Site 2 Bleacher - Dump Vessel Pump Datasheet

Site 2 Bleacher - Dump Vessel Pump Datasheet

Uploaded by

Choon Zhe ShyiCopyright:

Available Formats

Site 2 Bleacher - Dump Vessel Pump Datasheet

Site 2 Bleacher - Dump Vessel Pump Datasheet

Uploaded by

Choon Zhe ShyiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Site 2 Bleacher - Dump Vessel Pump Datasheet

Site 2 Bleacher - Dump Vessel Pump Datasheet

Uploaded by

Choon Zhe ShyiCopyright:

Available Formats

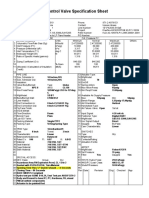

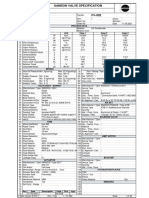

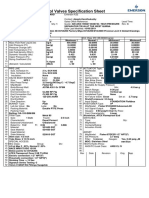

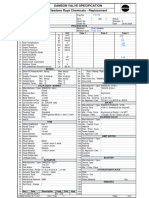

CENTRIFUGAL PUMP SPECIFICATION SHEET Doc. No..

PLANT: Site 2

SITE: EDENOR OLEOCHEMICALS SITE 2

PROJECT: Dump vessel pump / Bleacher Pump

1

2 Item Description Service Quantity

3

4 122P11 / 122P14 Dump vessel pump / Bleacher Pump Ethyl Ester 2 unit

5

6

7 PROCESS DATA

8 TYPE: End Suction SERVICE TYPE: continuous

9 PRESSURE: MATERIALS:

10 FLUID: Ethyl Ester Op. at suct., bar(A): Casing: SS316

11 Density, kg/m3: 850 Head, m 40 impeller: SS316

12 Viscosity, cP: 50 NPSH avail., m: 2 Shaft: SS316

13 Vap.pr. at op.temp., bar(A): Gaskets: Silicon

14 Corrosive compounds:

15 Toxic compounds:

16 Solids, %: 1%

Type of Sodium Palmitate, Activated

solid carbon, bleaching earth (clay) and

17 medium : Diatomaceous earth

18 Op. temp, °C: 120

19 Max. temp, °C: 150

20 Rated Flowrate, m3/h: 30 Mechanical Seal : API plnned seal 53A (12Litre seal port with low level switch)

(AES)

21 Min. op. flowrate, m3/h: 10

22 Contamination allowed: Seal flushing type: Yes

23 Insulation: Tracing: Jacket: Yes

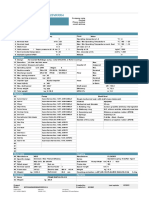

24 MOTOR: Volts: 415 Hertz: 50 Phases: 3 Poles:

25 Tropical.: Yes Protection: ATEX - Ia Start:

26

27 MANUFACTURER INFORMATION

28 Flowrate, m3/h: Inlet nozzle INCHES/ANSI#: Carter: Base-plate:

29 Pressure, m.l.c: Inlet nozzle INCHES/ANSI#: Ass. dwg:

30 Coupling (direct/gear):

31 PUMP MOTOR GEAR-BOX SPEED-VARIATOR

32 Manufacturer:

33 Model:

34 Order Nr.:

35 Order date:

36 Delivery date:

37 Power, kW:

38 Speed, rpm:

39 Shape:

40 Protection:

41 Gear box red. ratio:

42 Var. speed range:

43 Weight, kg:

46 Mechanical seal manufacturer: Model: Year:

47 Mechanical seal API plan:

48 Make requst for spare parts offer: For Nr. years

49 When ordering make request for Nr. manuals in ENGLISH language, and Nr. English

50 NOTES:

51 1. The motor must be selected for end of performance curve. Impeller diameter shall not be greater than 90% of the maximum one

52 2. Shut off head must be 110 % of operating head.

53 3. Flanges to be ANSI standard.

