel with notch 0.15 1.20 12 12 12 Optional 1 1 ASTM A350

V/Nb

Steels 12 toughness 12 12 12 2 to customer requirements 1

12 X65 Higher strength, tough weldable steel with 0.08 1.30 12 12 1 1 1 1 1 API 5LX

12 Flanged Steel good resistance to Hydrogen Induced Cracking 1 1 1 1 1 1 1 1 1

Alloy 4130 Standard 0.3% C CrMo steel with good 0.30 0.50 1.00 0.20 1 1 1 1 1 API 6A Type 2

Steels 1 combination of strength and toughness 1 1 1 1 1 1 1 1 1 NACE MR0175

1 1 1 1 1 1 1 1 1 1 1 1 AISI 4130

1 4140 Standard 0.4% C CrMo steel for use at higher 0.40 0.80 1.00 0.20 1 1 1 1 1 API 6A Type 2

1 1 strength levels 1 1 1 1 1 1 1 1 1 NACE MR0175

1 1 1 1 1 1 1 1 1 1 1 1 AISI 4140

1 4140 Mod Enhanced hardenability version of 4140 for 0.40 0.80 1.00 0.33 1 1 1 1 1 NACE MR0175

1 1 larger section sizes 1 1 1 1 1 1 1 1 1

1 4145 Standard 0.45% C CrMo steel for high strength 0.45 0.90 1.00 0.20 1 1 1 1 1 API Sections 4/5/6

1 1 in medium section sizes 1 1 1 1 1 1 1 1 1 AISI 4145

1 4145 Mod Enhanced hardenability version of 4145 for 0.47 1.10 1.10 0.33 1 1 1 1 1 API Sections 4/5/6

1 1 larger section sizes, suitable for drill collars 1 1 1 1 1 1 1 1 1

1 9Cr1Mo High strength alloy steel with corrosion 0.12 0.50 9.00 1.00 1 1 1 1 1 ASTM A199

1 1 resistance superior to the 41xx series 1 1 1 1 1 1 1 1 1 ASTM A213

1 1 1 1 1 1 1 1 1 1 1 1 NACE MR0175

Martensitic 410 13% Cr steel with high strength and better 0.10 0.50 13.00 1 1 1 1 1 1 ASTM A276

Stainless 1 corrosion resistance than alloy steel 1 1 1 1 1 1 1 1 1 ASTM A479

Steels 1 1 1 1 1 1 1 1 1 1 1 NACE MR0175

1 420 Lower ferrite 13% Cr steel for improved 0.20 0.80 13.00 1 1 1 1 1 1 ASTM A276

1 1 corrosion resistance and enhanced workability 1 1 1 1 1 1 1 1 1

1 F6NM 13% Cr steel with excellent low temperature 0.02 0.70 13.00 0.35 4.00 1 1 1 1 UNS 42400

1 1 impact properties and corrosion resistance 1 1 1 1 1 1 1 1 1 NACE MR0175

1 1 1 0.02 0.70 13.00 0.55 4.00 1 1 1 1 ASTM A182

Precipitation 520B Machinable corrosion resistant steel with 0.05 0.80 13.50 1.50 5.50 1 0.30 1.70 1

Hardening 1 freedom from distortion on heat treatment to 1 1 1 1 1 1 1 1 1

Stainless 1 high strengths 1 1 1 1 1 1 1 1 1

Steels 17/4 Improved corrosion resistant age-hardening 0.05 0.80 16.00 1 4.00 1 0.30 3.50 1 UNS S17400

1 1 stainless steel with minimal distortion and 1 1 1 1 1 1 1 1 1 ASTM A564

1 1 scaling on heat treating after machining 1 1 1 1 1 1 1 1 1 NACE MR0175

1 1 1 1 1 1 1 1 1 1 1 1 W 1.4548

Austenitic 304 Standard stainless steels for high corrosion 0.04 1.50 18.50 1 9.00 1 1 1 1 ASTM A182

