Correos Electrónicos CSM-RE2521-BLN-L

Correos Electrónicos CSM-RE2521-BLN-L

Uploaded by

Nahum Cesar Hernandez SorianoCopyright:

Available Formats

Correos Electrónicos CSM-RE2521-BLN-L

Correos Electrónicos CSM-RE2521-BLN-L

Uploaded by

Nahum Cesar Hernandez SorianoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Correos Electrónicos CSM-RE2521-BLN-L

Correos Electrónicos CSM-RE2521-BLN-L

Uploaded by

Nahum Cesar Hernandez SorianoCopyright:

Available Formats

Lenntech

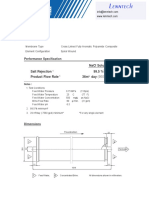

RE 2521-B L N

Low pressure grade RO element for brackish water

info@lenntech.com Tel. +31-152-610-900

www.lenntech.com Fax. +31-152-616-289

SPECIFICATIONS :

General Permeate flow rate: 300 GPD ( 1.1 m3/day)

Features Stabilized salt r ejection: 99.2%

Effective m embrane area: 12 ft2 (1.1 m2)

1. The stated product performance is based on data taken after 30 minutes of operationat the following

test conditions:

• 1,500 mg/L NaCl solution at 150 psig ( 1.0 MPa) applied pressure

• 15% recovery

• 77 o F (25 o C)

• pH 6.5 –7.0

2. Minimum salt rejection is 99.0%.

3. Permeate flow rate for each element may vary but will be no more than 15%.

4. All elements are vacuum sealed in a polyethylene bag containing 1.0% SBS (sodium bisulfite) solution and

individuallypackaged in a cardboard box.

Membrane type: Thin-Film Composite

Membrane m aterial: Polyamide(PA)

Element configuration: Spiral-Wound, FRP W rapping

Dimensions

Part Number

Model Name A B C D E Inter -

Brine Seal

connector

21.0 inch 2.5 inch 0.75 inch 1.1 inch 1.1 inch

RE 2521 -BLN 40000305 40000223

(534 mm) (64 mm) (19.1 mm) (28 mm) (28 mm)

1. Each membrane elementsuppliedwith one brine seal, one interconnector (coupler) and four o-rings.

2. All RE2521 elementsfit nominal2.5 inch (64 mm) I.D. pressure vessels.

The information provided in this document is solely for informative pu

rposes. It is the user’s responsibility to ensure the

appropriate usage of this product.Woongjin Chemical assumes no obligation, liability or damages incurred for the

misuse of the product or for the information provided in this document.This document does not express or implies any

warranty as to the merchantability or fitness of the product.

RE25 21-BLN

Low pressure grade RO element for brackish water

APPLICATION DATA :

Operating Limits · Max. Pressure Drop / Element 15 psi (0.1 MPa)

· Max. Pressure Drop / 240” Vessel 60 psi (0.41 Mpa)

· Max. O peratingPressure 600 psi (4.14 MPa)

· Max. Feed Flow Rate 6 gpm (1.36 m3/hr)

· Min. C oncentrate Flow Rate 1 gpm (0.23 m3/hr)

· Max. O peratingTemperature 113 oF (45 oC)

· Operating pH Range 2.0–11.0

· CIP pH Range 1.0–13.0

· Max.Turbidity 1.0 NTU

· Max. SDI (15 min) 5.0

· Max. C hlorine C oncentration < 0.1 mg/L

Design Guidelines for Various · Wastewater Conventional (SDI < 5) 8–12 gfd

Water Sources · Wastewater Pretreated by UF/MF (SDI < 3) 10–14 gfd

· Seawater, O pen Intake (SDI < 5) 7–10 gfd

· Seawater, Beach Well (SDI < 3) 8–12 gfd

· SurfaceW ater (SDI < 5) 12–16 gfd

· SurfaceW ater (SDI < 3) 13–17 gfd

· Well water (SDI < 3) 13–17 gfd

· RO permeate (SDI < 1) 21–30 gfd

Sa turation Limits · Langlier Saturation Index(LSI) <+1.5

†

(Using Antiscalants) · Stiff and Davis Saturation Index(SDSI) <+0.5

· CaSO 4 230% saturation

· SrSO 4 800% saturation

· BaSO 4 6,000% saturation

· SiO 2 100% saturation

†

The above saturation limits are typically accepted by proprietary antiscalant

manufacturers. It is the user’s responsibility to ensure proper chemical(s) and

concentration are dosed ahead of the membrane system to prevent scale

formation anywhere within the membrane syst em. Membrane elements fouled

or damaged due to scale formation are not covered by the limited warranty.