54 4. Coupling: Rubber tyre spacer (Fenner / Flander)

55 5. Motor to be IE3 and cast iron body. Motor brand accepted is ABB, Siemens, Brook Crompton and Teco.

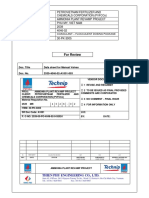

Rev. DESCRIPTION NAME NAME NAME Date

0 Issue for enquiry PREPARED Ashton Choon REVIEWED Ms Khong / Mr Ji APPROVED 29/04/2024

Q "= uA

r= 0.0508 m

A= 0.0081083709

Q= 0.0162167418 m3/s

58.380270336 m3/hr

49623.229786

You might also like

- TCV 205 BFV DatasheetDocument1 pageTCV 205 BFV DatasheetSardar PerdawoodNo ratings yet

- CSC134 (Past Year)Document7 pagesCSC134 (Past Year)muhammad haziq100% (1)

- Handbook Alcad Accu PDFDocument145 pagesHandbook Alcad Accu PDFsybinh97100% (1)

- 2EH Tank (EOS Tank Farm) To ESE 122R01Document3 pages2EH Tank (EOS Tank Farm) To ESE 122R01Choon Zhe ShyiNo ratings yet

- 95-P-01, 95-P-02, 93-P-03AB DatasheetDocument12 pages95-P-01, 95-P-02, 93-P-03AB DatasheetChoon Zhe ShyiNo ratings yet

- Air Heater Process Data Sheet: Design Conditions Shell SideDocument4 pagesAir Heater Process Data Sheet: Design Conditions Shell SideAnonymous tDeb8M0SyNo ratings yet

- Data Sheet of High Pressure PumpDocument2 pagesData Sheet of High Pressure Pumpsajeesh5113699No ratings yet

- PM-2491 AB FINAL - Documentation PDFDocument260 pagesPM-2491 AB FINAL - Documentation PDFEnder ZenginobuzNo ratings yet

- Microfinish Pump DataDocument2 pagesMicrofinish Pump DataPraveen PrajapatiNo ratings yet

- Data Sheet GS4 80-400-438 B 37Document4 pagesData Sheet GS4 80-400-438 B 37arshin wildanNo ratings yet

- Hump Hydraulics CalculationsDocument13 pagesHump Hydraulics CalculationsrutujaNo ratings yet

- Enerflex-041620 RFQ LN 42-PCV-0034 Rev 4 Vendor's DSDocument4 pagesEnerflex-041620 RFQ LN 42-PCV-0034 Rev 4 Vendor's DSHamza ShujaNo ratings yet

- CH-RA3 Page 2Document1 pageCH-RA3 Page 2Sonya LoveraNo ratings yet

- Data Sheet GS 125-400 75Document4 pagesData Sheet GS 125-400 75phuong.dinh310891No ratings yet

- Mtu Engine Model 20V4000G63L A. LT CIRCUIT (410 KW@ 30 M /HR) Heat Exchanger: Gl-13Lx36 Duty RequirementsDocument4 pagesMtu Engine Model 20V4000G63L A. LT CIRCUIT (410 KW@ 30 M /HR) Heat Exchanger: Gl-13Lx36 Duty RequirementsbaljeetjatNo ratings yet

- Control Valve Specification Sheet - PCV 3inch 600# R 1Document1 pageControl Valve Specification Sheet - PCV 3inch 600# R 1FIRMANSYAHNo ratings yet

- Data Sheet 150X125 FSS4KC 5 37 HDocument4 pagesData Sheet 150X125 FSS4KC 5 37 HPakin SornNo ratings yet

- Data SpesitxfikasiDocument4 pagesData Spesitxfikasidede rizkiNo ratings yet

- Bab Iv Gambaran Umum Objek PenetianDocument7 pagesBab Iv Gambaran Umum Objek PenetiansahawadiNo ratings yet

