Re8040-Be - 190312

Re8040-Be - 190312

Uploaded by

Willy ChandraCopyright:

Available Formats

Re8040-Be - 190312

Re8040-Be - 190312

Uploaded by

Willy ChandraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Copyright:

Available Formats

Re8040-Be - 190312

Re8040-Be - 190312

Uploaded by

Willy ChandraCopyright:

Available Formats

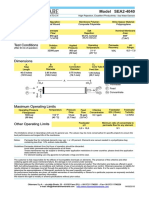

RE8040-BE

High productivity RO element with extended area for brackish water

SPECIFICATIONS:

General Permeate flow rate: 11,000 GPD (41.6 m3/day)

Features Nominal salt rejection: 99.7%

Effective membrane area: 400 ft2 (37.2 m2)

1. The stated product performance is based on data taken after 30 minutes of operation at the following

test conditions:

• 2,000 mg/L NaCl solution at 225 psig (1.55 MPa) applied pressure

• 15% recovery

• 77 oF (25 oC)

• pH 6.5–7.0

2. Minimum salt rejection is 99.5%.

3. Permeate flow rate for each element may vary +25 / -15%.

4. All elements are vacuum sealed in a polyethylene bag containing 1.0% SBS (sodium bisulfite) solution

and individually packaged in a cardboard box.

Membrane type: Thin-Film Composite

Membrane material: Polyamide (PA)

Element configuration: Spiral-Wound, FRP Wrapping

Dimensions Part Number

and

Weight Model Name A B C Weight Inter-

Brine Seal

connector

40.0 inch 7.9 inch 1.12 inch

RE8040-BE 15 kg SWA01049 SWA01043

(1,016 mm) (200 mm) (28.5 mm)

1. Each membrane element supplied with one brine seal, one interconnector (coupler) and four o-rings.

2. All RE8040 elements fit nominal 8.0 inch (203.2 mm) I.D. pressure vessels.

The information provided in this document is solely for informative purposes. It is the user’s responsibility to ensure

the appropriate usage of this product. Toray Advanced Materials Inc. assumes no obligation, liability or damages

incurred for the misuse of the product or for the information provided in this document. This document does not

express or implies any warranty as to the merchantability or fitness of the product.

Toray Advanced Materials Korea Inc.

For more information on our products, company and regional contacts, please visit our website at www.csmfilter.com.

Product Specification Sheet / Model RE8040-BE

Page 1 of 2 Rev.4.0 March 2019

RE8040-BE

High productivity RO element with extended area for brackish water

APPLICATION DATA:

Operating Limits · Max. Pressure Drop / Element 15 psi (0.1 MPa)

· Max. Pressure Drop / 240” Vessel 60 psi (0.41 Mpa)

· Max. Operating Pressure 600 psi (4.14 MPa)

· Max. Feed Flow Rate 75 gpm (17.0 m3/hr)

· Min. Concentrate Flow Rate 16 gpm (3.6 m3/hr)

· Max. Operating Temperature 113 oF (45 oC)

· Operating pH Range 2.0–11.0

· CIP pH Range 1.0–13.0

· Max. Turbidity 1.0 NTU

· Max. SDI (15 min) 5.0

· Max. Chlorine Concentration < 0.05 mg/L

Design Guidelines for Various · Wastewater Conventional (SDI < 5) 8–12 gfd

Water Sources · Wastewater Pretreated by UF/MF (SDI < 3) 10–14 gfd

· Seawater, Open Intake (SDI < 5) 7–10 gfd

· Seawater, Beach Well (SDI < 3) 8–12 gfd

· Surface Water (SDI < 5) 12–16 gfd

· Surface Water (SDI < 3) 13–17 gfd

· Well water (SDI < 3) 13–17 gfd

· RO permeate (SDI < 1) 21–30 gfd

Saturation Limits · Langlier Saturation Index (LSI) <+1.5

(Using Antiscalants)† · Stiff and Davis Saturation Index (SDSI) <+0.5

· CaSO4 230% saturation

· SrSO4 800% saturation

· BaSO4 6,000% saturation

· SiO2 100% saturation

†

The above saturation limits are typically accepted by proprietary antiscalant

manufacturers. It is the user’s responsibility to ensure proper chemical(s) and

concentration are dosed ahead of the membrane system to prevent scale

formation anywhere within the membrane system. Membrane elements fouled

or damaged due to scale formation are not covered by the limited warranty.

GENERAL HANDLING PROCEDURES

Elements contained in the boxes must be kept dry at Only use chemicals compatible with the membrane

room temperature (7–32°C; 40–95°F) and should not be elements and components. Use of such chemicals may

stored in direct sunlight. If the polyethylene bag is void the element limited warranty.

damaged, a new preservative solution (sodium bisulfite) Permeate pressure must always be equal or less than the

must be added and air-tight sealed to prevent drying and feed/concentrate pressure. Damage caused by permeate

biological growth. back pressure voids the element limited warranty.