Stainless 304L resistance 0.02 1.50 18.50 1 10.50 1 1 1 1

Steels 1 1 1 1 1 1 1 1 1 1 1

1 316 Standard stainless steels for corrosion 0.04 1.50 17.00 2.50 12.50 1 1 1 1 ASTM A182

1 316L resistance higher than 304 types 0.02 1.50 17.00 2.50 13.00 1 1 1 1

1 316LN 1 0.02 1.50 17.00 2.50 12.00 1 1 1 0.14

1 NB. Improved machinable versions of austenitic steels ( prefixed IM ) are also

available

Duplex 22/5 Higher strength steel with superior resistance 0.02 1.50 22.60 3.00 5.50 1 1 0.17

11 ASTM A182

Stainless 1 to stress corrosion cracking for chloride and/or 1 1 1 1 1 1 1 1 11 UNS S31803

Steels 1 sour gas conditions 1 1 1 1 1 1 1 1 11 NACE MR0175

1 25/7 Higher Cr duplex for improved pitting & 0.02 1.20 25.00 3.00 7.00 1 1 11 0.17

1 1 corrosion resistance 1 1 1 1 1 1 1 11 1

1 Super Duplex Enhanced higher strength duplex steel with high 0.02 0.50 25.50 3.50 7.00 1 1 0.70 0.23 UNS S32760

1 1 resistance to chloride stress corrosion cracking 1 1 1 1 1 1 1 "+0.70%W" 1

25/May/2010

You might also like

- Astm 1020 PDFDocument3 pagesAstm 1020 PDFbarrancabermeja24No ratings yet

- A778Document4 pagesA778bobNo ratings yet

- Stainless and Heat-Resisting Chromium Steel Plate, Sheet, and StripDocument2 pagesStainless and Heat-Resisting Chromium Steel Plate, Sheet, and StripAlejandro ValdesNo ratings yet

- A 176 - 99 PDFDocument2 pagesA 176 - 99 PDFipkm123No ratings yet

- 409 Data BulletinDocument12 pages409 Data BulletinWilliam PaivaNo ratings yet

- A498Document13 pagesA498rgi178No ratings yet

- High-Strength, Low-Alloy Carbon, Manganese, Columbium, Vanadium Steel of Structural Quality With Improved Notch ToughnessDocument2 pagesHigh-Strength, Low-Alloy Carbon, Manganese, Columbium, Vanadium Steel of Structural Quality With Improved Notch ToughnessMytzy Godoy TapiaNo ratings yet

- AISI Alloy 4130 Steel Supply Range& 4140Document6 pagesAISI Alloy 4130 Steel Supply Range& 4140ap taNo ratings yet

- AISI 4130 Steel - 25CrMo4 - 1.7218 - 708A25 - SCM430 - Special SteelDocument3 pagesAISI 4130 Steel - 25CrMo4 - 1.7218 - 708A25 - SCM430 - Special SteelGeorge LawrenceNo ratings yet

- A732A732MDocument6 pagesA732A732MAnderson TadeuNo ratings yet

- Stainless Steel 420 Material Chemical CompositionDocument3 pagesStainless Steel 420 Material Chemical Compositionr arumugamNo ratings yet

- Polished Rod Profile - NEWDocument7 pagesPolished Rod Profile - NEWKevin XuNo ratings yet

- Asme Sfa Sa 213Document14 pagesAsme Sfa Sa 213Mayank SinglaNo ratings yet

- High-Strength Carbon-Manganese Steel of Structural Quality: Standard Specification ForDocument3 pagesHigh-Strength Carbon-Manganese Steel of Structural Quality: Standard Specification Forprajakt_pieNo ratings yet

- Material Specification: Specification: B-1 Revision Date: 09/06/2016 Revision Level: AEDocument13 pagesMaterial Specification: Specification: B-1 Revision Date: 09/06/2016 Revision Level: AEReginaldo SantosNo ratings yet

- Higher-Strength Martensitic Stainless Steel Plate, Sheet, and StripDocument2 pagesHigher-Strength Martensitic Stainless Steel Plate, Sheet, and StripMaxNo ratings yet