- bp3d CimmDocument17 pagesbp3d Cimmkuntasee.duckNo ratings yet

- Data Sheet GS 80-200 30Document4 pagesData Sheet GS 80-200 30Sumet ZackkungNo ratings yet

- Technical Data: MPD100A/06A/BE2500/W25VRRR4Document3 pagesTechnical Data: MPD100A/06A/BE2500/W25VRRR4ahmdabdelaziz997No ratings yet

- Data Sheet 3D 40-160 4.0Document6 pagesData Sheet 3D 40-160 4.0Gokula Krishnan CNo ratings yet

- Samson Valve Specification: Process DataDocument49 pagesSamson Valve Specification: Process DataMuhammed TamerNo ratings yet

- Ebara 3PF 32-160 PDFDocument6 pagesEbara 3PF 32-160 PDFEddie GuillénNo ratings yet

- Technical Data: MPA50B/08B/BD450/L25VCCC4Document3 pagesTechnical Data: MPA50B/08B/BD450/L25VCCC4Abdulraheem SalmanNo ratings yet

- 2539 4046 02 A1001 003 - Datasheet For Manual Valve - Rev ADocument8 pages2539 4046 02 A1001 003 - Datasheet For Manual Valve - Rev ANguyễn ThựcNo ratings yet

- Mtu Engine Model 12V4000G23 A. LT CIRCUIT (200 KW at 29 M /HR) Heat Exchanger: Gl-13Lx22 Duty RequirementsDocument4 pagesMtu Engine Model 12V4000G23 A. LT CIRCUIT (200 KW at 29 M /HR) Heat Exchanger: Gl-13Lx22 Duty RequirementsbaljeetjatNo ratings yet

- Ed0581b-1639e 01 Ap1Document5 pagesEd0581b-1639e 01 Ap1Erol DAĞNo ratings yet

- Ad-030 94343Document3 pagesAd-030 94343ibrahim salemNo ratings yet

- 150x125 FS4LA 5 45 - 50HzDocument5 pages150x125 FS4LA 5 45 - 50Hzhoàng đình sơnNo ratings yet

- Data Sheet 3LP 40-200 116Document6 pagesData Sheet 3LP 40-200 116Marissa MoránNo ratings yet

- Mtu Engine Model12V4000G63 A. LT CIRCUIT (260 KW at 29 M /HR) Heat Exchanger: Gl-13Lx24 Duty RequirementsDocument4 pagesMtu Engine Model12V4000G63 A. LT CIRCUIT (260 KW at 29 M /HR) Heat Exchanger: Gl-13Lx24 Duty RequirementsbaljeetjatNo ratings yet

- WFI Plant Cooling Water Exchanger PHEDocument2 pagesWFI Plant Cooling Water Exchanger PHEdaniyalahmad119No ratings yet

- Fire Pump From 7. FC - Fix EquipmentDocument1 pageFire Pump From 7. FC - Fix EquipmentIlyas Rangga RamadhanNo ratings yet

- Data - Sheet Hora CV Act DetailsDocument2 pagesData - Sheet Hora CV Act DetailsAnand K. MouryaNo ratings yet

- Ficha Técnica Bomba Ebara 3M 50-160 - 156 (No Incluye Motor)Document6 pagesFicha Técnica Bomba Ebara 3M 50-160 - 156 (No Incluye Motor)Miguel Ignacio YarangaNo ratings yet

- Data - Sheet - 3SFH - 40-160 - 4.0 - SINGLE PUMPDocument6 pagesData - Sheet - 3SFH - 40-160 - 4.0 - SINGLE PUMPMinaShokryNo ratings yet

- Z10150 1/1C-L6C SD: Operating DataDocument3 pagesZ10150 1/1C-L6C SD: Operating DataDerkung BenowatNo ratings yet

- Data Sheet 3D 40-160 3.0Document6 pagesData Sheet 3D 40-160 3.0phuong.dinh310891No ratings yet

- UN3C-T 3M 40-160. 4.0 Booster Pump CatalogueDocument16 pagesUN3C-T 3M 40-160. 4.0 Booster Pump CatalogueFILID MADNo ratings yet

