5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0

5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0

Uploaded by

Msach RoysCopyright:

Available Formats

5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0

5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0

Uploaded by

Msach RoysOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0

5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0

Uploaded by

Msach RoysCopyright:

Available Formats

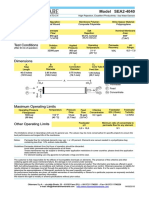

NE8040-ARM50

Acid Resistant NF Membrane

SPECIFICATIONS:

General Permeate flow rate1 : 7,000 GPD (26.5 m3/day)

Features MgSO4 rejection 1 : 99.0%

CaCl2 rejection 2 : 85 - 95%

Effective membrane area: 400 ft2 (37.2 m2)

1. The stated product performance is based on data taken after 30 minutes of operation at the following

test conditions:

• 2,000 mg/L MgSO4 solution at 75 psig (0.52 MPa) applied pressure

• 15% recovery

• 77 oF (25 oC)

• pH 6.5–7.0

2. The stated product performance is based on data taken after 30 minutes of operation at the following

test conditions:

• 500 mg/L CaCl2 solution at 75 psig (0.52 MPa) applied pressure

• 15% recovery

• 77 oF (25 oC)

• pH 6.5–7.0

3. Minimum MgSO4 rejection is 98%.

4. Permeate flow rate for each element may vary +30 / -15%.

5. Elements are supplied as dry-type. Dry elements are sealed in a poly bag and individually boxed.

Membrane type: Thin-Film Composite

Membrane material: Polyamide (PA)

Element configuration: Spiral-Wound, FRP Wrapping

Dimensions Part Number

and Model Name A B C Weight

Weight Inter-connector Brine Seal

40.0 inch 7.9 inch 1.12 inch

NE8040-ARM50 15 kg SWA01049 SWA01043

(1,016 mm) (200 mm) (28.5 mm)

1. Each membrane element supplied with one brine seal, one interconnector (coupler) and four o-rings.

2. All NE8040 elements fit nominal 8.0 inch (203.2 mm) I.D. pressure vessels.

The information provided in this document is solely for informative purposes. It is the user’s responsibility to ensure

the appropriate usage of this product. Toray Advanced Materials Korea Inc. assumes no obligation, liability or damages

incurred for the misuse of the product or for the information provided in this document. This document does not

express or implies any warranty as to the merchantability or fitness of the product.

Toray Advanced Materials Korea Inc.

For more information on our products, company and regional contacts, please visit our website at www.csmfilter.com.

Product Specification Sheet / Model NE8040-ARM50

Page 1 of 2 Rev.1.0 March 2020

NE8040-ARM50

Acid Resistant NF Membrane

APPLICATION DATA:

Operating Limits · Max. Pressure Drop / Element 15 psi (0.1 MPa)

· Max. Pressure Drop / 240” Vessel 60 psi (0.41 Mpa)

· Max. Operating Pressure 600 psi (4.14 MPa)

· Max. Feed Flow Rate 75 gpm (17.0 m3/hr)

· Min. Concentrate Flow Rate 16 gpm (3.6 m3/hr)

· Max. Operating Temperature 113 oF (45 oC)

· Operating pH Range 3.0–10.0

· CIP pH Range 2.0–11.0

· Max. Turbidity 1.0 NTU

· Max. SDI (15 min) 5.0

· Max. Chlorine Concentration < 0.05 mg/L

Design Guidelines for Various · Wastewater Conventional (SDI < 5) 8–12 gfd

Water Sources · Wastewater Pretreated by UF/MF (SDI < 3) 10–14 gfd

· Seawater, Open Intake (SDI < 5) 7–10 gfd

· Seawater, Beach Well (SDI < 3) 8–12 gfd

· Surface Water (SDI < 5) 12–16 gfd

· Surface Water (SDI < 3) 13–17 gfd

· Well water (SDI < 3) 13–17 gfd

· RO permeate (SDI < 1) 21–30 gfd

Saturation Limits · Langlier Saturation Index (LSI) <+1.5

(Using Antiscalants)† · Stiff and Davis Saturation Index (SDSI) <+0.5

· CaSO4 230% saturation

· SrSO4 800% saturation

· BaSO4 6,000% saturation

· SiO2 100% saturation

†

The above saturation limits are typically accepted by proprietary antiscalant

manufacturers. It is the user’s responsibility to ensure proper chemical(s) and

concentration are dosed ahead of the membrane system to prevent scale

formation anywhere within the membrane system. Membrane elements fouled

or damaged due to scale formation are not covered by the limited warranty.