GENERAL HANDLING PROCEDURES

Elements contained in the boxes must be kept dry at Keep elements moist at all times after initial wetting.

room temperature (7–32°C; 40 –95°F) and should not be Avoid excessive pressure and flow spikes.

stored in direct sunlight. If the polyethylene bag is

damaged, a new preservative solution (sodium bisulfite) Only use chemicals compatible with the membrane

must be added and air-tight seal

ed to prevent drying and elements and components. Use of such chemicals may

biological growth. void the element limited warranty.

Permeate from the first hour of operation should be Permeate pressure must always be equal or less than the

discarded to flush out the preservative solution. feed/concentrate pressure. Damage caused by permeate

back pressure voids the element limited warranty.

Elements should be immersed in a preservative solution

during storage, shipping and system shutdowns to prevent

biological growth and freezing. The standard storage

solution contains 1% by weight sodium bisulfite or sodium

metabisulfite (food grade). For short term storage (i.e.

one week or less) 1% by weight sodium metabisulfite

solution is adequate for preventing biological growth.

Lenntech

info@lenntech.com Tel. +31-152-610-900

www.lenntech.com Fax. +31-152-616-289

You might also like

- Checking Bacterial ContaminationDocument11 pagesChecking Bacterial ContaminationAayush Pawar60% (5)

- Guia Chiller York YcavDocument310 pagesGuia Chiller York YcavNahum Cesar Hernandez SorianoNo ratings yet

- Urban Geography, City of Doha.Document65 pagesUrban Geography, City of Doha.Prince Rizaldy S. Heti-ayonNo ratings yet

- Re8040-Be - 190312Document2 pagesRe8040-Be - 190312Willy ChandraNo ratings yet

- Re8040-Br400 - 190312 - PMKDocument2 pagesRe8040-Br400 - 190312 - PMKMsach RoysNo ratings yet

- CSM Re8040 SHN LDocument2 pagesCSM Re8040 SHN LSundari RaviNo ratings yet

- Re2540-Blf 171201Document2 pagesRe2540-Blf 171201LưuVănViếtNo ratings yet

- RE16040-BE - 200907 - HSHDocument2 pagesRE16040-BE - 200907 - HSHMsach RoysNo ratings yet

- 1-1. NE8040-40 - 200311 - LHK - Ver 1.0Document2 pages1-1. NE8040-40 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0Document2 pages5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0Msach RoysNo ratings yet

- Re8040-Ce - 190312 - PMKDocument2 pagesRe8040-Ce - 190312 - PMKMsach RoysNo ratings yet

- 5-2. NE4040-ARM50 - 200311 - LHK - Ver 1.0Document2 pages5-2. NE4040-ARM50 - 200311 - LHK - Ver 1.0Msach RoysNo ratings yet

- 4-2. NE4040-HRM - 200311 - LHK - Ver 1.0Document2 pages4-2. NE4040-HRM - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 4-1. NE8040-HRM - 200311 - LHK - Ver 1.0Document2 pages4-1. NE8040-HRM - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 3-1. NE8040-90 - 200311 - LHK - Ver 1.0Document2 pages3-1. NE8040-90 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 1-2. NE4040-40 - 200311 - LHK - Ver 1.0Document2 pages1-2. NE4040-40 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 2-1. NE8040-70 - 200311 - LHK - Ver 1.0Document2 pages2-1. NE8040-70 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Membrane UnitDocument2 pagesMembrane UnitFauzyNo ratings yet

- Ne4040 SRMDocument2 pagesNe4040 SRMMsach RoysNo ratings yet

- 2-2. NE4040-70 - 200311 - LHK - Ver 1.0Document2 pages2-2. NE4040-70 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Sea2 4040 PDFDocument1 pageSea2 4040 PDFMd. Suruz ZamanNo ratings yet

- Datasheet LG SW 400 SR G2 ENGDocument1 pageDatasheet LG SW 400 SR G2 ENGMohamed MotaweaNo ratings yet

- OltremareDocument1 pageOltremareAfraz ShaikhNo ratings yet

- LG SW 440 SRDocument1 pageLG SW 440 SRkylealamangoNo ratings yet

- Datasheet LG BW 400 R Dura ENGDocument1 pageDatasheet LG BW 400 R Dura ENGSaul RosalesNo ratings yet

- System ManualDocument14 pagesSystem ManualCareers SSPNo ratings yet

- SWC4 MaxDocument1 pageSWC4 MaxaltayehmNo ratings yet

- Cat. Sondas Ph-Redox enDocument2 pagesCat. Sondas Ph-Redox enFranco YnquillaNo ratings yet

- Nano SW MaxDocument1 pageNano SW Maxfelipe RezendeNo ratings yet

- 001x7 Resin SDSDocument11 pages001x7 Resin SDSinnomatt139No ratings yet

- Eutalloy 1202Document2 pagesEutalloy 1202Siddharth DasNo ratings yet

- Data Sheet: LG SW 4040 RDocument1 pageData Sheet: LG SW 4040 RAcquetech AcquetechNo ratings yet