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocument4 pagesSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINo ratings yet

- Data Sheet 3D 40-125 4.06Document6 pagesData Sheet 3D 40-125 4.06Cristopher Jimenez JaramilloNo ratings yet

- Control Valve Specification Sheet ISMAEL CABALLERODocument1 pageControl Valve Specification Sheet ISMAEL CABALLERORodrigoNo ratings yet

- DuraCirc 53 Hi-Flow Horizontal Bottom Tech SpecDocument3 pagesDuraCirc 53 Hi-Flow Horizontal Bottom Tech SpecDiego BorgesNo ratings yet

- Control Valve Specification Sheet - LCV 2inch 600# R 1Document1 pageControl Valve Specification Sheet - LCV 2inch 600# R 1FIRMANSYAHNo ratings yet

- 90 m3 at 105 Mtrs - Bore WellDocument3 pages90 m3 at 105 Mtrs - Bore WellHossein ForouzanNo ratings yet

- EIL Data Sheet TemplateDocument2 pagesEIL Data Sheet Templatebaladharan05No ratings yet

- 10.... 50 DS51.5Document4 pages10.... 50 DS51.5tinhNo ratings yet

- Data Sheet 3M 32-160 4.06Document6 pagesData Sheet 3M 32-160 4.06Edilberto Alegato (EPPI)No ratings yet

- 1-Fisher Specification and Sizing Sheets - RevCDocument3 pages1-Fisher Specification and Sizing Sheets - RevCheikelNo ratings yet

- Ebara 90M3H@39M 100X80 FSS2GC 5 15KWDocument4 pagesEbara 90M3H@39M 100X80 FSS2GC 5 15KWtrungNo ratings yet

- Samson 24-03-20 - 001 - IQ24-0082 - Typ 3241-7 - Ciadana Raya Chemicals - ISASheetDocument2 pagesSamson 24-03-20 - 001 - IQ24-0082 - Typ 3241-7 - Ciadana Raya Chemicals - ISASheetdeath noteNo ratings yet

- CrudoDocument2 pagesCrudoAndrés Felipe TáutivaNo ratings yet

- Control Valve Specification SheetDocument1 pageControl Valve Specification SheetJuan Krloz CastañedaNo ratings yet

- Control Valve Specification Sheet: Fisher 2 Inches, Fisher 2 Inches, None,, Globe NPS 1/2 CL150 Fisher/24000SBDocument2 pagesControl Valve Specification Sheet: Fisher 2 Inches, Fisher 2 Inches, None,, Globe NPS 1/2 CL150 Fisher/24000SBJavier LopezNo ratings yet

- Data Sheet of Filtered WaterCentrifugal PumpDocument2 pagesData Sheet of Filtered WaterCentrifugal Pumpsajeesh5113699No ratings yet

- Technical Specification 2 1 - 0 0 0 3 - 2 3 1 R e V - 0Document7 pagesTechnical Specification 2 1 - 0 0 0 3 - 2 3 1 R e V - 0Chakravarthy BharathNo ratings yet

- Description Value: Printed From Grundfos CAPSDocument5 pagesDescription Value: Printed From Grundfos CAPSDima ArfNo ratings yet

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsFrom EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsRating: 5 out of 5 stars5/5 (1)

- 2EHP Process Duration (180124-060224)Document4 pages2EHP Process Duration (180124-060224)Choon Zhe ShyiNo ratings yet

- Nitrogen Blanketing System - Breather Valve Data SheetDocument5 pagesNitrogen Blanketing System - Breather Valve Data SheetChoon Zhe ShyiNo ratings yet

- ESE Bleacher - Level Transmitter RFQ (30-4-2024)Document1 pageESE Bleacher - Level Transmitter RFQ (30-4-2024)Choon Zhe ShyiNo ratings yet