GENERAL HANDLING PROCEDURES

Elements contained in the boxes must be kept dry at Keep elements moist at all times after initial wetting.

room temperature (7–32°C; 40–95°F) and should not be

Avoid excessive pressure and flow spikes.

stored in direct sunlight.

Only use chemicals compatible with the membrane

Permeate from the first hour of operation should be

elements and components. Use of such chemicals may

discarded to flush out the preservative solution. void the element limited warranty.

Used elements should be immersed in a preservative

Permeate pressure must always be equal or less than the

solution during storage, shipping and system shutdowns feed/concentrate pressure. Damage caused by permeate

to prevent biological growth and freezing. The standard back pressure voids the element limited warranty.

storage solution contains 1% by weight sodium bisulfite or

sodium metabisulfite (food grade). For short term storage

(i.e. one week or less) 1% by weight sodium metabisulfite

solution is adequate for preventing biological growth.

Toray Advanced Materials Korea Inc.

For more information on our products, company and regional contacts, please visit our website at www.csmfilter.com.

Product Specification Sheet / Model NE8040-ARM50

Page 2 of 2 Rev.1.0 March 2020

You might also like

- Runxin F77B1 Automatic Filter ValveDocument2 pagesRunxin F77B1 Automatic Filter ValveMsach RoysNo ratings yet

- Fo Analysis Reports Prabhu YuvikaDocument17 pagesFo Analysis Reports Prabhu YuvikaSumit ChandwaniNo ratings yet

- Production of Phthalic Anhydride From O-XyleneDocument216 pagesProduction of Phthalic Anhydride From O-XyleneoleputoNo ratings yet

- WorkingfactoriesDocument397 pagesWorkingfactorieskachappilly2012No ratings yet

- 4-1. NE8040-HRM - 200311 - LHK - Ver 1.0Document2 pages4-1. NE8040-HRM - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 1-1. NE8040-40 - 200311 - LHK - Ver 1.0Document2 pages1-1. NE8040-40 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 5-2. NE4040-ARM50 - 200311 - LHK - Ver 1.0Document2 pages5-2. NE4040-ARM50 - 200311 - LHK - Ver 1.0Msach RoysNo ratings yet

- 3-1. NE8040-90 - 200311 - LHK - Ver 1.0Document2 pages3-1. NE8040-90 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Re8040-Br400 - 190312 - PMKDocument2 pagesRe8040-Br400 - 190312 - PMKMsach RoysNo ratings yet

- 4-2. NE4040-HRM - 200311 - LHK - Ver 1.0Document2 pages4-2. NE4040-HRM - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Re8040-Be - 190312Document2 pagesRe8040-Be - 190312Willy ChandraNo ratings yet

- 2-1. NE8040-70 - 200311 - LHK - Ver 1.0Document2 pages2-1. NE8040-70 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 1-2. NE4040-40 - 200311 - LHK - Ver 1.0Document2 pages1-2. NE4040-40 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- RE16040-BE - 200907 - HSHDocument2 pagesRE16040-BE - 200907 - HSHMsach RoysNo ratings yet

- 2-2. NE4040-70 - 200311 - LHK - Ver 1.0Document2 pages2-2. NE4040-70 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Ne4040 SRMDocument2 pagesNe4040 SRMMsach RoysNo ratings yet

- Re8040-Ce - 190312 - PMKDocument2 pagesRe8040-Ce - 190312 - PMKMsach RoysNo ratings yet

- Re2540-Blf 171201Document2 pagesRe2540-Blf 171201LưuVănViếtNo ratings yet

- CSM Re8040 SHN LDocument2 pagesCSM Re8040 SHN LSundari RaviNo ratings yet

- Membrane UnitDocument2 pagesMembrane UnitFauzyNo ratings yet

- Correos Electrónicos CSM-RE2521-BLN-LDocument2 pagesCorreos Electrónicos CSM-RE2521-BLN-LNahum Cesar Hernandez SorianoNo ratings yet

- Nano SW MaxDocument1 pageNano SW Maxfelipe RezendeNo ratings yet

- Sea2 4040 PDFDocument1 pageSea2 4040 PDFMd. Suruz ZamanNo ratings yet

- Datasheet LG SW 400 SR G2 ENGDocument1 pageDatasheet LG SW 400 SR G2 ENGMohamed MotaweaNo ratings yet

- OltremareDocument1 pageOltremareAfraz ShaikhNo ratings yet

- LG SW 440 SRDocument1 pageLG SW 440 SRkylealamangoNo ratings yet

- Datasheet LG BW 400 R Dura ENGDocument1 pageDatasheet LG BW 400 R Dura ENGSaul RosalesNo ratings yet