- a213/a213m 05b无缝铁素体和奥氏体合金钢锅炉、过热器和换热器管Document12 pagesa213/a213m 05b无缝铁素体和奥氏体合金钢锅炉、过热器和换热器管Edisson CordovaNo ratings yet

- Steel Sheet, Zinc-Aluminum-Magnesium Alloy-Coated by The Hot-Dip ProcessDocument3 pagesSteel Sheet, Zinc-Aluminum-Magnesium Alloy-Coated by The Hot-Dip ProcessMohammed Khalid100% (1)

- 1.2379 Tool SteelDocument8 pages1.2379 Tool Steelsmith willNo ratings yet

- High Strength, Low Alloy Steels: Tion (Ordinary Rusting, Which Is The Most Common KindDocument7 pagesHigh Strength, Low Alloy Steels: Tion (Ordinary Rusting, Which Is The Most Common KindWilly UioNo ratings yet

- Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip For Pressure Vessels and For General ApplicationsDocument3 pagesChromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip For Pressure Vessels and For General ApplicationsVi AnNo ratings yet

- Kapitel 02 DINO Techn TeilDocument8 pagesKapitel 02 DINO Techn TeilBoulHich BoulHichNo ratings yet

- 7 - Wrap Up Session For Mid Term TestDocument36 pages7 - Wrap Up Session For Mid Term TestFiky ArdiansyahNo ratings yet

- Astm A356 A356m 21Document5 pagesAstm A356 A356m 21VenkateshNo ratings yet

- Introduction To Steel Classification and Standard: Suwarno, PHDDocument22 pagesIntroduction To Steel Classification and Standard: Suwarno, PHDmirfanwibisono100% (1)

- Plates, Carbon Steel, Structural Quality, Furnished To Chemical Composition RequirementsDocument3 pagesPlates, Carbon Steel, Structural Quality, Furnished To Chemical Composition RequirementsOsama TaghlebiNo ratings yet

- Materials Castings E00510 SulzerDocument5 pagesMaterials Castings E00510 SulzerAmir SafdarNo ratings yet

- Aalco Metals LTD Stainless Steel 14021 Bar 311Document2 pagesAalco Metals LTD Stainless Steel 14021 Bar 311joseocsilvaNo ratings yet

- Precipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and StripDocument6 pagesPrecipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and StripMaximiliano VerardoNo ratings yet

- Alloy SteelDocument33 pagesAlloy SteelDhana LakshmiNo ratings yet

- Type 410 Stainless SteelDocument2 pagesType 410 Stainless SteelPravin PawarNo ratings yet

- Type 410 Stainless SteelDocument2 pagesType 410 Stainless SteelPravin PawarNo ratings yet

- ASTM A573-A573M-00aDocument2 pagesASTM A573-A573M-00aNadhiraNo ratings yet

- Astm A-693Document7 pagesAstm A-693Sales VindindiaNo ratings yet

- Precipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and StripDocument9 pagesPrecipitation-Hardening Stainless and Heat-Resisting Steel Plate, Sheet, and StripfatinNo ratings yet

- ASTM A693 16 (Reapproved 2022) Precipitation - Hardening - Stainless - andDocument8 pagesASTM A693 16 (Reapproved 2022) Precipitation - Hardening - Stainless - andVijay KumarNo ratings yet

- Steel Castings, Austenitic Manganese: Standard Specification ForDocument3 pagesSteel Castings, Austenitic Manganese: Standard Specification ForJosh HansenNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- A 1026 - 03 - QtewmjyDocument2 pagesA 1026 - 03 - QtewmjyAdrian GonzalezNo ratings yet

- 7 Tool Steels1Document12 pages7 Tool Steels1ontc0109No ratings yet

- Lect 9. Steel Classification and PropertiesDocument28 pagesLect 9. Steel Classification and PropertiesRio BuiNo ratings yet

- 1415712636wpdm - Stainless Steel Grade AISI 409Document2 pages1415712636wpdm - Stainless Steel Grade AISI 409Anurag SarkarNo ratings yet

- A167-99 (2009) Withdrawn 2014Document3 pagesA167-99 (2009) Withdrawn 2014sgjsevenpNo ratings yet