Permeate from the first hour of operation should be

discarded to flush out the preservative solution.

Elements should be immersed in a preservative solution

during storage, shipping and system shutdowns to prevent

biological growth and freezing. The standard storage

solution contains 1% by weight sodium bisulfite or sodium

metabisulfite (food grade). For short term storage (i.e.

one week or less) 1% by weight sodium metabisulfite

solution is adequate for preventing biological growth.

Keep elements moist at all times after initial wetting.

Avoid excessive pressure and flow spikes.

Toray Advanced Materials Korea Inc.

For more information on our products, company and regional contacts, please visit our website at www.csmfilter.com.

Product Specification Sheet / Model RE8040-BE

Page 2 of 2 Rev.4.0 March 2019

You might also like

- Beyond TelepathyDocument364 pagesBeyond Telepathyneonpanther94% (18)

- Fields of Fire Training ManualDocument39 pagesFields of Fire Training ManualMichael Welker100% (1)

- Questionnaire - An Analysis On Investor Behaviour On Various Investment Avenues in IndiaDocument5 pagesQuestionnaire - An Analysis On Investor Behaviour On Various Investment Avenues in IndiaRakesh79% (52)

- Marketing Failure of A Product - Camay DesireDocument16 pagesMarketing Failure of A Product - Camay DesireMUHAMMAD MUDASSAR TAHIR NCBA&ENo ratings yet

- Re8040-Br400 - 190312 - PMKDocument2 pagesRe8040-Br400 - 190312 - PMKMsach RoysNo ratings yet

- RE16040-BE - 200907 - HSHDocument2 pagesRE16040-BE - 200907 - HSHMsach RoysNo ratings yet

- 1-1. NE8040-40 - 200311 - LHK - Ver 1.0Document2 pages1-1. NE8040-40 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Re2540-Blf 171201Document2 pagesRe2540-Blf 171201LưuVănViếtNo ratings yet

- 5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0Document2 pages5-1. NE8040-ARM50 - 200311 - LHK - Ver 1.0Msach RoysNo ratings yet

- CSM Re8040 SHN LDocument2 pagesCSM Re8040 SHN LSundari RaviNo ratings yet

- Re8040-Ce - 190312 - PMKDocument2 pagesRe8040-Ce - 190312 - PMKMsach RoysNo ratings yet

- Correos Electrónicos CSM-RE2521-BLN-LDocument2 pagesCorreos Electrónicos CSM-RE2521-BLN-LNahum Cesar Hernandez SorianoNo ratings yet

- 3-1. NE8040-90 - 200311 - LHK - Ver 1.0Document2 pages3-1. NE8040-90 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 5-2. NE4040-ARM50 - 200311 - LHK - Ver 1.0Document2 pages5-2. NE4040-ARM50 - 200311 - LHK - Ver 1.0Msach RoysNo ratings yet

- 4-1. NE8040-HRM - 200311 - LHK - Ver 1.0Document2 pages4-1. NE8040-HRM - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 4-2. NE4040-HRM - 200311 - LHK - Ver 1.0Document2 pages4-2. NE4040-HRM - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 1-2. NE4040-40 - 200311 - LHK - Ver 1.0Document2 pages1-2. NE4040-40 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- 2-1. NE8040-70 - 200311 - LHK - Ver 1.0Document2 pages2-1. NE8040-70 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Ne4040 SRMDocument2 pagesNe4040 SRMMsach RoysNo ratings yet

- 2-2. NE4040-70 - 200311 - LHK - Ver 1.0Document2 pages2-2. NE4040-70 - 200311 - LHK - Ver 1.0Kenz ZhouNo ratings yet

- Membrane UnitDocument2 pagesMembrane UnitFauzyNo ratings yet

- Datasheet LG SW 400 SR G2 ENGDocument1 pageDatasheet LG SW 400 SR G2 ENGMohamed MotaweaNo ratings yet

- OltremareDocument1 pageOltremareAfraz ShaikhNo ratings yet

- Sea2 4040 PDFDocument1 pageSea2 4040 PDFMd. Suruz ZamanNo ratings yet

- Datasheet LG BW 400 R Dura ENGDocument1 pageDatasheet LG BW 400 R Dura ENGSaul RosalesNo ratings yet

- Nano SW MaxDocument1 pageNano SW Maxfelipe RezendeNo ratings yet

- LG SW 440 SRDocument1 pageLG SW 440 SRkylealamangoNo ratings yet

- Data Sheet: LG SW 4040 RDocument1 pageData Sheet: LG SW 4040 RAcquetech AcquetechNo ratings yet