- Esna1 LF2 LD 4040Document1 pageEsna1 LF2 LD 4040Soledad OrtegaNo ratings yet

- SE20Document5 pagesSE20seyedmajidgNo ratings yet

- Membrane LG CW 4040 SFDocument1 pageMembrane LG CW 4040 SFPT Deltapuro IndonesiaNo ratings yet

- D&M Technical Spec SSD-1X - BNDocument18 pagesD&M Technical Spec SSD-1X - BNMarc LefrancqNo ratings yet

- Signet 2536 Rotor-X Paddlewheel Flow SensorsDocument6 pagesSignet 2536 Rotor-X Paddlewheel Flow SensorsMETHOR SERVICE GROUPNo ratings yet

- Data Sheet: LG SW 4040 RDocument1 pageData Sheet: LG SW 4040 RAcquetech AcquetechNo ratings yet

- System ManualDocument14 pagesSystem ManualCareers SSPNo ratings yet

- Model 500-600 Series II (FM-1280 Rev.A)Document6 pagesModel 500-600 Series II (FM-1280 Rev.A)Carlos Miguel LópezNo ratings yet

- Membrane LG BW 400RDocument1 pageMembrane LG BW 400RPT Deltapuro IndonesiaNo ratings yet

- Shimadzu Tmp-3403Document5 pagesShimadzu Tmp-3403Hitendra HasalparaNo ratings yet

- Flow SensorDocument8 pagesFlow SensorAchmad Nuriel AnwarNo ratings yet

- Data Sheet: LG BW 400 EsDocument1 pageData Sheet: LG BW 400 EsZi Wei LeongNo ratings yet

- SWC4 MaxDocument1 pageSWC4 MaxaltayehmNo ratings yet

- Datasheet LG MaxRO R ENGDocument1 pageDatasheet LG MaxRO R ENGAhmed GomaaNo ratings yet

- 550series - HydraustarDocument8 pages550series - HydraustarvijaykumarnNo ratings yet

- Datos Tecnicos FlujometroDocument4 pagesDatos Tecnicos FlujometroJuverCupeNo ratings yet

- LG SW 440 GRDocument1 pageLG SW 440 GRkylealamangoNo ratings yet

- RDDA Es Metric A4Document1 pageRDDA Es Metric A4Daniel GómezNo ratings yet

- Brochure Spark H2ODocument4 pagesBrochure Spark H2OEder LopesNo ratings yet

- RELITE 3AS - Strongly Basic ResinDocument2 pagesRELITE 3AS - Strongly Basic ResinPanca Erlangga SiregarNo ratings yet

- GSX-431 GSX-431: 4.0 X 2.5mm SM Crystal For 4.0 X 2.5mm SM Crystal For Bluetooth / Wireless Bluetooth / WirelessDocument6 pagesGSX-431 GSX-431: 4.0 X 2.5mm SM Crystal For 4.0 X 2.5mm SM Crystal For Bluetooth / Wireless Bluetooth / WirelessMikeDonovanNo ratings yet

- Data Sheet: LG BW 4040 EsDocument1 pageData Sheet: LG BW 4040 EsAcquetech AcquetechNo ratings yet

- Membrane Element SWC - 2540: PerformanceDocument1 pageMembrane Element SWC - 2540: PerformanceAshish GulrandheNo ratings yet

- Iso 8217 2017Document7 pagesIso 8217 2017MiletzyNo ratings yet

- Nap-Gard 7-2500 PDFDocument2 pagesNap-Gard 7-2500 PDFPietro ViganNo ratings yet

- Mini Gaskleen High-Flow Filter Assemblies: DescriptionDocument2 pagesMini Gaskleen High-Flow Filter Assemblies: Description3DP HelloNo ratings yet

- BQUA - Swc5 MaxDocument1 pageBQUA - Swc5 MaxBassemNo ratings yet

- MDM6000 DGP DAP Intelligent Differential Pressure Mounted GaugeDocument11 pagesMDM6000 DGP DAP Intelligent Differential Pressure Mounted GaugeMohammad Reza HasanpourNo ratings yet

- Electrodes For Hollow Perforated ElectrodesDocument14 pagesElectrodes For Hollow Perforated ElectrodesPraful N KNo ratings yet

- Flow MeterDocument16 pagesFlow Metertrancongphuong.elecNo ratings yet

- Gatekeeper Gpu Ix Media Gas Purifiers 10961Document7 pagesGatekeeper Gpu Ix Media Gas Purifiers 10961KGC SaintifikNo ratings yet

- SGA-09 CatalogueDocument4 pagesSGA-09 Cataloguegiteshshah.projectNo ratings yet

- First POE - TF4 TF8Document6 pagesFirst POE - TF4 TF8Shashwata ChattopadhyayNo ratings yet