- Alloy and Structural Alloy Steel, Sheet and Strip, Hot-Rolled and Cold-RolledDocument4 pagesAlloy and Structural Alloy Steel, Sheet and Strip, Hot-Rolled and Cold-RolledPushkar GopalNo ratings yet

- Martensitic Stainless SteelDocument3 pagesMartensitic Stainless SteelVysakh VasudevanNo ratings yet

- ASTM A213Document13 pagesASTM A213danial.caoNo ratings yet

- F 899 - 02 Surgical SteelDocument8 pagesF 899 - 02 Surgical Steelhafiz munawarNo ratings yet

- Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip For Pressure Vessels and For General ApplicationsDocument11 pagesChromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip For Pressure Vessels and For General Applicationsromildasantos.psNo ratings yet

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)matiullahNo ratings yet

- Seamless Carbon-Molybdenum Alloy-Steel Boiler and Superheater TubesDocument3 pagesSeamless Carbon-Molybdenum Alloy-Steel Boiler and Superheater TubesالGINIRAL FREE FIRENo ratings yet

- PDFsam - B 365 - 12Document4 pagesPDFsam - B 365 - 12mike.jensen0581No ratings yet

- OK Tigrod 12.61: Tig Rods (Gtaw) Mild Steel RodsDocument1 pageOK Tigrod 12.61: Tig Rods (Gtaw) Mild Steel RodsHusam AhmedNo ratings yet

- Seamless and Welded Austenitic Stainless Steel Tubing (Small-Diameter) For General ServiceDocument4 pagesSeamless and Welded Austenitic Stainless Steel Tubing (Small-Diameter) For General ServiceAlejandro GonzálezNo ratings yet

- Technical Center 1Document3 pagesTechnical Center 1nimeshchanchaniNo ratings yet

- Material - (1 4462)Document2 pagesMaterial - (1 4462)Ashutosh PathakNo ratings yet

- Astm A 283M-00 PDFDocument2 pagesAstm A 283M-00 PDFMemelas FerMaxNo ratings yet

- Specification For Precipitation-Hardening Nickel Alloy Bars, Forgings, and Forging Stock For High-Temperature ServiceDocument9 pagesSpecification For Precipitation-Hardening Nickel Alloy Bars, Forgings, and Forging Stock For High-Temperature ServicerbagriNo ratings yet

- CC401Document1 pageCC401Aditya maulana NurjamanNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- Pages414from Speciality SteelDocument1 pagePages414from Speciality SteelBalaji RGNo ratings yet

- 28 From Dot - 31361 - DS1Document1 page28 From Dot - 31361 - DS1Balaji RGNo ratings yet

- Pages402from Speciality SteelDocument1 pagePages402from Speciality SteelBalaji RGNo ratings yet

- Pages401from Speciality SteelDocument1 pagePages401from Speciality SteelBalaji RGNo ratings yet

- 12 From Dot - 31361 - DS1Document1 page12 From Dot - 31361 - DS1Balaji RGNo ratings yet

- Pages404 From Speciality SteelDocument1 pagePages404 From Speciality SteelBalaji RGNo ratings yet

- Surface Finish 101 4Document1 pageSurface Finish 101 4Balaji RGNo ratings yet

- Surface Finish 101 19 PDFDocument1 pageSurface Finish 101 19 PDFBalaji RGNo ratings yet

- E2698 Page 006Document1 pageE2698 Page 006Balaji RGNo ratings yet

- Project Plan Template - WsDocument2 pagesProject Plan Template - WsBalaji RGNo ratings yet

- Surface Finish 101 2Document1 pageSurface Finish 101 2Balaji RGNo ratings yet

- Specification Sheet: 17-4PH (UNS S17400) : A 17Cr-4Ni-3Cu Precipitation Hardening Martensitic Stainless SteelDocument2 pagesSpecification Sheet: 17-4PH (UNS S17400) : A 17Cr-4Ni-3Cu Precipitation Hardening Martensitic Stainless SteelBalaji RGNo ratings yet