- ESE Bleacher 122V22 - Level Transmitter RFQ (30-4-2024)Document1 pageESE Bleacher 122V22 - Level Transmitter RFQ (30-4-2024)Choon Zhe ShyiNo ratings yet

- 2EHP Production Cycle Time Report (April 2024)Document8 pages2EHP Production Cycle Time Report (April 2024)Choon Zhe ShyiNo ratings yet

- MEF Pump Spec SummaryDocument1 pageMEF Pump Spec SummaryChoon Zhe ShyiNo ratings yet

- Adiabatic CoolingDocument10 pagesAdiabatic CoolingChoon Zhe ShyiNo ratings yet

- Rubber Analysis With PerkinElmer TGA 8000Document3 pagesRubber Analysis With PerkinElmer TGA 8000Choon Zhe ShyiNo ratings yet

- Pump Head Calculation - Waste Water PumpDocument8 pagesPump Head Calculation - Waste Water PumpChoon Zhe ShyiNo ratings yet

- POLYVEST HT enDocument4 pagesPOLYVEST HT enChoon Zhe ShyiNo ratings yet

- SCN Lsuk Lsa.22 088 L Fairmont Bs7188 MyDocument1 pageSCN Lsuk Lsa.22 088 L Fairmont Bs7188 MyChoon Zhe ShyiNo ratings yet

- Ecolastic EPDM Granules - Abestos - 19082022Document4 pagesEcolastic EPDM Granules - Abestos - 19082022Choon Zhe ShyiNo ratings yet

- Ollital Quotation ZG-160YRD Manual Type (Lab Open Mill)Document3 pagesOllital Quotation ZG-160YRD Manual Type (Lab Open Mill)Choon Zhe ShyiNo ratings yet

- Analysis of Rubber Without Using Instrument - 28 Sept 2022Document54 pagesAnalysis of Rubber Without Using Instrument - 28 Sept 2022Choon Zhe ShyiNo ratings yet

- FYP 2 Submission ChecklistDocument2 pagesFYP 2 Submission ChecklistChoon Zhe ShyiNo ratings yet

- EURECA Paper TemplateDocument4 pagesEURECA Paper TemplateChoon Zhe ShyiNo ratings yet

- Detail DesignDocument108 pagesDetail DesignChoon Zhe ShyiNo ratings yet

- Textiles - Tests For Colour FastnessDocument10 pagesTextiles - Tests For Colour FastnessChoon Zhe ShyiNo ratings yet

- Polymers: Brief Overview On Bio-Based Adhesives and SealantsDocument20 pagesPolymers: Brief Overview On Bio-Based Adhesives and SealantsChoon Zhe ShyiNo ratings yet

- Polymers: Lignin-Based Polyurethanes: Opportunities For Bio-Based Foams, Elastomers, Coatings and AdhesivesDocument21 pagesPolymers: Lignin-Based Polyurethanes: Opportunities For Bio-Based Foams, Elastomers, Coatings and AdhesivesChoon Zhe ShyiNo ratings yet

- Surfaces 03 00042 v2Document27 pagesSurfaces 03 00042 v2Choon Zhe ShyiNo ratings yet

- Pneu Portable ChairDocument3 pagesPneu Portable ChairblessyNo ratings yet

- Electronic Ignition Lock (EIS), Component DescriptionDocument2 pagesElectronic Ignition Lock (EIS), Component DescriptionrudiNo ratings yet

- EN DX17Z Brochure D4600110 07-2019 LowResDocument8 pagesEN DX17Z Brochure D4600110 07-2019 LowResTarandeep KaurNo ratings yet

- Tokyo Keiki IncDocument4 pagesTokyo Keiki Incarlindojl0% (1)

- The Future of Branch Banking in A Digital WorldDocument6 pagesThe Future of Branch Banking in A Digital WorldMohammad NayeemNo ratings yet

- Large Dry Chemical Fire Suppression Systems: AnsulDocument8 pagesLarge Dry Chemical Fire Suppression Systems: AnsulLogan Marquez AguayoNo ratings yet