- LG SW 440 GRDocument1 pageLG SW 440 GRkylealamangoNo ratings yet

- Technical Information Sheet: 7-2508 Pipe CoatingDocument3 pagesTechnical Information Sheet: 7-2508 Pipe Coatingreza329329No ratings yet

- Microdyn BWRO-1Document2 pagesMicrodyn BWRO-1Rogerio SilvaNo ratings yet

- Membrane LG CW 4040 SFDocument1 pageMembrane LG CW 4040 SFPT Deltapuro IndonesiaNo ratings yet

- Esna1 LF2 LD 4040Document1 pageEsna1 LF2 LD 4040Soledad OrtegaNo ratings yet

- Nap-Gard 7-2500 PDFDocument2 pagesNap-Gard 7-2500 PDFPietro ViganNo ratings yet

- Brochure Spark H2ODocument4 pagesBrochure Spark H2OEder LopesNo ratings yet

- Toray SUL G20FTS Reverse Osmosis Element LDocument2 pagesToray SUL G20FTS Reverse Osmosis Element LGRUPO FILTRANTESNo ratings yet

- Datasheet LG MaxRO R ENGDocument1 pageDatasheet LG MaxRO R ENGAhmed GomaaNo ratings yet

- Membrane LG BW 400RDocument1 pageMembrane LG BW 400RPT Deltapuro IndonesiaNo ratings yet

- Signet 2536 Rotor-X Paddlewheel Flow SensorsDocument6 pagesSignet 2536 Rotor-X Paddlewheel Flow SensorsMETHOR SERVICE GROUPNo ratings yet

- 80315-01 r4 Technical Data Sheet PX-Q300Document1 page80315-01 r4 Technical Data Sheet PX-Q300JOSÉ VILLALOBOS CORALNo ratings yet

- RELITE 3AS - Strongly Basic ResinDocument2 pagesRELITE 3AS - Strongly Basic ResinPanca Erlangga SiregarNo ratings yet

- 550series - HydraustarDocument8 pages550series - HydraustarvijaykumarnNo ratings yet

- DOW™ Electrodeionization Modules: Product InformationDocument2 pagesDOW™ Electrodeionization Modules: Product InformationjonnelNo ratings yet

- SE20Document5 pagesSE20seyedmajidgNo ratings yet

- QMC 10 08Document2 pagesQMC 10 08maherNo ratings yet

- Data Sheet: LG BW 400 EsDocument1 pageData Sheet: LG BW 400 EsZi Wei LeongNo ratings yet

- Dfs-Manual-2 13 15Document37 pagesDfs-Manual-2 13 15Enderson RamosNo ratings yet

- Membrana RO Industrial 4x40 y 8x40Document2 pagesMembrana RO Industrial 4x40 y 8x40luisNo ratings yet

- Membrane Element SWC - 2540: PerformanceDocument1 pageMembrane Element SWC - 2540: PerformanceAshish GulrandheNo ratings yet

- CSM Re2012 LP LDocument2 pagesCSM Re2012 LP LHerlanFebriandaNo ratings yet

- Hydranautics SWC5 LD LDocument1 pageHydranautics SWC5 LD LAlexis Jara VidalNo ratings yet

- Data Sheet: LG BW 4040 EsDocument1 pageData Sheet: LG BW 4040 EsAcquetech AcquetechNo ratings yet

- D&M Technical Spec SSD-1X - BNDocument18 pagesD&M Technical Spec SSD-1X - BNMarc LefrancqNo ratings yet

- BQUA - Swc5 MaxDocument1 pageBQUA - Swc5 MaxBassemNo ratings yet

- Model 500-600 Series II (FM-1280 Rev.A)Document6 pagesModel 500-600 Series II (FM-1280 Rev.A)Carlos Miguel LópezNo ratings yet

- Datasheet LG BW 400 R G2 ENGDocument1 pageDatasheet LG BW 400 R G2 ENGAhmed GomaaNo ratings yet

- Datasheet SGX BLD1 - Rev1.1Document5 pagesDatasheet SGX BLD1 - Rev1.1iyergvNo ratings yet

- Modern Glass CharacterizationFrom EverandModern Glass CharacterizationMario AffatigatoNo ratings yet

- Manual de Servicio Knight LonchivarDocument52 pagesManual de Servicio Knight LonchivarNahum Cesar Hernandez SorianoNo ratings yet

- Correos Electrónicos 712268KHB-I-O - Rev D - 100305277 - 2000558126 (34301) PDFDocument84 pagesCorreos Electrónicos 712268KHB-I-O - Rev D - 100305277 - 2000558126 (34301) PDFNahum Cesar Hernandez SorianoNo ratings yet