- Surface Finish 101 1Document1 pageSurface Finish 101 1Balaji RGNo ratings yet

- Surface Finish 101 3Document1 pageSurface Finish 101 3Balaji RGNo ratings yet

- SINAMA - Surface Roughness ConversionDocument1 pageSINAMA - Surface Roughness ConversionBalaji RGNo ratings yet

- 17-4 PH PropertiesDocument3 pages17-4 PH PropertiesBalaji RGNo ratings yet

- QCS 2014Document3 pagesQCS 2014insasofttNo ratings yet

- Design For Manufacture & Environment: Function Structure - BlenderDocument10 pagesDesign For Manufacture & Environment: Function Structure - Blender1prathamNo ratings yet

- Reactivity of IronDocument3 pagesReactivity of IronqamhNo ratings yet

- Titanium Alloys Piping Welding: Functional SpecificationDocument29 pagesTitanium Alloys Piping Welding: Functional Specificationbrahim amiraNo ratings yet

- Materials System SpecificationDocument11 pagesMaterials System SpecificationZubair RaoofNo ratings yet

- Libroduplex PDFDocument183 pagesLibroduplex PDFHugo PeñaNo ratings yet

- 5-Submerged Arc Welding (SAW)Document9 pages5-Submerged Arc Welding (SAW)abastosuaptNo ratings yet

- L.A.B Mabhali, N. Sacks, S. Pityana: Article InfoDocument9 pagesL.A.B Mabhali, N. Sacks, S. Pityana: Article InfoRakesh ChandraNo ratings yet

- Discovering Metals - A Historical OverviewDocument12 pagesDiscovering Metals - A Historical OverviewMonisha SharmaNo ratings yet

- Sa 537Document6 pagesSa 537Mauricio Carestia100% (1)

- Weldinghuide Eng BohlerDocument515 pagesWeldinghuide Eng BohlerJorge VasquezNo ratings yet

- Submerged Arc WeldingDocument11 pagesSubmerged Arc Weldingmiteshpatel191No ratings yet

- Bab I Pendahuluan 1.1. Steel MakingDocument2 pagesBab I Pendahuluan 1.1. Steel MakingRebecca FrancisNo ratings yet

- MPS SampleDocument8 pagesMPS SampleMuhamad Amar Hakimmie SuhaimiNo ratings yet

- Certilas CatalogDocument308 pagesCertilas CatalogLuiz Henrique Mourão InacioNo ratings yet

- Nas 1832Document3 pagesNas 1832staedtlerpNo ratings yet

- VF730 & VF733 - AGA ApprovedDocument8 pagesVF730 & VF733 - AGA ApprovedJamyansuren TseveendorjNo ratings yet

- List 1Document51 pagesList 1Anonymous Kr13NEBNo ratings yet

- Corrosion Inhibiting AdmixturesDocument3 pagesCorrosion Inhibiting AdmixturesMalak HindiNo ratings yet

- Project PPT - OKDocument28 pagesProject PPT - OKkrushna NikamNo ratings yet

- WPQ Process As Per ISO-9606-1 2013Document4 pagesWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Career EssayDocument7 pagesCareer Essayapi-315865478100% (2)

- Internal PaintingDocument9 pagesInternal Paintingtzimtiger50% (2)

- ABC WebDocument258 pagesABC WebNermina HodžićNo ratings yet

- Series 4030: SubmittalDocument2 pagesSeries 4030: SubmittalPSC RFQNo ratings yet

- Design - Part 3 - TWI PDFDocument7 pagesDesign - Part 3 - TWI PDFSumantaNo ratings yet

- Project Reoprt On JSW SteelsDocument30 pagesProject Reoprt On JSW SteelsSakthi Krishnan100% (1)

- Inservice DefectsDocument4 pagesInservice DefectsMr.SafetyNo ratings yet

- Field Applied External Coatings For Nuayyim Piping and Steel StructuresDocument2 pagesField Applied External Coatings For Nuayyim Piping and Steel Structuresishaq_khanNo ratings yet

- ASTM A36 MildDocument4 pagesASTM A36 MildjyothiNo ratings yet