- As 2054-1977 Spirit Levels For Use in Precision EngineeringDocument7 pagesAs 2054-1977 Spirit Levels For Use in Precision EngineeringSAI Global - APACNo ratings yet

- Presentation 1Document30 pagesPresentation 1Adil RazzaqNo ratings yet

- Fluids Test: Multiple ChoiceDocument2 pagesFluids Test: Multiple Choicesobre1982100% (1)

- Parameters and ArgumentsDocument29 pagesParameters and Argumentslashanj2No ratings yet

- Description: Princeton Technology Corp. PT2395Document4 pagesDescription: Princeton Technology Corp. PT2395Виталий ИвановNo ratings yet

- Modern Techniques For Protecting and Monitoring of Transmission LinesDocument203 pagesModern Techniques For Protecting and Monitoring of Transmission LinesSrinivasan Srini100% (2)

- Expansive Soils. by Lee D Jones, British Geological Survey Ian Jefferson, School of Civil Engineering, University of BirminghamDocument3 pagesExpansive Soils. by Lee D Jones, British Geological Survey Ian Jefferson, School of Civil Engineering, University of BirminghamCharan Tej RudralaNo ratings yet

- TrerwtDocument154 pagesTrerwtvinicius gomes duarteNo ratings yet

- 1 Base SAS Training 12th May 2015Document494 pages1 Base SAS Training 12th May 2015Vedavathy TCNo ratings yet

- Cold Work Permit Hse-PtwDocument2 pagesCold Work Permit Hse-PtwHSE S480% (10)

- Escrick Park Application Form - YDRC MembersDocument1 pageEscrick Park Application Form - YDRC MembersHannah HamiltonNo ratings yet

- ANSI-IsA-12.20.01-2009 - General Requirements For Electrical Ignition Systems For Internal Combustion Engines in Class I, Division 2 or Zone 2, Hazardous Classified) LocationsDocument38 pagesANSI-IsA-12.20.01-2009 - General Requirements For Electrical Ignition Systems For Internal Combustion Engines in Class I, Division 2 or Zone 2, Hazardous Classified) LocationsZhuowen LiNo ratings yet

- GAF SS 805 Instruction ManualDocument25 pagesGAF SS 805 Instruction Manualvmarcenne100% (2)

- Using The Calendar File in Short-Term Scheduling in GEOVIA MinexDocument4 pagesUsing The Calendar File in Short-Term Scheduling in GEOVIA MinexKorchak JohnNo ratings yet

- Hatco FSHC Flav R SavorDocument2 pagesHatco FSHC Flav R Savorwsfc-ebayNo ratings yet

- Phoenix Book To OrderDocument2 pagesPhoenix Book To OrderDvy D. VargasNo ratings yet

- Unit Electrical Installations To Buildings: StructureDocument44 pagesUnit Electrical Installations To Buildings: StructureKosygin LeishangthemNo ratings yet

- VisualAge PLI Programming Guide Ver 2.1Document587 pagesVisualAge PLI Programming Guide Ver 2.1neokci100% (1)

- Specification For Base PaperDocument3 pagesSpecification For Base PapervenkNo ratings yet

- Shatru ko Haraane ke Behtarin Totke Upay शतर् ुको हरान ेक ेबहेतरीन टोटक ेउपाय Spells to Defeat Enemies Jagran Today Knowlege and Information Sharing in Hindi and English Haryanvi Masti Hindi BlogDocument50 pagesShatru ko Haraane ke Behtarin Totke Upay शतर् ुको हरान ेक ेबहेतरीन टोटक ेउपाय Spells to Defeat Enemies Jagran Today Knowlege and Information Sharing in Hindi and English Haryanvi Masti Hindi Blogajay bhatnagar0% (1)

- 739686Document2 pages739686bluebird1969100% (1)

- Shenzhen RJC Industrial Co., LTDDocument39 pagesShenzhen RJC Industrial Co., LTDyou liangNo ratings yet