- Signet 2536 Rotor-X Paddlewheel Flow SensorsDocument6 pagesSignet 2536 Rotor-X Paddlewheel Flow SensorsMETHOR SERVICE GROUPNo ratings yet

- Membrane LG CW 4040 SFDocument1 pageMembrane LG CW 4040 SFPT Deltapuro IndonesiaNo ratings yet

- System ManualDocument14 pagesSystem ManualCareers SSPNo ratings yet

- 550series - HydraustarDocument8 pages550series - HydraustarvijaykumarnNo ratings yet

- SWC4 MaxDocument1 pageSWC4 MaxaltayehmNo ratings yet

- Membrane LG BW 400RDocument1 pageMembrane LG BW 400RPT Deltapuro IndonesiaNo ratings yet

- Membrana RO Industrial 4x40 y 8x40Document2 pagesMembrana RO Industrial 4x40 y 8x40luisNo ratings yet

- Data Sheet: LG BW 4040 EsDocument1 pageData Sheet: LG BW 4040 EsAcquetech AcquetechNo ratings yet

- LG SW 440 GRDocument1 pageLG SW 440 GRkylealamangoNo ratings yet

- Datasheet LG MaxRO R ENGDocument1 pageDatasheet LG MaxRO R ENGAhmed GomaaNo ratings yet

- SE20Document5 pagesSE20seyedmajidgNo ratings yet

- Data Sheet: LG BW 400 EsDocument1 pageData Sheet: LG BW 400 EsZi Wei LeongNo ratings yet

- Hydranautics Hydracore70 MembraneDocument1 pageHydranautics Hydracore70 MembraneOuassouNo ratings yet

- De400001 SM-6Document3 pagesDe400001 SM-6seve1No ratings yet

- Datos Tecnicos FlujometroDocument4 pagesDatos Tecnicos FlujometroJuverCupeNo ratings yet

- Toray TML20D LDocument2 pagesToray TML20D LEber saidNo ratings yet

- Eutalloy 1202Document2 pagesEutalloy 1202Siddharth DasNo ratings yet

- Datasheet LG BW 400 R G2 ENGDocument1 pageDatasheet LG BW 400 R G2 ENGAhmed GomaaNo ratings yet

- Microdyn BWRO-1Document2 pagesMicrodyn BWRO-1Rogerio SilvaNo ratings yet

- TM 800 ADocument2 pagesTM 800 Ama_princess7840No ratings yet

- Esna1 LF2 LD 4040Document1 pageEsna1 LF2 LD 4040Soledad OrtegaNo ratings yet

- Flow SensorDocument8 pagesFlow SensorAchmad Nuriel AnwarNo ratings yet

- 001x7 Resin SDSDocument11 pages001x7 Resin SDSinnomatt139No ratings yet

- RELITE 3AS - Strongly Basic ResinDocument2 pagesRELITE 3AS - Strongly Basic ResinPanca Erlangga SiregarNo ratings yet

- MG Chemicals Sn63Pb37 No Clean Leaded Solder Paste 4860P Technical Data SheetDocument7 pagesMG Chemicals Sn63Pb37 No Clean Leaded Solder Paste 4860P Technical Data SheetAbdulrahman AlabdanNo ratings yet

- Mar Cor: 700 Series Portable Medical DeviceDocument2 pagesMar Cor: 700 Series Portable Medical Deviceعايد التعزيNo ratings yet

- Membrane Element SWC - 2540: PerformanceDocument1 pageMembrane Element SWC - 2540: PerformanceAshish GulrandheNo ratings yet

- HM 4040 - BWE: High Performance Brackish Water RO ElementDocument2 pagesHM 4040 - BWE: High Performance Brackish Water RO Elementmaksudur4100% (1)

- Mini Gaskleen High-Flow Filter Assemblies: DescriptionDocument2 pagesMini Gaskleen High-Flow Filter Assemblies: Description3DP HelloNo ratings yet

- MetaCeram-25040.. Castollin EutecticDocument2 pagesMetaCeram-25040.. Castollin EutecticAndrés MolinaNo ratings yet

- DuPont FilmTec Seamaxx 440 LDocument4 pagesDuPont FilmTec Seamaxx 440 Lventas.benyiNo ratings yet

- DOW™ Electrodeionization Modules: Product InformationDocument2 pagesDOW™ Electrodeionization Modules: Product InformationjonnelNo ratings yet

- LG Chem LG BW 4040 ES L PDFDocument1 pageLG Chem LG BW 4040 ES L PDFhonoviw115No ratings yet

- Model 500-600 Series II (FM-1280 Rev.A)Document6 pagesModel 500-600 Series II (FM-1280 Rev.A)Carlos Miguel LópezNo ratings yet