- Microdyn BWRO-1Document2 pagesMicrodyn BWRO-1Rogerio SilvaNo ratings yet

- Understanding Membrane Distillation and Osmotic DistillationFrom EverandUnderstanding Membrane Distillation and Osmotic DistillationNo ratings yet

- Spindo Brochure - Ornamental TubesDocument8 pagesSpindo Brochure - Ornamental TubesMsach RoysNo ratings yet

- Spindo Brochure - Industrial PipesDocument8 pagesSpindo Brochure - Industrial PipesMsach RoysNo ratings yet

- GM GB Diaphragm Dosing PumpDocument6 pagesGM GB Diaphragm Dosing PumpMsach RoysNo ratings yet

- Re8040-Ce - 190312 - PMKDocument2 pagesRe8040-Ce - 190312 - PMKMsach RoysNo ratings yet

- ProspectusDocument29 pagesProspectusdmomsdNo ratings yet

- Virtual Reality Technology Applied in Teaching and Research in Civil Engineering EducationDocument12 pagesVirtual Reality Technology Applied in Teaching and Research in Civil Engineering EducationSEP-PublisherNo ratings yet

- IGS NT Installation Guide 08 2018 r3Document149 pagesIGS NT Installation Guide 08 2018 r3Jhonattan Hugo Portugal MorunoNo ratings yet

- KentDocument42 pagesKentwddrfNo ratings yet

- SG 242105Document556 pagesSG 242105aicihakeruNo ratings yet

- CommonDocument78 pagesCommonAnon AnonNo ratings yet

- Rubber Roller DesignDocument20 pagesRubber Roller DesignGaneshNo ratings yet

- Statistics First Year Intitial PracticalDocument3 pagesStatistics First Year Intitial PracticalAlexa LeachNo ratings yet

- Approved Vendor ListDocument2 pagesApproved Vendor Listcutty54No ratings yet

- PDF Diagrama Electrico Del Motor DLDocument16 pagesPDF Diagrama Electrico Del Motor DLNacho Akiba-keiNo ratings yet

- Lesson 4 Analyzing The Structure: SolidworksDocument21 pagesLesson 4 Analyzing The Structure: SolidworksAdar OsNo ratings yet

- Alton SN CatalogDocument29 pagesAlton SN Catalogrobertoperez525No ratings yet

- E1030-00 Examination of Metallic Castings-Radiography PDFDocument11 pagesE1030-00 Examination of Metallic Castings-Radiography PDFShrinath BhatNo ratings yet

- Load - Frequency Control (Automatic Generation Control) : Chapter-1Document19 pagesLoad - Frequency Control (Automatic Generation Control) : Chapter-1BhanuNo ratings yet

- Affect of Subgrade Soils On Pavement DesignDocument29 pagesAffect of Subgrade Soils On Pavement DesignRenugopalNo ratings yet

- Regulador 5 - 3,3V LD1117 Home Sony PDFDocument44 pagesRegulador 5 - 3,3V LD1117 Home Sony PDFErnandesTorresBarbosaNo ratings yet

- Checklist For Control Room BackfillingDocument1 pageChecklist For Control Room BackfillingRupesh KhandekarNo ratings yet

- AM12 Appliance ModuleDocument26 pagesAM12 Appliance ModuleMiguel Ángel Nieto MeralNo ratings yet

- Making Plastic BallsDocument6 pagesMaking Plastic Ballsforthework301No ratings yet

- Post Tensioning in Building StructuresDocument25 pagesPost Tensioning in Building StructuresBaranitharan ANo ratings yet

- The Science Company® Material Safety Data Sheet: 1. Product and Company IdentificationDocument4 pagesThe Science Company® Material Safety Data Sheet: 1. Product and Company IdentificationjeriNo ratings yet

- Antlr PDFDocument37 pagesAntlr PDFDinoop P0% (1)

- Perhitungan Magnesium AnodeDocument2 pagesPerhitungan Magnesium AnodeAndre KurniawanNo ratings yet

- Earth RammersDocument2 pagesEarth RammersLin LeninNo ratings yet

- Electron Beam Crosslinking TechnologyDocument14 pagesElectron Beam Crosslinking TechnologyChaitanya ShakyaNo ratings yet

- Service Information Letter (Horizonte PN 1180) 2006-006R1Document4 pagesService Information Letter (Horizonte PN 1180) 2006-006R1Biblioteca Brasil AviationNo ratings yet

- 5-Single Station CellsDocument21 pages5-Single Station CellsManoesh JohnNo ratings yet

- Effort Distribution On Waterfall and AgileDocument12 pagesEffort Distribution On Waterfall and Agileanandapramanik100% (2)