- Correos Electrónicos 712268KHB-I-O - Rev D - 100305277 - 2000558126 (34301) PDFDocument84 pagesCorreos Electrónicos 712268KHB-I-O - Rev D - 100305277 - 2000558126 (34301) PDFNahum Cesar Hernandez SorianoNo ratings yet

- AM-700 DMX Coder Manual Eng.Document6 pagesAM-700 DMX Coder Manual Eng.Nahum Cesar Hernandez SorianoNo ratings yet

- SDS Altratene 30% OS-SF - November - 2021 - EUDocument6 pagesSDS Altratene 30% OS-SF - November - 2021 - EUmaha guettariNo ratings yet

- Daily Report Analysis Sea Water Reverse Osmosis & Log Sheet: Month TrainDocument10 pagesDaily Report Analysis Sea Water Reverse Osmosis & Log Sheet: Month Trainmahesa34No ratings yet

- Kumar Et Al. 2022Document11 pagesKumar Et Al. 2022Miguel OlivoNo ratings yet

- Hydraulic Traffic Reduce SystemDocument12 pagesHydraulic Traffic Reduce Systempraneeth pkNo ratings yet

- Power Factor Penalty Utility Bill (Digital File)Document2 pagesPower Factor Penalty Utility Bill (Digital File)AlbertoNo ratings yet

- Action Plan On SigaDocument2 pagesAction Plan On Sigarubyneil cabuang100% (1)

- Perspectives and Mediums & ParagraphDocument4 pagesPerspectives and Mediums & ParagraphMariam ItaniNo ratings yet

- Hips MSDSDocument5 pagesHips MSDSkathiravanpr_6744097No ratings yet

- Pemanasan Global:: Dampak Dan Upaya MeminimalisasinyaDocument25 pagesPemanasan Global:: Dampak Dan Upaya MeminimalisasinyaSiyanulla OllshopNo ratings yet

- Directed Writing Clean EnvironmentDocument2 pagesDirected Writing Clean Environmentyudrea88No ratings yet

- Taller 2 - First ConditionalDocument8 pagesTaller 2 - First ConditionalLUZ ABEIBA TAPIERO PARAMONo ratings yet

- CEM 602 HomeWorkDocument5 pagesCEM 602 HomeWorkneelNo ratings yet

- Biomedical Waste ManagementDocument37 pagesBiomedical Waste ManagementDr.Rajesh KamathNo ratings yet

- FDS Soec Adjuvantmcpoudre enDocument7 pagesFDS Soec Adjuvantmcpoudre enanggun pramestyNo ratings yet

- SCR Qs Chapter IIDocument23 pagesSCR Qs Chapter IIdouglas100% (1)

- GEOG PART II HONS SEM4 Factors of Soil FormationDocument3 pagesGEOG PART II HONS SEM4 Factors of Soil FormationkarlforsuhNo ratings yet

- Garita AssignmentDocument2 pagesGarita Assignmentapi-619738021No ratings yet

- Blue Lined Climate Change Environment InfographicDocument1 pageBlue Lined Climate Change Environment InfographicGem CarmelNo ratings yet

- Nabila Azra Aisyah - 081911433014 - D3 - Luas Minimum Dan Metode KuadratDocument11 pagesNabila Azra Aisyah - 081911433014 - D3 - Luas Minimum Dan Metode KuadratNabila AzraNo ratings yet

- Gen Z As FarmersDocument2 pagesGen Z As FarmersRhea Albos AntonioNo ratings yet

- Algeria Sustainable Transformation of Energy SystemDocument40 pagesAlgeria Sustainable Transformation of Energy SystemKumar VaibhavNo ratings yet

- Environment Law ScriptDocument4 pagesEnvironment Law ScriptSindhuja BajajNo ratings yet

- 01 Heart of The Tree PDFDocument4 pages01 Heart of The Tree PDFyudh bNo ratings yet

- S3E1 SIP Deck 1Document38 pagesS3E1 SIP Deck 1jimmytabliganNo ratings yet

- First Grade Master Spelling ListsDocument3 pagesFirst Grade Master Spelling Listsjakeredmond8167No ratings yet

- Environmental Science and Policy: Ina Tessnow-Von Wysocki, Philippe Le Billon TDocument11 pagesEnvironmental Science and Policy: Ina Tessnow-Von Wysocki, Philippe Le Billon TMuhammadSalmanButtNo ratings yet

- Case Study of A Food Production System ModDocument4 pagesCase Study of A Food Production System Mod241nnwNo ratings yet

- Ocean Acidification and Human Health: ReviewDocument20 pagesOcean Acidification and Human Health: Reviewgolden abidemNo ratings yet