- BQUA - Swc5 MaxDocument1 pageBQUA - Swc5 MaxBassemNo ratings yet

- Juki HZL-K85 Sewing Machine Service ManualDocument39 pagesJuki HZL-K85 Sewing Machine Service ManualiliiexpugnansNo ratings yet

- Summative Assignment and RubricDocument3 pagesSummative Assignment and Rubricapi-509660639No ratings yet

- United States Attorney Eastern District of New York: U.S. Department of JusticeDocument2 pagesUnited States Attorney Eastern District of New York: U.S. Department of JusticeAristegui NoticiasNo ratings yet

- L&D EndDocument26 pagesL&D EndPriyankaNo ratings yet

- 09 ELMS Quiz 1 ARG EntrepDocument5 pages09 ELMS Quiz 1 ARG EntrepJonamel QuiditNo ratings yet

- 37. (Form 2023) Đề thi thử tốt nghiệp 2023 Sở GD Hà Nội (Lần 1)Document5 pages37. (Form 2023) Đề thi thử tốt nghiệp 2023 Sở GD Hà Nội (Lần 1)phuonganh14032910No ratings yet

- Case Note Excellent1 AnnotatedDocument8 pagesCase Note Excellent1 AnnotatedDavid RoseNo ratings yet

- Agricultural Crop Production (Acp) NC I: Prepare Materials, Tools and Equipment For Horticultural Production WorkDocument27 pagesAgricultural Crop Production (Acp) NC I: Prepare Materials, Tools and Equipment For Horticultural Production WorkMuffy FernandezNo ratings yet

- Articles of Impeachment of Joe BidenDocument5 pagesArticles of Impeachment of Joe BidenTim Brown100% (1)

- Course Syllabus: Aurora Pioneers Memorial CollegeDocument10 pagesCourse Syllabus: Aurora Pioneers Memorial CollegeLorisa CenizaNo ratings yet

- Information Rights Management (IRM)Document12 pagesInformation Rights Management (IRM)niiconsultingNo ratings yet

- Adult Orthodontics: P.Sivakalyani PGDocument161 pagesAdult Orthodontics: P.Sivakalyani PGMini RobertNo ratings yet

- The Trinity in The Name of God, Elohim - Jesus Holy Spirit Jewish Messiah BibleDocument3 pagesThe Trinity in The Name of God, Elohim - Jesus Holy Spirit Jewish Messiah BiblerahmanNo ratings yet

- Dr. Mareau's IslandDocument2 pagesDr. Mareau's IslandMarijoy MabbaguNo ratings yet

- Dialnet ABriefHistoryOfTheEvolutionOfWoundCare 8578753Document3 pagesDialnet ABriefHistoryOfTheEvolutionOfWoundCare 8578753GabiNo ratings yet

- NCERT Solutions For Maths Complex Numbers Class 11 Chapter 4 - Complex Numbers & Quadratic Equations PDFDocument19 pagesNCERT Solutions For Maths Complex Numbers Class 11 Chapter 4 - Complex Numbers & Quadratic Equations PDFdeeptikaushik36No ratings yet

- Health Dorito Effect AdvancedDocument2 pagesHealth Dorito Effect AdvancedluciapichiNo ratings yet

- PRA UN A SiswaDocument8 pagesPRA UN A SiswaMichelleNo ratings yet

- Chapter 1 - Sectors in Food Service IndustryDocument2 pagesChapter 1 - Sectors in Food Service Industryjm.vietnam123No ratings yet

- 11876COMPREHENSIVE LIST OF PHOBIAcrwillDocument5 pages11876COMPREHENSIVE LIST OF PHOBIAcrwillAbhi YadavNo ratings yet

- Notice: Antidumping: Large Newspaper Printing Presses and Components Assembled or Unassembled From— Various CountriesDocument2 pagesNotice: Antidumping: Large Newspaper Printing Presses and Components Assembled or Unassembled From— Various CountriesJustia.comNo ratings yet

- ADAS Calibration GuideDocument15 pagesADAS Calibration GuidesigaieuNo ratings yet

- Spark Interview QuestionsDocument19 pagesSpark Interview Questionssantosh kumarNo ratings yet

- (9789004349773 - Entrepreneurship in Africa) Chapter 11 Dangote Cement The Challenges of Pan-African ExpansionDocument26 pages(9789004349773 - Entrepreneurship in Africa) Chapter 11 Dangote Cement The Challenges of Pan-African ExpansionMulten PlanNo ratings yet

- TeachingPreparednessofPre ServiceTeachers PerceptiontoPracticeDocument23 pagesTeachingPreparednessofPre ServiceTeachers PerceptiontoPracticeShyra SerencioNo ratings yet

- Be A Person of Habits: Habit #52Document4 pagesBe A Person of Habits: Habit #52Jyles SirabNo ratings yet